This Section covers the testing and maintenance of all commonly employed studio units from the microphone to the line output terminals. Preventive maintenance and overall studio checks are then outlined.

13-1. MICROPHONES

The microphone is perhaps one of the most delicate pieces of equipment associated with broadcasting systems. Yet it is apparent to the experienced operator that with careful handling the microphone can outlast many sets of tubes and component electrical parts in the amplifier.

When it is necessary to transport microphones from one place to an other, it is best to use a special box containing no other equipment. The box should contain sufficient padding not only to take up shocks of exterior bumps, but to prevent free movement of the microphone in the box.

Sponge-rubber seat pads are excellent for lining the box, and heavy felt material is good to wrap around the instrument to prevent movement by filling the empty space.

Microphones having permanent magnets as component parts (moving-coil or ribbon types, etc.) should not be placed on a work bench or any place where there is a possibility that iron chips or filings might be attracted to the magnet.

The reader will find it helpful to review Section 6-9 ( Audio System technology) and Fig. 6-50 with associated text for proper microphone grounding techniques. Also review Section 7-2 for stereo microphone input wiring and phasing, and Fig. 7-6 for examples of specific microphone wiring.

First Steps in Testing There are a number of troubles in modern high-quality microphones which should be treated only at the factory of the manufacturer. It is the purpose of this section to acquaint the reader with test procedures that will determine what to do and what not to do regarding repairs. It is, however, obvious that the average technician is unable to check field-response pat terns or run frequency-response curves which require laboratory apparatus and soundproof rooms.

First, of course, it is necessary to have a good audio amplifier of known characteristics and the proper input circuit and impedance to match the microphone under test. There are three general classifications of troubles:

no response at all, high noise level with or without some signal, and no noise level but a weak and perhaps distorted signal.

As in all of the troubles of microphones, it is necessary to picture the relation of the input circuit to the schematic of the microphone. For ex ample, consider a typical high-impedance input circuit with an open-circuit jack. The high-impedance microphone uses a two-conductor cable, the braided shield about the "hot" lead serving as the ground, or jack-sleeve, connection.

If the response from the microphone is zero when it is connected to an amplifier known to be good, several possibilities exist. Either the "hot" lead is open (if the grounded side were open noise would result) , a short exists, or the internal element of the microphone is defective. The first places to check for a defect are in the plug or the point where the cable leaves the microphone housing.

In the case of the open-circuit jack, some noise usually exists before a microphone is plugged into the input. If this noise is lost on the insertion of the plug but no response is obtained, a short is indicated. If the noise level remains the same or is slightly raised in intensity, an open is likely.

If a closed-circuit jack is used, a short will not result in lower noise level, but an open will probably raise the input noise, although very slightly in some cases.

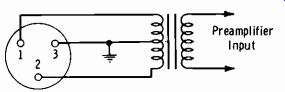

Fig. 13-1 shows a typical low-impedance microphone circuit with three-

conductor cable. In this case, an open in either the number 1 or number 2 wire will cause either a dead microphone or one with extremely "thin" frequency response. Obviously, a short in the pair would also cause no response. A break in the shielding (number 3) will usually result in a higher noise level than normal, or possible hum pickup.

Fig. 13-1. Typical low-impedance microphone input.

Preamplifier Input

Sometimes the trouble is only intermittent and must be traced by jiggling the cable, starting at the plug and working back a foot or so at a time to the microphone housing. This is done by rapidly looping and straightening a small section of cable between the hands. The following is a good general procedure to check for microphone and cable troubles.

1. Check the plug and receptacle. All types are encountered in micro phone input circuits. Some simple two-conductor microphones use the familiar jack and jack plug; some use a metal shell which is insulated from the outer conductor and which has a single pin in the center. For the latter kind, the receptacle is a matching female type with a spring connector to grip the center pin tightly and a knurled metal ring connector for the outer conductor. The three-conductor circuits vary considerably in design, but all are general as far as inspection is concerned. Some have on the receptacle shell a small lever which must be depressed in order to pull the plug from the receptacle.

Other types have on the shell of the plug a small knurled knob which must be depressed. In connecting the plug to the receptacle, it is properly oriented in the receptacle, and when pressure is applied, a pin springs up through a hole in the receptacle and locks the two parts together.

Plug connections that are made inside the shell require removal of the shell for inspection. In some cases the shell and plug body are both threaded and may simply be unscrewed. Others are held together by clamps and screws. Some cable conductors are soldered to the pins; some are held by screws on pin lugs.

Check the connections to the pins for looseness, corrosion, dirt, faulty insulation, broken wires, or bent pins. Check the plug for dam age, dirt, or corrosion. Check the shell for dents, cracks, dirt, or corrosion. While the assembly is taken apart, clean everything with a cloth and cleaning fluid. Corrosion may be removed with a small strip of crocus cloth.

Check connectors of the spring type for proper contact and tension.

In cases where the plug is difficult to connect or remove, coat the pins thinly with petroleum jelly or some other suitable lubricant.

2. Check the microphone cable in sections of about 10 inches to a foot.

Loop and un-loop this amount of cable between the hands while slowly twisting it. Listen to the output of the amplifier and continue to do each small section this way for at least a quarter of a minute.

