A television’s high-voltage circuits provide the very high voltage needed by the CRT. They also provide additional B÷ supplies not normally produced by low-voltage sources. These circuits are much more stable than the power supplies used in earlier televisions because they are more efficient and produce less heat. Also, there are fewer components external to the horizontal output transformer (flyback); therefore, there are fewer places where problems can arise. The high voltage stages are shown in FIG. 1.

There are several types of high-voltage power supplies. This Section discusses typical high-voltage circuits and provides troubleshooting techniques for these circuits.

==

Note: Make sure you follow the safety guidelines in Section 2, Working Safely, when working on high-voltage circuits. In particular, read the sections Avoiding Electrical Shocks When Servicing High- Voltage Circuits and CRTs and Avoiding X-Ray Radiation and High-Voltage Limits. Also, when you troubleshoot high-voltage circuits, make sure you use a high-voltage probe and use an isolation transformer. Do not use a VOM or DMM without high voltage capabilities.

==

FIG. 1. The high-voltage stages (shaded).

When you test the voltages on the high-voltage circuits, compare the values you get with the values on the schematic.

Flyback Transformers

The flyback transformer is an integrated transformer with several low-voltage windings and most often contain molded high-voltage diodes.

The regulated B+ voltage supplied to the horizontal output circuit helps to regulate the output. If the B+ increases or decreases, the output from the high-voltage circuit would increase or decrease, respectively. Additional methods of stabilizing the high voltage are used, including using the flyback to regulate itself, and operating with a certain amount of core saturation to prevent high-voltage buildup.

If the flyback is working, you will find high voltage at the CRT’s anode connection. However, before you take the measurement, make sure the high- voltage probe’s ground lead is grounded to the chassis CRT dag ground.

To measure the high voltage range, set the brightness and contrast controls to maximum and measure the voltage at the second anode button. Then, set the brightness and contrast controls to minimum and measure the voltage again. This is the range in which the television normally operates.

Troubleshooting a Flyback Transformer

The symptoms of a defective flyback transformer can vary. When you test the flyback transformer, follow these steps:

1. Ground the chassis before troubleshooting the flyback transformer.

2. Unplug the television from the wall outlet.

3. Smell the transformer. A flyback transformer with burned connections or components smells like burned paraffin.

4. If preliminary circuit checks do not show the defect, remove the trans former from the circuit.

5. Use an ohmmeter to check each pin. Refer to the schematic for the expected values.

If any winding has a reading that indicates it is open, replace the trans former.

Shorted Flyback Transformer

When a flyback transformer shorts, the transformer may arc and be very warm. This is because the insulation between the windings can break down, causing high-voltage arcing. Another symptom of a shorted flyback to watch for is excessive brightness on the screen with heavy noise lines due to internal arcing.

Use a variable line transformer to reduce the AC input to 75V. Then, slowly increase the voltage until you detect the arcing. You may be able to see the arcing in a low light setting. Poor solder joints where the flyback is soldered to the board often cause arcing. If a resistance check or the flyback windings indicate any winding of the flyback is open, replace the flyback.

