AFTER the mechanism has been mounted and the amplifier and control system constructed, some mechanical adjustments must be made before setting the equalization as described in the next Section.

Make these adjustments before cutting discs for any purpose, because improper alignment of any of the mechanical parts can injure or destroy some part of the system.

The exact order in which the adjustments are made is a matter of suggest that the following order be adopted.

Feed Mechanism Alignment

If an overhead feed mechanism is used, check its alignment with the top of the turntable. The assembly should rest on a level surface.

Gravity plays a part in the functioning of the mechanism, particularly the resting of the cutter and stylus on the record. Use a carpenter's spirit level to determine that the top of the turntable is level.

Next, be sure that the horizontal portions of the feed mechanism especially the trolley on which the cutter mount travels, and the lead screw-are parallel to the top of the turntable. In most cases, the height of the center post is fixed, determining the height of the inside end of the lead screw and trolley above the turntable. Using either the trolley or the lead screw as the reference, measure this height carefully. Use dividers or inside calipers, not the eye. Then make certain that the outside end of the trolley or lead screw is exactly the same distance above the rim of the turntable. Almost all overhead type table machines are provided with a height adjustment for the outside post, to allow parallel alignment with the table.

With swinging-arm mechanisms, the important consideration is that the shaft which goes through the motor board and supports the rear end of the cutter arm be absolutely vertical.

Be sure to have a typical blank disc on the turntable during parallel adjustment of overhead mechanisms, since the thickness of the disc on which the center post rests will cause a slight misalignment if adjustment is made without it.

See that the outside post of the mechanism is tightly fastened to the motor board at the right place. A small error in its placement will throw the entire mechanism out of line and create unnecessary friction.

If the outside post is correctly placed, the center post can be lowered onto its position over .the turntable easily. It should never have to be forced down over the center pin.

Lubrication

The next step-and one that should be repeated at frequent intervals throughout the life of the equipment-is to see to lubrication.

Secure the manufacturer's instructions for motor, turntable, and feed mechanism, and follow them religiously. Too much friction at any point will destroy the speed regulation and wows will result in the finished recordings. Improper or insufficient lubrication can damage such parts as the turntable bearing, making complete replacement unavoidable. A small amount of oil on the smooth rods or trolleys on which the cutter mount travels and on the lead screw is necessary. Wipe them with an oil-soaked rag. Do not drop oil on them directly, since it will drip onto the turntable and the disc. Unless the manufacturer recommends another type of oil, light machine oil is suitable.

Stylus Angle

Now insert a good stylus in the cutter. Unless steel styli will be used for all recordings, make the adjustments with a sapphire or stellite stylus. Be sure the flatted portion of the shank is in contact with the end of the setscrew. An error here will damage both stylus and disc.

With the motor off, lower the cutter and stylus gently on the surface of a disc of the type and quality to be used during future operations. Be certain that there is no appreciable vibration in the room and that neither you nor the equipment is jarred.

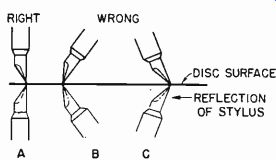

With the eye on the level of the turntable, look past the stylus toward the center of the turntable. Observe the cutting face of the stylus tip and its reflection in the shiny surface of the record. If the stylus and its reflection make a straight line, the cutting face is perpendicular to the disc ; and good results can be expected. (See Fig. 1001.) If the stylus and its reflection are not a straight line, adjustment must be made. It is true, however, that many manufacturers recommend that the stylus be canted very slightly in the direction shown in Fig. 1001-b.

The angle should be so small that a casual glance will create the impression that the stylus is vertical. Follow the manufacturer's recommendations.

There are 2 means in general use for adjusting the stylus angle. In many mountings, the cutter may be raised or lowered, or spacers may be inserted between cutter and mounting. If no such adjustment is provided, a stylus of different length must be used-shorter if the situation is as in Fig. 1001-b, longer if as in Fig. 1000-c. Styli are normally sold in 2 standard lengths, known simply as "short" and "long." If neither size is satisfactory, the shank of a long stylus may be clipped off a little with a pair of diagonal cutters. This is a last resort only. Clip very care fully and observe the result after each cutting. Occasionally, the height of the entire mechanism can be adjusted; but be sure that it is parallel to the turntable.

