Back in 1997 I received a sample of a then-new optocoupler from Silonex called the Audiohm. Resistive optocouplers use an LED whose light output is optically coupled to a photoresistor. In the past I have used the Clairex CLM6000 in some guitar effects projects. This device used cadmium sulfide (CdS) as the photoresistive material (see sidebar entitled Photosensitive Materials). The Audiohm uses a proprietary mixture of CdS and cadmium selenide (CdSe), and is reported to have lower noise and distortion than either a purely CdS or CdSe device alone.

Silonex has listed a number of advantages for use of the Audiohm as a control element in analog audio circuits. These include:

• A fully isolated controlled variable resistor

• Relatively low drive current

• Good distortion performance

• Zero charge injection (no clicks)

• Inherent time constant that offers smooth on/off switching

Until recently, there was no application information for the devices. There is now a study that looks at the proper ties of these devices from the perspective of an audio engineer. The website also offers a number of interesting application notes and circuits:

• Compressor

• Limiter

• Soft Switching

• Level Controls and Cross-Faders

The site says additional applications are coming soon: VCA replacement, ex pander, and noise gate. I also found a Leslie Effects Rotor Adapter on the Internet (search on LERA).

ANALOG OPTICAL SOUND

Modern optocouplers are not the first use of optical audio processing. The most common method once used an optical process whereby a transparent line was recorded along one side of movie film. The strip varied in width according to the frequency of the sound, and was known as a variable-area soundtrack.

As the film passed by an audio pick up, bright light from an exciter lamp was focused through the transparent line by a lens. The light that passed through the film shone on a photocell. The light was changed to electrical cur rent by the photocell. Wider parts of the strip allowed more light, which caused the photocell to produce more current.

A variation of this method was known as variable-density soundtrack. It used a strip that varied in transparency rather than width. The more transparent the strip, the more light that shone through.

The biggest problem with these methods was that the natural graininess of the film and any scratches from handling produced a lot of background noise. In the 1950s magnetic recording became popular and eventually supplanted optical soundtracks. Photoelectric sound films were decades ahead of the optical analog LaserDisc first demonstrated by Philips and MCA in 1972.

Phototubes had a large-area light- sensitive cesium (or other alkaline metal) cathode surface and a collecting anode contained in a glass vacuum tube bulb. When light impinged on the cathode it emitted photoelectrons in proportion to the intensity of the incident light, which were then focused on the plate. The early image orthicon television cameras used a variation of this device called a photomultiplier tube.

PHOTO 1: Audiohm available packages. (Now carried by Crest

Components, Australia)

+++++++++++

PHOTOSENSITIVE MATERIALS

The liberation of electrons from materials when exposed to light is known as the photoelectric effect Heinnch Hertz recorded the first experimental evidence of the photoelectric effect in 1887 when he was investigating the production and reception of electromagnetic (EM) waves The first experiments with the photoelectric effect were performed on contact rectification materials such as copper oxide arid selenium (the first semiconductor rectifiers were made from these compounds) Later it was noticed that if light fell on a semiconductor junction its conductivity increased This was first noted in the early 1950s when experimentation with diode and transistor applications became widespread Germanium diodes were about 200 times more sensitive to light than selenium cells Analog designers found that if light fell onto the glass cases of their circuit diodes the analog performance was thrown off. The main types of photosensitive semi conductor devices are:

1. Photoconductive cells (light dependent resistors) consist of a semiconductor sub stance (cadmium sulfide cadmium selenide cadmium telluride lead sulfide and so on) whose electrical resistance vanes with the intensity of illumination falling on the cell Connections to the cell are by means of two lead electrodes.

Photoconductivity occurs in semiconductor materials due to the higher electrical conductivity that results from increases in the number of free carriers that are generated when photons are absorbed. Many of these semiconductors are compounds of the II. VI element groups in the periodic table In darkness the photoconductor resistance is very high. If a voltage is applied to the cell material only a small dark current will flow. This is the characteristic thermal equilibrium current. When light shines on the photoconductor and is absorbed by the crystal its electrons are excited decreasing the cell resistance.

For cadmium sulfide (CdS) material the light must have a wavelength shorter than 515 nm. At shorter wavelengths the light is absorbed near the surface of the crystal inducing electron hole recombination.

If a CdS cell is left in total darkness for more than 10 hours the value of its resistance is maximized This is the true or equilibrium dark resistance. In practical applications where the CdS cell is used at various light levels the previous light levels affect the dark resistance.

This is called the light history effect CdS cells require a certain amount of tune to respond to incident light. This limits its the ability of the cell to detect rapidly changing light levels.

The response rise time is expressed as the time required for the resistance to reach 63% of its saturation value after illumination.

The decay time is the time required for the resistance to decay to 37% of its saturation value after the light is removed. An amorphous selenium alloy is used on the drums of laser printers and copiers CdS cells are used in flame detectors in the exposure meters for automatic cam eras for counting moving objects and in automatic door-opening systems.

2. Photovoltaic cells convert light directly into electrical energy without the need for an external source of current Silicon solar cells convert sunlight directly into electric energy They are usually connected in panels as a source of electric power in satellites and may someday provide electricity for private homes.

3. Optocouplers (opto diodes transistors and thyristors) are used to provide galvanic isolation between circuits to pro vent shock hazards and to transfer digital data

+++++++++++

AUDIOHM ANALOG MODE

In analog mode, the Audiohm optocoupler performs the function of a current-controlled variable resistor. An LED emits light that is directly proportional to the LED control current. The CdS/CdSe photoresistor changes its resistance in proportion to the Light level. When used in analog mode the photoresistor reportedly has considerably less distortion than an FET and is more cost effective than a voltage-controlled amplifier (VCA) or digital potentiometer.

