24. Power Transformers for Electronics

Power transformers used in electronic applications are called upon to deliver alternating voltages that may be higher than or lower than or equal to the line voltage. Normally, heaters of indirectly heated tubes, or filaments of directly heated tubes, are designed to be used at voltages ranging from 1.5 to 70 volts. The vast majority of power transformers used in radio and television fall into the 6.3-volt or 12.6-volt class. These, as well as certain types of bias supplies employed in radio transmitters and industrial electronic circuits, utilize step-down transformers in which the primary-to-secondary turn ratios are proper fractions.

Plates and screens of vacuum tubes often require de potentials higher than the peak a-c voltage provided by the line. For these applications, a plate power transformer working into a rectifier filter system is common. Such power transformers are designed with step-up turns ratios engineered to meet the needs of the particular circuit. Plate power transformers fall into one of two classifications. They may be transformers with untapped secondary windings and used for half-wave or bridge rectification or they may contain a secondary centertap for a full-wave rectifier circuit.

Most small transformers intended for standard electronic equipment contain more than one secondary winding. For example, a power transformer used in a communications receiver might have a 500-volt center-tapped secondary winding to provide 250 volts rms to each of the plates of a full-wave rectifier, a 5-volt winding rated at 2 or 3 amperes for the filament or heater of the rectifier tube, and one or more 6.3-volt windings for the heaters of the amplifiers, detector, power output tube, etc.

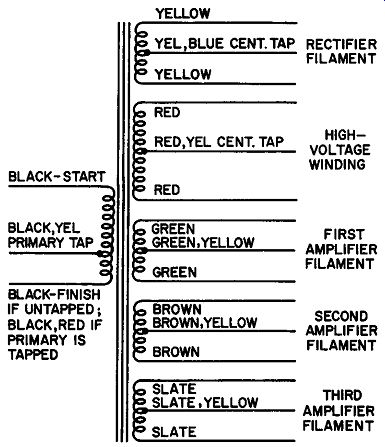

Fig. 14. Power transformer color code. This code is applicable to all types

of power transformers provided with emerging, insulated wire leads, whether

or not they are combination types.

Some plate or combination power transformers are equipped with a tapped primary winding as well. Such transformers can be adapted more easily to locations in which the line voltage is slightly more or less than the nominal value given for most transformers. (The nominal line voltage used by most transformer manufacturers is 120 volts. Tube manufacturers consider 117 volts the nominal line voltage.) In recent years, the so-called small isolation transformer has appeared in transformer design literature. Generally, these transformers have a single secondary winding, with the same number of turns as the primary, and are intended merely to isolate the equipment from the a-c lines, to reduce the danger of serious shock. When electronic equipment is directly connected to the lines, there is always the hazard that an ostensibly "grounded" chassis is really connected to the ungrounded leg of the a-c line.

If it were, the full line voltage then would exist between the chassis and any grounded object in the vicinity.

25. Color Code for Power Transformers

Combination power and filament transformers, isolation transformers, and straight filament transformers are always color-coded, to enable convenient identification of the various windings, or they are provided with labeled binding posts or solder lugs. This is also true of plate transformers equipped with wire leads. (The applicable color code is given in Fig. 14.) The color code does not provide information relating to the actual a-c voltages available.

These must be obtained from the manufacturer and generally appear on a specification sheet included in the package or on the packing carton itself. The same is also true of the current ratings of the various secondary coils.

26. Relation of Power Transformer to Rectifier-Filter System

In the normal application of power transformers in electronic equipment, filament winding ratings are always selected to meet the requirements imposed upon the transformer by the low-voltage load. For example, if a rectifier tube is specified 5 volts at 2 amperes, the filament winding should have the same rating. To be safe, it is insufficient to have a filament winding that has a higher current rating than the load. If the load does not take as much current as the winding is capable of providing at the rated voltage, then the voltage is likely to be too high. This shortens tube life.

On the other hand, if the load demands more current than the rated transformer winding, the applied voltage will be too low, the transformer may begin to overheat, or both effects may occur simultaneously. Since filament windings may be obtained easily for a wide range of loads, there is no excuse for slipshod selection of the filament transformer.

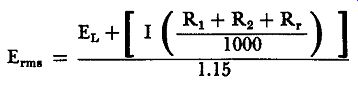

Fig. 15. Typical choke-input filter system in power supply showing voltage

drops and load current.

The choice of output voltage for the high-voltage or plate winding, however, is not quite as simple. Since we are interested in obtaining a plate winding whose output voltage (a-c, rms) will yield a given d-c voltage at a given load current, the problem is one of first choosing a filter system and then calculating the voltage drops.

