This overlooked feature can offer better sound for a small investment.

Proper damping means better tracking, cleaner reproduction, reduced distortion, and clearer stereo.

By James Brinton [Mr. Brinton, a specialist in science and technology, has been Boston bureau manager for the journal Electronics and is president of the Boston Audio Society.]

FOR MOST OF US, half the fun of buying a new component is boning up on terms and specifications. Most audiophiles are steeped in "effective mass," "pivot friction," "skating force," and other tonearm terms but have heard little about arm damping. Yet given a good design to start with-that is, one with low effective mass and low pivot friction—damping could contribute more to playback performance at less additional cost than almost any other tonearm feature.

A properly damped tone arm and cartridge, compared with an otherwise identical combination, has these advantages: better tracking of warped records, cleaner reproduction of low-frequency information, greater immunity to shock and vibration, reduced high-frequency playback distortion, and-particularly with some of today's very-high-compliance phono cartridges-a dramatically solidified stereo image. In addition, because damping reduces or nearly eliminates the subsonic resonances characteristic of most arm-cartridge combinations, the once irksome task of matching an arm to a cartridge becomes simpler.

Damping appears under several labels. Pivot damping and viscous damping generally mean the same thing. There also is a related approach called "counterweight decoupling," which is far more common than viscous damping.

If damping is known to audio designers, and if it has all these advantages, why haven't manufacturers adopted it before? They have, in fact, and have been using it since the 1950s and perhaps be fore then, although never very widely.

Early examples of damped arms would be the 1960-vintage Weathers and ESL models; the Weathers unit (now reincarnated by Win Laboratories) was viscous damped while the ESL used a decoupled counterweight. Today, a list of damped tone arms would include British designs like the Decca, the KMAL, and the Audio and Design arms--all with viscous damping in one form or another. Arms with decoupled counterweights are widely available today on record changers and single-play units (Dual and Lenco, for example, have applied the idea with considerable success), and separate arms with this form of damping include the SME, the Audio-Technica, and the Connoisseur.

This is far from a complete list, since damping isn't one of those characteristics raved about in advertisements. Even if the engineering department realizes its value, the fact that damping is part of a design often gets lost somewhere in the sales and advertising departments. Thus, a feature that might help sell a tone arm can become a well-kept secret.

There is, to the sales-oriented executive or retailer, a rationale for ignoring viscous damping. It can be difficult to manage in shipment; perhaps worse, the inexpert audiophile might mistake the "feel" of an arm with viscous damping for that of one with high mass or friction, with the possible result being a lost sale.

How Arm Damping Works

Because counterweight decoupling is easier to manage in the factory, during shipment, and in the store, it is employed more often than viscous damping. It usually consists of a flexible coupling between the counterweight and the body of a tonearm--perhaps a sleeve or rod or doughnut of rubber or plastic. This allows the arm and the counter weight to vibrate independently to some extent. In practice, with a simple decoupled counterweight, an arm-cartridge combination will have two lower-amplitude resonant peaks instead of the single higher-amplitude peak that would have appeared without decoupling. So decoupling ameliorates, but does not fully eliminate, the problem of subsonic resonances.

Harder to implement, and less convenient for maker and retailer, viscous damping can do a much more thorough job of solving the resonance problem. In its simplest form, viscous damping, or pivot damping, consists of a drop or two of very thick fluid-heavy petroleum or one of the ubiquitous silicones perhaps-placed in the tone arm's bearings. The fluid serves two purposes: First, it reduces whatever friction there is in the pivot; and second, it drastically reduces the effect of sudden or large movements on the motion of the arm. But the smaller, slower movements necessary for accurate tracking even of warped records are not interfered with. This selectivity is pivot damping's most desirable feature. Shock, vibration, and resonances are damped out quickly; the desirable arm movements actually become smoother and less encumbered by friction.

Thus, viscous damping has the same relation ship to the vibrations and movements of your tone arm that shock absorbers do to those of your automobile.

Anything mechanical vibrates. Obviously, if the tone arm vibrates while you are playing a record, the vibration is going to be coupled to the stylus cantilever of the phono cartridge. Think of the stylus tip as analogous to a wheel on an automobile and the semi-elastic cantilever suspension as an automobile spring. Shock can be transmitted both from the road to the auto body and from the body to the wheel via the spring.

Any stylus cantilever motion not due to groove modulations is-or becomes-distortion in the cartridge's output. The cartridge, after all, can't be expected to tell the difference between motion caused by the groove and that caused by the movements of the arm alone. Now while it is just about impossible to keep a mechanical system like an arm and cartridge assembly from vibrating, viscous damping can be used not only to keep the level of the vibration low, but also to make the arm-cartridge system stop vibrating sooner than it ordinarily would have. With today's very-low-friction arms, this is important.

When an arm-cartridge combination is "excited" into vibration by acoustical feedback, a warp, or a shock, it continues to move up and down or from side to side about its pivots at its resonant frequency-say, anywhere from about 15 Hz down, depending on the cartridge used, the mass of the arm, and other factors. The length of time it will continue bouncing will be inversely related to pivot friction. With current low-friction designs, a single shock can engender movements that might take minutes to die away naturally.

