Tape recording has played a large part in the history of digital audio, and continues to be important although the rapid adoption of recorders based on hard disks and optical disks is having a significant effect. Tape recording using the rotary-head principle pioneered in video recorders is used in digital audio alongside the more conventional stationary head approach. Both of these will be considered here. The reader is referred to Sections 6 and 7 for an explanation of coding and error-correction principles.

FIG. 1 Types of rotary-head recorder. (a) Helical scan records long

diagonal tracks. (b) Transverse scan records short tracks across the tape.

1. Types of recorder

Digital audio become economic with the development of high-density recorders in the 1970s. The necessary rate of almost two megabits per second for a stereo signal can today be recorded with a very low tape consumption. It is not so long ago, however, that the data rate itself was a problem. When head and tape technology were less advanced than they are today, wavelengths on tape were long, and the only way that high frequencies could be accommodated was to use high speeds. High speed can be achieved in two ways. The head can remain fixed, and the tape can be transported rapidly, with obvious consequences, or the tape can travel relatively slowly, and the head can be moved. The latter is the principle of the rotary-head recorder. FIG. 1 shows the general arrangement of the two major categories of rotary-head recorder. In transverse-scan recorders, relatively short tracks are recorded almost at right angles to the direction of tape motion by a rotating headwheel containing, typically, four heads. In helical-scan recorders, the tape is wrapped around the drum in such a way that it enters and leaves in two different planes. This causes the rotating heads to record long slanting tracks. In both approaches, the width of the space between tracks is determined by the linear tape speed. The track pitch can easily be made much smaller than in stationary-head recorders.

The use of rotary heads was instrumental in the development of the first video recorders. As video signals consist of discrete lines and frames, it was possible to conceal the interruptions in the tracks of a rotary-head machine by making them coincident with the time when the CRT was blanked during flyback.

If digital sample data are encoded to resemble a video waveform, which is known as pseudo-video or composite digital, they can be recorded on a fairly standard video recorder. Digital audio recorders have been made using quadruplex video recorders, one-inch video recorders, U-matic cassette recorders, and the smaller consumer formats. The device needed to format the samples in this way is called a PCM adaptor.

Digital audio recorders have also been made which use only the transport of a video recorder, with specially designed digital signal electronics. Instead of using analog FM, it is possible to use digital recording, as described in Section 6, to make a direct digital recorder. The machines built by Decca fall into this category.

The final category of digital audio recorder using rotary heads is one in which direct digital recording is used with a transport specially designed for audio use with no compromises due to a video-based ancestry. DAT is such a machine.

FIG. 2 Block diagram of PCM adaptor. Note the dub connection needed

for producing a digital copy between two VCRs.

2. PCM adaptors

FIG. 2 shows a block diagram of a PCM adaptor. The unit has five main sections. Central to operation is the sync and timing generation, which produces sync pulses for control of the video waveform generator and locking the video recorder, in addition to producing sampling-rate clocks and timecode. An ADC allows a conventional analog audio signal to be recorded, but this can be bypassed if a suitable digital input is available. Similarly a DAC is provided to monitor recordings, and this too can be bypassed by using the direct digital output. Also visible in FIG. 2 are the encoder and decoder stages which convert between digital sample data and the pseudo-video signal.

An example of this type of unit is the PCM-1610/1630 which was designed by Sony for use with a U-matic Video Cassette Recorder (VCR) specifically for Compact Disc mastering. Section 4 showed how many audio sampling rates were derived from video frequencies. The Compact Disc format is an international standard, and it was desirable for the mastering recorder to adhere to a single format. Thus the PCM-1610 only worked in conjunction with a 525/60 monochrome VCR. There was no 625/50 version. Thus even in PAL countries Compact Discs were mastered on 60Hz VCRs to allow the traditional international inter change of recordings. The PCM-1610 was intended for professional use, and thus was not intended to be produced in volume. For this reason the format is simple, even crude, because the LSI technology needed to implement more complex formats was not available.

A typical line of pseudo-video is shown in FIG. 3. The line is divided into bit cells and, within them, black level represents a binary zero, and about 60 per cent of peak white represents binary one. The reason for the restriction to 60 per cent is that most VCRs use non-linear pre-emphasis and this operating level prevents any distortion due to the pre-emphasis causing misinterpretation of the pseudo-video. The use of a two-level input to a frequency modulator means that the recording is essentially frequency-shift keyed (FSK).

FIG. 3 Typical line of video from PCM-1610. The control bit conveys

the setting of the pre-emphasis switch or the sampling rate depending on

position in the frame. The bits are separated using only the timing information

in the sync pulses.

As the video recorder is designed to switch heads during the vertical interval, no samples can be recorded there. In all rotary-head recorders, some form of time compression is used to squeeze the samples into the active parts of unblanked lines. This is simply done by reading the samples from a memory at an instantaneous rate which is higher than the sampling rate. Owing to the interruptions of sync pulses, the average rate achieved will be the same as the sampling rate. The samples read from the memory must be serialized so that each bit is sent in turn.

It was shown in Section 7 that digital audio recorders use extensive interleaving to combat tape dropout. The PCM-1610 subdivides each video field into seven blocks of 35 lines each, and interleaves samples within the blocks. A simple crossword error-correction scheme is used.

Some VCRs have dropout compensators built in, which repeat a section of the previous line to conceal the missing picture information. Such circuits must be disabled when used with PCM adaptors because they interfere with the error-correction mechanism.

