Keeping Records Clean

The incredible power of the scanning electron microscope provides some fascinating verifications-and contradictions-of conventional record-playing theory.

By George Alexandrovich

above: The contact area of a typical stylus is no larger than a single lens

of a butterfly's eye (though somewhat larger than its whiskers, right).

All photos courtesy Stanton Magnetics.

IT may come as a surprise to most people to learn that we really don't know much about phonograph records. Yes, we can manufacture them rather easily (though with varying degrees of quality), but we still lack data on exactly how they work, how we can best keep them clean and noise-free, and what can be expected of the aver age disc in terms of damage resistance and useful life. Part of the difficulty lies in determining precisely what is on a record to begin with. Playing it provides only tentative answers because record-playing systems are themselves imperfect. On the other hand, the fine details of a record groove are exceedingly small and an informative view of the groove requires a depth of field, degree of magnification, and resolution conventional optical microscopes can't provide.

The scanning electron microscope (SEM) is an instrument that makes it possible to photograph record grooves for study. It yields startling resolution at enormous magnifications, but it is expensive and its use is time-consuming. A good day's work with it might result in the examination of only a quarter of a second of recorded information. Fortunately, there are investigators who are not deterred by this, among them the indefatigable George Alexandrovich of Stanton Magnetics, some of whose remarkable SEM photos (and interpretations thereof) appear in the following pages. Although much of what he has to say is surprising and even controversial, Mr. Alexandrovich assures us that it is not his intention to up set any apple carts. Rather, he has merely proceeded from the evidence be fore him to a series of educated guesses. There will almost certainly be those who will dispute his conclusions, but we think you'll agree that the evidence itself is certainly worth looking at.

-Ralph Hodges

----------------------

WE all tend to acquire bad habits in caring for our audio equipment-especially our records. We leave them on the turntable to gather dust, or we reinsert them in their jackets carelessly. We scratch them in handling or in playing, we neglect to clean them properly (or at all), and we stack them, even in their jackets, in ways that produce warps. Such bad habits can be changed, but there are other factors related to sound-reproduction quality that are either beyond our control or that we don't understand well enough to do anything about. The record material itself, stylus wear, groove wear, and the use of cleaning and lubricating devices all affect not only sound quality but record life. Given so many possible influences, it is little wonder that few people are willing to state with assurance which causes of wear are most pernicious and which cleaning techniques are effective, which useless or worse.

At Stanton Magnetics, we are fortunate in having a uniquely useful piece of equipment, the scanning electron microscope. It enables us to look into the record groove, see things not many researchers have been able to see be fore, and subsequently correlate the results of this visual analysis with measurements on phono cartridges and records. The SEM is capable of magnifying an object 160,000 times (for comparison, a magnification of only 10,000 times would produce an image at least fifty times larger than that seen with a good-quality optical microscope).

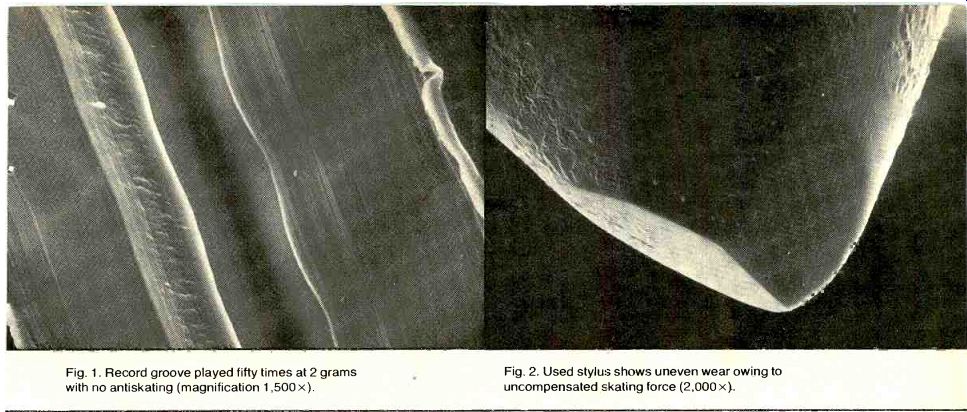

Using the SEM, we can easily demonstrate the effect of tone-arm skating force, for example. In Figure 1, note that the inner wall of a repeatedly played record groove is worn more than the outer one, definite indication of the kind of stylus-force imbalance that proper antiskating force could have corrected. Note further, in Figure 2, that the stylus that played this groove suffered wear on the left side as well, a predictable result of this kind of imbalance. Through close-up viewing and through measuring the area of con tact between stylus and groove, we can calculate precisely the pressures involved. Earlier theoretical assumptions based on purely electrical measurements could not reveal the whole story, nor could they satisfactorily explain why records sounded the way they did.