Something else is needed, like a shock absorber, to stop the bounce quickly. Viscous damping does the job. Because it does, the cartridge will convert far less of the arm's movement into unwanted electrical output. And that means less distortion.

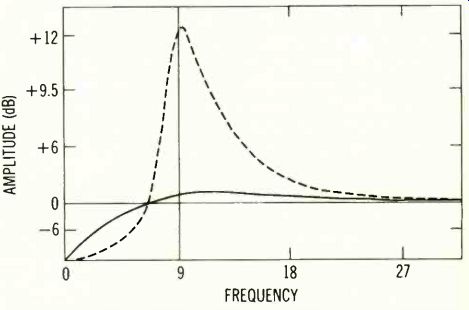

---------- Theoretical curves compare bass resonance in a damped

arm (solid line) with that of same arm minus damping (dashed). Actual

values will of course depend on mass and compliance values.

Some Practical Tests

How important is this? After all, you can't hear "sounds" below 20 Hz. True, but you can hear their effects--and enjoy their absence.

Lately the Boston Audio Society, with the guidance and encouragement of Dr. S. L. Phoenix of Cornell University's Department of Mechanical Engineering, has been experimenting with viscous damping. The results have been exciting.

Usually damping was added to existing tone arms, since it is a rare audiophile who has enough know-how to build his own arm. This was a sometimes sticky job (see the box for do-it-yourselfers), but the payoffs often were dramatic.

Some members of the group had experienced difficulties using the ADC XLM cartridge, for ex ample. The cartridge got rave reviews and turned into something of an audio cult symbol. But its users had found that in some arms it could bottom out on warps, mistrack, or otherwise disappoint.

With the tone arm damped, however, the XLM sailed unperturbed over warps and traced grooves with less distortion than ever.

Similarly, some members had complained that the Shure V-15 Type III (which also has plenty of admirers so appreciative as to represent some thing of a cult) produced "a somewhat vague stereo image." Directionality and placement of instruments weren't as sharp as with some other cartridges, they had felt. But when it was mounted in a damped tone arm, the Shure gave what its users now felt was near-pinpoint localization.

There were other experiences with other cartridges. Some experimenters reported cleaner, tighter bass reproduction. Some appeared to suffer less preamplifier overload in critical pickup-input combinations. A few reported no striking difference in performance, but almost all of these either had outdated tone arms with high mass or friction, or were using low-compliance phono cartridges.

The most demanding audiophiles--those with the most advanced arms and most compliant cartridges--noticed the most improvement. Could it be that the better the record-playing equipment, the greater the need for damping? There was another side to these admittedly in formal tests. Some of the group used good cartridges in marginal arms, added damping, and noticed improved performance. Does this make damping a cure for so-so tone-arm design? No, but it might indicate that the movement of the past few years toward ever lower masses and friction may have reached a point of diminishing returns: Some resistance to arm motion may be desirable.

But why did things sound different? The group still is trying to answer this to its satisfaction, but there are some pretty fair guesses.

There are no absolutely flat records; arms and cartridges are continually being forced into resonance by nearly invisible warps. Higher-quality arms and cartridges, especially, respond readily to them. And there is no such thing as perfect acoustic isolation for any record player. Again the result is resonant vibration, this time triggered by shock, room vibration, and acoustic feedback.

Just getting these resonance products out of the cartridge's output should have cleaned up the sound, and seemingly did. After all, there was now less subsonic material and consequently less audible intermodulation between the resonances, their harmonics, and the music.

This freedom from sub-sonics may be especially important to owners of some super-preamps with response reaching almost to DC. Unless they are removed by damping, or filtered out electronic ally, signals due to arm-cartridge resonances not only could enter the preamp at levels several times as high as midrange musical signals, but also could be boosted by as much as 60 dB by RIAA equalization that (incorrectly) continues its rising bass characteristic into the subsonic region. Some of the better preamps offer a switchable subsonic filter as a preventive for the severe overloading that resonance-rumble interaction can cause in phono preamp stages-even those that have plenty of headroom at higher frequencies.

There are other, less obvious payoffs, some still being explored, such as damping's effect on tracking-force variations. Among the advantages that may emerge is reduced record wear due to the suppression of instantaneous tracking-force extremes.

Like other electromagnetic transducers, a magnetic phono cartridge has a region of best performance--its so-called linear region-within which it accurately transforms the movements of its stylus cantilever into an electronic equivalent of the groove modulations. Tracking forces are specified not only to assure decent groove tracing, but also to place the stylus cantilever in about the center of its linear range of motion (that is, of vertical flexing) with respect to the cartridge body. But tracking force is a static specification, and record playing is a dynamic situation; when a rising warp is encountered the effective tracking force will be in creased as the arm is forced upward and/or the cantilever spring flexed toward the cartridge body. As the record surface descends, the effect is reversed. Thus begins the so-called Pogo-stick effect that, particularly in an undamped arm, can cause continuing variations in instantaneous tracking force and even make the stylus hop out of the groove altogether.