A PCM adaptor for Compact Disc mastering was also developed by JVC.

[1. This format had a more powerful error-correction system, and could be used with VHS recorders; again only 525/60 machines were supported. ]

For consumer use, a PCM adapter format was specified by the EIAJ 2 which would record stereo with fourteen-bit linear quantizing. These units would be used with a domestic VCR. Since the consumer would expect to be able to use the VCR for conventional TV recording as well, the EIAJ format is in fact two incompatible formats. One uses a sampling rate of 44.0559 kHz in conjunction with 525/59.94 NTSC timing, and one uses 44.1 kHz sampling with 625/50 PAL timing. In the popular PCM-F1, Sony produced a variation on the format which allowed sixteen-bit linear quantizing.

The PCM-F1 was built with LSI technology for low mass-production cost. Owing to the low cost of the product, it found application in professional circles, and indeed served as the introduction to digital audio for many people. Being a consumer product, only one convertor was used between digital and analog domains. This was multiplexed between the two audio channels, resulting in a timeshift between samples of half the sample period, or about 11s. This was not a problem in normal use, since the opposite shift was introduced by the multiplexed convertor used for replay. The standard PCM-F1 was not equipped with digital outputs or inputs, and accordingly not too much trouble was taken in controlling DC offsets due to convertor drift. When enthusiasts began to modify the unit to fit digital connections, these problems became significant.

Several companies manufactured adaptor units incorporating digital filters to remove DC offsets and the 11 s shift to produce a standard AES/EBU output.

In contrast to the formats described above, which used the signal circuitry of video recorders virtually unmodified, the digital recorders developed by Decca3 for vinyl and Compact Disc mastering use only the transport and servomechanisms of a 625/50 one-inch open-reel video recorder, and make a direct digital recording on the diagonal tracks using MFM channel code.

3. Introduction to DAT

When an existing video recorder is used as a basis for a digital audio recorder, the video bandwidth is already defined, and in most cases is much greater than necessary. Furthermore, the signal-to-noise ratio of video recorders is much too high for the purposes of storing binary. The result of these factors is that the tape consumption of such a machine will be far higher than necessary.

FIG. 4 Appearance of DAT cassette. Access to the tape is via a hinged

lid, and the hub-drive holes are covered by a sliding panel, affording

maximum protection to the tape. Further details of the recognition holes

are given in Table 1. (Courtesy TDK)

As digital audio became established, and markets opened up for large numbers of machines, it was no longer necessary to borrow technology from other disciplines, because it was economically viable to design a purpose-built product. The first of this generation of machines is DAT (digital audio tape). By designing for a specific purpose, the tape consumption can be made very much smaller than that of a converted video machine. In fact the DAT format achieved more bits per square inch than any other form of magnetic recorder at the time of its introduction.

The origins of DAT are in an experimental machine built by Sony, 4 but the DAT format has grown out of that through a process of standardization involving some eighty companies.

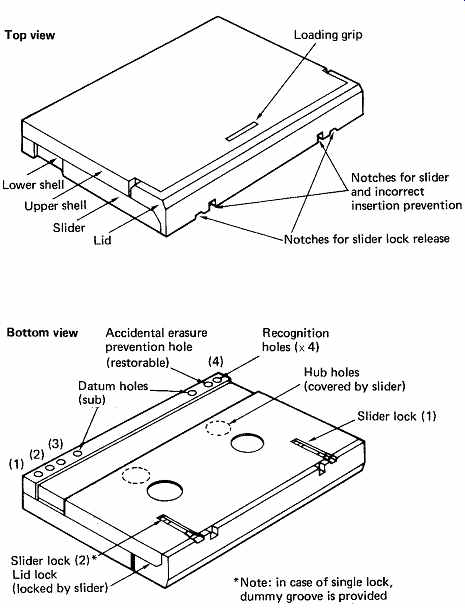

The general appearance of the DAT cassette is shown in FIG. 4. The overall dimensions are only 73mm x 54mm x 10.5mm which is rather smaller than the Compact Cassette. The design of the cassette incorporates some improvements over its analog ancestor. [5] As shown in FIG. 5, the apertures through which the heads access the tape are closed by a hinged door, and the hub drive openings are covered by a sliding panel which also locks the door when the cassette is not in the transport. The act of closing the door operates brakes which act on the reel hubs. This results in a cassette which is well sealed against contamination due to handling or storage. The short wavelengths used in digital recording make it more sensitive to spacing loss caused by contamination.

As in the Compact Cassette, the tape hubs are flangeless, and the edge guidance of the tape pack is achieved by liner sheets. The flangeless approach allows the hub centers to be closer together for a given length of tape. The cassette has recognition holes in four standard places so that players can automatically determine what type of cassette has been inserted. In addition there is a write-protect (record-lockout) mechanism which is actuated by a small plastic plug sliding between the cassette halves. The end-of-tape condition is detected optically and the leader tape is transparent. There is some freedom in the design of the EOT sensor. As can be seen in FIG. 6, transmitted-light sensing can be used across the corner of the cassette, or reflected-light sensing can be used, because the cassette incorporates a prism which reflects light around the back of the tape. Study of FIG. 6 will reveal that the prisms are molded integrally with the corners of the transparent insert used for the cassette window.

FIG. 5 Exploded view of DAT cassette showing intricate construction.

