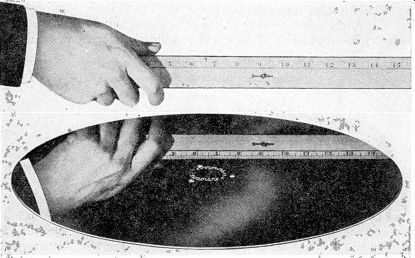

THE discs used in making instantaneous records--those which can be played back immediately without processing, the type with which we are concerned-are all basically similar. The best quality discs consist of a flat aluminum base, coated with a special composition. This composition used to be misnamed "acetate" (it is usually cellulose nitrate, actually), and the discs are still popularly known as acetate discs. Fig. 201 shows a typical recording disc. Note the extreme smoothness and regularity of the surface.

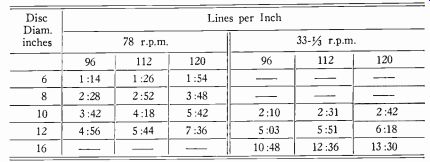

Table 2-1-Recording time in minutes.

Fig. 201--Typical mirror-smooth recording disc.

Cardboard and similar materials are often used as bases in smaller sized discs for reasons of economy. These materials do not provide a hard enough backing to allow good cutting of the higher frequencies.

They are porous, and their comparatively coarse texture makes a smooth coating almost impossible. This causes surface noise. Generally, they are used only for voice recording in cases where audio quality and durability are not important.

Tables 2-1 and 2-2 show disc diameters and recording times avail able at the standard turntable speeds of 33 1/3 and 78 r.p.m. (see Section 3) and at various pitches of the lead screw (see Section 4). For any other conditions than those listed, use the formula:

NS T=-, where R T is recording time in minutes; N is feed screw pitch, in lines per inch; S is recording space, in inches; R is r.p.m. of turntable.

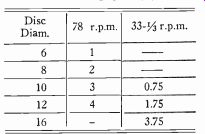

Table 2-2-Recording space (S) in inches.

Recording space depends on the record size, but a 12-inch disc, for instance, does not allow 12 inches of recording space. At least A inch must be left around the rim ; the label usually takes up about 3 inches; and another inch must be left around the label. When recording at 33 1/3 r.p.m., it is best not to use the space under 8 inches diameter, due to loss of high frequencies (see Section 11). Values in Table 2-1 have been figured on this basis, and Table 2-2 gives recording space for each size of disc at each speed. When using the formula, substitute the value shown in Table 2-2 for the factor S. Diameters over 12 inches should not be recorded at 78 r.p.m., because the speed of the disc as it passes the stylus becomes so great that the stylus will be quickly worn down.

Each manufacturer makes several grades of discs. They vary principally in type and thickness of base and thickness of coating. Where cost is important, the second-best grade will usually be entirely satisfactory for all but the highest-quality professional work.

It is wise to try several brands and grades, since preference varies with individuals. Except for occasional amateur special purposes, how ever, no base material but aluminum is acceptable. Never use un branded or factory-reject discs. Coating is usually uneven, and the cutting stylus is very likely to be ruined. Be sure the discs will lie flat on the turntable.