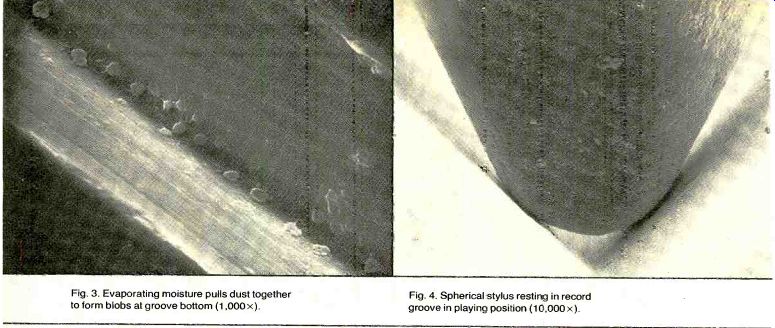

To understand what happens when a record is played, imagine that you have shrunk to 1/100,000 of your normal size and find yourself standing at the bottom of a V-shaped phonograph groove looking along a slow curve whose tortuous contours are ever-varying in width, depth, and shape. The feeling would likely be akin to that experienced at the bottom of a canyon created by a prehistoric river. If you start moving along the bottom of this canyon-like groove, the first thing you encounter are large "boulders," dirt washed down from the walls by liquid cleaners and never completely re moved afterward (see Figure 3). When the cleaning liquid evaporated, its surface tension brought particles of dust together to form these agglomerations.

----

Fig. 1. Record groove played fifty times at 2 grams with no antiskating (magnification 1,500x). Fig. 2. Used stylus shows uneven wear owing to uncompensated skating force (2,000x).

Look further down the groove and try to visualize a stylus traveling through it at the speed of 40 miles per second (144,000 miles per hour!) in a wild, careering race as it tries to maintain its contact with the groove walls through all the jarring twists and turns.

If you look at the walls of the groove, you will find distinctly visible tracks about one third of the way up from the groove bottom. These are the marks of the stylus' previous passage. They do not reach entirely to the groove bottom because the stylus is designed to ride higher up in the groove, as shown in Figure 4, where it will not have to plow its way through the boulders. Although it doesn't look like it, the groove walls are being compressed by stylus pressures as high as 30,000 pounds per square inch.

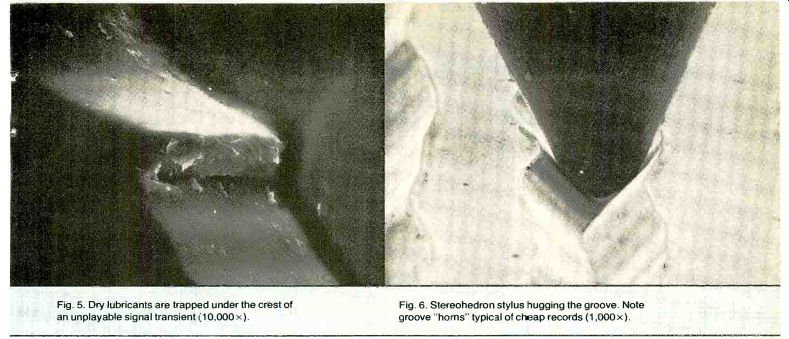

Further along, you suddenly come upon a vertical crevice in the groove wall (see Figure 5-the white deposits are dry lubricant material that became trapped in the wall crevice). When the original master disc for the record was cut, the audio signal at this point caused the cutting stylus to execute a turn so tight that it ripped a gouge in the lacquer material. This came about be cause the overzealous cutting engineer, in trying to record as loud a signal as possible, exceeded the capabilities of the medium. The defect was replicated throughout the subsequent record-producing process, and here it is (almost) perfectly preserved in the final pressing. What will happen when the stylus tries to play this part of the groove? The result will probably be distortion, since the groove detail is far more tortuous than could be traced by even the thinnest-edge stylus.

The sides of the diamond stylus tip should be smooth and rounded where they touch the groove walls, as illustrated in Figures 4 and 6. A stylus when it becomes worn, develops flat spots instead of rounded contours where it touches the groove walls. It may seem logical to expect that the "curved" modulation of the groove would gently round a stylus, but in stead the modulation acts pretty much like a straight file, polishing the sides flat (see Figure 2 again). Moreover, the edge of the flat gets sharper and sharper as wear increases, and at some point a badly worn stylus starts shaving vinyl off the groove walls. As can be seen under the scanning electron microscope, dust is attracted to the record, mixes with these vinyl shavings as well as de posits from oily fingers, liquid cleaners, and antistatic fluids, and ends up looking like slush in the thaw after a winter snow storm.

