AMAZON multi-meters discounts AMAZON oscilloscope discounts

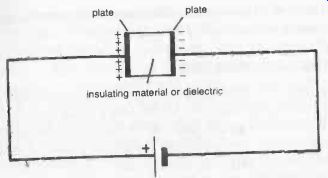

A capacitor is basically a device which stores an electric charge. Physically, it consists of two metal plates or electrodes separated by an insulating material or dielectric. Application of a dc voltage across the capacitor will produce a deficiency of electrons on the positive plate and excess of electrons on the negative plate--Fig. 5-1. This differential accumulation of electrons represents an electric charge, which builds up a certain level (depending on the voltage) and then remains at that level.

As far as dc is concerned, the insulator acts as a blocking device for current flow (although there will be a certain transient charging current which stops as soon as the capacitor is fully charged). In the case of ac being applied to the capacitor the charge built up during one half cycle becomes reversed on the second half of the cycle, so that effectively the capacitor conducts current through it as if the dielectric did not exist. Thus as far as ac is concerned, a capacitor is a coupling device.

There are scarcely any electronic circuits carrying ac which do not incorporate one or more capacitors, either for coupling or shaping the overall frequency response of the network. In the latter case, a capacitor is associated with a resistor to form an RC combination (see Section 6). The charge/discharge phenomenon associated with capacitors may also be used in other types of circuits (e.g. , the photographic electronic flash is operated by the charge and subsequent discharge of a capacitor triggered at the appropriate moment).

Like resistors, capacitors may be designed to have fixed values or be variable in capacity. Fixed capacitors are the main building blocks of a circuit (together with resistors). Variable capacitors are mainly used for adjusting tuned circuits.

Fig. 5-1. Illustrating how a capacitor builds up a charge when connected to

a dc voltage, blocking current flow.

FIXED CAPACITORS

Fixed capacitors fall into two main categories: non -polarized capacitors, and polarized or electrolytic capacitors. The main thing which determines the type of capacitor is the dielectric material used.

Non -polarized capacitors consist, basically, of metallic foil interleaves with sheets of solid dielectric material, or equivalent construction.

The important thing is that the dielectric is ready made before assembly. As a consequence, it does not matter which plate is made positive or negative.

The capacitor will work in just the same way, whichever way it is connected in a circuit, hence the description "non -polarized." This is obviously convenient, but this form of construction does limit the amount of capacitance which can be accommodated in a single package of reasonable physical size.

Up to about 0.1 microfarads, the package can be made quite small, but for capacitance values much above 1 microfarad, the physical size of a non-polarized capacitor tends to become excessively large in comparison with other components likely to be used in the same circuit.

This limitation does not apply in the case of an electrolytic capacitor.

Here, initial construction consists of two electrodes separated by a thin film of electrolyte. As a final stage of manufacture, a voltage is applied across the electrodes which has the effect of producing a very thin film of non conducting metallic oxide on the surface of one plate to form the dielectric.

The fact that capacitance of a capacitor increases the thinner the dielectric is made means that very much higher capacitances can be produced in smaller physical sizes. The only disadvantage is that an electrolytic capacitor made in this way will have a polarity corresponding to the original polarity with which the dielectric was formed, this correct polarity being marked on the body of the capacitor. If connected the wrong way in a circuit, the reversed polarity can destroy the dielectric film and permanently ruin the capacitor.

There is also one other characteristic which applies to an electrolytic capacitor. A certain amount of "unused" electrolyte will remain after its initial forming. This will act as a conductor and can make the capacitor quite "leaky" as far as dc is concerned. This may or may not be acceptable in particular circuits.

NONPOLARIZED CAPACITOR TYPES

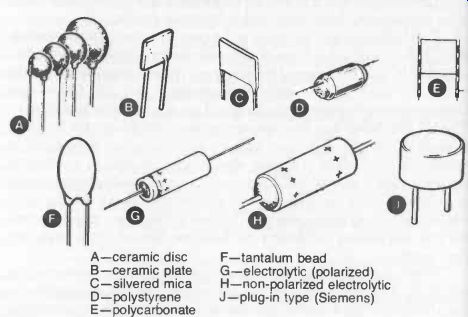

Various types of construction are used for nonpolarized capacitors, most of which are easily identified by the shape of the capacitor--see Fig. 5-2. There is no need to go into detail about the actual constructions. Their specific characteristics are important, though, as these can determine the best type to use for a particular application.