When the lid opens, it pulls the ears on the brake plate, releasing the

hubs. Note the EOT/BOT sensor prism molded into the corners of the clear

window. (Courtesy TDK)

The high coercivity (typically 1480 oersteds) metal powder tape is 3.81mm wide, the same width as Compact Cassette tape. The standard overall thickness is 13m. A striking feature of the metal tape is that the magnetic coating is so thin, at about 3m, that the tape appears translucent. The maximum capacity of the cassette is about 60m.

When the cassette is placed in the transport, the slider is moved back as it engages. This releases the lid lock. Continued movement into the transport pushes the slider right back, revealing the hub openings. The cassette is then lowered onto the hub drive spindles and tape guides, and the door is fully opened to allow access to the tape.

FIG. 6 Tape sensing can be either by transmission across the corner

of the cassette, or by reflection through an integral prism. In both cases,

the apertures are sealed when the lid closes. (Courtesy TDK)

FIG. 7 The use of time compression reduces the wrap angle necessary,

at the expense of raising the frequencies in the channel.

FIG. 8 The simple mechanism of DAT. The guides and pressure roller

move towards the drum and capstan and threading is complete.

In DAT, threading is simplified because the digital recording does not need to be continuous. DAT extends the technique of time compression used to squeeze continuous samples into intermittent video lines. Blocks of samples to be recorded are written into a memory at the sampling rate, and are read out at a much faster rate when they are to be recorded. In this way the memory contents can be recorded in less time. FIG. 7 shows that when the samples are time-compressed, recording is no longer continuous, but is interrupted by long pauses. During the pauses in recording, it is not actually necessary for the head to be in contact with the tape, and so the angle of wrap of the tape around the drum can be reduced, which makes threading easier. In DAT the wrap angle is only 90° on the commonest drum size. As the heads are 180° apart, this means that for half the time neither head is in contact with the tape. FIG. 8 shows that the partial-wrap concept allows the threading mechanism to be very simple indeed. As the cassette is lowered into the transport, the pinch roller and several guide pins pass behind the tape. These then simply move toward the capstan and drum and threading is complete. A further advantage of partial wrap is that the friction between the tape and drum is reduced, allowing power saving in portable applications, and allowing the tape to be shuttled at high speed without the partial unthreading needed by videocassettes. In this way the player can read subcode during shuttle to facilitate rapid track access.

Table 1 The significance of the recognition holes on the DAT cassette.

Holes 1, 2 and 3 form a coded pattern; whereas hole 4 is independent.

The track pattern laid down by the rotary heads is shown in FIG. 9.

The heads rotate at 2000 rev/min in the same direction as tape motion, but because the drum axis is tilted, diagonal tracks 23.5mm long result, at an angle of just over six degrees to the edge. The diameter of the scanner needed is not specified, because it is the track pattern geometry which ensures interchange compatibility. For portable machines, a small scanner is desirable, whereas for professional use, a larger scanner allows additional heads to be fitted for confidence replay and editing. It will be seen from FIG. 9 that azimuth recording is employed as was described in Section 6. This requires no spaces or guard bands between the tracks. The chosen azimuth angle of ± 20° reduces crosstalk to the same order as the noise, with a loss of only 1 dB due to the apparent reduction in writing speed.

FIG. 9 The two heads of opposite azimuth angles lay down the above

track format.

Tape linear speed determines track pitch.

In addition to the diagonal tracks, there are two linear tracks, one at each edge of the tape, where they act as protection for the diagonal tracks against edge damage. Owing to the low linear tape speed the use of these edge tracks is somewhat limited.

Several related modes of operation are available, some of which are mandatory whereas the remainder are optional. These are compared in Table 1. The most important modes use a sampling rate of 48 kHz or 44.1 kHz, with sixteen-bit two's complement uniform quantization.

Alongside the audio samples can be carried 273 kbits/s of subcode (about four times that of Compact Disc) and 68.3 kbits/s of ID coding, whose purpose will be explained in due course. With a linear tape speed of 8.15mm/s, the standard cassette offers 120min unbroken playing time.

Initially it was proposed that all DAT machines would be able to record and play at 48 kHz, whereas only professional machines would be able to record at 44.1 kHz. For consumer machines, playback only of prerecorded media was proposed at 44.1 kHz, so that the same software could be released on CD or prerecorded DAT tape. Now that a SCMS (serial copying management system) is incorporated into consumer machines, they too can record at 44.1 kHz. For reasons which will be explained later, contact duplicated tapes run at 12.225mm/s to offer a playing time of 80min. The same subcode and ID rate is offered. The above modes are mandatory if a machine is to be considered to meet the format.

Option 1 is identical to 48 kHz mode except that the sampling rate is 32 kHz. Option 2 is an extra-long-play mode. In order to reduce the data rate, the sampling rate is 32 kHz and the samples change to twelve-bit two's complement with non-linear quantizing. Halving the subcode rate allows the overall data rate necessary to be halved. The linear tape speed and the drum speed are both halved to give a playing time of four hours.

All the above modes are stereo, but option 3 uses the sampling parameters of option 2 with four audio channels. This doubles the data rate with respect to option 2, so the standard tape speed of 8.15mm/s is used.