Broken insulation or wires will definitely show up in this test.

If a break is found, it is far better to replace the entire cable than to remove and splice the faulty section of cable. Of course, splicing may be done in emergencies when new cable cannot be obtained.

Some microphones have a switch for turning them off and on to allow greater flexibility in their applications. If this switch is a sealed type with non-accessible contacts, it can simply be checked for proper working order and, if suspected to be faulty, replaced. If the contacts are accessible, inspect the terminal connections for tightness and cleanliness, and check the mounting for firmness.

While operating the switch, observe all moving parts for freedom of movement, and look closely at the stationary spring contacts to ascertain their tension and if there is good or doubtful electrical contact. Contacts that have lost tension may be tightened with the fingers or pliers. Tighten all terminals. Any section of the switch that is dusty, corroded, or pitted should be cleaned with a dry cloth. For more serious conditions, the cloth can be moistened with cleaning fluid and the affected parts rubbed vigorously.

When the points of contact with the moving blade show signs of excessive wear, replace the entire switch. Crocus cloth dipped in cleaning fluid may be used to clean them. For severe corrosion, No. 0000 or No. 000 sandpaper should be used and the contacts polished clean.

If dryness and binding are noticed, apply a drop of instrument oil with a toothpick at the point of friction. Do not allow the oil to flow into the electrical contacts.

These steps are the preliminaries to checking a faulty microphone. A great majority of the common faults are found in the receptacles, plugs, or cables. If these items are not at fault, it is necessary to proceed according to the type of microphone used.

Ribbon and Combination Microphones

When cables and plugs have been definitely eliminated as sources of trouble, the transformer and terminal-block connections should be checked.

Do not check transformer continuity with a battery-powered continuity checker without first removing the ribbon connections. Better yet, place a resistance of 47,000 ohms minimum in series with the checker test leads.

Otherwise, permanent damage to the ribbon may result. Transformers may be replaced, but if the ribbon or ribbon assembly is damaged, the micro phone must be returned to the manufacturer for factory repair. The only replacements normally made in the field are replacements of the cover, transformer, mounting parts, cables, and plugs.

Also remember that the microphone lines must not be checked with an ohmmeter without first disconnecting the ribbon microphone. The line then may be checked (unterminated) for high-resistance shorts or (terminated) for opens or high-resistance connections.

Hum and noise may occur in any part of the audio circuit. In the micro phone circuit, it can result from ground loops or imbalance caused by faulty or improper cable connections to the bus or preamplifier board.

Magnetic fields from power transformers or electrical machinery may in duce hum into the microphone transformer or ribbon. This may sometimes be minimized by turning, tilting, or relocating the microphone relative to the magnetic field.

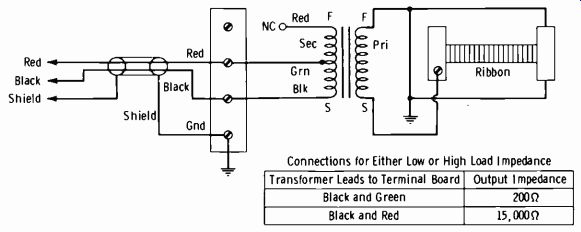

Another source of hum and noise is ground current between the microphone cable and the preamplifier. Fig. 6-50 (Section 6) shows the recommended practice for wiring. Fig. 13-2 shows the color coding and terminal-block connections for proper impedance matching of a typical microphone.

Microphone Phasing

It is well known that correct phasing may be important to the operation of any system employing more than one microphone simultaneously. This is especially true when two similar microphones are placed in a symmetrical relationship to a performer. In a lesser measure, correct phasing may be important for optimum operation of certain amplitude-modulated transmitters because of predominantly unsymmetrical aspects of speech wave forms.

Polarity of a microphone or a microphone transducer element refers to in-phase or out-of-phase conditions of voltage developed at its terminals with respect to the pressures of the sound wave causing the voltage. An exact in-phase relationship can be taken to mean that the phase of the voltage is coincident with the phase of the sound-pressure wave causing the voltage. In practical microphones, this perfect relationship may not always be attainable.

The in-phase terminal of a microphone is that terminal of the connector or conductor that is connected to the in-phase terminal of the transducer.

On microphones using a connector as specified in EIA Standard TR-118, the in-phase terminal is No. 1, the out-of-phase terminal is No. 2, and the ground terminal is G. On a microphone with a cable but no connector, the out-of-phase terminal is black.

The polarity of a pressure (or omnidirectional) microphone does not vary with the direction of arrival of the sound wave. The polarity of a gradient microphone is reversed for sound waves directed toward the rear of the microphone. There may be a substantial phase shift in the micro phone at the low- and high-frequency ends of the spectrum. Therefore, the definition of polarity is generally restricted to the midpoint of the useful transmission band.

Fig. 13-2. Schematic diagram of a typical microphone.

When the outputs of two or more microphones are connected to a mixing circuit, it is necessary that the outputs of all the microphones have the same phase relation. Otherwise, the output of one microphone will oppose the output of another, resulting in a reduction in output and the introduction of varying degrees of distortion.

