Today, the electrical performance of a communications receiver can be mathematically predicted with the help of computers. As a result, the amount of circuit design required by a manufacturer is minimal. Of much more significance is the amount of performance that can be achieved for the price. The question remains how to build a high performance low cost receiver. The answer lies in how the receiver is setup mechanically, or how it is packaged. Designing a communications receiver with stringent cost and labor boundaries automatically leads to the idea of using plug-in modules, as previously discussed.

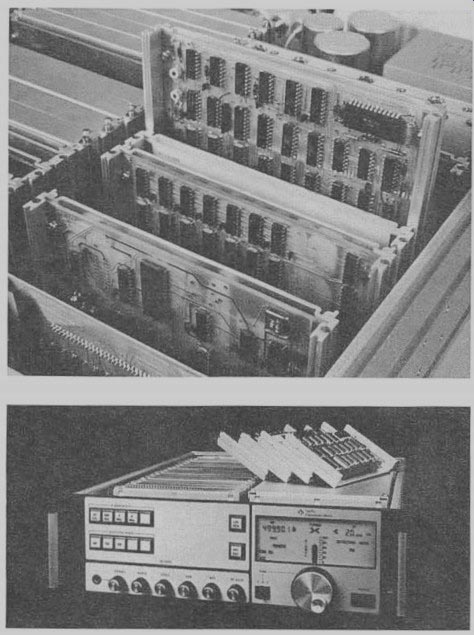

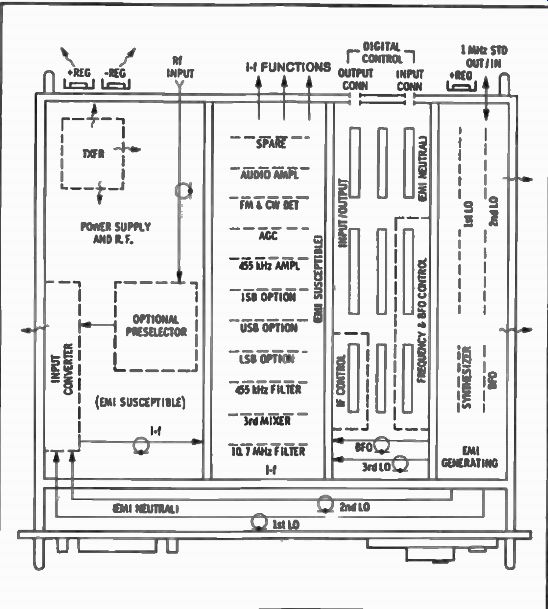

These modules would functionally resemble the block diagram of the receiver, and can be individually manufactured and tested before integration into the receiver's frame. Fault isolation is automatically achieved with the use of diagnostic computers, as shown in Figs. 1 and 2, thus reducing the manufacturing cost and allowing for more performance to be incorporated in the design for the same price. Figure 3 shows the extensive use of module boards in the Norlin SR-2090 communications receiver.

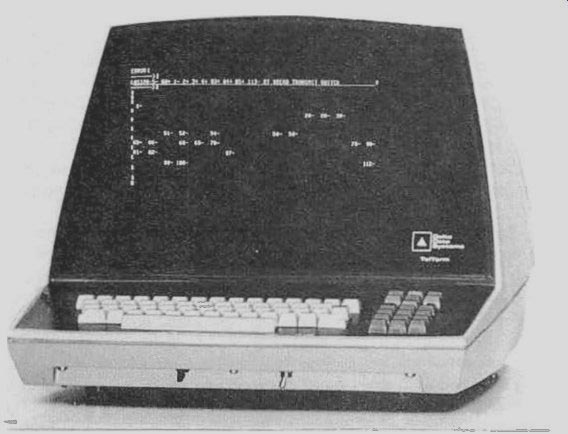

Fig. 1. Diagnostic computer used for automatic testing of module-boards.

Fig. 2. Actual display of faults on the cri of a diagnostic computer.

Fig. 3. Mechanical layout of the SR-2090 communications receiver

shows a modular approach (courtesy of Norlin Communications).

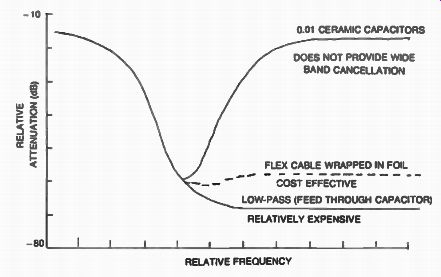

Fig. 4. Relative attenuation and cost of different methods of noise

cancellation for interconnect lines in a communications receiver.

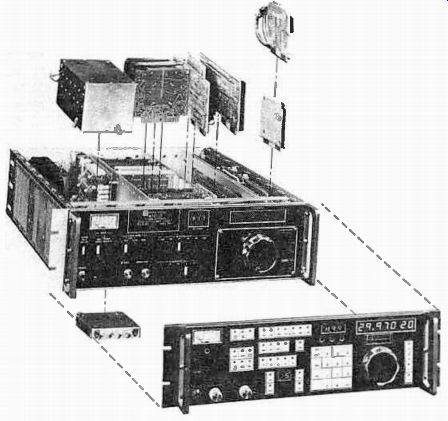

Fig. 5. Packaging of the Watkins-Johnson WJ-8718 HF receiver (courtesy

of Watkins-Johnson Company).

Fig. 6. Mechanical layout of the WJ-8718 HF receiver.

Because of the performance goals required in a communications receiver, the problem of interconnecting the modules economically and efficiently becomes a major cost element of the design. Demanding shock, vibration, and temperature requirements, as well as electromagnetic interference (EMI) standards call for new and economical ways of packaging. The problem is further aggravated by the highly digital nature of today's communications receiver. As many as a hundred control lines are sometimes needed to allow functional access to the various modules from the main microprocessor as well as from the commands and interfaces located on the front and back panels. The digital noise generated by these lines can greatly interfere with the performance of the receiver. Introducing lowpass filters in each one of the lines would prove too excessive for the cost of the receiver, while the use of ceramic capacitors to by-pass each circuit would only provide suppression at the self-resonant frequency of the capacitors. The economical solution to the problem is the use of a special flexible flat cable which is wrapped in metal foil. This provides a cost effective solution as shown in Fig. 4. It has been found that the filtering provided by this type of interconnection technique costs five times less than conventional line filtering. The method has been successfully applied in production by Watkins-Johnson Co. in an attempt to manufacture a low-cost, high-performance communications receiver, the WJ-8718. Watkins-Johnson Co. in an attempt to manufacture a low-cost, high performance communications receiver, the WJ-8718.

Additional manufacturing cost reductions have been obtained by the elimination of time consuming milling and tapping of the chassis, while substituting punching and bending of sheet metal parts. The use of nuts and washers has been reduced to a minimum while emphasis was put on efficient ways of interconnecting the functional blocks. Extensive use of automated board assembly as well as automatic test equipment (ATE) makes the manufacturing of the WJ-8718 HF receiver one of the most automated production processes of its kind, allowing for a true low-cost, high-performance communications receiver at a fraction of the cost of other comparable receivers. Figure 5 shows an exploded view of the WJ-8718 receiver at the subassembly level. Shown in Fig. 6, is the mechanical layout of the receiver.

In conclusion, receivers can be built today with exceptional performance, but the manufacturing cost can make them prohibitively expensive. The greatest task remains how to get the most performance for the lowest cost. While electrical design remains important in this regard, the solution lies in using more ingenious packaging techniques, as well as the automation of production lines and testing techniques.