Fig. 1001--Stylus and its reflection should form a straight line (A). If

not (B or C), adjustment must be made.

Depth of Cut

The next adjustment is for depth of cut. Start the turntable, engage the lead screw with the cutter mount; and, with no signal applied, lower the stylus gently on the disc. (Never start the turntable with the stylus resting on the record.) After a few revolutions, raise it again and observe the chip. It should be about the thickness of a very coarse human hair, and should have no tendency to crumble. Since the cross section has the shape of an isosceles triangle, it is impractical to measure the thread with a micrometer. It would be impossible to know whether the micrometer was reading the groove depth or width.

It is possible, however, to measure the groove width with a calibrated microscope. If this method is used, groove width should be set at .006 inch. With an uncalibrated microscope, the "land" between grooves should be roughly 1/3 the width of a groove at normal pitches.

The adjustment for cutting depth can be made by varying the tension of a counter-weighting spring. A knurled thumbscrew is usually provided. If no adjustment is provided or its range is inadequate, additional weight can he added. Small pieces of solder can be twisted around some convenient portion of the cutter (NOT the setscrew). The spring may be stretched; or if none is provided, one can be installed. What ever the method, cutter weight must be adjusted for proper groove depth and width. If grooves are too shallow and narrow, the pickup needle will not track and will skid across the disc. If they are too deep and wide, overcutting into adjacent grooves may take place, or the stylus tip may hit the base material and break. Make the adjustments in very small steps and check and readjust if necessary at any time.

Turntable Speed

The speed of the turntable is important. If the motor is synchro-nous, its initial speed is controlled by the line frequency. Its motion, however, is impeded by the drag of the stylus through the disc coating and, with all but the most powerful motors, the table revolves more slowly while cutting than without load. To determine the speed of the table during cutting, procure a stroboscope disc.

Slip the stroboscope disc over the turntable center pin, on top of the blank disc. The black lines are so spaced that, when the turntable is running at 78.26 r.p.m. under a fluorescent or neon light fed by a 60-cycle power source, persistence of vision will make the lines appear to stand still. If the table is revolving too fast, the lines will appear to turn clockwise ; if too slowly, they will move counterclockwise.

With no cutting in progress, all but the most expensive tables will run slightly fast-perhaps 80 to 82 r.p.m. With the stylus on the revolving disc (cutting), the stroboscope lines should appear to stand still, indicating that table speed has been reduced to 78 r.p.m.

Before worrying too much about speed variations, check to see that low speed is not caused by a dull stylus, a bad blank disc, or too great a depth of cut. High speed can be caused by too shallow a cut and sometimes by dried-out discs.

In rim-driven turntables, a thumbscrew is usually provided for adjusting the pressure of the idler against the turntable rim. Within a small range this adjustment will also vary the speed.

Thread Disposal

Control of the thread or chip resulting from cutting a disc should be decided upon during the initial adjustments. If recording is done from inside-out no precautions need be taken. The average stylus usually throws the thread inward. But if outside-in recordings are made, a brush will have to be procured. One of these is shown in Fig. 409. A strip of felt rests on the disc and sweeps the thread toward the center, where it winds up around the center post. A suction motor may be connected to a hose, the end of which is fastened to a metal tube mounted on the cutter assembly so that the mouth of the tube is beside the stylus tip. In such an arrangement, the motor must not create a.f. or r.f. interference.

It is also possible to use a soft camel's-hair brush to sweep away the thread during recording, but this requires the constant attention of the operator who-even though he is not the performer-has more important duties elsewhere. A brush should be on hand, however, for no method of automatic thread disposal is infallible and occasionally a thread will have to be removed from accidental entanglement with the stylus. This is a delicate operation at best and must be done gently so the stylus is not made to jump over the thread.

CAUTION!

Dispose of the thread--all of it--in water or in a closed metal container which is used for no other purpose. Most disc coatings are cellulose nitrate compounds, and nitrate is a prime ingredient of explosives! The disc is fire-resistant, but the thread is highly inflammable.