To check the phasing of two or more microphones, connect one micro phone to the associated amplifier input, and set the volume control to obtain the desired output when talking into the microphone. Then connect the second microphone in parallel with the first, and, without changing the volume-control setting, hold both microphones close together and speak into them. If the volume decreases from the previous level, reverse the connections of one of the microphone cables at the microphone plug. Similarly check each additional microphone for phasing. If it is necessary, reverse the cable connections to correct the phasing to match that of the microphone already connected.

In practice, polarity turnover may occur between microphone channels due to installation of different types of amplifiers. Turnover also may be due to the installation of the same type of amplifier-pad combinations when no attention was given to color-coded wiring with identical connections.

This is best checked by employing a signal generator and oscilloscope. See Section 13-8.

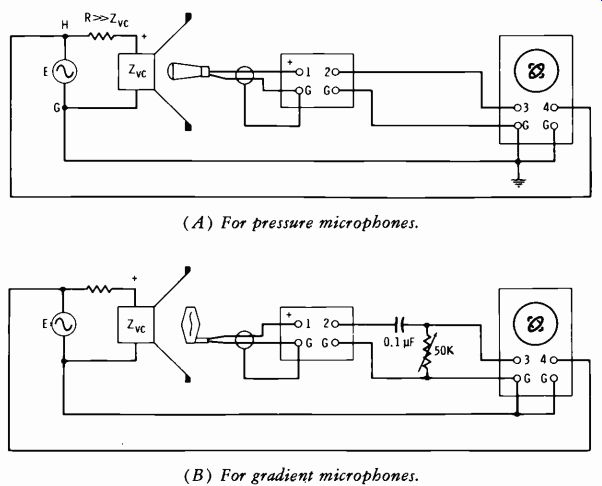

For those interested in the exact standardization of microphone polarity, set up the circuit of Fig. 13-3A. The EIA suggests the following procedure:

(A) For pressure microphones. (B) For gradient microphones.

Fig. 13-3. Method for checking microphone phasing.

1. Check the proper phasing of the oscilloscope and amplifier. To do this, connect one terminal of the oscillator to ground; connect the other (H) terminal to terminal 1 of the amplifier and terminal 4 of the oscilloscope. The trace on the oscilloscope should be a line slanting from lower left to upper right.

2. Determine the in-phase terminal of the speaker. This is done by connecting a battery across the voice coil so that the cone moves toward the microphone; the terminal connected to the positive terminal of the battery is the in-phase terminal of the speaker. Connect the resistor (R) between the H terminal of the oscillator and the in-phase terminal of the speaker. The value of R should be at least 5 times the impedance of the voice coil.

3. Adjust the oscillator output for a suitable acoustic output from the speaker. Connect the microphone to the amplifier, and position the diaphragm of the microphone as close as possible to the surface of the vibrating cone. Check the orientation of the oscilloscope trace. If the trace is a slanted line or ellipse with its major axis oriented from lower left to upper right, then the in-phase terminal of the micro phone is the terminal connected to the "high" terminal of the amplifier (terminal 1) . The relationship should be constant throughout a range of frequencies (100 to 400 Hz).

When the outlined procedure is applied to a gradient (velocity) micro phone, the trace is in the form of a circle. This is because of the out-of-

phase relationship between pressure and velocity in a spreading wave. To remedy this, a phase-shift network consisting of, say, a 50,000-ohm resistor and a 0.1-µF capacitor may be connected as shown in Fig. 13-3B. Except for this one detail, the measurement can be performed exactly the same way as described before.

13-2. TURNTABLES

Preventive maintenance on turntables consists largely of cleaning, lubrication, and occasional adjustments in the speed-changing mechanisms to prevent chattering or binding. The mechanical details of the drive mechanism, along with detailed servicing procedures, are normally contained in the instruction manual for the particular turntable used. Always include the lubrication schedule or chart in the regular preventive-maintenance schedule.

The turntable alone (not considering the pickup and arm assembly with associated preamplifier) has three basic characteristics which concern the maintenance department: wow and flutter, rumble, and tolerance of operating speed.

The specifications of a typical broadcast-type turntable might be given as follows:

Wow and flutter: 33 1/3 rpm, 0.25 percent half of peak-to-peak 45 rpm, 0.20 percent half of peak-to-peak 78 rpm, 0.20 percent half of peak-to-peak Rumble: (All speeds) 35 dB below reference of 100 Hz test record with a 1.4 cm/s stylus velocity Speed: 33 1/3 rpm-x-0.2 percent 45 rpm ±0.2 percent 78.26 rpm ±0.2 percent

Wow is a low-frequency modulation effect caused by variations in groove velocity. It may occur in recording, playback, or both. The NAB standards recommend that the maximum instantaneous deviation of the mean speed should not exceed 0.1 percent for recording turntables or ±0.2 percent for playback turntables.

Flutter is similar to wow but is at a higher frequency (up to 200 Hz) .

This also may occur in both recording and playback. The ear is very sensitive to this type of distortion.

Rumble is a low-frequency, steady-state tone or series of random pulses generated at the pickup stylus. It is caused by vibrations of the turntable.

The variation in the groove of a lateral recording is termed modulation.