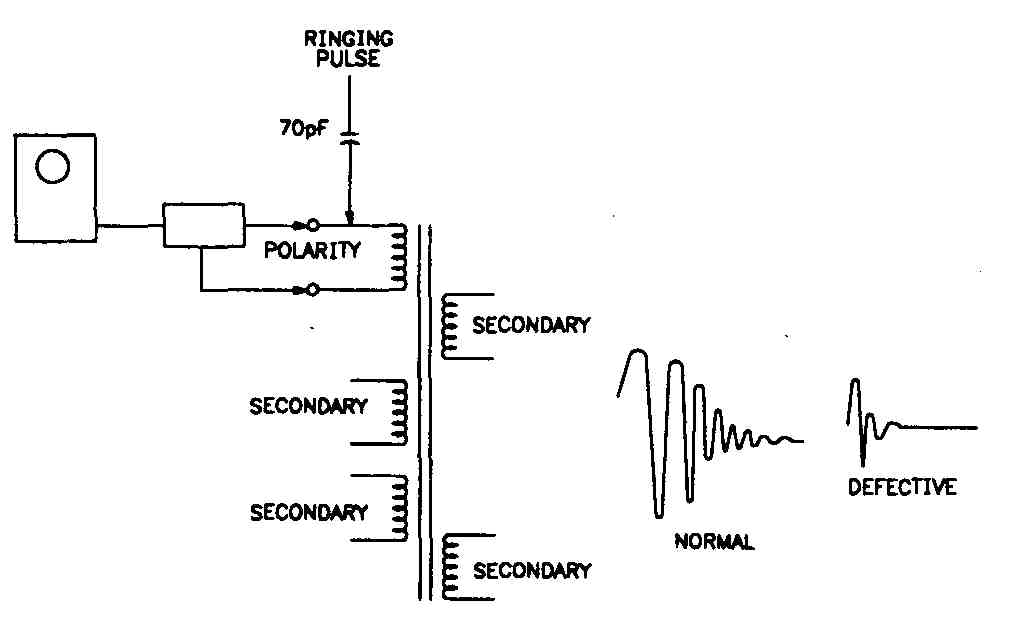

If the flyback is not open, remove the flyback from the chassis and try ringing it using a signal generator. When you ring the flyback, you inject a sawtooth waveform, or ringing pulse, across the primary windings of the flyback and use an oscilloscope to measure the secondary for a waveform, shown in FIG. 2.

Also, you can unsolder the connections and measure the resistance of the transformer’s windings. Compare the measured values to those in the appropriate DATASHEET.

You can check the focus control by using a high-voltage probe and changing the focus setting. If the focus control is broken, you may have erratic focus voltage and see lines in the picture.

Noisy Transformer

A ticking sound or a high-pitched squeal coming from the television can indicate a problem with the flyback. There might be a loose mounting bolt or the core of the transformer may be vibrating. Locate the faulty transformer and replace it. If the transformer appears to be shut down, reduce the AC input if the high voltage returns, and measure the input and output with a high-voltage probe.

You can hold a rolled-up paper tube up to the transformer to help isolate the sound from the other sounds the chassis is making by using the tube as a stethoscope.

If the transformer is vibrating, it may produce a high-pitched, irritating squeal. Unplug the chassis and inspect the transformer for loose bolts or for a cracked ferrite core. Clean off the old solder from the transformer and from the board. Carefully tighten the bolts, then reposition the transformer and resolder the connections.

Excessive Voltage Level

Excessive voltage from a defective flyback transformer can damage the CRT or chassis circuits. It also can cause the chassis to shut down. A high-voltage shutdown circuit typically monitors a pulse from the flyback. If it exceeds a predetermined level, the horizontal oscillator will stop operating.

An insufficient high-voltage level can cause a focus problem. This condition could be caused by a leaky flyback transformer. However, poor focus also can be caused by faulty CRT connections, or a faulty focus control or low- drive signal. Measure the voltage at the CRT’s anode terminal. Then, refer to the television schematic for the correct voltage range. If the voltage is normal, look for the problem in the CRT. If the voltage is low, use signal tracing and test the voltage path back through the high-voltage circuit.

Replacing a Flyback Transformer

If after testing the flyback thoroughly you find that it is deflective, replace it with an exact replacement:

1. Unplug the television from the wall outlet.

2. Discharge the CRT before working on the flyback transformer.

3. If applicable, write down which color lead connects to each terminal and component connected to the transformer.

4. Using a low-wattage soldering iron, slowly heat each connection until the connections are broken and you can lift the transformer. If necessary, clip any leads that are frayed. Note any special routing of the leads.

5. Gently press the new transformer into place.

6. Using your notes, solder the leads and components to the transformer terminals.

7. Visually check all connections for loose solder or sharp solder points that may cause arcing.

8. Using a DMM, check each winding on the transformer. Refer to the schematic for the correct measurements.

Boost Voltage

Boost voltage (200V) is considered to be “high.” The boost voltage typically originates in the flyback circuit.

If the boost voltage is not working properly, you might see vertical deflection problems and picture dimming, or other symptoms associated with low-voltage conditions. Look at the schematic and locate the boost. The problem can be a leaky diode, capacitors, or a faulty flyback winding.

X-Ray Protection

X-ray radiation is caused by excessively high voltage. Federal regulations require that television manufacturers protect consumers from X-ray radiation. One of the protection circuits causes the horizontal oscillator circuits to shut down if excessively high voltage is detected. Others may cause the vertical, on/off or power supply circuits to shut down.