Disc Hygiene

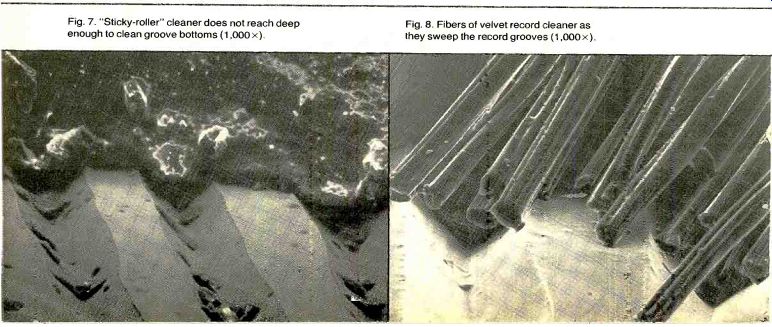

What can be done about cleaning up this slush, which obviously contributes nothing positive to the playback qualities of the disc? Choosing between the many record-care products on the market is difficult. A few of them are good, most of them do the job only partially, and a good many of them are useless or worse. Take, for instance, the mechanical devices designed to clean records by picking up dust on the tacky surface of a roller (Figure 7). Although they are fine for cleaning the flat elevations between the grooves and for picking up the larger pieces of dirt from the grooves themselves, no matter how much pressure you apply, they cannot fully penetrate the groove.

The only way we have found to make a record groove at least appear clinically clean is to "launder" it in an ultra sonic bath. Special record brushes have to be used to remove the most stubborn particles. Brushes using nylon fibers with tapered ends seem to work best for us. Figure 8 shows another type of bristle that can be effective.

The question of record-cleaning sub stances is a sticky one (sometimes liter ally). I tend to be cautious about applying anything to my discs until I have at least some evidence that no harm will result. A simple test I use is to thoroughly clean a small area of a mirror with a tissue, and then apply the sub stance. If, after drying, it leaves any residue on the glass-perhaps in the form of a milky film or a tacky coating--I tend to be wary of it until I'm convinced it is totally safe. Of course, even a cleaning solution that passes this test is not necessarily free of possible chemical interactions with the record material; it may remove plasticizers, lubricants, and other beneficial additives from it.

Having done my best to establish that the product does no harm, I then start experimenting with it (on expend able discs) to see if it does any good.

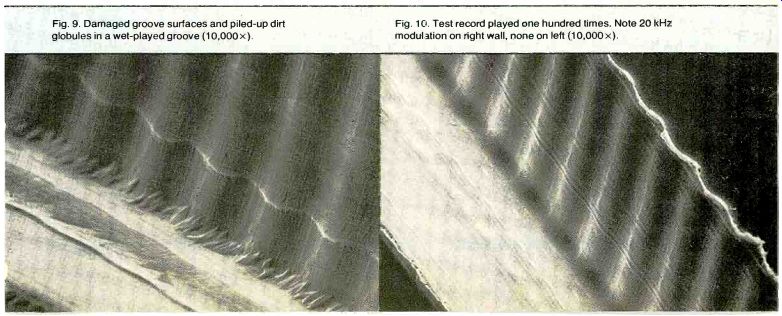

Quite often only some of the several claims made for a cleaner hold true, and I have to decide if I would be better off using ordinary water with a few drops of liquid detergent (still the best method I know of for cleaning old discs). I have used many dishwashing and household detergents, and all seem safe-as long as the records are rinsed completely. (The effect of this method on the record label, however, can be less benign.) However concerned I may be about getting a disc clean and noise-free, I am more concerned about avoiding physical damage to its grooves. I don't, for example, play a record wet, as is recommended with at least one European record-cleaning system. In studying some SEM photos of records played wet, I have noticed unusual forms of wear on the surface of the groove walls (Figure 9). I suspect that, when a record is played normally (dry, that is), a microscopically thin--perhaps a couple of molecules thick--layer of vinyl melts because of the tremendous pressure (as high as 15 tons per square inch) the stylus exerts on the groove walls and because of the speed with which the stylus moves through the groove.

------------- Fig. 3. Evaporating moisture pulls dust together to form

blobs at groove bottom (1,000 x). Fig. 4. Spherical stylus resting in record

groove in playing position (10,000x).