The movement to one side of the mean path at a given time is termed the amplitude of modulation. When the recording is that of a sine wave, the maximum transverse velocity of the stylus tip occurs when the tip passes through the mean path, with zero velocity at the extremities of travel. The maximum transverse velocity can be determined by the formula:

VT = 2 pi fA where, VT is the maximum transverse velocity in centimeters per second, f is the frequency in hertz, A is the peak amplitude in centimeters.

The rms transverse velocity is then:

rms transverse velocity = 1.41 arfA

The recorded level of a sine-wave test record is specified in terms of the rms velocity at 1 kHz, or in decibels with a reference level of 1 cm/s rms stylus velocity. Thus if a given test record specifies that a 1000-Hz reference level is 10 dB above 1 cm/s rms velocity, the resultant rms velocity is 3.16 cm/s. (Use the voltage-dB table for conversion.) Plus 16 dB becomes 6.31 cm/s, etc.

Whenever the manufacturer specifies rumble, he normally gives the conditions of measurement. For example, RCA specifies the rumble of the BQ-2B turntable as 35 dB below the reference of a 100-Hz test record with 1.4-cm/s stylus velocity, using an NBC Type ND-301 scratch and rumble meter (modified per NAB standards), with building rumble at-50 dB.

Turntable rumble can be checked with the station noise and distortion meter on an arbitrary basis as follows:

1. With the stylus in the 100-Hz test-record groove, set the reference level to the output of the turntable preamplifier. Use a low-pass filter which has a sharp cutoff above 300 Hz between the preamplifier output and the noise meter.

2. Place the stylus in the 1000-Hz (or higher) groove, and take the noise measurement on the noise meter. Use a groove as near the outer edge as possible, since rumble is most predominant with the stylus near the outer rim of the turntable.

NOTE: If the characteristics of the preamplifier are unknown, run a noise check on the preamplifier only, keeping the low-pass filter in place. This should be at least 58 to 60 dB below normal output. This measurement is made in the conventional manner as follows:

A. Feed sufficient 100-Hz tone input from the external test oscillator to obtain the rated output level of the preamplifier.

B. Remove the tone. Place the proper terminating resistor on the input and read the noise level.

When a turntable begins to develop rumble, the most common cause is lack of proper cleaning and lubrication of the drive mechanism. Adhere scrupulously to the manufacturer's instructions for cleaning and lubricating.

As a general rule, it is not advisable to remove dust or dirt from the drive mechanism (or turntable platter) by air pressure. Use slightly oily, lint-

free cloth to wipe the bushings and thrust balls before lubricating. The hub and spindle should also be treated in this manner.

Such items as rubber idlers and motor pulleys should be wiped with the same type of cloth dampened with naphtha or cleaning fluid. Wipe the in side surfaces of the platter rim (when rim driven) the same way. Be sure there is no oil on the motor pulley or rubber idlers. Do not use excessive amounts of cleaning fluid on rubber idlers since it may attack the rubber.

Check any shock mounts on the turntable motor or other parts. These may need to be replaced. Check all tensions specified in the instruction manual. Always keep the proper scales on hand for these measurements.

Wow and flutter are caused by small imperfections in the motor and/or the drive mechanism. They will be evident as a cyclic variation in the pitch when a steady tone such as the 1000-Hz band of a test record is reproduced.

The term "wow" is applied to the very slow cyclic variation, the term "flutter" to the more rapid variation, up to around 200 Hz.

The actual measurement of wow and flutter requires special equipment.

Such measurements are not normally made by station personnel. When the defect is noticeable, use the same maintenance procedures that are outlined above for rumble. An eccentric disc or turntable will also tend to cause wow. When all maintenance procedures have been tried and the condition persists, it is very likely that the motor needs to be replaced.

The turntable speed is checked by means of a stroboscope disc illuminated by a lamp supplied from the ac line. A neon bulb is best for this application. The stroboscope disc is simply placed on the turntable platter and the neon bulb held directly above it. There are 92 bars for 78 rpm and 216 bars for 331/4 rpm. Not more than 21 dots per minute should drift past the visual reference point in either direction. If the dots drift in the direction of rotation, the speed is high. If the drift is opposite to the rotation, the speed is low. Most turntables employ a means of vernier control of the platter speed.

13-3. THE STYLUS, PICKUP HEAD, AND PREAMPLIFIER

Basic theory was covered in Section 4. Also review Figs. 6-30 and 6-31 with associated text for a visualization of constant-amplitude and constant-velocity recording methods.

The Pickup Unit

Pickup arms for broadcast use have an adjustable feature allowing control over the stylus pressure against the record groove. It is important that this amount of pressure be correctly adjusted for optimum system performance and minimum record and stylus wear. Several good makes of special-type scales for this purpose are on the market and should be a part of the equipment of every maintenance department. The pressure must be measured with the stylus in playing position. Thus when the scales are used, they must be placed off the turntable and adjusted so that the stylus is at playing height when the pressure is measured.

When the trouble has been traced to the pickup unit, the first step is to check the stylus. Excessive record noise and signal distortion are often caused by a defective stylus tip. Check the tip under a strong light and magnifying glass; chips or excessive wear may be readily detected in this manner. Of course, the easiest and best check is to replace the stylus with a new one if it is immediately available. In cases of permanent-type stylus assemblies (usually using diamond tips), the head must be removed and returned to the factory for stylus replacement if the tip has been damaged by dropping or other accidents.

