Each report about an item of electronic test equipment is based on examination and operation of the device in the ELECTRONIC SERVICING laboratory. Personal observations about the performance, and details of new and useful features are spotlighted along with tips about using the equipment for best results.

By Carl Babcoke

---------- Sencore model LC-53 is a complete analyzer of inductors

and capacitors. It tests inductances in henries, and has a ringing test

for "Q" (shorted turns). Capacitors are checked for both capacitance

and leakage. Autoranging eliminates all range switches,

Sencore model LC-53 "Z Meter" is a unique inductor-capacitor tester with many automatic features. The inductance of a coil or transformer can be checked by one pushbutton. Another button gives a direct reading of capacitance. Both functions have automatic ranging and digital readout for accurate and easy testing of components.

Capacitor leakage is measured at 12 dc voltages between 3V and 600V with the leakage current displayed on the digital readout. The relative "Q" of unknown inductors is tested by the Sencore ringing method, and the number of rings is shown on the readout.

Power comes from the 120V line, so there are no batteries to run down at inconvenient times. Al though the unit usually is considered to be for bench use, transportation or storage in a vertical position is made easy by the combination handle and tilt stand, a place to store the power cable, and plastic feet at the unit's back panel.

Testing inductors

Inductances in henrys are tested in the LC-53 by measuring the ac voltage that results from varying the coil current by a specific amount. Six automatically selected ranges cover inductances between 1 microhenry (1 uH) and 9,990 milli-henries (9.990mH or 9.99H). Decimal position also changes automatically, and LEDs at the right of the digital display (Figure 1) indicate whether the reading is in pH or mH. In-circuit tests are possible if the circuit resistances are fairly high. The Sencore manual gives the limits.

Figure 1 LEDs light up behind these markings to show whether the readout

is in pF, uF, uA, uH or mH.

Figure 2 The true inductance in pH or mH is indicated when the inductor value button is pressed. This flyback checked 10.9mH.

These tests resemble ohmmeter readings in their simplicity (Figure 2). Connect the hook-type test probes to the inductor terminals and then press the inductor-value button. That's all. One LED lights to show whether the reading is in pH or mH, and the digital display gives the reading with correct decimal placement.

For small inductances where the test-lead inductance becomes a source of error, the probes should be placed approximately where the measurement will be made. The hook probes are shorted together, the value button is pressed, and the lead-zero knob is rotated slowly until the readout is 00.0 with the minus sign showing occasionally.

(Slow rotation is required because about two seconds are required for each reading when the probes are shorted.) After the zeroing, tests of small inductances can be made accurately.

When the inductance value is above 10H or if no inductor is connected to the test leads, the display will show 8880 with the three eights blinking. This is the overrange indication.

Ringing tests--For coils of unknown inductance ratings or for shorted-turns tests of vertical- and horizontal-sweep components, a ringing test that shows relative "Q" is included. This test is about the same as supplied by the Sencore YF-33 Ringer.

The probes are connected to the inductor, the ringing-test button is pressed, and the impedance-match knob is rotated through all six positions (Figure 3). The readout shows the number of rings before the amplitude drops to the standard value. Use the knob position that gives the highest number of rings, for accuracy. For most sweep coils, a reading of more than 10 indicates a normal coil.

Test results--Many inductors in an old color TV chassis were checked for value and ringing. One peaking coil measured 380uH and 24 rings. Another gave readings of 4.2uH with five rings. The delay line measured 1.66mH and no rings.

An out-of-circuit audio transformer's 4 ohm winding read 8.10mH and two rings, while the primary measured 8910mH and five rings.

These tests were interesting but did not prove whether or not the inductors were defective, since the ratings were not known. New coils with factory ratings were tested next.

A stock peaking coil was marked 250uH. It measured 244uH and 17 rings. A 12uH coil checked 12.1uH.

These are very accurate readings.

However, at first a 1.35uH peaking coil tested 0.9uH. A careful reading of the manual found the Sencore method of obtaining accuracy with reactances under 2uH. The lead-zero control is offset to give a 2uH reading with test leads shorted together. Then the reading is made and the 2uH subtracted. With this corrected method, the reading was 1.5uH, which is very good for such a low value.

Many technicians probably wonder if the inductance value test can find shorted turns as well as the ringing test does. One old flyback was checked with these comparative results: the primary measured 10.6mH and gave 95 rings, with a 5-turn short, the readings were 9.7mH with 30 rings; when the 2-turn rectifier-filament winding was shorted, the readings changed to 10.5mH and 25 rings. The inductance test can show serious cases of shorted turns, but the ringing test is more sensitive to just a few shorted turns.

Comments---Notice that the inductance-value tests require direct cur rent. Therefore, coils in series with a blocking capacitor cannot be tested; they read as if open.

Tests of inductor's values in henries are repeated continuously as long as the value button is depressed. So, if the coil under test changes in inductance, the reading changes at the next sampling.

However, the ringing test is different. It rings the inductor only once for each press of the ringing button or rotation of the impedance-matching knob to the next position.

Then the readout retains the number of rings, even if the inductance is disconnected. Releasing the ringing button (or any rotation of the impedance knob) initiates a new reading, which without an inductor becomes zero. This is normal operation and it has no drawbacks.

It is mentioned only for information to prevent questions later on, and because this is different from operation of the YF-33 Ringer and the built-in ringing function of the VA-48. Their ringing is continuous.

Testing capacitors

Capacitances are measured in the LC-53 by charging the capacitor under test through a specified resistance and counting the time required for the capacitor charge to rise to +5V (one time-constant).

The instrument auto-ranges through 10 available ranges to provide capacitance readings between 1 picofarad (1 pF) and 199,900 microfarads (199,900 uF).

All readouts are direct-reading with LEDs at the right indicating whether the reading is in pF or uF.

The decimal moves as needed, and one or two zeros are added at the end to till out any required number.

Accuracy is rated at of reading plus the resolution error, or 5% plus resolution error for values over 1000pF.

----------- Figure 3 A ringing test for relative "Q" (including

shorted turns) is performed by pressing the inductor ringing test button

and rotating the impedance match knob for the highest readout of rings.

Model CA-55 has the same capacitor tests as the LC-53, but it does not check inductors.

To test most capacitances, connect the test clips to the out-of-circuit capacitor, press the capacitor value button, notice from the LEDs whether the value is ex pressed in pF or pF, and then read the value on the digital display.

For accuracy of capacitances lower than 1000pF, the test lead should be placed where it will not be moved very much when it is connected. Without anything connected to the test clips, press the value button and slowly adjust the lead-zero control for 00.0 with the negative sign flashing occasionally.

Then make the capacitance measurement.

Capacitances of less than 2pF sometimes read 00.0 because of the auto-ranging window. Therefore, for these small values, offset the zeroing adjustment to provide a 2pF reading without a capacitor, make the capacitance reading, and subtract the 2pF from it. The remainder is the true capacitance.

Readings of most capacitance values are seen on the digital display immediately after the value button is pressed. However, very large values require longer. For example, a 50,000 uF capacitor has a delay of about five seconds before the reading appears. Any capacitor that does not give a reading within 30 seconds probably is excessively leaky and should be replaced.

Polarity of the test leads is not important except for electrolytic types. For those, the red clip should go to the positive capacitor lead and the black clip to the negative.

A 39G144 test lead adapter is furnished for connecting to large terminals.

Leakage tests--Model LC-53 has an excellent leakage test for capacitors.

The applied-voltage switch selects dc voltages of 3V, 6V, 10V, 15V, 25V, 50V, 100V, 200V, 300V, 400V, 500V and 600V, as shown in Figure 4. Two amounts of leakage current are selected by the leakage-range switch. The 9.990 uA range is for large electrolytics or others that have high leakage. Other types should be measured on the 99.9uA setting of the leakage-range switch.

Ceramic, polyester, polycarbonate or mica dielectric capacitors should not show any leakage current on the display. Any that have leakage are detective and should be re placed.

----- Figure 4 - Two ranges of leakage cur rent and 12 levels of dc voltage

are available for testing capacitor leakage. The digital readout shows

the leakage current in uA.

Electrolytics usually show some leakage. A chart that lists permissible electrolytic leakage according to capacitance is mounted underneath the LC-53 cabinet where it can be pulled out for reference.

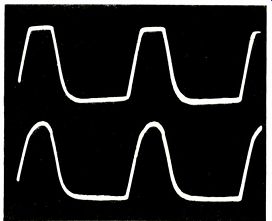

There is a small precaution when testing small capacitances for leak ages. Without a capacitor connected to the test leads, the leakage voltage consists of positive-going 60Hz pulses (Figure 5). If a resistor is connected across the test leads instead of a capacitor, the measured voltage (and current) will be only 1/3 to 1/2 of the rated value. For the full rated voltage, the capacitor under test needs to be .03 uF or larger. Of course, if a very small capacitance value (say 12pF) must be tested at the full 600V, a larger capacitances having low leakage can be paralleled with it during the leakage test.

----- Figure 5 Without a capacitor across the test leads, the dc leakage

voltage consists only of positive-going pulses.

A test capacitor of 0.3pF or so brings the average voltage up to the marked values. Top trace is the 15V waveform while the 500V waveform is shown below.

The leakage test can be used to reform many old electrolytic capacitors. These reforming methods must apply the dc voltage for an hour or so. To keep the leakage button depressed, a 39G145 rod is included with the analyzer. It is placed between the button and the carrying handle, which is moved near the test buttons.

When none of the buttons are pressed, the test leads are shorted together, thus discharging the external capacitors. No leakage voltage is applied to the test leads until the leakage button is pushed.

Comments

For protection of the analyzer from charged capacitors and other external overloads, a 1-A slow-blow fuse is located behind the BNC test lead connector. The fuse can be removed and replaced by unscrewing the BNC connector.

A 48-page operation and maintenance manual is supplied with the analyzer. It has much detailed information about the instrument and how to use it for many unusual tests. One section explains how the LC-53 can be used to test SCRs, TRIACs, HV diodes and coaxial cable.

Inductor and capacitor readings were very accurate when measuring components of known values. Busy technicians should appreciate the convenience of merely pressing a button or two for the majority of tests. The LC-53 is recommended for all electronic-service shops.

Model CA-55 Sencore model CA-55 capacitor analyzer has capacitor-testing functions that are identical to those described for the LC-53. The switches are arranged differently because the inductor tests are not there.

Model CA-55 capacitor analyzer sells for $495, and model LC-53 inductor/capacitor analyzer is priced at $695.

Also see: Digitization of low-frequency signals