Incorrect tracking force, whether it is too low or too high, momentarily moves the cantilever out of its optimum location. Either way, tracing suffers.

There may be repeated, if momentary, losses of contact with either or both groove walls and repeated instants at which tracking force exceeds the bearing strength of the groove walls. And the angular flexing of the cantilever will produce what is aptly known as "warp wow"--a change in relative stylus-groove velocity and hence a waver in the music's pitch. With damping, this sort of abuse seems to be greatly reduced because the stylus more consistently is in good contact with the groove walls and its cantilever less often is deflected outside its optimum range of movement.

One listener felt that, simply because the stylus no longer was being subjected to as much unwanted movement at resonant frequencies, the effect was as if someone had stopped fiddling with his system's volume and balance controls. It was, to him, similar to switching from a turntable with flutter to one without-only the difference was not in pitch, but in space. The feeling of "uncertainty" was gone.

Another reason for apparently cleaner sound may be that, because of improved tracing, there is less of the high-frequency "chatter" usually caused by the stylus rattling about in the groove.

Although mostly above 20,000 Hz, this chatter could be indirectly responsible for some audible distortion.

On the basis of these experiments, then, the desirable properties of arm damping seem amply confirmed. But, like most techniques, it can be abused. Too much damping, for example, can make a tone arm respond arthritically to warps and shocks and (though it might make for a nearly non-resonant arm-cartridge combination) reintroduces excessive cantilever flexing and hence some tracking problems. It's a question of finding optimum values.

In practice, the buyer of a damped tone arm needn't worry about overdamping. The arm de signers have taken the problem into account and generally will have picked an amount of damping that will fill the needs of a wide variety of cartridges. The arm may over-damp or under-damp slightly without causing problems, while still obtaining nearly all of damping's advantages.

If there's no viscous-damped arm available for your particular needs, you can compromise by selecting one of the many good designs using counterweight decoupling. But bear in mind that, while decoupling lessens resonance difficulties, it may not be as complete a solution as viscous damping.

Do-It-Yourself Tone-Arm Damping

If you are the adventurous sort--and handy--you can duplicate the experiments mentioned in the body of this article. They involve little investment in either time or money and can pay large dividends in improved phono reproduction.

Although several approaches were tried, the easiest to manage is the one described here. Not only is it simple to apply, but it also allows the user to vary the amount of damping and thus approach the optimum amount for his arm and cartridge. It was developed by Robert Graham of the MIT-Lincoln Laboratory.

The parts required are: a nylon cable clamp, a nylon nut and bolt, some stiff brass wire, and a small amount of brass sheet stock. Lighter metal could be used and would, in fact, be preferable. Also necessary is a small trough--say, 1 inch in both depth and width and about 2 1/2 inches long--capable of holding about half a cup of STP motor oil additive.

The figure shows how these elements go together to form a tonearm "damper." Note that the amount of damping can be varied by pushing the clamp closer to, or farther away from, the arm's pivots. In practice, the distance of the damping paddle from the pivots will be decided by the space between the turntable and the arm's vertical shaft; the paddle must move freely with the arm as it tracks to the inner grooves of a record--it shouldn't touch anything but the STP damping fluid.

Horizontal damping appears to be a bit less critical than vertical damping, so begin your experiments by epoxying a paddle at right angles to the wire and making it about 1/2 inch square. Attach the damping assembly to your arm and-carefully pour the STP in the trough, covering the paddle.

Leave room below the lip of the trough so that the fluid won't lap over when you move the arm. (This is the messy part of homemade damping; but if you don't spill, you won't have to clean up.) Now check for improved tracking of warped discs; with near-optimum damping, no movement of the stylus cantilever should be visible. The stylus cantilever and the cartridge body should appear to move as a unit. Increase or decrease the paddle area until you achieve this condition. If you have a set of test records, you might go further and optimize the paddle area for best low-frequency tracking or square-wave response.

Chances are that you will slightly over- or under-damp your arm, but your approximation will be close enough. After obtaining the correct amount of horizontal damping, add a vertical paddle and experiment with it until there is as little side-to-side cantilever movement as possible when playing warped or off-center records.

If all this seems a little bit ad hoc, bear in mind that it will give good results cheaply. But be warned: The experiment may convert you to an avid arm-damping enthusiast (as, obviously, it did me).

-J.B.

above: The "paddle" referred to in the text is the horizontal vane visible near the bottom of the trough (which is filled with STP) in the drawing. Trough must be positioned so that paddle never touches its sides or bottom only the STP dumping fluid.

-------------

(High Fidelity, Jul. 1975)

Also see:

Understanding Tonearms (Audio, June 1980)--part 1

Understanding Tonearms (Audio, June 1980)--part 2

How to Judge Record-Playing Equipment (by Edward J. Foster; Apr. 1977)

Dual manual turntables (ad, Jul. 1975)