This is analogous to the case with ice skating, in which one really skates not on ice but on a thin film of water which turns back into ice as soon as the blade passes over it. In the case of the phono graph disc, if liquid is present in the groove the vinyl does not melt (it takes almost 5000 F to melt it) and the in creased friction causes scouring as the stylus is dragged through the groove.

Presence of liquid in a groove may give the false impression that just be cause it is quieting some surface noise it is actually cleaning the groove. This is partly true, because the liquid dis solves many soluble dirt particles and keeps them in suspension during the playing of the record-until the liquid evaporates and the dirt cakes up on the groove bottom again (see Figure 9 again).. On the other hand, I believe that the liquid over-damps the stylus, thus preventing it from following the groove undulations freely (try swishing the tip of a fishing rod rapidly through the water for some idea of how this might take place).

PLAYING records dry, however, presents us with another problem: the electrostatic attraction to the record surface of dust floating in the air. Quite a bit has been written about the harmful effects of electrostatic charges on disc playback. I consider the attraction of dust to the surface of a record the moss harmful effect, one that calls for the very best we can do with cleaning devices and de-staticizers. An electro static charge all by itself is not harmful, especially in the case of cartridges with truly grounded stylus assemblies that provide a direct path to earth ground through the system wiring. In cartridges with ungrounded styli, static charges accumulate on the tip of the cantilever and attract a good deal of dust which may interfere with tracking, especially at high frequencies. It is possible for this charge on the cantilever to arc over inside the cartridge to one of the grounded metal parts, thus creating a "snap" sound through the speakers.

Electrostatic charges have several sources. The first is friction of the record surface against molecules of air as the record rotates on an insulating mat.

Another source is the friction of the record surface against the jacket or inner sleeve as it is being pulled out.

---- Fig. 7. "Sticky-roller" cleaner does not reach

deep enough to clean groove bottoms (1,000x). Fig. 8. Fibers of velvet record

cleaner as they sweep the record grooves (1,000x).

----- Fig. 5. Dry lubricants are trapped under the crest

of an unplayable signal transient (10,000x). Fig. 6. Stereohedron stylus

hugging the groove. Note groove "horns" typical

of cheap records (1,000x).

Record Wear

Of continuing concern to audiophiles is the oft-heard admonition never to play a record-or a part of one-two or more times in succession. The theory is that the vinyl (which is inevitably de formed to some degree by the stylus pressure) requires a "rest period" to recover from the trauma of play. It is supposed that without such a rest period, permanent injury is added to the temporary insult. To check this, I took a walk downstairs to our quality-control station, where new cartridges coming off the production line get their final checkout on a test disc. Cartridges are tested at a rate exceeding one hundred per hour, and a lot of records are used up in the process. I took a test record that had just been discarded after being played one hundred times in succession and compared it to a brand-new copy.

Except for a slight rolloff at high frequencies and a barely noticeable degradation of channel separation, the record was still okay. Under the SEM (Figure 10), the groove-wear patterns appeared absolutely identical to those found on records receiving normal use.

Not long ago we were life-testing an automatic-turntable shutoff mechanism. The tone arm was set to play the last band of the record, lift, then return to the beginning of the last band and play it again, and again, etc. The turntable went through 30,000 cycles of this to prove the reliability of the tone-arm lift mechanism--and then we suddenly realized that we had just played part of a record 80,000 times in succession! We rushed to listen to it and, to our amazement, it actually sounded better than some of our less-played records.

Looking at the groove under the SEM, we could see that the stylus had produced a "footprint" on the groove walls that conformed to the shape of the stylus tip, and it seemed that once a certain amount of wear had occurred, no further damage to the groove took place. I estimate that the entire test was also equivalent to approximately 1,000 hours of playing time for the stylus, but there was hardly any wear visible on it although the tracking force was 1.5 grams. Note that there were no special precautions taken in running this test and no use of cleaning agents or groove lubricants. My conclusions from all this are that, with today's phono cartridges, record wear and sound quality are the same whether you play the disc repeatedly at one time or wait days between playings. Apparently, if you exercise reasonable care in regard to storage and hygiene, and if you are using a well-designed stylus assembly whose diamond tip is in good shape, your discs are not likely to be damaged by the playing process. Phonograph records, contrary to our fears, are unusually tough and durable; in general, they are the most "forgiving" sound-storage medium we know of.

---- Fig. 9. Damaged groove surfaces and piled-up dirt globules

in a wet-played groove (10,000x). Fig. 10. Test record played one hundred

times. Note 20 kHz modulation on right wall, none on left (10,000 x).

Also see:

The Shorter Guide to Cartridge Shopping (July 1981)

Source: Stereo Review (USA magazine)