Be certain that the stylus is properly secured in the holder. In the case of a bent-shank stylus, the bend must be properly aligned with the record grooves, not turned even slightly in either direction from the center of the groove.

Check all of the spaces around the stylus entrance for dust or lint that often clogs the free spaces around the stylus holder or the pole pieces in magnetic pickups. These spaces must be cleaned thoroughly. A low-pres sure air stream aids considerably in this process.

Pickup heads must be examined closely for breaks in connections, wire, or shielding. Plugs and receptacles must be examined as previously suggested for microphone maintenance. When terminal boards or connecting panels are used, they should be carefully inspected for cracks, breaks, dirt, and loose connections or mountings. Each connection should be examined.

Tighten all clean terminals, screws, lugs, and mounting bolts, being careful not to overtighten since this can cause cracks or breakage. Any connection that is dirty, rusty, or corroded should be disconnected. Clean each part individually and thoroughly with a clean cloth or crocus cloth moistened with cleaning fluid. Then replace and tighten the connection.

In the magnetic-type pickup, extreme care must be exercised in removing the cover to prevent damage to the delicate stylus and/or armature assembly. Check the centering of the armature between the pole pieces.

Always check the air gaps for collections of dust and lint. In many in stances, transformers are located inside the pickup arm. All leads and connections must be carefully checked for continuity and tightness. In some of the older-type magnetic pickups, the bushings and supports that center the armature become worn and deteriorated. Replacements for these parts must be ordered by model and part number from the manufacturer. It is always advisable and often cheaper in the long run to return the pickup head to the factory for repair. This is imperative in the case of the very high-quality magnetic pickups used in broadcasting and similar applications where a permanent-type precious-metal stylus tip is employed.

Checking Frequency Response

The broadcast engineer finds it interesting and helpful to know the actual frequency response of a given pickup unit. This information is necessary if complete individual equalization circuits are to be checked not only to meet the requirements of compensating a certain recording characteristic but also to compensate for the deficiencies of the pickup unit.

Equalization, for example, would be unnecessary ( indeed harmful) if the pickup unit has an inherent high-frequency rolloff.

Bear in mind that the overall combination of the stylus, pickup head, arm, and preamplifier with equalizer must provide the complementary re production characteristic given in Table 6-6 (Section 6). If the equalizer is external to the preamplifier, the preamplifier response curve is normally flat. However, most modern phono preamplifiers incorporate the equalizer as part of the preamplifier itself, and this must be considered by the maintenance technician running response tests.

Obviously, in order to check the frequency response of a reproducer unit, a frequency run must first be made on the amplifier. This is done in the orthodox manner using a variable-frequency audio oscillator (30 to 15,000 Hz) and a volume indicator on both the output of the oscillator and the output of the amplifier under test. Of course, a single volume indicator could be used with a suitable switching arrangement. The single tone is fed into the amplifier at the same level for each frequency, and the volume-indicator output-meter reading is noted. The reference frequency is usually 1000 Hz; that is, the gain is adjusted on the amplifier so that output meter reads 0 dB at 1000 Hz. Deviations at the other frequencies in the range to be tested are then observed and plotted as a graph.

For checking pickup units, major recording firms put out frequency test records that usually start with a 1000-Hz reference tone to set the level.

They then go to 10,000 Hz and work down to 20 or 30 Hz, with a voice identification immediately before each tone. The output volume indicator on the amplifier is read for each frequency, the output level having been adjusted to zero at 1000 Hz as in the oscillator test. The curve thus obtained may then be plotted against the amplifier curve to obtain the pickup response curve.

If the amplifier response curve were perfectly flat, the pickup-curve run would be the actual response of the unit. Assume, however, that the amplifier curve is +4 dB at 2000 Hz and the pickup curve is +1 dB. The pickup response, therefore, is actually-3 dB at this frequency, since the 4-dB gain of the amplifier at this point on the curve must be subtracted from the pickup curve.

Test records made to EIA standards have two sides. Side A is intended for frequency-response measurements at normal levels, and side B tests the tracking ability of the pickup at different levels. Intermodulation test records are also available for checking distortion in terms of intermodulation-which is more meaningful than simple harmonic-distortion tests.

The entire subject of intermodulation tests and measurements for studio equipment (including playback pickup heads and preamplifiers) is covered in Section 13-13.

Stereo Pickups

The dual-channel stereo system must be maintained tightly in the following characteristics: closely matched frequency response, closely matched phase-frequency response, and maximum separation (minimum cross talk) .

