Impedance Transformers

Q. I want to buy a good pair of microphones for my open-reel recorder, but I'm told I will need to put out an additional $20 each for "impedance transformers." Why?

PAUL D. WATSON; Tarleton, Texas

A. Microphone impedance transformers (also sometimes called "cable transformers") are a usually necessary "inter face" that adapts the output characteristics of high-quality microphones to the input characteristics of many consumer tape machines.

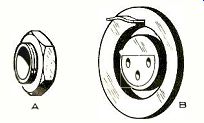

Most top-quality microphones are designed to be "low-impedance" (250 ohms or less) and are intended for use with "balanced" cables-that is, cables with two inner conductors plus an outer braided shield. Most tape-recorder microphone jacks, on the other hand provide a "high-impedance" (2,000 to 50,000 ohms) input (A) and are "unbalanced," which means that the plug at the end of the cable has two conductors or contact points, as on a standard or miniature phone plug.

A. Many microphones are designed for high-impedance unbalanced operation, and these can be plugged into consumer recorders directly. But they are undesirable for serious live recording for two reasons: first, high-impedance cables must be kept quite short (about 12 to 15 feet at most) or they will roll off the high-frequency response; second, unbalanced, high-impedance lines are susceptible to hum and noise pickup.

Low-impedance balanced lines solve both the high-end rolloff and the hum pickup problems and permit cable runs of hundreds of feet. (With the cable-length restriction on high-impedance mikes, your recorder would probably be close enough to the mikes physically that its motor noise might be picked up.) Professional recorders (and mixing consoles) are designed to use "low-Z, balanced" micro phones directly, and they usually have three-pin "Cannon-type" connectors (B). (They also cost enough more to cover their built-in $20 microphone transformers!) When connecting the transformers for use with home recorders, be sure to put them at the far end of the cable and near the recorder, not at the microphone end of the mike cables.

That way, only a very short length of single-conductor shielded cable (from transformer output to recording input) will be required.

Relapping Heads

Q. The heads on my reel-to-reel deck show definite signs of wear. I've heard that professionals "re-lap" worn heads instead of just replacing them. Is there any way this can be done for the tape heads in home recorders?

MAXWELL CARTER; Decatur, Ga.

A. Yes, there is, and since a new set of heads may well cost over $100-plus the labor of having a technician install them relapping may be worth considering.

When tape heads wear, two things happen simultaneously. First, ridges appear on the face of the head at the edges of the tape path where it cuts into the head. Second, the point of contact between the tape and the head be comes flattened. Both will cause loss of the proper tape-to-head contact (which shows up audibly as erratic high-frequency performance), and the ridges can actually do permanent damage to the edge of a tape that is slightly wider than normal or is skewing. Re-lapping (or re-polishing) the head eliminates the wear groove on the head face and restores it to a close approximation of the original rounded contour at the point of contact.

There are professionals who re-lap heads for recording studios, but their services may be hard to come by (as well as prohibitively ex pensive) for the home recordist. But if the wear groove on the head has gotten sufficiently deep for you to catch your fingernail on, either replacement or relapping is called for.

Nortronics has recently begun marketing the QM-707 Handylap kit, which contains everything you need to do a first-class job on about a half-dozen heads. (They also make available refills of the extraordinarily precise lapping films necessary, so you could make a small business of head lapping for friends if you want to.) Frankly, while in the past I had imposed on a couple of skilled lapidary friends who had given a new lease on life to several tape heads that were otherwise headed for the wastebasket, I was initially very skeptical about my own ability-and that of readers who have never done this sort of thing before-to attain the necessary precision. Using the kit and following the directions in the extremely clear instruction booklet, however, I've become a believer: it can be done.

Not every tape head, of course, can successfully be restored to "like-new" performance by relapping. The average gap thickness in a tape head is between 16 and 22 mils (thousandths of an inch). If normal wear or the additional abrasion of the re-polishing process brings you ultimately to the bottom of the gap, where it begins to widen excessively, there is no alternative to complete replacement. However, a professional is likely to be able to re-lap a head, at a guess, twice during its useful life, and a home recordist, who might wait a bit longer initially, may be able to re-lap only once. Even at that, however, he will be doubling the life of a head he would otherwise have discarded.

I don't mean to make this sound overly easy; unless you have the necessary test tapes and other equipment, you will still have to get a service technician to install the re-lapped heads just as if he were putting in new ones.

And the Handylap kit isn't free, either: it carries a $65 suggested list price, though that may be discounted somewhat by a local dealer. Nortronics will send you a list of dealers from whom the QM-707 is available if you write them at:

8105 Tenth Avenue North, Minneapolis, Minn. 55427, attention of Mr. J. B. Strand.

In any case, compare costs carefully before investing.

Antique Restoration

Q. I've been a great open-reel tape enthusiast for nearly thirty years. Now I'm finding that an occasional older tape develops a squeal and sort of chatters as it passes over the heads of my deck. I suspect that some of these older tapes weren't of the best quality, and probably the lubricant is drying out. But since some of my favorite music is on them, is there anything I can do to make them playable again?

FRANCIS J. FOSBURY; Coral Springs, Fla.

A. Not only the lubricant (if any), but the plasticizer used in these old tapes has dried out, and what you really need is one final squeal-free pass-so that you can dub the material onto a more modern tape and discard the originals.

There are commercial "head lubricants" you can get in audio shops (they usually have a silicon base), but they probably won't help much. While I offer no guarantees, you might try taking one of these old reels and putting it into a metal film can together with a piece of moist blotting paper. Seal it up with tape to keep it airtight, and give it a day or so to let some of the moisture in the blotting paper penetrate into the older tape. Upon removal, you might be able to dub that treasured "ol die" before it has a chance to dry out again.

Also see:

AUDIO BASICS The Cassette: A Short History

Source: Stereo Review (USA magazine)