If a choke-input filter is used, the rms voltage delivered by the transformer to each rectifier diode will depend upon the desired d-c output voltage, the voltage drop in the rectifier tubes, the voltage drops in the chokes, and the current taken by the load.

These quantities are related by the equation:

(34)

where Erma = Required rms secondary voltage of the transformer's voltage secondary to each diode. If this is a half-wave rectifier circuit, then Erma is the total secondary voltage. If it is a full-wave rectifier circuit, then Erma is the output voltage each side of center tap. E1 , = Voltage that is desired across the load, I = Rated full load current (in ma), R 1 = Resistance of one choke, R, = Resistance of second choke, and Er = Voltage drop across rectifier (s). (See Fig. 15.) Example s. Find the rms secondary voltage required to yield a d-c output voltage of 250 volts from a choke input filter having the following specifications: Choke No. I has a 200 ohms resistance and Choke No. 2 has a 1100 ohms resistance. The load current is 50 ma and the average rectifier resistance is 1000 ohms.

Solution. Substituting in Equation (!14): E = 1.1 [250 + 50 ( 200 + 11OO) + .050 X 1000) rme 1000 = !157,5 volts

Clearly, the rms output rating of the transformer could be reduced by employing a rectifier with less internal resistance and by using chokes of lower d-c resistances.

The use of a capacitor-input filter of the type shown in Fig. 16 allows a much lower rms output rating possible for the same d-c voltage.

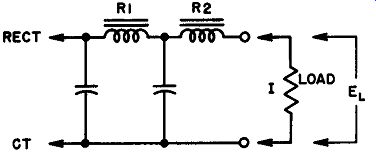

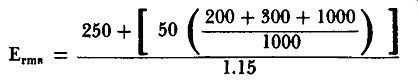

The equation that provides a close approximation to the rms voltage required to provide an output voltage EL in a capacitor input type of filter system is:

(35)

Fig. 16. Capacitor-Input filter substituted for the choke-input filter of

Fig. 15. Chokes have the same resistance; rectifier resistance is also the

same.

Using the values from the previous example and substituting in Equation (35) , the required rms output voltage from the transformer must be:

Although there seems to be little reason for using a choke-input filter, choke-input filters are very popular. Far better voltage regulation is obtainable and higher load currents are possible with choke-input filter systems. [See Vacuum Tube Rectifiers edited by Alexander Schure. John F. Rider Publisher, Inc., 1958.]

27. Relation of Volt-Ampere Rating to Filter System

Transformers are generally designed for a predetermined maxi mum allowable temperature rise. When a capacitor-input filter is employed, a very high ratio of peak-to-average current may flow in the secondary winding of the transformer. This excessive ratio may result in considerably more heat in the winding than anticipated by calculating energy losses on the basis of actual power delivered to the load. This would necessitate using a transformer whose volt-ampere rating is appreciably higher than the value required for a choke-input filter. Thus, conditions very often demand the use of a choke-input filter.

In a given power supply using a choke-input filter, the choice of the first inductance in the filter system must be made on one of the following bases.

(a) If the peak rectifier current must not exceed the d-c load current, the inductance of the first choke should be related to the load resistance of the power supply:

L = 0.001 X RL (36)

where L is in henries, and the load resistance, RL, is in ohms. To fulfill the conditions stated, L must be equal to, or larger than, the value given in Equation (36). For example, in the illustration previously given, the power supply must provide 250 volts at 50 ma full load. Hence, at full load, the load resistance is: E 250 R = - = - = 5000 ohms I .05

To prevent the output voltage from exceeding the average voltage to the filter, the choke should have an inductance of 0.001 X 5000 = 5 henries, or more.

This inductance value is called the critical value, and is especially important when the load current is small.

(b) Very often, the rectifier can handle consider ably more peak current than the average d-c load current. In such cases, it is possible to use a smaller choke without endangering the tube, provided that a choke of lower inductance will still provide the desired amount of filtering.

(c) When the load current is large, care must be exercised to insure that the peak rectifier current does not exceed the d-c load current by too high a percent age. If the first choke has a value equal to or greater than the value given by Equation (37), the peak rectifier current will not exceed the d-c load current by more than approximately 10%. L = 0.002 RL (37)

Using the figures of the example previously discussed, this requires a choke of:

L = 0.002 x 5000 = 10 henries

This value is called the optimum value of inductance for a choke-input filter network.