A common example of a high-voltage shutdown circuit is shown in FIG. 3. If the circuit detects excessive voltage in the high-voltage circuit, the television shuts down. A sample pulse from the flyback is rectified and fed to one end of a zener diode. If the high voltage increases, so does the sample pulse. If the voltage rises to a predetermined level, the zener typically stops the horizontal circuit from oscillating, shuts down the set, or triggers the horizontal oscillator to reduce the high voltage.

Some televisions have an extremely stable high-voltage circuit or a high voltage hold-down circuit. In these televisions, shutdown due to excessively high voltage is infrequent.

FIG. 3. A high-voltage shutdown circuit.

If you need to troubleshoot a high-voltage shutdown circuit, use a variable line transformer to reduce the AC input to 75V. Slowly increase the voltage. Mea sure the sample pulse and output to the high-voltage shutdown circuit. Then, check the components and connections around the circuit. Sometimes it may be necessary to disable the shutdown circuit to locate the problem.

Focus Circuits

High-voltage bleeder resistors can be used to help stabilize high voltage in televisions. The bleeder resistor is most often connected in the low side of the horizontal output transformer high-voltage winding, as shown in FIG. 4, to regulate the first 100 mA, a range that the flyback circuit does not regulate. This helps the flyback operate more efficiently.

The bleeder resistor also keeps the focus voltage in a constant relationship with the CRT’s second anode voltage. The focus voltage is approximately 20% of the anode voltage. If the focus voltage is incorrect, the picture will not be correctly focused. If the focus voltage is not present, the raster does not appear, even though you might see a flash when you turn off the television. If the bleeder resistor is an integral part of the flyback transformer, you have to re place the whole flyback transformer. ( FIG. 5.)

Bleeder resistors also bleed off the high voltage charge on the CRT when the TV is turned off. This prevents damage to the CRT screen by a small bright dot in the center of the screen, which tends to damage the phosphor on the screen.

FIG. 5. A schematic clip showing the current focus bleeder in the flyback.

Automatic Brightness Limiter (ABL) Circuit

Another method of monitoring the high-voltage and keeping the picture in focus while protecting the CR1 is the automatic brightness limiter (ABL) circuit, shown in FIG. 6. As its name implies, this circuit limits the current from the flyback to the electron guns in the CRT, thus limiting the picture’s brightness and preventing blooming on the screen. The ABL circuit is in the video processing stage and samples the voltage to the CRT’s second anode. The circuit uses the sample to determine whether to limit the drive signal to the CRT’s electron guns.

Troubleshooting High-Voltage Circuits

Open or shorted components, which results in no raster, are the most common source of problems in the high-voltage circuits. However, with shorted components, you may see the burned components or connections. Also, in the case of a shorted CRT, the high-voltage circuits may not work correctly, or you may see high-voltage arcing in the CRT neck. If components are leaky, causing lower voltage values, the picture may appear dim, out of focus and narrow horizontally.

As you can see, the symptoms of high-voltage problems are similar to problems caused by circuits and components in other stages in the chassis. The main difference is that you must take extra precautions due to the very high voltage potential in order to prevent getting shocked. Therefore, use the following troubleshooting steps to help you determine whether the symptoms you see are caused by a high-voltage circuit or by circuits in another stage.

FIG. 6. A brightness limiter

In the following steps, use a high-voltage probe or a DMM:

1. Check the output of the horizontal output circuit. If a transistor is leaky, the voltage will be low. If this is the case, the picture will be narrow horizontally and the circuit may show signs of overheating and smell “hot.” If a transistor is open, there will be no high voltage. If a transistor is shorted, the fuse will blow or the television will shut down.

2. Check the input to the base of the horizontal output circuit. If there is no input, check the horizontal circuits.

Quiz

1. Why should extra precautions be taken when working around the flyback?

2. What circuit reduces the current of the CRT?

3. What circuit monitors the high voltage level and shuts down the set if the level gets too high?

4. From where does the boost voltage originate?

5. What does the bleeder resistor do when the receiver is turned off?

Key

1. Because of the very high voltage potential.

2. The ABL circuit.

3. The X-ray protection or shutdown circuits.

4. The flyback.

5. It bleeds off the high-voltage charge on the CRT to prevent the CRT from burning a spot in the center of the screen.