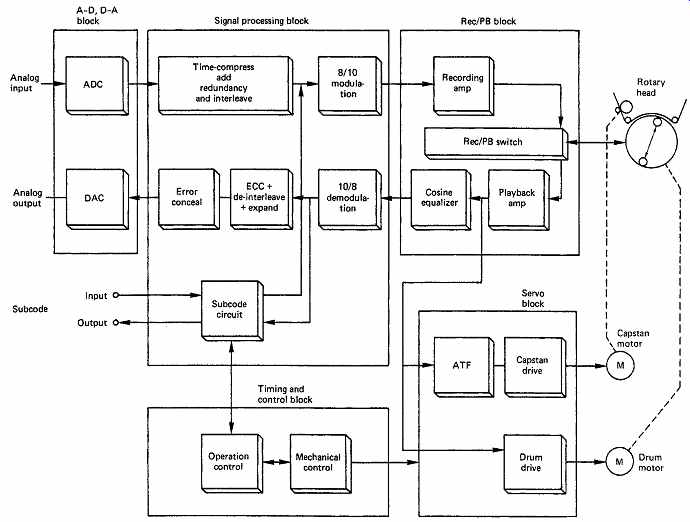

FIG. 10 shows a block diagram of a typical DAT recorder, which will be used to introduce the basic concept of the machine and the major topics to be described. In order to make a recording, an analog signal is fed to an input ADC, or a direct digital input is taken from an AES/EBU interface. The incoming samples are subject to interleaving to reduce the effects of error bursts. Reading the memory at a higher rate than it was written performs the necessary time compression. Additional bytes of redundancy computed from the samples are added to the data stream to permit subsequent error correction. Subcode information such as the content of the AES/EBU channel status message is added, and the parallel byte structure is fed to the channel encoder, which combines a bit clock with the data, and produces a recording signal according to the 8/10 code which is free of DC (see Section 6). This signal is fed to the heads via a rotary transformer to make the binary recording, which leaves the tape track with a pattern of transitions between the two magnetic states.

On replay, the transitions on the tape track induce pulses in the head, which are used to re-create the record current waveform. This is fed to the 10/8 decoder which converts it to the original data stream and a separate clock. The subcode data are routed to the subcode output, and the audio samples are fed into a de-interleave memory which, in addition to time expanding the recording, functions to remove any wow or flutter due to head-to-tape speed variations. Error correction is performed partially before and partially after de-interleave. The corrected output samples can be fed to DACs or to a direct digital output.

In order to keep the rotary heads following the very narrow slant tracks, alignment patterns are recorded as well as the data. The automatic track-following system processes the playback signals from these patterns to control the drum and capstan motors. The subcode and ID information can be used by the control logic to drive the tape to any desired location specified by the user.

4. Track following in DAT

As with any recorder intended for consumer use, economy of tape consumption is paramount, and this involves numerous steps to use the tape area as efficiently as possible. As magnetic tape is flexible and is manufactured to finite tolerances, there will always be some error between the path of the replay head and the recorded track. In the relatively wide tracks of analog audio recorders this is seldom a problem.

The high-output metal tape used in DAT allows an adequate signal-to noise ratio to be obtained with very narrow tracks on the tape. This reduces tape consumption and allows a small cassette, but it becomes necessary actively to control the relative position of the head and the track in order to maximize the replay signal and minimize the error rate.

The track width and the coercivity of the tape largely define the signal to-noise ratio. A track width has been chosen which makes the signal-to crosstalk ratio dominant in cassettes which are intended for user recording.

Prerecorded tapes are made by contact duplication, and this process only works if the coercivity of the copy is less than that of the master. The output from prerecorded tapes at the track width of 13.59m would be too low, and would be noise-dominated, which would cause the error rate to rise. The solution to this problem is that in prerecorded tapes the track width is increased to be the same as the head pole. The noise and crosstalk are both reduced in proportion to the reduced output of the medium, and the same error rate is achieved as for normal high coercivity tape.

The 50 percent increase in track width is achieved by raising the linear tape speed from 8.15 to 12.225mm/s, and so the playing time of a prerecorded cassette falls to 80min as opposed to the 120min of the normal tape.

The track-following principles are the same for prerecorded and normal cassettes, but there are detail differences which will be noted.

Tracking is achieved in conventional video recorders by the use of a linear control track which contains one pulse for every diagonal track. The phase of the pulses picked up by a fixed head is compared with the phase of pulses generated by the drum, and the error is used to drive the capstan. This method is adequate for the wide tracks of analog video recorders, but errors in the mounting of the fixed head and variations in tape tension rule it out for high-density use. In any case the control-track head adds undesirable mechanical complexity. In DAT, the tracking is achieved by reading special alignment patterns on the tape tracks themselves, and using the information contained in them to control the capstan.

FIG. 11 In the track-following system of DAT, the signal picked up

by the head comes from pilot tones recorded in adjacent tracks at different

positions. These pilot tones have low frequency, and are unaffected by

azimuth error. The system samples the amplitude of the pilot tones, and

subtracts them.

FIG. 12 (a) A correctly tracking head produces pilot-tones bursts

of identical amplitude. (b) The head is off track, and the first pilot

burst becomes larger, whereas the second becomes smaller. This produces

the tracking error in the circuit of FIG. 11.