1. Paper dielectric capacitors, generally recognizable by their tubular form, are the lest expensive but generally bulky, value for value, compared with more modern types. Their other main limitation is that they are not suitable for use at frequencies much above 1 MHz, which virtually restricts their application to audio circuits. They are generally available in values from 0.05 µF up to 1 or 2µF, with working voltages from 200 to 1,000 volts. Plastic -impregnated paper dielectric capacitors may have much higher working voltages.

2. Ceramic capacitors are now widely used in miniaturized audio and rf circuits. They are relatively inexpensive and are available in a wide range of values from 1 pF to 1 µF with high working voltages, and also characterized by high leakage resistance. They are produced in both discs and tubular shapes and as metallized ceramic plates.

3. Silver-mica capacitors are more expensive than ceramic capacitors but have excellent high -frequency response and much smaller tolerances, so are generally regarded as superior for critical applications. They can be made with very high working voltages.

A-ceramic disc B-ceramic plate; C-silvered mica; D-polystyrene; E-polycarbonate; F-tantalum bead G-electrolytic (polarized); H-non-polarized electrolytic; J-plug-in type (Siemens)

Fig. 5-2. Examples of modern capacitors.

4. Polystyrene capacitors are made from metallic foil interleaved with polystyrene film, usually with a fused polystyrene enclosure to ensure high insulation resistance. They are noted for their low losses at high frequencies (i.e., low inductance and low series resistance), good stability and reliability. Values may range from 10 pF to 100,000 pF, but working voltage generally falls substantially with increasing capacitance (e.g., as low as 60 volts for a '100,000 pF polystyrene capacitor).

5. Polycarbonate capacitors are usually produced in the form of rectangular slabs with wire end connections designed to plug into a printed circuit board. They offer high values (up to 1µF) in very small sizes, with the characteristics of low losses and low inductance. Like polystyrene capacitors, working voltages become more restricted with increasing value.

6. Polyester film capacitors are also designed for use with printed circuit boards, with values from 0.01 µF up to 2.2 µF. Value for value they are generally larger in physical size than polycarbonate capacitors. Their low inherent inductance makes them particularly suitable for coupling and decoupling applications.

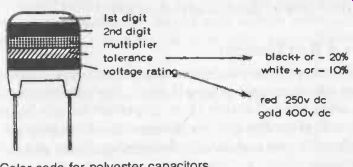

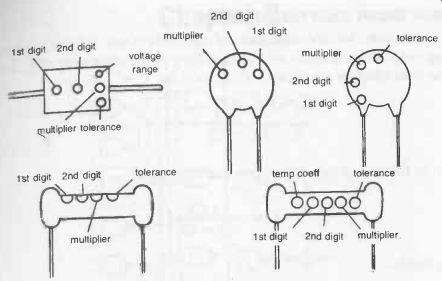

Values of polyester film capacitors are indicated by a color code consisting of five color bands, see Fig. 5-3.

7. Mylar film capacitors can be regarded as a general-purpose film type, usually available in values from 0.001 µF up to 0.22µF, with a working voltage up to 100 volts dc.

ELECTROLYTIC CAPACITORS

The original material used for electrolytic capacitors was aluminum foil, together with a paste electrolyte, wound into a tubular form with an aluminum outer cover, characterized by "dimpled" rings at one or both ends. The modern form of aluminum electrolytic capacitor is based on etched -foil construction, enabling higher capacitance values to be achieved

Fig. 5-3. Color code for polyester capacitors.

in smaller can sizes. Values available from 1µF up to 4,700 µF (or even larger, if required). Working voltages are generally low, but may range from 10 volts up to 250 or 500 volts dc, depending on value and construction. A single lead emerges from each end, but single -ended types are also available (both leads emerging from one end), and can--types with rigid leads in one end for plugging into a socket. Single -ended types are preferred for mounting on printed -circuit boards.

The other main type of electrolytic is the tantalum capacitor. This is produced both in cylindrical configuration with axial leads, or in tantalum-bead configuration. Both (and the latter type particularly) can offer very high capacitance values in small physical sizes, within the range 0.1 to 100 µF. Voltage ratings are generally low; from 35 volts down to less than 10, volts dc.