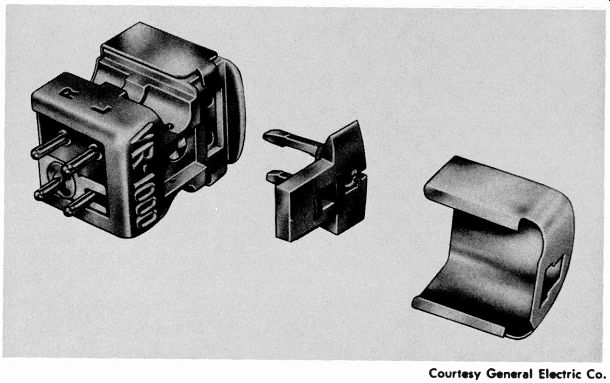

The basic theory of operation of the variable-reluctance stereo pickup cartridge was covered in Section 4. Fig. 13-4 illustrates the General Electric Type VR-1000 stereo cartridge showing the stylus replacement feature.

The broadcast-type VR-1000-5 employs a 0.5-mil diamond stylus and a tracking force of 1 to 3 grams.

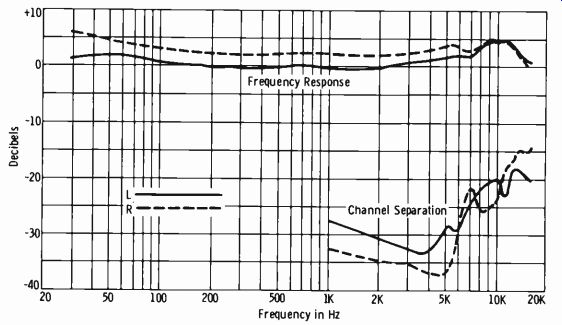

Fig. 13-5 shows the frequency response and channel separation of the VR-1000-5 cartridge. The solid line represents the left channel, and the dashed line is a plot for the right channel. On the lower portion of the graph, the dashed line represents the signal induced in the right channel by modulation in the left channel, and the solid line represents the signal induced in the left channel by modulation in the right channel.

When a stereo test record is used, the left channel (solid line) is given a reference level of 0 dB (at 1000 Hz) . With left-channel modulation only, the signal of the right channel is measured and plotted. In Fig. 13-5, the separation at 1000 Hz is 32 dB. The separation is then measured at frequencies up to 15,000 Hz. Without changing gains, the right-channel frequency response is measured. In Fig. 13-5, it is observed that this particular cartridge has a slightly higher output in the right channel. Although the responses of the two channels should be within a few decibels of each other for close frequency-response match, the actual output amplitude difference is of small significance since the respective channel faders are adjusted in practice for matched-level outputs.

Fig. 13-4. A variable-reluctance stereo cartridge.

Fig. 13-5. Frequency response and channel separation, GE VR-1000-5 cartridge.

When frequency-response measurements are being made at the outputs of the pickup preamplifiers, it is obvious that the frequency response of the amplifier alone must first be plotted. This is then used for any correction factor necessary at a particular frequency. When channel separation is measured the noise level of each amplifier must be well below 60 to 70 dB down from the reference output level. This is to avoid measuring noise on the meter rather than actual signal.

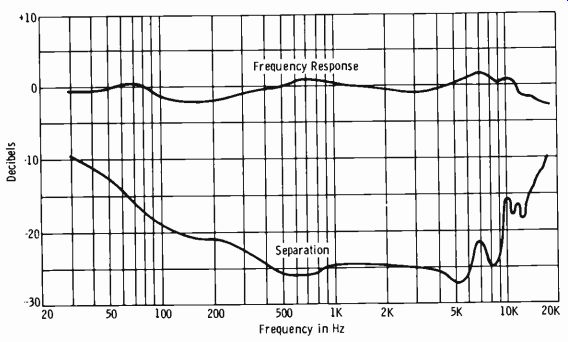

Channel separation in a stereo pickup deteriorates at both the low- and high-frequency ends of the audio spectrum, as shown by Fig. 13-6. These curves, which are for a later version of GE stereo pickup (the VR-22 series) , show the separation (lower curve) from 30 Hz to 20 kHz, in addition to the overall frequency response (upper curve) . For completeness, the specifications of this pickup are listed in Chart 13-1.

Fig. 13-6. Typical frequency response and channel separation of GE VR-22

series cartridge.

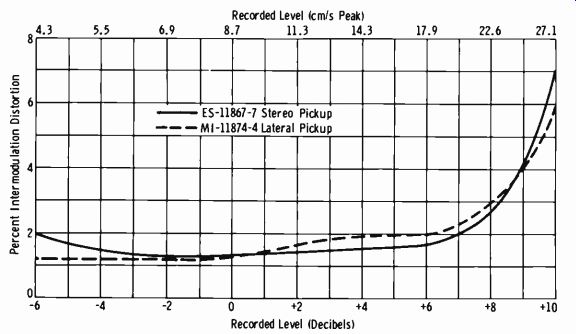

The RCA universal pickup cartridge has been designed especially for broadcast applications. This cartridge performs in both stereophonic and monophonic applications; the mode of operation is determined by external electrical connections to the cartridge. A replacement stylus is a feature of the cartridge design; the stylus plugs directly into the cartridge and is easily replaced. This plug-in feature also allows a user to buy one type of cartridge and several sizes of inexpensive styli in order to take care of all record-playing requirements. Fig. 13-7 illustrates the intermodulation distortion of the cartridge in both stereo and lateral applications.

