HHB CDR-800 Professional Compact Disc Recorder.

HHB Communications USA, LLC, 1410 Centinela Ave., Los Angeles, CA 90025, (310) 319-1111, FAX (310) 319-1311, Website www.hhbusa.com.

HHB Communications is a British-based firm specializing in digital audio recording equipment and media for the professional audio industry. In addition to CD recorders, HHB manufactures portable DAT recorders, a line of vacuum-tube processors (including mike preamps, compressors, and parametric equalizers), and studio monitor loudspeakers (including near-field monitors and powered sub woofers). HHB also distributes the Genex line of high bit rate, high sampling rate magneto-optical digital recorders. Their complete line of digital media includes professional-quality recordable compact discs (CD-R), ADAT tapes, MiniDiscs (MD), and rewriteable magneto-optical (MO) discs.

The CDR-800 Compact Disc recorder (Photo 1) has been on the market for over two years. At the time it was introduced, the CDR-800 represented a price breakthrough in professional CD recorders. The list price of $2200 has become irrelevant, since the unit now sells for around $1200 at most pro audio dealers.

The CDR-800 looks suspiciously like the Pioneer PDR-05 and PDR-99 consumer CD recorders, which are essentially identical-the PDR-99 is marketed as part of Pioneer's Elite line, and features their glossy Urushi front panel and Rose wood side panels. While based on the consumer models, the CDR-800 is actually manufactured by Pioneer for the pro audio user, and incorporates a number of features not found on the consumer units. The Pioneer consumer players have only unbalanced (RCA) analog in puts and outputs, along with S/PDIF and Toslink digital inputs and outputs. To these interfaces, the CDR-800 adds balanced XLR analog inputs, along with a balanced XLR AES/EBU digital input (Photo 2).

All analog and digital outputs on the CDR-800 remain unbalanced. This may appear odd at first, but most pro audio users are likely to use the CDR-800 with an external digital processor for play- back, making balanced analog outputs unnecessary. One other important difference between the CDR-800 and its Pioneer counterparts concerns the types of recordable CDs you can use. The Pioneer consumer machines will only recognize consumer-type CD-R blanks. The CDR-800 will also work with computer type CD blanks. The CDR-800 is also equipped with standard 19-inch rack mounts One important feature of the CDR-800 is Pioneer's Stable-Platter mechanism (Photo 3), which includes a full-size platter upon which the CD is placed upside down. There are a couple of advantages to this system. First, the disc is supported over its entire surface, minimizing vibration, which, in turn, should reduce clock jitter. This serves the same purpose as the disc dampers many of us have used, but Pioneer's solution is far more effective. Second, the laser now faces down, so it is far less likely to accumulate dust.

PHOTO 1: Front view of the HHB CDR-800 Professional Compact Disc Recorder and its remote control.

PHOTO 2

PHOTO 3

Operation

Operationally, the HHB CDR-800 is extremely well thought out, and is really not much more difficult to operate than an analog cassette deck. For the most part, the manual is clearly written, and includes numerous illustrations. Input and output connections are straightforward, but the rear panel also contains a couple of switches that you may need to reset. A three-position slide switch located between the balanced analog input connectors selects either the unbalanced RCA line inputs or the balanced XLR connectors at +4dBu or -8dBu levels.

A digital out switch mutes the digital outputs if only the analog outputs are used. You select digital copy permission/prohibition with a pair of DIP switches, which you can set to allow un limited copies of your recording, one time-only copying, or no copying at all.

Since the CDR-800 is a professional product, it is not bound by the consumer Serial Copy Management System--the user controls the copy management.

Input selection is done with a momentary contact button on the front panel- you toggle through the various analog and digital inputs by repeatedly depressing the button. The CDR-800 has five modes of operation-three are automatic and two are manual. One of the most useful of the automatic modes is ID-SYNC for recording from DAT sources. This mode copies index numbers from your DAT and automatically turns them into track numbers on your CD-R.

The AES/EBU interface does not transmit DAT ID codes, so you must use the S/PDIF connection. To do so, simply load a blank disc and toggle the INPUT SELECTOR until the correct input appears-the display should recognize DAT as the source at this point. Now, cue up your DAT tape to a point about five seconds ahead of the first DAT index number you wish to record. Next, toggle the DIGITAL SYNCHRO button until ID-SYNC appears in the display. The CDR-800 will begin a short setup procedure, which takes a few seconds.

After this setup, ID-SYNC returns to the display, and SYNC flashes in red. You are now ready to begin recording. Simply press the play button on your DAT recorder-when the next index number appears, the CDR-800 automatically be gins recording, making that index number track 1 on the CD. You don't even need to press RECORD on the CDR-800.

-----------------

TABLE 1:

MANUFACTURER'S SPECIFIC

Applicable discs: CD and CD-R

Frequency response: 2Hz-20kHz

Playback S/N: 110dB (EIAJ)

Playback dynamic range: 97dB (EIAJ)

Playback THD: 0.0027% (EIAJ)

Recording S/N (analog RCA input): 90dB

Recording dynamic range (analog RCA input): 90dB

Recording THD (analog RCA input): 0.005%

Recording S/N (S/PDIF digital input): 105dB

Recording dynamic range (S/PDIF digital input): 95dB

Recording THD (S/PDIF digital input): 0.003%

Wow and flutter: Less than measurable limit (+0.001% weighted peak) (EIAJ)

Analog input impedance: 10k

Analog XLR line input level: +4 or +8dBu, switchable

Analog RCA line input level: 500mVRMS

Analog output voltage: 2V RMS

Power supply: US model: 120V AC, 60Hz; European model: 220-230V AC, 50/60Hz

Power consumption: 21W Weight: 6.2kg (13 lbs. 11 02)

Dimensions: 482mm (W) x 294mm (D) x 134mm (H) (18" x 11" x 5")

------------

Each subsequent DAT index number automatically generates a track number on the CD. It makes sense to prepare a DAT master, including all of the index points you desire, before making a CD-R.