The Audiohm product line consists of 27 devices that are available in either platform or axial packages, both for through-hole installation (Photo 1). Sorted devices are available for applications where tracking is important, such as multi-channel volume control.

Sionex employs highly developed processing of the CdS and CdSe photoconductive layer. They claim this guarantees the lowest possible ohmic contact and reduces parasitic capacitance, resulting in devices with ultra low distortion.

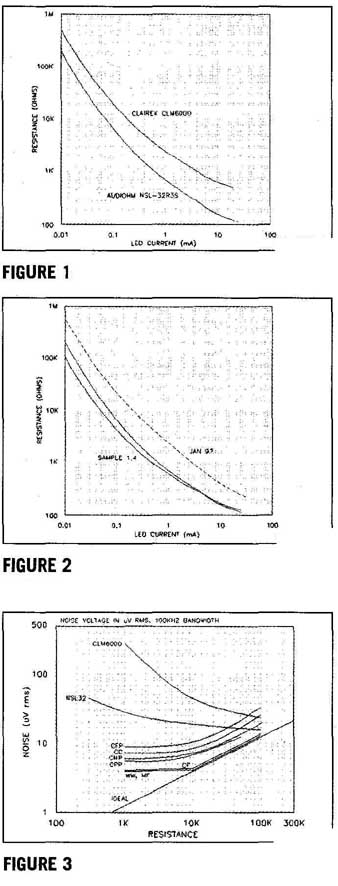

FIG. 1: Resistance versus LED current. FIG. 2: Resistance tracking versus LED

current. FIG. 3: Noise versus resistance.

MEASUREMENTS

I connected one of the Audiohm NSL 32R3S devices and an old Clairex CLM6000 CdS cell, with their LEDs in series with a DC current source. The resistance change with LED control cur rent is shown in Fig. 1. The change is very logarithmic in nature, much more so than a log (audio) taper potentiometer. The CdS cell has a different slope than the Audiohm.

Next I took four samples of the sorted NSL32 devices and ran the same test. I also included the sample de vice from 1997. The four sorted devices track within about 5.5dB at the highest resistance, and improve to less than 1dB below 1k resistance. Note that the curves cross each other near 250-ohm. The earlier device has a similar slope, but does not track the four sorted samples.

Since the optocoupler is a current injection semiconductor device, it has higher noise than that of a resistor. I connected a number of fixed and vari able resistors across a 6V DC battery and measured the AC noise over a bandwidth of 100kHz. I measured the potentiometer noise from their wipers to one of the end terminals.

The graph in Fig 3 shows the Johnson noise of the resistors (plus any noise from the battery) and the noise generated by the Audiohm and Clairex optoisolators. Note the reversed slope of the opto-isolator curves. The discontinuity below 4uV is the noise floor of my test setup.

The curves are compared with theoretical “ideal” resistance that has no excess noise. From bottom to top at 10k resistance, the tested devices are:

• Ideal fixed resistor (theoretical)

• Wirewound and metal film fixed resistors (WW, MF)

• Carbon film fixed resistor (CF)

• Conductive plastic pot (CPF)

• Cermet pot (CMP)

• Carbon composition fixed resistor

• Carbon film pot

• Audiohm N5L32

• Clairex CLM6000

Figure 4 shows the shunt attenuator application circuit from the Sionex web site. The audio input signal is applied to a series 10k limiting resistor. The Audiohm is connected at the audio output side to ground. LED current from some control interface (current source, digital-analog converter, and so on) varies the resistance of the photoresistive element.

The equivalent circuit of the photoresistor is shown on the right side of Fig 4. Rv is considered to be an “ideal” resistance that varies with the LED light intensity. Cp is the parasitic capacitance of a few pF. Rb is the bulk dark resistance of the cell layer, and Rs is the minimum resistance of the cell layer at saturation light intensity. Rb and Rv show a marked negative voltage dependency, such that resistance decreases with increasing voltage across the photocell.

Figure 5 shows the graph from the Silonex data for the shunt attenuator circuit in Fig 4. When LED control current is first applied, the cell resistance is so high that the nonlinear response has no effect on distortion. As attenuation starts to increase, there is a peak in the distortion due to resistance nonlinearity and noise.

As the cell resistance drops further, less of the input voltage appears across the cell. Noise is inversely proportional to cell resistance, and cell nonlinearity is proportional to the cell voltage, so the distortion drops rapidly. From there the distortion rises gradually until it reaches the second (but much lower) peak, where cell resistance is at or below the series resistance.

There are other graphs on the web site for series attenuation (the worst distortion case) and different configurations of series/shunt attenuation. Silonex also compares the various methods of audio switching in terms of voltage, isolation, drive requirements, and on/off resistance.

The optocoupler cell layer has an inherent response time delay. The rise time, TR, is 5ms to 63% of final conductance at I_F = 5mA. The decay time to 100k-ohm after removal of I_F is 10ms. The N5L325R2 has a much slower decay time of 500ms. This may be advantageous, depending on the end application.

FIG. 4: Shunt attenuator application and photoresistor equivalent circuit

FIG. 5: Attenuation and THD+N versus control current

SOURCE

Also see: A 1 PPM IM DISTORTION ANALYZER