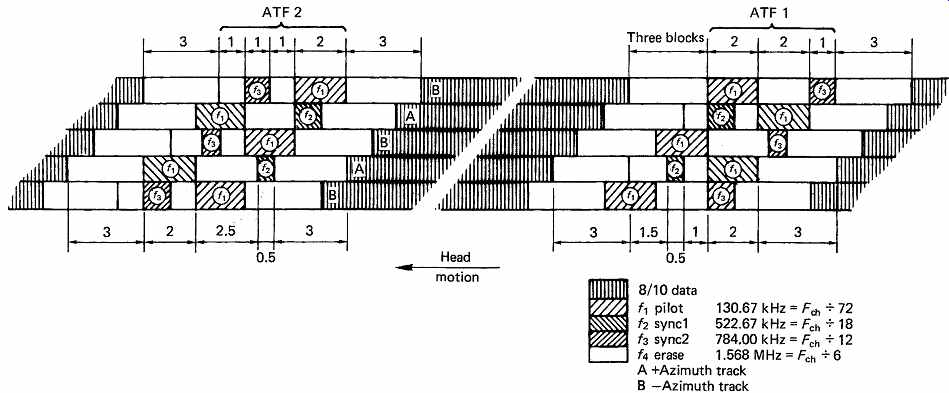

DAT uses a technique called area-divided track following (ATF) in which separate parts of the track are set aside for track-following purposes. FIG. 11 shows the basic way in which a tracking error is derived. The tracks at each side of the home track have bursts of pilot tone recorded in two different places. The frequency of the pilot tone is 130 kHz, which has been chosen to be relatively low so that it is not affected by azimuth loss. In this way an A head following an A track will be able to detect the pilot tone from the adjacent B tracks.

In FIG. 12(a) the case of a correctly tracking head is shown. The amount of side-reading pilot tone from the two adjacent B tracks is identical. If the head is off track for some reason, as shown in FIG. 12(b), the amplitude of the pilot tone from one of the adjacent tracks will increase, and the other will decrease. The tracking error is derived by sampling the amplitude of each pilot-tone burst as it occurs, and holding the result so the relative amplitudes can be compared.

There are some practical considerations to be overcome in implementing this simple system, which result in some added complication. The pattern of pilot tones must be such that they occur at different times on each side of every track. To achieve this there must be a burst of pilot tone in every track, although the pilot tone in the home track does not contribute to the development of the tracking error. Additionally there must be some timing signals in the tracks to determine when the samples of pilot tone should be made. The final issue is to prevent the false locking which could occur if the tape happened to run at twice normal speed.

FIG. 13 The area-divided track-following (ATF) patterns of DAT. To

ease generation of patterns on recording, the pattern lengths are related

to the data-block dimensions and the frequencies used are obtained by dividing

down the channel bit clock Fch. The sync signals are used to control the

timing with which the pilot amplitude is sampled.

FIG. 13 shows how the actual track-following pattern of DAT is laid out.

The pilot burst is early on A tracks and late on B tracks.

Although the pilot bursts have a two-track cycle, the pattern is made to repeat over four tracks by changing the period of the sync patterns which control the pilot sampling. This can be used to prevent false locking. When an A head enters the track, it finds the home pilot-burst first, followed by pilot from the B track above, then pilot from the B track below. The tracking error is derived from the latter two. When a B head enters the track, it sees pilot from the A track above first, A track below next, and finally home pilot. The tracking error in this case is derived from the former two. The machine can easily tell which processing mode to use because the sync signals have a different frequency depending on whether they are in A tracks (522 kHz) or B tracks (784 kHz). The remaining areas are recorded with the interblock gap frequency of 1.56MHz which serves no purpose except to erase earlier recordings. Although these pilot and synchronizing frequencies appear strange, they are chosen so that they can be simply obtained by dividing down the master channel-bit-rate clock by simple factors. The channel-bit-rate clock, Fch, is 9.408MHz; pilot, the two sync frequencies and erase are obtained by dividing it by 72, 18, 12 and 6 respectively.

The time at which the pilot amplitude in adjacent tracks should be sampled is determined by the detection of the synchronizing frequencies. As the head sees part of three tracks at all times, the sync detection in the home track has to take place in the presence of unwanted signals. On one side of the home sync signal will be the interblock gap frequency, which is high enough to be attenuated by azimuth. On the other side is pilot, which is unaffected by azimuth.

This means that sync detection is easier in the tracking-error direction away from pilot than in the direction towards it. There is an effective working range of about +4 and -5 m due to this asymmetry, with a dead band of 4m between tracks. Since the track-following servo is designed to minimize the tracking error, once lock is achieved the presence of the dead zone becomes academic. The differential amplitude of the pilot tones produces the tracking error, and so the gain of the servo loop is proportional to the playback gain, which can fluctuate due to head contact variations and head tolerance. This problem is overcome by using AGC in the servo system. In addition to subtracting the pilot amplitudes to develop the tracking error, the circuitry also adds them to develop an AGC voltage. Two sample-and-hold stages are provided which store the AGC parameter for each head separately.

The heads can thus be of different sensitivities without upsetting the servo. This condition could arise from manufacturing tolerances, or if one of the heads became contaminated.

5. Aligning for interchange

One of the most important aspects of DAT maintenance is to ensure that tapes made on a particular machine meet the specifications laid down in the format. If they do, then it will be possible to play those tapes on any other properly aligned machine. In this section the important steps necessary to achieve interchange between transports will be outlined.

When the cassette is lowered into the transport it seats on pillars which hold it level. The tape within the cassette is guided by liner sheets which determine the height of the tape pack above the transport baseplate. The first step in aligning the transport is to ensure that all the guides the tape runs past on its way to and from the scanner are at the same height as the tape. FIG. 14 shows that the guides are threaded so that they can be screwed up and down. In the correct position, the tape will stay in the cassette plane and distortion will be avoided.

FIG. 14 Conceptual view of DAT transport with tape path straightened

for simplicity. Note the slotted guides which can be turned by screwdriver

on threaded posts in order to adjust the height of the tape above the deck.

This must be set to feed the tape cleanly from the cassette to the scanner.

(Sony Broadcast and Communications)

Once the tape can be passed through the machine without damage, the basic transport functions can be checked. Since tape tension affects the track angle, obtaining the correct tension is essential before attempting any adjustments at the scanner. As the DAT mechanism is so small, it is not possible to fit a conventional tape tension gauge. Instead, special test cassettes are made which incorporate torque meters into the reel hubs.

Use of these test cassettes will allow the tension to be checked in various transport and shuttle modes. Since the scanner friction is in the opposite sense when the tape is reversed, the back tension must be higher than for forward mode to keep the average scanner tension constant. In some transports the tension-sensing arm is not statically balanced, and the tape tension becomes a function of the orientation of the machine. In this case the adjustment must be made with the machine in the attitude in which it is to be used.

The track spacing on record is determined by the capstan speed, which must be checked. As the capstan speed will be controlled by a frequency generating wheel on the capstan shaft, it is generally only necessary to check that the capstan FG frequency is correct in record mode. A scratch tape will be used for this check.

Helical interchange can now be considered. Tape passing around the scanner is guided in three ways. On the approach, the tape is steered by the entrance guide, which continues to affect the first part of the scanner wrap. The center part of the scanner wrap is guided by the machined step on the scanner base. Finally the last part of the wrap is steered by the exit guide. Helical interchange is obtained by adjusting the entrance and exit guide heights so that the tape passes smoothly between the three regions.

In video recorders, which use wider tape, it will often also be found necessary to adjust the angle of the guides. In DAT the tape is so narrow that it will flex to accommodate angular errors, and the guides only need a height adjustment.

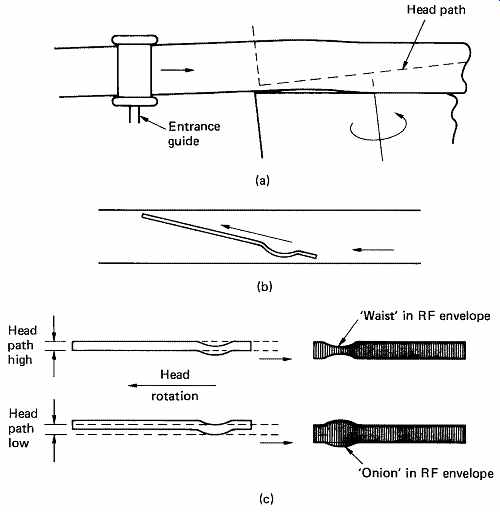

FIG. 15 The effects of guide misalignment shown exaggerated for clarity.

In (a) the entrance guide is too low and forces the tape to flex as it

enters the scanner. In (b) the tape relaxes to produce a bent track. In

(c) an alignment tape is being played and the transport has bent the tracks.

The RF envelope will show different disturbances as the tracking is offset

above or below optimum. A correctly aligned transport has an envelope which

collapses uniformly as the tracking is offset.

As tape is flexible, it will distort as it passes round the scanner if the entrance and exit guides are not correctly set. The state of alignment can be assessed by working out the effect of misalignments on the ability of the replay head to follow tape tracks. FIG. 15(a) shows an example of the entrance guide being too low. The tape is forced to climb up to reach the scanner step, and then it has to bend down again to run along the step. If straight tracks were originally recorded on the tape, they will no longer be straight when the tape is distorted in this way. FIG. 15(b) shows what happens to the track. Since in an azimuth recording machine the head is larger than the track, small distortions of this kind will be undetectable. It is necessary to offset the tracking deliberately so that the effect of the misalignment can be seen.

If the head is offset upwards, then the effect will be that the RF signal grows in level briefly at the beginning of the track, giving the envelope an onion-like appearance on an oscilloscope. If the head is offset downwards, the distortion will take the track away from the head path and the RF envelope will be waisted. If the misalignment is in the exit guide, then the envelope disturbances will appear at the right-hand end of the RF envelope. The height of both the entrance and exit guides is adjusted until no disturbance of the RF envelope is apparent whatever tracking error is applied. One simple check is to disable the track-following system so that the capstan runs at approximately playback speed with no feedback. The tracking will slowly drift in and out of registration. Under these conditions the RF envelope should remain rectangular, so that the amplitude rises and falls equally over the entire head sweep. A rough alignment can be performed with a tape previously recorded on a trustworthy machine, but final alignment requires the use of a reference tape.

Once the mechanical geometry of the transport is set up, straight tracks on tape will appear straight to the scanner, and it is then possible to set up the automatic track-following system so that optimum tracking occurs when the tracking error is zero. This is done by observing the RF level on playback and offsetting the tracking adjustment to each side until two points are found where the level begins to fall. The adjustment is then placed half-way between these points. If the machine has a front panel tracking adjustment, it should be set to zero whilst the internal adjustment is made.