The CDR-800 will also copy other digital sources the same way, including MiniDisc, Digital Compact Cassette, and CD, using the AL-SYNC mode. There is also a 1-SYNC mode that allows automatic copying of 1 track from any of the above digital sources. After the one track of the original has been recorded, the recording process stops. You can add additional tracks to your recording, using this mode, until the CD-R is filled to capacity.

The CDR-800 also allows manual copying of analog or digital sources, one track at a time. During manual recording, the CDR-800's REC LEVEL and REC BALANCE function the same as on any other recording device. You can record an individual track, stop, and continue at a later time. If you manually record a single track, a process called "fixation" automatically takes place before and after the track is recording. During fixation, the lead-in and lead-out information for that track is written.

When you have finished recording a CD, you must perform a process called "finalization," which allows the CD-R to be played on any conventional CD player. During this process, the absolute lead in and lead-out information for the entire disc, and the table of contents, are writ ten to the CD, along with a code that pre vents further recording on the disc.

Once you have finished recording a disc, press the FINALIZE button. After a few seconds of setup, the display will indicate a time of 4:03 or 4:07, depending on the length of the recording. This is the amount of time it will take to finalize the disc.

Now, press the PAUSE button to begin the process. The time display begins counting down-when it reaches 0:00, the process is complete, and the CD-R may be played in any CD player. The CDR-800 has a SKIP-ID function that can be used during finalization. This function allows you to effectively eliminate any unwanted tracks on your CD after it has been recorded. Suitably equipped CD players will then ignore those tracks during playback.

The CDR-800 is supplied with a re mote control that duplicates the functions of the front-panel controls. You must use the remote to enter track numbers for CD playback-numeric buttons RTT EE---- for track selection are not included on the main chassis of the CDR-800. Re mote-control operation can be defeated with a DIP switch on the rear panel. The rear panel of the CDR-800 is also fitted with an 8-pin DIN Parallel Remote sock et, which allows you to construct your own wired remote control, duplicating PLAY, PAUSE, RECORD, STOP,MANUAL TRACK NO., WRITE, and the two TRACK SEARCH BUTTONS. A connection diagram is included in the CDR-800 manual.

Circuitry and Construction

As Photo 4 shows, the CDR-800 is packed with circuitry. There are no less than 13 PC boards in the CDR-800, varying in size from large servo and audio digital boards to several very small boards, including the headphone amp. Two power transformers are used, one for the audio and digital circuitry, and an other dedicated to the servo. Like most products of Far East origin, the CDR-800 uses standard 3-terminal IC regulators for the power supplies. Several of these regulators are located on the two power supply PC boards, but the analog/digital board and the servo board each house a pair of local IC regulators.

CD-R Basics

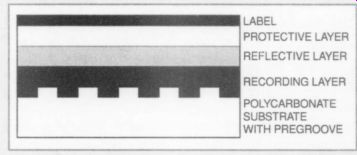

The physical structure of a CD-R disc is shown in Fig. 1. The recordable CD is molded with a continuous groove spiral from the inside to the outside of the disc's polycarbonate substrate. The "pre grooved" disc is necessary in order to provide the recorder with a physical reference. The groove also contains timing information that the recorder uses to keep the CD spinning at the correct speed at all points along the disc surface.

After the polycarbonate substrate is molded, the disc is spin-coated with the recording layer, an organic dye such as cyanine, phthalocyanine, or azo.

The recording layer is then coated with a vacuum-deposited reflective layer, followed by a spin coat of protective lacquer. Most CD-R manufacturers add a label coating to further protect the disc from scratches. Special discs are available with a label area compatible with an ink jet printer specifically made for printing CD-R discs.

LABEL non-burned areas.

The most common organic dye found in CD-R disc is cyanine. Azo dye, originally developed for types of optical recording media, is also used for CD-R discs. Cyanine and azo-based discs are sensitive to ultraviolet light, as well as heat and humidity. As such, their archival life expectancy is only about ten years.

The recording surface of most CD-R discs is green, while some appear blue.

This is due to the type of dye used and the color of the reflective layer. Silver and gold reflective layers yield a different color when they reflect light back through the organic dye.

More recently, the Japanese firm Mitsui has developed a CD-R disc using phthalo cyanine dye. These discs are gold in color, in part due to the gold reflective layer.

The phthalocyanine discs are far less susceptible to the degrading effects of light, heat, and humidity, and are expected to have an archival life in excess of 100

FIGURE 1: Cut-away view of a CD-R recordable CD.

The pregrooved polycarbonate substrate is coated with an organic dye recording layer and a reflective layer. During recording, the laser beam burns the organic dye, momentarily raising the temperature of the dye to over 300°F.

Also see: