The history of magnetic recording covers a period spanning more than half a century. Yet magnetic recording remained practically undeveloped until shortly before the beginning of World War II. From its inception in 1898 until its real commercial application in Germany, starting in 1935, magnetic recording remained little more than a scientific curiosity. Historians of invention during that era regarded it as scarcely worth mentioning.

Fig. 1-1. Valdemar Poulson of Copenhagen, Denmark, Built the First Magnetic

Recorder in 1 893. Called the Danish Edison, He is the Father of Important

Inventions in the Field of Magnetic Recording.

Valdemar Poulsen of Copenhagen, Denmark, pictured in Fig. 1-1, built the first magnetic recorder in 1893. His "Telegraphone" magnetically recorded crosswise on a steel piano wire, but the wire would twist which threw the crosswise recording out of alignment, thus ruining its quality. To overcome this difficulty, Poulsen replaced the wire with a more bulky and cumbersome steel tape which could not twist. Shown in Fig. 1-2 is the Telegraphone manufactured in the United States by the American Telegraphone Company around 1920. The spools of wire are mounted horizontally and turned by a 100-volt motor. No provision for automatic rewind was made. Spools of wire were interchanged for rewind and playback.

Fig. 1-2. The "Telegraphone" Designed by Valdemar Poulsen and

Manufactured in the United States by the American Telegraphone Company

Around the Year 1920. (Courtesy of Popular Electronics.)

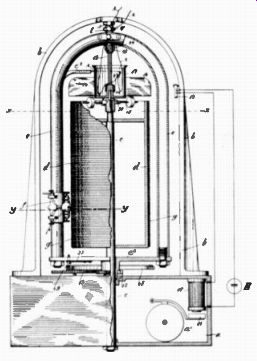

In his United States patent granted on the ''Telegraphone," illustrated in Fig. 1-3, Poulsen called it an "apparatus for electromagnetically receiving, recording, reproducing, and distributing articulate speech." Poulsen's invention was completely unique and original, not the outgrowth of further refinement of a fundamental discovery made earlier. Recorded scientific history does not disclose or even give a possible clue as to where Poulsen got his idea. Although historians of invention passed Poulsen's invention by with scarcely a nodding mention, the "Telegraphone" was nevertheless a sensation in its day.

In 1900 at the Paris Exposition the "Telegraphone" won the Grand Prix. Technical journals and newspapers were filled with references about the recorder.

The "Telegraphone" particularly captured the imagination of investors in the United States. Poulsen was able to raise without great effort the then princely sum of $5,000,000 in capital stock at a par value of $10 a share for the manufacture of the "Telegraphone." Its backers visualized its chief use as an office dictating device. The machine was capable of recording for 30 minutes with its wire traveling at an amazing velocity of 7 feet per second. The machine required earphones, operating without an electronic amplifier which was not destined to be discovered until twenty-five years later.

A series of financial misfortune beset Poulsen's United States firm, the American Telegraphone Company. Lacking present day persuasive promotion and selling techniques coupled with inherent defects in the recorder itself, the firm soon collapsed and the stock became valueless. A Danish firm was also organized in 1909 to manufacture the "Telegraphone." It closed its doors in 1916 without having commercially marketed a single recorder.

Fig. 1-3. A Drawing of Valdemar Poulsen's "Telegraphone" Taken

from the American Patent.

Electronic engineers who examine Poulsen's patent today are amazed at how closely his machine, crude as it was, resembles the modern magnetic recorder. His recorder worked, and Poulsen proceeded to commercially market the "Telegraphone." Oscar Dupue, in an account of his experiences with Burton Holmes, then the world's leading travelogue exponent, recalled having used the "Telegraphone" ++ .

"I have mentioned previously the second trip to Norway in 1907 to make another film of the fjord trips. It was on this trip that I purchased a Poulsen wire recorder in Copenhagen ... I was able to operate it in my steamer cabin while en route home. I had a lot of fun talking into it and playing back, and soon I had a procession of passengers eager to record and hear their own voices. Several theatrical notables were present, including the famous Jimmie Powers .... he was full of hit songs and stories, so we recorded a few. When he finished, I spoke into the recorder saying that Powers' record was made on the twenty-eighth day of August, 1907, in mid-ocean aboard the S. S. Augusta Victoria. Thirty years later I re-recorded Powers' voice on film. The wire had retained the record as clearly as when it was first made."

Since Poulsen had a working magnetic recorder fifty years ago why did magnetic recording have to wait until World War n to be fully developed? One obvious answer to this question lies in Poulsen's recorder. Since the recorder originally employed wire and later a steel tape, it was undoubtedly very awkward and difficult to operate.

++ Oscar Dupue, "My First Fifty Years in Motion Pictures." Journal of the society of Motion Picture Engineers, December, 1947.

Fig. 1-4. Dr. Lee de Forest, Pictured Here, Invented the Vacuum Tube

Which Made It Possible for the First Time to Satisfactorily Reproduce

the Weak Signals Recorded on Magnetic Tape.

Because the speed at which the tape traveled in recording was as fast as was practical for the mechanism to handle, it was impossible to speedup the rewind time. Also, since it recorded crosswise, or in a Perpendicular direction, the quality could not have been too good, a though undoubtedly it represented an achievement when contrasted to the sound standard prevailing at the time. Frequency response was limited. The dynamic recording range did not exceed approximately 20 decibels. The noise level was excessively high. However the main reason for the lack of development can be attributed to the low acoustical output of magnetic recording in comparison with the then competitive mechanical systems such as disc recordings.

Not until Dr. Lee de Forest, pictured in Fig. 1-4, invented the vacuum tube grid was it possible to obtain sufficient amplification to satisfactorily reproduce the weak signal on magnetic tape. In fact, the relative positions of the now fast rising magnetic recording medium and phonograph industry might today have been reversed through a little-known experiment conducted in 1912. But as is so frequent in the history of invention, the full significance of the experiment was not realized at the time.

Dr. Lee de Forest himself writes: "Speaking of the necessity for the three-electrode tube amplifier in connection with magnetic tape recording and reproducing, you may be interested to know that in the spring of 1912 I used the tube as an amplifier in connection with the old steel wire Poulsen Telegraphone.

I am sure this is the first combination of those two great inventions.

No one could foresee at that early date the immense development and priceless applications of the magnetic tape Telegraphone. In fact, one of the very first applications of the three-electrode tube as an amplifier was in connection with the Telegraphone."

Fig. 1-5. In Perpendicular Magnetic

Recording, High Frequencies are Possible Only at High Tape Speeds

Since the Magnetic Field From the Head Is Not Concentrated. The Magnetization

is Perpendicular to the Tape.

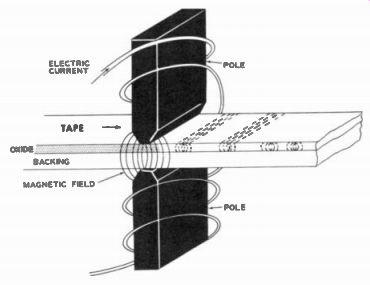

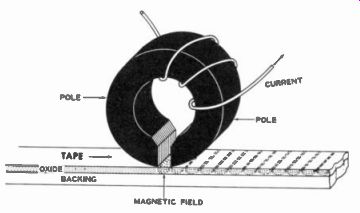

Other roadblocks besides amplification to be removed were the abandonment of perpendicular magnetization in favor of longitudinal magnetization and the discovery of AC or high frequency bias technique.

Originally the magnetic field was recorded perpendicular to the recording medium (wire, steel band, or tape). (See Fig. 1-5.) While this system worked, it required very high tape speeds since the magnetic field in the region of the tape could not be concentrated but covered a rather wide area.

However, with the invention of the ring type head the magnetic field could be confined as far as the tape is concerned to the area between the pole pieces or to the magnetic gap. This permitted recording wavelengths as short as .00025 inches (for video recording, wavelengths are now being recorded to even a fraction of this amount).' Thus, with the ring type head and longitudinal recording (recording in the direction of tape travel rather than perpendicular to it as illustrated in Fig. 1-6), engineers were able to make practical low tape speeds and the storing of a large amount of information on a small reel.

MAGNETIC FIELD

Fig. 1-6. In Longitudinal Magnetic Recording, High Frequencies at Far

Slower Speeds Are Possible Since the Magnetization is in the Direction

of Tape Travel.

The AC or high frequency bias technique was discovered by W. L. Carlson and G. W. Carpenter of the U. S. Navy. The AC bias technique eliminated the high background noise generally associated with recordings made using the older DC bias method. However, even with the removal of these obstacles, the progress of magnetic recording was slowed for many years through lack of imagination and any serious desire to perfect existing techniques.

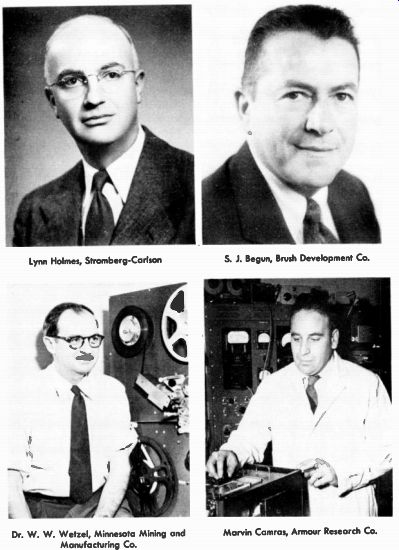

The present high state of development is due in large measure to the work of such leaders in the field as AEG in Germany, manufacturers of the Magnetophone; the Bell Telephone Laboratories; Lynn Holmes of the Stromberg-Carlson Company; S. J. Begun of the Brush Development Company; Marvin Camras of the Armour Research Foundation; and, Minnesota Mining and Manufacturing Company's Dr. W. W. Wetzel. (See Fig. 1-7.) When magnetic recording bobbed up from obscurity during the middle twenties, the Naval Research Laboratory saw in Poulsen's invention a promising method for transmitting telegraph signals at an exceptionally high speed. It was hoped that, at normal speed, messages could be recorded on wire, then transmitted at high speed to cut down sending time. The project was subsequently abandoned because of the difficulty in handling wire at high speeds. However, the discovery of the AC biasing theory resulted as a by-product from the Navy's early developmental work.

Also during the twenties in Germany, a promoter gifted with imagination and vision, impressed with the future of magnetic recording, formed a company, the Telegraphic -Patent-Syndikat.

Fig. 1-7. Pioneers in the Development of Magnetic Recording in the United

States. Dr. W. W. Wetzel, Minnesota Mining and Marvin Camras, Armor

Research Co. Manufacturing Co.

This firm, founded by Kurt Stille, was organized to sell manufacturing licenses to produce a magnetic recorder-reproducer. Using high impact sales methods uncommon in Europe, Stille sold his license to produce a modified and improved "Telegraphone" to a variety of European concerns. One recorder, produced under Stille's licensing agreement, used steel tape. Known as the "Blattnerphone", this recorder was seriously considered for early talking motion pictures.

In England several movies were completed, actually using a sound track recorded on synchronized steel tape.

In Germany, particularly, a variety of magnetic recorders were marketed during the early thirties, all operating with either wire or steel bands. One of the more prominent German concerns was the Echophone Company to whom Kurt Stille sold a license agreement. It was the first recorder to use a magazine load device rather than reels, considerably simplifying loading and threading the recorder. The Echophone Company subsequently sold out to the International Telephone and Telegraph Company which then resold its patents to the C. Lorenz Company, another German firm, who completely re-designed the machine. The new recorder was marketed under the trade name "Textophone." The "Textophone," among other magnetic recorders, were on the German domestic market in 1933 when the Nazi Party swept into power. The Nazi Party and the Gestapo were large consumers of magnetic recording equipment of all types.

Working independently, another German, an inventor named Pfleumer, was busily engaged conducting experiments with various types of recording mediums including paper and plastic tapes coated with iron oxide particles. Sensing a large and growing market, the Allgemeine Electrizitats Gesellschaft (AEG), the German equivalent to General Electric Company, joined hands with the I. G. Farben Company, and took over Pfleumer' s early pioneering work in coating paper and plastic materials. The grain size of the magnetic materials was relatively large. The early paper tape, coated with the powdery magnetic substance, closely resembled sandpaper. When the tape was run through recorders, a spray of powder clouded the air.

The first Magnetophone, produced by AEG, was exhibited in 1935 at the German Annual Radio Exposition in Berlin. Although the Magnetophone was inferior to many earlier German magnetic recorders, it was an instantaneous success, the hit of the exhibition.

Employing coated paper tape as opposed to wire or steel bands, the magnetic recording tape cost only fifteen cents per minute of recording time; the price of steel bands was a dollar or more per minute.

Naturally, paper tape was less wieldy, threaded easily, and was infinitely more convenient to store.

Meanwhile, in the United States, Bell Telephone Laboratories was the only large corporate name in the electronics field to be associated with magnetic recording. Bell Telephone Laboratories designed a steel tape recorder, the Mirrophone, that was put to work announcing the weather and time signals on the telephone. At the New York World's Fair, the Mirrophone amazed thousands of visitors who recorded their voice into the machine and gasped in surprise to hear a chance remark of a moment instantly played back with full fidelity. The Mirrophone was also a featured electronic performer in the Bell Telephone exhibits which toured the schools of the nation as part of a continuing public-relations program.

Fig. 1-8. An Early Brush Development Company Sound mirror with Cover

Removed.

Magnetic recording equipment had not been manufactured commercially in the United States until 1937 when the Soundmirror, a steel tape recorder, was placed on the market. Brush Development Company purchased rights to the Soundmirror which was originally built by Acoustic Consultants. Fig. 1-8 shows one of the early Brush Soundmirror recorders. The cover is removed so that the mechanical layout may be seen. Although the machine could record only one minute on a steel tape, countless applications were immediately found for it. Brush inaugurated an intensive research program which made many fundamental contributions to the body of knowledge comprising magnetic recording techniques. During World War II, Brush built large quantities of magnetic recording equipment for the Armed Services. In cooperation with the Office of Scientific Research and Development, Brush helped develop coated paper-tape and plated-wire recording mediums.

Armour Research Foundation was also prominent in the early development of magnetic recording. The chief contribution of the Armour Research Foundation lies in its intensive campaign launched to acquaint the public with the full potentialities of magnetic recording.

It also supplied magnetic recording equipment to the Armed Services during World War n. However, because of limited shop facilities, General Electric and several other companies took over production of the Armour Research Foundation's recorder.

Immediately following the end of World War II, Webster-Chicago and Sears, Roebuck and Company began large-scale wire recorder production. War workers with pockets still filled with money provided a wide market base of home consumers, topped off with specialized office dictation uses and other applications. Encouragingly large quantities of wire recorders were sold during the first few months of large-scale production. However, commercial television began to show promise of sweeping the country and with automatic home appliances, automobiles, and other types of consumer products increasingly available, sales of wire recorders began to slow. The anticipated wire -recording boom failed to materialize.

During World War II all avenues of exchanging technical information between Germany and the outside world were closed.

But work on the magnetic recording process progressed, despite shortages and hardships imposed by the war. Substantial improvements were being made on the AEG Magnetophone.

Near the close of World War II, a corps of Allied scientists and technicians was sent to Germany to investigate reports of a highly developed magnetic tape and tape recorder system for general recording purposes.

American technicians were amazed to find that the Magnetophone, employing AC bias and using a coated paper tape, was able to record a full 10,000 cycles with a low signal-to-noise ratio and negligible wow and flutter. Although experimental American wire recorders under carefully controlled conditions could now attain 10,000 cycles, wire had many defects when compared to tape. Quick to see the advantages of the tape system over other recording methods, the investigators returned prototypes of the recorder and samples of the tape to the United States. Immediately an intensive developmental program was begun, aimed at opening up the field of magnetic recording.

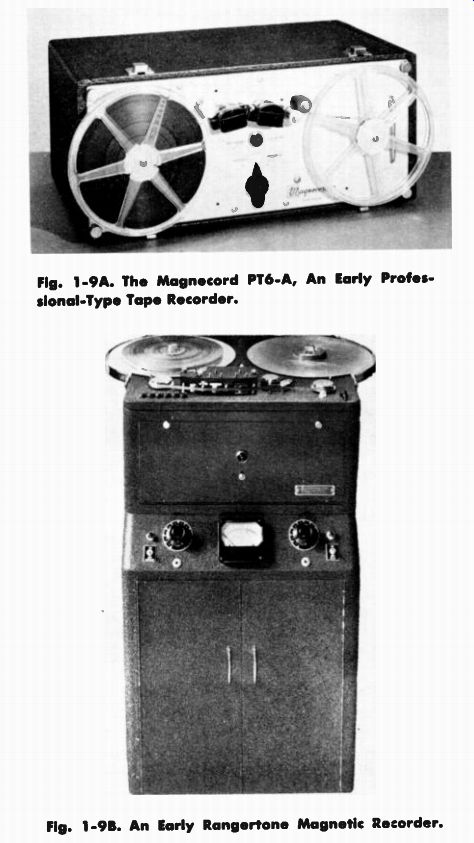

The United States Alien Property Custodian held all patents on the Magnetophone and would license any American firm to produce the equipment on application. Although any company that wished to duplicate the Magnetophone could do so, large corporations still showed little interest. For the first few years following the war, practically all manufacture of professional recorders was done by three small and then little-known organizations: Magnecord, Inc., Rangertone, Inc., and Ampex Electric Company. Samples of early units manufactured by these companies are shown in Fig. 1-9A B and C. ' '

While the early American recorders were directly copied from the German AEG Magnetophone, the German magnetic tape was found to be far from satisfactory.

The early German tapes used a type of oxide known as "raven red," a term borrowed from the barn paint of the same name. Literally a high grade of barn paint, the oxide was painted on a paper backing.

The major deficiencies of the German tape were three in number.

Fig. 1-9A. The Magnecord PT6-A, An Early Professlonal-Type Tape Recorder.

Fig. 1-9B. An Early Rangertone Magnetic Recorder.

First, the output available from German tape was very low and required large' amplifiers in the recorders for satisfactory performance.

Second, the tape had poor response at short wave lengths, and this necessitated driving the tape at a high velocity to maintain adequate frequency response. Finally, the uniformity of the German tape lot to lot and even within a single reel varied widely and made standardization of equipment and recording procedure difficult.

Fig. 1-9C. An Early Ampex Magnetic Recorder.

Because of the limitations imposed by the German tape, in building the Magnetophone, the Germans arbitrarily selected a high velocity speed that would give good frequency response within practical limits. The first American machines were built with a tape speed as close as possible in round English numbers to the German speed, 76 centimeters per second. The first American recorder speed turned out to be 30 inches per second, the approximate English numerical equivalent, enabling the playback of recorded German tape.

Early attempts at manufacturing magnetic tape were made by the Brush Development Company and Indiana Steel who used a unique magnetic iron material with high coercive force but which was difficult to record and erase. Minnesota Mining and Manufacturing Company in mastering the production of high-quality magnetic tape, made substantial improvements over the earlier German attempts. The task was not an easy one. The technical specifications for the production of quality magnetic tape were substantially more exacting than any other type of tape coating process previously known.

The problem of high tape speed was solved by the introduction of a new type of magnetic oxide. The new oxide gave the American tape about 12 db more output than was available with the German tape.

The higher coercitivity of the oxide gave the tape excellent high frequency response characteristics, making possible the adoption of slower tape speeds.

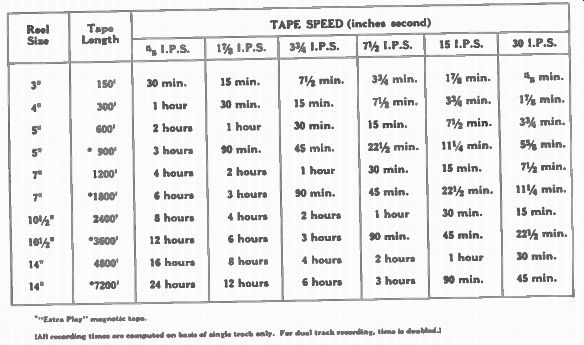

TABLE 1. Uninterrupted Recording Time for Various Magnetic Tape Speeds

and Tape Lengths.