FIG. 16 Even with correct tape path geometry, a machine can record

data in the wrong place along the track if the scanner phase is misadjusted.

The scanner pulse generator signal is re-phased or delayed in order to

make the adjustment.

The final interchange adjustment is to ensure that the scanner timing is correct. Even with correct geometry, the tracks can be laid down at the correct angle and spacing, but at the wrong height on the tape, as FIG. 16 shows. The point where recording commences is determined by the sensor which generates a pulse once per revolution of the scanner. The correct timing can be obtained either by physically moving the sensor around the scanner axis, or by adjusting a variable delay in series with an artificially early fixed sensor. A timing reference tape is necessary that has an observable event in the RF waveform. The tape is played, and the sensor or delay is adjusted to give the specified relative timing between the event on the reference tape and the sensor pulse. When this is correct, the machine will record tracks in the right place along the helical sweep.

6. DAT data channel

The channel code used in DAT is designed to function well in the presence of crosstalk, to have zero DC component to allow the use of a rotary transformer, and to have a small ratio of maximum and minimum run lengths to ease overwrite erasure. The code used is a group code where eight data bits are represented by ten channel bits, hence the name 8/10. The details of the code are given in Section 6.

FIG. 17 The sync block of DAT begins with a sync pattern of ten channel

bits, which does not correspond to eight data bits. The header consists

of an ID code byte and a block address. Parity is formed on the header

bytes. The sync blocks alternate between 32 data (or outer code) bytes

and 24 data bytes and 8 bytes of R-S redundancy for the inner codes.

The basic unit of recording is the sync block shown in FIG. 17. This consists of the sync pattern, a three-byte header and 32 bytes of data, making 36 bytes in total, or 360 channel bits. The subcode areas each consist of eight of these blocks, and the PCM audio area consists of 128 of them. Note that a preamble is only necessary at the beginning of each area to allow the data separator to phase-lock before the first sync block arrives. Synchronism should be maintained throughout the area, but the sync pattern is repeated at the beginning of each sync block in case sync is lost due to dropout.

The first byte of the header contains an ID code which in the PCM audio blocks specifies the sampling rate in use, the number of audio channels, and whether there is a copy-prohibit in the recording. The second byte of the header specifies whether the block is subcode or PCM audio with the first bit. If set, the least significant four bits specify the subcode block address in the track, whereas if it is reset, the remaining seven bits specify the PCM audio block address in the track. The final header byte is a parity check and is the exclusive-OR sum of header bytes one and two.

FIG. 18 (a) The ATF patterns are at the ends of the track, and in

the presence of track curvature the tracking error is exaggerated. (b)

The ATF patterns are part-way down the track, minimizing mistracking due

to curvature, and allowing a neat separation between subcode and audio

blocks.

The data format within the tracks can now be explained. The information on the track has three main purposes, PCM audio, subcode data and ATF patterns. It is necessary to be able to record subcode at a different time from PCM audio in professional machines in order to update or post-stripe the timecode. The subcode is placed in separate areas at the beginning and end of the tracks. When subcode is recorded on a tape with an existing PCM audio recording, the heads have to go into record at just the right time to drop a new subcode area onto the track.

This timing is subject to some tolerance, and so some leeway is provided by the margin area which precedes the subcode area and the interblock gap (IBG) which follows. Each area has its own preamble and sync pattern so the data separator can lock to each area individually even though they were recorded at different times or on different machines.

The track-following system will control the capstan so that the heads pass precisely through the center of the ATF area. FIG. 18 shows that, in the presence of track curvature, the tracking error will be smaller overall if the ATF pattern is placed part-way down the tracks. This explains why the ATF patterns are between the subcode areas and the central PCM audio area. The data interleave is block-structured. One pair of tape tracks (one + azimuth and one - azimuth), corresponding to one drum revolution, make up an interleave block. Since the drum turns at 2000 rev/min, one revolution takes 30ms and, in this time, 1440 samples must be stored for each channel for 48 kHz working.

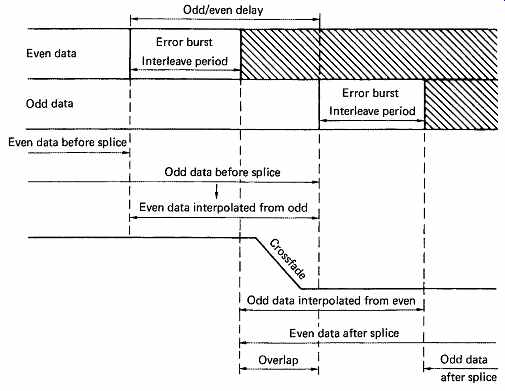

The first interleave performed is to separate both left- and right channel samples into odd and even. The right-channel odd samples followed by the left even samples are recorded in the + azimuth track, and the left odd samples followed by the right even samples are recorded in the - azimuth track. FIG. 19 shows that this interleave allows uncorrectable errors to be concealed by interpolation. At (b) a head becomes clogged and results in every other track having severe errors.

The split between right and left samples means that half of the samples in each channel are destroyed instead of every sample in one channel. The missing right even samples can be interpolated from the right odd samples, and the missing left odd samples are interpolated from the left even samples. FIG. 19(c) shows the effect of a longitudinal tape scratch. A large error burst occurs at the same place in each head sweep.

As the positions of left- and right-channel samples are reversed from one track to the next, the errors are again spread between the two channels and interpolation can be used in this case also.