When the optimum value is employed, conditions (a) and (c)

are generally satisfied in most standard power supplies. Since the optimum value exceeds the critical value, at very low load cur rents-such as no drain beside that of the bleeder resistance-the output voltage will not rise above the average input voltage to the filter. When the load current rises to its maximum rated value, the inductance will still be sufficient to prevent excessive rectified peak current.

28. Filament Transformer Ratings

Most vacuum tubes in modern electronic equipment are heater types and are designed for a-c operation at relatively low voltage levels. Other than in special applications, as in high-gain voltage amplifiers employed in high-fidelity equipment, these tubes are heated directly by the a-c from a transformer. Although there has been some indication of a manufacturing trend in television receivers in the direction of series strings, it appears likely that this practice will be abandoned in favor of parallel connection of tube filaments directly across a low-voltage winding of the transformer.

A transformer of this type must be designed to carry the sum of all the currents drawn by the parallel group. In many instances, particularly in higher quality transformers, the low-voltage winding is center-tapped, to permit better balance for minimizing hum.

Currents flowing in the filament or heater circuits of even medium-power tubes are, in general, quite high. Consideration must, therefore, be given to the possibility of voltage drops in the conducting wires, since under-voltage, as well as over-voltage, may be injurious to tubes. It is common practice in transmitter circuits to supply each high power filament its own filament transformer (located near the tube to avoid the long runs of connecting wires that inevitably appear when the power supply is located some distance from the other equipment) . The thoriated tungsten filaments used in transmitting tubes are especially subject to deterioration, when operated at less than their rated voltages.

29. Rewinding Filament Transformer Secondaries

Filament transformers are available in many voltage and cur rent ratings. Since they are not particularly expensive, few technicians attempt to wind or to rewind transformers. On the other hand, the appearance of transistorized equipment on the electronic scene has precipitated a demand for low-voltage transformers of all types. The service technician or engineer who finds that he requires a definite a-c voltage suitable for a testing jig, or a work bench power supply for transistors, may be interested in rewinding an old transformer to his own specifications. It is not a difficult task. It involves a small number of turns and the wire used is large enough to be handled without special precautions.

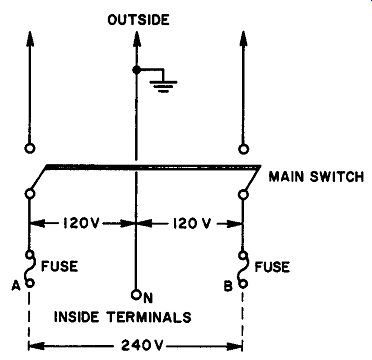

Fig. 17. Three-wire residential and factory wiring.

Note that no fuse or switch is used in series with the neutral leg.

The primary volt-ampere rating of the transformer to be re wound should first be determined from the transformer label or from the manufacturer's catalog. If a secondary volt-ampere rating of 90% of the primary winding rating is anticipated, the transformer can probably be used without concern. First, marking them carefully for later identification, remove the leads from the old terminals. As the core is disassembled, note the manner in which the laminations fit together, so that they can be replaced the same way. If the primary is wound under the secondary, merely remove the turns from an old filament winding, counting as you go in order to establish the turns-per-volt ratio. If the secondary is under the primary, the turns may still be pulled out after cutting away the side fiber insulation. The number of turns to be added in rewinding is determined by the volts-per-turn ratio as follows.

Suppose that you have established the old winding turns-per-volt ratio to have been 5 turns-per-volt; assume it was a 5-volt winding. (This would be the ratio if this winding originally had 25 turns so that 25 turns to 5 volts gives a ratio of 5: 1.) Should you now want a 9-volt winding, you would use 45 turns.

The wire selected for rewinding depends upon the current your load will draw. You must remain within the 90% primary volt ampere rating limit. It is a good idea to confine your choice of wire to the smallest size that will allow 1000 circular mils/ampere.

(The current ratings of various wire sizes may be obtained from any electrical or electronics handbook.) The insulation used be tween the core and the first winding, and between the windings themselves should be a good grade of linen paper (not friction tape) , and should be wound in several layers, unless the transformer is to be used in high-voltage circuits. In that case, varnished transformer cambric should be used instead of linen paper.

30. Connection of Transformers to Power Lines

Low-power transformers, i.e., 200 watts or less, used in homes and commercial establishments are simply connected to a 120-volt line, via wall or baseboard receptacles. When power requirements exceed this value, it may be necessary to take further steps to insure safe operation. The present trend in home and small factory wiring involves the use of the three-wire system in which 240 volts exists between the two "outside" wires, while the potential difference between each of these and the neutral, or grounded wire, is 120 volts. (See Fig. 17.) Appliances and machines are connected between the neutral and either of the two outside wires, if they are designed for 120-volt operation, or between the two outside wires (A and B) if they are heavy-duty 240-volt devices.