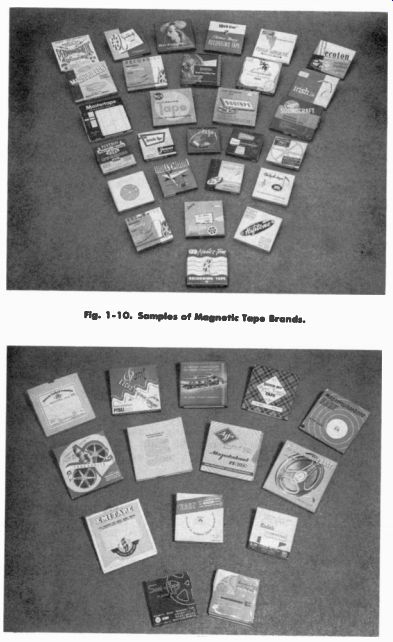

(top) Fig- 1-10. Samples of Magnetic Tape Brands. (above) Fig. 1-11.

Samples of Brands of Magnetic Tape Available Throughout the World.

With the improvements made in magnetic tape, recorder speeds were progressively halved, first from 30 to 15 inches per second, then from 15 to 7 1/2, 3 3/4, and 1 7/8. Table I gives the recording time obtainable at each speed for various size reels. Since in copying or duplicating tapes, it is easier to build machines that work in multiple speeds of each other, each progressive speed change was obtained by dividing by two.

At the present time there are more than forty brands of magnetic tape on the American market alone, the great majority being private labels. Some of these brands are shown in Fig. 1-10. The major manufacturers of magnetic tape in the United States are Minnesota Mining and Manufacturing Company, Audio Devices, Reeves Soundcraft, Orradio Industries, Technical Tape Corporation, and Ferro Print Company. Fig. 1-11 shows a sampling of magnetic tapes available throughout the world. The magnetic tape field is a very competitive one, accounting for rapid technological advances and improvements.

Tape speed is one important factor in determining the upper frequency limit of a recorder. Until recently it was possible to obtain, using an arbitrary rule of thumb measurement, one thousand cycles of response for every inch of tape speed. For example, if a recorder operated at a tape speed of 15 ips (inches per second), it was possible to get 15,000 cycles response. However, recent improvements in magnetic heads, recorder design, and still further advances in magnetic tape construction permit the doubling of frequency response. Tape response at 7 1/2 ips now goes .out to 15,000 cycles and beyond.

The Revere Camera Company helped expand the growing home market for recorders by pioneering the 3 3/4 ips speed, made possible by subsequent developments in the manufacture of magnetic tape.

Fig. 1-12. A Typical Professional Recording Studio Installation of the

NBC Radio Network, New York City.

Professional tape speeds have narrowed down to 15 inches per second for high quality audio work, while 7 1/2 ips is quite popular in the radio broadcasting field. In the recording industry 15 ips is the most popular speed for its convenience in editing. The home tape recorder speeds are now generally standardized at 3 3/4 and 7 1/2 ips. Voice and ordinary music recordings taped from the radio use 3 3/4 inches per second, while 7 1/2 ips is preferred for serious high fidelity home recording. At both extremes are the 30 ips speed, which still finds some advocates in the recording industry, and the 1 7/8 ips used for long time, voice-quality recordings, primarily in dictation applications.

Fortunately, however, the length of playing time need not be sacrificed for faster tape speeds since the recent introduction of a much thinner magnetic tape. With a reduction in the coating thickness of 50% and backing thickness of 30%, 1800 feet of magnetic tape can now be wound on a single 7-inch plastic reel which formerly held only 1200 feet. This, in effect, represents a 50% increase in playing time.

The tape recorder has now become the fundamental recording tool for all professional applications. A typical professional installation is shown in Fig. 1-12. Even though discs are marketed in large numbers, they are but copies from master magnetic tapes. Voices from theatre screens were originally recorded, re-recorded and edited on magnetic film. Packaged regional and network radio shows, as well as much local programming, are broadcast from magnetic tape. In all professional recording applications tape has virtually replaced every other recording medium as the prime source of high quality sound.

Fig. 1-13. A Number of Home-Type Recorders Featuring Push-Button Operation.

The more recent tape recorders have been ingeniously designed to make recording as simple as possible. A number of machines are pushbutton operated (see Fig. 1-13), still others have greatly simplified control mechanisms. Well on its way toward becoming America's new pastime hobby, home tape recording is as simple as clicking a camera shutter for ever increasing thousands of American sound enthusiasts. No matter how inexperienced or inept the tape recorder owner may be, the chances are overwhelming that he will come up with acceptable sound on his tapes.

-------