Fig. 13-7 shows intermodulation distortion, which is a measure of the nonlinear distortion occurring at the lower test frequency. The RCA 12-5 39 test record on which the graph is based contains 400 and 4000 Hz mixed 4 to 1. Harmonic-distortion methods at 400 Hz could have been applied, but they have been found to be much less practical than the intermodulation method. Ten percent intermodulation distortion is not notice able without a chance for direct comparison. This is comparable to a figure of 2 or 3 percent harmonic distortion. Intermodulation-distortion techniques are covered in Section 13-13.

In stereo broadcasting, it is of prime importance to be extremely careful in maintaining the proper polarities of the left and right channels. Particular attention must be given in the initial installation and, whenever new facilities are added, to the correct interconnections to maintain the proper phase of the two channels over the audio-frequency spectrum of 30 to 15,000 Hz.

-----------

Chart 13-1. Specifications of GE VR-22 Series Cartridge (Specifications are similar for the 0.5-mil diamond stylus Model VR-225 and the 0.7-mil diamond stylus Model VR-227, except as noted.) Frequency Response: 20 through 20,000 Hz, +3 dB (VR-225); 20 through 17,000 Hz (V R-227) Output: 5 millivolts, minimum, at stylus velocity of 3.8 cm/s Separation Between Channels: Up to 25 dB nominal Channel Balance, at 1000 Hz: One dB or better Inductance: 307 millihenries, nominal Resistance. 1386 ohms per channel, nominal Load: 47K-100K, 47K optimum Lateral Compliance: 4 X 10^-6 cm/dyne (VR-225); 2.5 X 10^-6 cm/dyne (VR-227), nominal Vertical Compliance: 3 X 10^-6 cm/dyne (VR-225); 2 X 10^-6 cm dyne (VR-227), nominal Tracking Force: Two grams minimum under optimum conditions-three grams for average use-four grams maximum (VR-225). Five to seven grams with VR-227 Dimensions: Width, 0.575 inch; height, 0.7 inch including stylus tip; length, 1.18 inches Mounting: For 7/16-inch or 1/2-inch mounting centers All measurements taken from RCA Victor stereophonic test record Number 12-5-71 and 12-5-73

--------------------------

Fig. 13-7. Percent intermodulation distortion for one type of stereo cartridge.

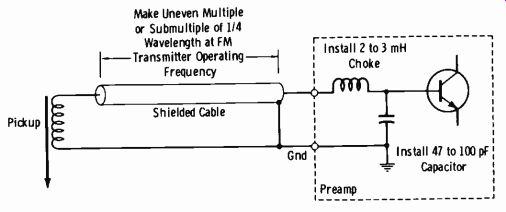

The most prevalent form of trouble in pickups located near an fm transmitter (as when the transmitter is in the same building as the operating center) is rectification of the strong rf field at the phono preamplifier input.

This rf interference can be eliminated by observing the precautions shown on Fig. 13-8. Many preamplifiers have built-in rf filtering networks, but some do not. Even when these are incorporated, the length of the shielded pickup cable is most usually left to the individual installation requirements.

Be sure to cut this cable to an odd multiple (or sub-multiple) of a quarter wavelength at the operating frequency of the fm transmitter. For example, a quarter-wavelength at 100 MHz is 0.75 meter, or 29.5 inches. Be certain that the shield of the pickup cable is connected only at the preamplifier ground terminal, and that the preamplifier ground is properly connected to the station ground.

Pick-up Make Uneven Multiple or Sub-multiple of 114 Wavelength at FM

-Transmitter Operating Frequency Shielded Cable

Gnd 4 Install 2 to 3 mH Choke Preamp

'Install 47 to 100 pF

- Capacitor

Fig. 13-8. Precautions to minimize fm-to-am rectification in vicinity of

strong rf field from transmitter.

13-4. JACKS

Jacks, since they constitute either series or parallel connections in the signal path, must be kept free of dust and dirt and in perfect contact adjustment. They should be vacuum cleaned frequently, or preferably, a thin high-pressure stream of forced air should be blown through each sleeve from front and rear and be followed by a thorough vacuuming. Jack contacts may be kept clean by regular insertions and removals of patch-cord plugs (Fig. 13-9) .

Visual inspection of jacks and mounting structures should be made during this process to check for the proper operation and tightness of mounting. If jacks have not been maintained in this manner for a long period of time, a regular jack-burnishing tool may be used.

When the burnishing tool is used, the handle is adjusted in such a way that about 2 1/8 inches protrudes. This prevents the blade from touching the insulation in the spring pileup and prevents damage to the insulation. Insert the blade carefully in the jack until it just meets the normal contact. A slight turning movement of the tool will then tend to lift the normal spring from the normal contact, and a light forward pressure will allow the blade to slip easily between the contacts.

13-5. KEYS AND SWITCHES

Keys and switches vary considerably in their structure and functioning, but all types have a means of opening and closing single or multiple circuits by spring contacts and blade assemblies. Dirt or dust causes the majority of troubles here. Contacts usually may be cleaned with a clean, dry, lint-free cloth. A clean strip of silk is useful since it collects dust particles from the contacts by static electricity when it is drawn through the contacts while a light pressure is held on the blades or spring sheaves by the fingers.

In the more serious situations, a toothpick immersed in carbon tetrachloride may be drawn through the contacts and then discarded to prevent its being reused.