The error-correction system of DAT uses product codes and was treated in detail in Section 7.

FIG. 19 (a) Interleave of odd and even samples and left and right

channels to permit concealment in case of gross errors. (b) Clogged head

loses every other track.

Half of the samples of each channel are still available, and interpolation is possible. (c) A linear tape scratch destroys odd samples in both channels. Interpolation is again possible.

7. Sound and subcode in shuttle

In all DAT applications it is important to be able to read subcode in shuttle so that wanted areas of the recording can be reached rapidly. In audio recorders, it is also useful to be able to hear at least some sound in shuttle so that the desired part of the recording can be located by ear.

When helical scan recordings are made, the geometry of the tape tracks results from the ratio of the scanner and tape speeds. If it is desired to follow the tracks properly at other than normal speed, then both scanner speed and tape speed must change in the same proportion. Since the scanner speed is locked directly to the sampling clock, it follows that some speed variation can be had simply by changing the clock frequency on replay. If a reference sampling rate fed to a professional DAT machine is reduced in frequency slightly, this will have the effect of slowing down the scanner and all signal processing logic. The slower scanner will now find that the tape tracks are passing through the machine too quickly, and the ATF system will build up a tracking error which in turn causes the capstan to slow down.

This mechanism will be adequate over a small range, perhaps half a semitone, but clearly cannot be used for shuttle. Even if it were possible to turn the scanner at 200x normal speed, it is doubtful whether any useful head contact would be achieved.

When the tape is shuttled, the track-following process breaks down and the heads cross tracks randomly. The head-to-tape speed is the vector sum of the scanner peripheral speed and the tape linear speed. In most formats this is dominated by the head speed, and so the angle at which the heads cross the tracks is relatively shallow. FIG. 20 shows that using a replay head which is wider than the track allows a reasonable length of track to be correctly recovered even at shuttle speeds. Provided the sync blocks are made shorter than the minimum distance shown, it is possible to recover some data. DAT takes advantage of this effect to allow some sound to be heard in shuttle, to allow the subcode to be read for track searching, and to pick up timecode. The heads in a two-headed machine will typically be 20 m wide, which is a full 50 per cent wider than the track. This wider replay head is also necessary to replay the wider tracks which are used on contact-duplicated tapes owing to the reduced coercivity needed by the duplication process.

FIG. 20 During shuttle, the heads cross tracks randomly as shown here

(exaggerated). Owing to the use of azimuth recording, a head can only play

a track of its own type (0 or 1) but as the head is typically 50 per cent

wider than the track it is possible to recover normal signal for the periods

above marked A. If sync blocks are shorter than this period, they can be

picked up intact. In fact a slightly longer pickup will be possible because

the replay system may tolerate a less-than-perfect signal. In any case

the final decision is made by checking that the sync block recovered contains

valid or correctable codewords.

The shuttle readout process is aided by modifying the scanner speed so that the head-to-tape speed remains the same whatever the linear tape speed. Since the scanner turns with the tape direction in DAT, this means speeding up the scanner in forward shuttle and slowing it down in reverse. The effect is that off-tape signals have a constant frequency, and so the filters and phase-locked loops in the replay circuits will be able to stay in lock and recover data whenever the head is sufficiently close to the track centerline.

The data areas of the track consist of numerous short sync blocks, and each one of these is self-contained in that the data separator can resynchronize at the beginning of each, and each contains a Reed- Solomon codeword. If the head crosses the tracks at a shallow angle, then it is highly probable that one or more sync blocks will be recovered correctly. Clearly it is not possible to predict which blocks these will be.

In fact, total recovery is not necessary, because the goal is to produce a simulation of the recording at much more than normal speed, and this can readily be done by sending to the output convertors only every nth sample from the recording. Provided the tape format is designed with this in mind, the track crossings in shuttle will automatically reduce the off tape data rate.

FIG. 21 shows the principle in simplified form. A head crosses a number of tracks in one rotation and picks up a sync block from each. The interleave used on recording means that the memory which is filled from the successfully recovered sync blocks now contains samples which are more or less evenly spaced throughout a number of tracks. Since each sync block must be independent in this mode, it is important that both bytes of a given sample are in the same sync block. Reference to Figure 7.38 will show that the use of alternate symbols in the columns when forming inner codewords has this effect.

FIG. 21 In shuttle the tracking process breaks down and bursts of

data are recovered as the heads cross tracks. After de-interleave the bursts

of data are uniformly spread throughout the frame. (Azimuth is neglected

here for simplicity.)

Each subcode track consists of eight sync blocks, but the subcode data rate which can be supported is much less than this would indicate because it is necessary to repeat the subcode information many times in successive tracks to guarantee that it can be read when the heads cross tracks in shuttle. There are a number of incompatible timecodes which have been designed for the various television standards, but it was not appropriate to adopt them because it was desired to have a world standard for DAT timecode which would be independent of television standards. Since the scanner speed in DAT is locked to the sampling rate, it is possible to deduce the exact time by counting head revolutions. There are exactly 100 revolutions in 3 seconds, so it is possible to have a timecode for DAT which counts in hours, minutes, seconds and DAT frames. This timecode is recorded on tape, but real machines will have gearbox software which allows them to convert the tape timecode into any of the television or film timecode formats where necessary. For synchronizing two or more DAT machines, the DAT timecode can be used directly.