Observe that there is neither a fuse nor a switch in the neutral leg. If this line should be opened, full potential would exist across A and B. In addition, the voltage between the neutral and either outside line would still be present, as a result of the series connection between appliances divided between the two circuits.

In practice, household appliances and small machines are divided as equally as possible across A and N, and B and N to equalize the load on both incoming "hot" wires. 120-volt rated transformer primaries are connected from either outside leg to neutral, while those of 240-volt rating are connected directly from A to B. In applications where very heavy drains are to be placed on the lines, it is often advisable to use an isolation transformer having a 2: l step-down ratio. The primary of this transformer is connected from A to B, while its secondary steps down the voltage from 240 volts to 120 volts, for use with standard transformers. This approach results in perfect equalization of the current drain in each of the incoming wires.

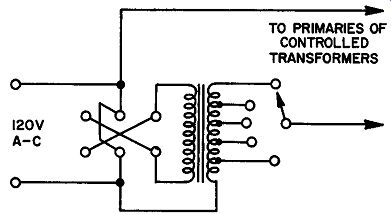

31. Transformer Primary Control

Line voltages, even in industrial areas, are seldom constant throughout a 24-hour period. As the current demand of a community increases, either at the approach of evening or an unexpected storm, line voltages tend to decrease. Certain applications of transformer-operated equipment demand automatic control of primary voltage, to avoid malfunctioning as a result of fluctuating line voltage. In such applications, either voltage-regulated d-c power supplies are used or constant-voltage transformers are employed. The latter will be discussed in Section 6.

Where manual control of the transformer primary voltage is permissible, several methods may be used. High quality transformers having tapped primary windings are available. These enable the user to apply the input voltage to taps designed for 105 volts up to 125 volts, so that the secondary voltage is very closely equal during all normal fluctuation periods.

Fig. 18. Auxiliary-transformer control of input voltage to primaries of power

transformers.

A second method of manual control is illustrated in Fig. 18. An inexpensive tapped secondary step-down transformer serves to boost or buck the line voltage for adjustment purposes. The auxiliary transformer should have a secondary tapped every 2 or 3 volts over a 5- to 20-volt range. When phased in series aiding, it will add to the line voltage. When phased opposite to the feed lines, it will oppose the input voltage. A reversing switch provides for either phasing arrangement, thereby making it possible to boost or buck the line voltage at will over a 5- to 20-volt range.

The secondary should be capable of carrying the full primary current of all the controlled transformers connected to it. This method is substantially better than using a series-dropping resistor in the primary winding to reduce line voltage, since it provides for either bucking or boosting, without appreciably affecting the voltage regulation. Primary voltage control can also be accomplished by means of a variable autotransformer. The autotransformer is dealt with in Section 6.

32. Secondary Windings in Series

For test circuits and other special applications, low-voltage transformer secondaries may be series-connected, to increase the avail- able voltage range. For example, a 5 volt and 6 volt pair may be connected in series-aiding to obtain 11 volts, or in series-bucking to obtain 1 volt of a-c. When using secondary windings in series, the maximum permissible current that may be drawn from the combination is limited by the winding having the lowest current rating.

Proper phasing for either the aiding or bucking arrangement is determined by a-c voltage measurement, while current ratings must be obtained from the manufacturer's specifications for the particular transformer used.

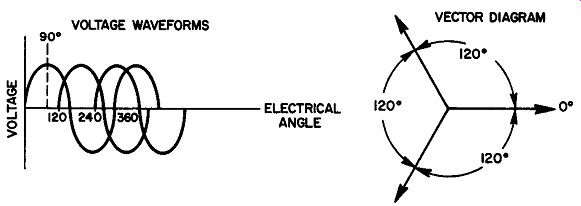

Fig. 19. Voltages in a three-phase distribution system. Each adjacent voltage

is out-of-phase by 120.

33. Distribution Systems

Although a complete discussion of commercial power distribution systems is beyond the scope of this guide, a discussion of power transformers would not be complete without mentioning polyphase distribution systems.