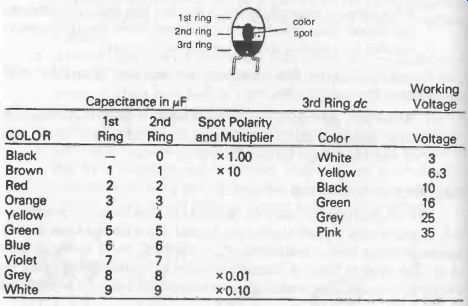

All electrolytic capacitors normally have their value marked on the body or case, together with a polarity marking (+ indicating the positive lead). Tantalum-bead capacitors, however, are sometimes color coded instead of marked with values. This color coding is shown in Fig. 5-4, while other codes which may be found on other types of non-polarized capacitors are given in Fig. 5-5.

Fig. 5-4. Color code for tantalum bead capacitors.

Fig. 5-5. Other coding systems used on capacitors.

Tolerance of Fixed Capacitors

As a general rule, only silver-mica capacitors are made to close tolerances (plus or minus 1 percent is usual). The tolerance on other types of capacitors is usually between 10 and 20 percent and may be even higher (as much as 50 percent) in the case of aluminum foil electrolytics. Because of the wide tolerances normal with electrolytics, choice of actual value is seldom critical.

VARIABLE CAPACITORS

Variable capacitors are based on interleaved sets of metal plates, one set being fixed and the other movable. The plates are separated by a dielectric which may be air or a solid dielectric. Movement of one set of plates alters the effective area of the plates, and thus the value of capacitance present.

There is also a general distinction between tuning capacitors used for frequent adjustment (e.g., to tune a radio receiver to a particular station) and trimmer capacitors used for initial adjustment of a tuned circuit. Tuning capacitors are larger, more robust in construction and generally of air-dielectric type. Trimmer capacitors are usually based on a mica or film dielectric with a smaller number of plates, capacitance being adjusted by turning a central screw to vary the pressure between plates and mica.

Because they are smaller in size, however, a trimmer capacitor may sometimes be used as a tuning capacitor on a sub -miniature radio circuit, although special miniature tuning capacitors are made, designed to mount directly on a printed-circuit board.

In the case of tuning capacitors, the shape of the vanes determines the manner in which capacitance changes with spindle movement.

These characteristics usually fall under one of the following descriptions:

1. Linear-where each degree of spindle rotation produces an equal change in capacitance. This is the most usual type chosen for radio receivers.

2. Logarithmic-where each degree of spindle movement produces a constant percentage change in frequency of a tuned circuit.

3. Even frequency-where each degree of spindle movement produces an equal change in frequency in a tuned circuit.

4. Square law--where the change in capacitance is proportional to the square of the angle of spindle movement.

BASIC CIRCUIT RULES FOR CAPACITORS

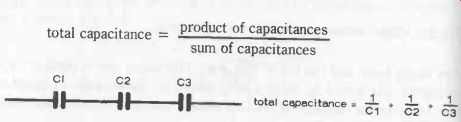

The rules for total capacitance of capacitors in series and in parallel is' opposite to that for resistors. For capacitors connected in series (Fig. 5-6), the total effective capacitance (C) is given by:

I=

C C1 C2 C3 or, in the case of two dissimilar capacitors

In words, C = C1.C2 C1 + C2 total capacitance-product of capacitances sum of capacitances ClC2 C3 total capacitance L1 1 1 C1 C2 C3

Fig. 5-6. Capacitors in series.

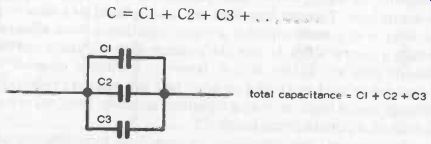

For capacitors connected in parallel (Fig. 5-7):

C = C1 + C2 + C3 + total capacitance = C1 + C2 +C3 C3

Fig. 5-7. Capacitors in parallel.

This capacitance effect, of course, is only apparent in an ac circuit. In a dc circuit a capacitor simply builds up a charge without passing current. In a practical ac circuit, a capacitor also exhibits reactance (see Section 2), and because of its construction, may also exhibit a certain amount of inductance (see Section 7).