In the single-phase, three-wire system of power feed to residential and small factory electrical installations a neutral leg and two "live" legs are involved. The voltage between the two outside wires is equal to the sum of the voltages between either outside wire and the neutral. When power is derived from more than one set of armature windings in the powerhouse generator, the system is said to be polyphase. In general, polyphase systems are either two-phase (or quarter-phase) and three-phase. In the two-phase system, each phase is distinct from the other. The voltage between two wires of one phase always lags 90° behind the voltage between two wires of the other phase. Thus, each phase is independent of the other, and four wires are generally used for distribution. (Two-phase distribution is no longer popular.) Today, depending upon the magnitude and demands of the appliances and devices that use the electric power, single-phase and three-phase are favored.

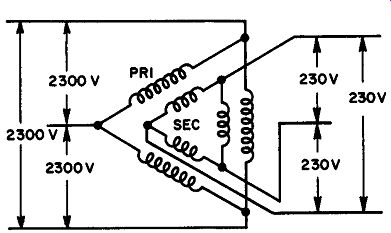

Fig. 20. Delta and star connection of three-phase generator.

Fig. 21. Delta-delta connection of a three-phase transformer to a three-phase

line.

Power in a three-phase system is derived from three sets of armature windings on the generator, and is usually distributed by three wires. The voltage across any one phase always differs from the voltage across either of the other two phases by an angle of 120°. (See Fig. 19.) The armature sections of a three-phase generator may be connected to the feed wires that supply the loads, using either the delta-connection or the star-connection. These two methods of connections are illustrated in Fig. 20.

34. Voltage and Current Magnitudes in Three-Phase Systems

Even a cursory examination of the delta-connected generator of Fig. 20 shows that the voltage between any two adjacent wires must be the same as the voltage in each phase of the armature winding. This is also true of the voltage between the two outside wires in the delta-connection. However, the star-connection may produce a voltage between any two line wires that is 1.73 times as great as the voltage in each phase of the armature winding.

Suppose that a three-phase alternator produced 2300 volts across each of its armatures. In the delta-connection, 2300 volts of 3-phase a-c would be available between any two of the three line wires.

In the star-connection, the same alternator would deliver 3980 volts across each pair of line wires. In either case, the total power delivered to the load would be the same, since the current-per-line wire would be correspondingly smaller at the higher voltage, if the current rating of the armature windings is not to be exceeded.

In a star-connected generator, the armature windings carry the same current as the line wires. In the delta type, the current is divided between two armature coils. Thus, more current than that flowing in each armature coil is delivered to the line. Therefore, it follows that the current in each wire of a balanced three-phase three-wire system is equal to the current in each phase of the load if the loads are Y-connected. In the delta-connection, the current in each wire is 1.73 times as great as the current in each phase of the load.

Fig, 22. Three single-phase transformers in a delta-delta connection to a three phase line.

35. Three-Phase Transformer Connections

Transformers may be connected to a three-wire, three-phase line in several different ways. Either three single-phase transformers or one three-phase transformer may be used. Consider a distribution transformer system in which a 10:1 step-down ratio is to be obtained between the 2300 volt lines and the load. In this case the load would be designed for 230-volt operation. Figure 21 illustrates how a single three-phase transformer might be connected in the delta-delta arrangement.

In Fig. 22, three single-phase transformers are connected to a three-phase line to provide similar performance. Except for space requirements, either arrangement is capable of providing the same efficiency.

36. QUIZ

1. Explain why a power transformer intended for use with a full-wave rectifier system generally is designed with a secondary centertap. Use a diagram to help you in your explanation.

2. Why are some plate power transformers equipped with a tapped primary as well as a tapped secondary?

3. Determine the filament winding rating of a power transformer that is to supply four type 6L6G tubes with heater current. The tubes are to be parallel-connected.

4. What output voltage would be obtained from a two-section choke input filter network (choke resistances 150 ohms and 200 ohms, respectively) at a load current of 200 ma, if the power transformer rms output is 790 volts.

The rectifiers are mercury-vapor types with a nominal 15-volt voltage drop.

5. Using the data given in Question 4, find the output voltage from a capacitor-input filter network with the 200-ohm choke in a single pi-filter.

6. Explain what is meant by the critical value of inductance in a filter network.

What is meant by the optimum value!

7. What is the function of the centertap in the low-voltage secondary winding of a filament transformer that supplies heater voltage for high-gain amplifier tubes?

8. Explain what is meant by a "three-wire, single-phase system with one neutral." Draw a diagram to help in your explanation.

9. A transformer has two 6.3-volt secondary windings and one 2.5-volt winding.

Draw a circuit diagram showing how these would be connected to obtain approximately 10 volts, indicating the phase relationships between the three windings.

10. Although the Y-Y connection of three-phase transformers has not been discussed, draw a circuit showing how this method of transformer connection would be used to supply 230 volts to a factory from a 2300 volt three phase line.