Fig. 13-9. Method of "exercising" a jack field.

The mountings of keys or switches should be checked for tightness.

Tighten every loose connection. Watch the mechanism as the key or switch is operated, and note the tension of the spring or stationary contacts. If the tension appears to be insufficient, adjust it with the fingers or long-nose pliers, or use a special switch and relay tool with a slotted end. Be very careful not to make it too tight.

13-6. FADERS (ATTENUATORS)

A regular cleaning schedule is necessary for continued, reliable, and noise-free operation of fader controls. Contacts should be cleaned with a clean, soft cloth and carbon tetrachloride. Also clean the leaves in this manner; be careful not to disturb the tension of the individual leaves. To help prevent wear, some engineers recommend a light lubrication of the contacts by applying a very slight amount of un-medicated petroleum jelly on a clean cloth.

Never disturb the tension of the leaves against the contacts unless absolutely necessary. If the attenuator must be dismantled, the leaves should be adjusted by means of the sliding mounting screw until there is just enough pressure to allow a reliable contact. Attenuators that turn hard against the fingers have excessive pressure between leaves and contacts, and their life is shortened.

13-7. AMPLIFIERS AND LOGIC CIRCUITRY

This text is not a detailed treatment of servicing techniques, and a fundamental radio background is assumed from the beginning. However, for the purpose of completeness in studio maintenance, helpful hints are given here for locating troubles in audio amplifiers. We will consider the tube-type amplifier first.

Filaments Do Not Light

When all filaments fail, it may generally be assumed either that the ac power line has failed or a fuse in the amplifier rack or amplifier has blown.

First check all ac switches for the proper operating position. Then check the position of any circuit breakers involved. After that, check the fuses.

Faulty switches may nearly always be detected by feel when one operates them. If a snap is not apparent, jumper the contacts until the switch can be replaced.

If only one tube fails to light, it is usually a bad tube. First wiggle the tube with a strong pressure against the socket. If the filament lights, a loose or rosin connection on the socket terminals may exist, or the contact springs may not have enough tension to maintain reliable contact with the tube prongs. See Section 14 for a detailed discussion of vacuum tubes and socket maintenance.

Filaments Light, No Response

First replace the rectifier tube with one known to be good. If trouble persists, check the plate voltages starting with the output of the filter system. Then check the output stage and so on back to the first stages. If all voltages are normal, check the continuity of the output transformer. If this test shows nothing wrong, the best procedure (assuming normal plate voltage) is to use a signal generator and headphones (with a series 0.1-µF capacitor) to trace the signal to the faulty stage. If no plate voltage exists or the voltage is very low, check the condition of the electrolytic capacitors and the continuity of the filter circuits. Check the wiring for continuity.

Check the condition of the power-supply switch and fuse holders. If voltage does not exist or is low in only one stage (in which case a small distorted signal is usually present), check the continuity and values of all resistors in the plate and cathode circuits, and the wiring to the component parts. In some cases, low plate voltages may be due to excessive plate cur rents which in turn may be caused by low or nonexistent grid bias or by a leaky coupling capacitor that places a positive voltage on the grid of the following stage. These cases require point-to-point analysis using any of the recognized methods of servicing, such as signal tracing, point-to-point resistance measurements, etc.

Amplifier Noise

Hum and noise are common troubles. First, try to locate the approximate origin of the noise by using the normal operating controls. For example, is the noise heard with all switches and attenuators off? If so, the noise could be in the monitor amplifier or high-level amplifier circuits. The possible sources of noise will, of course, vary depending on the layout existing at a particular installation.

It is always best to replace tubes first in case of noise. If this procedure does not clear up the trouble, look for loose connections or an apparent rosin connection. Move the wiring back and forth with the monitor-amplifier gain turned up. Wiggle the tubes in their sockets. If a faulty spring contact exists, see Section 14 for socket maintenance. Tap all coupling capacitors and resistors. If a distinct electrical noise (as distinguished from acoustic noise) exists, replace the part with an exact replacement. Examine all ground connections closely for looseness or bad soldering.

Steady noise (not intermittent) may be caused by some form of inductive interference. If input transformers are constructed in such a way that their windings may be oriented in any direction, try a reorientation for minimum noise pickup from any possible ac field. Some microphones are unusually sensitive to stray ac fields. If noise is coming from any particular microphone circuit, check the microphone and cable locations for interfering fields. This is particularly important at remote locations.

Servicing Printed Circuits

Care must be taken not to break or crack the board by undue stress or to damage the bonding adhesive by applying too much heat during soldering.

The following tools are required: a small (25-watt) soldering iron, pair of small diagonal cutters, pair of small long-nose pliers, scribe or pick, and small knife.

A. If it is necessary, remove the hardware fastening the board to the chassis and remove the board, or tilt it up if it is hinged.

B. Isolate the defective component. If it is necessary to disconnect a component from the circuit for test, heat the junction of the component lead and the printed wiring with the soldering iron. Concentrate the heat on the component lead rather than on the etched wiring pattern. Pry up and straighten the bent-over portion of the component lead with a knife blade, and then pull the lead through the hole with pliers.

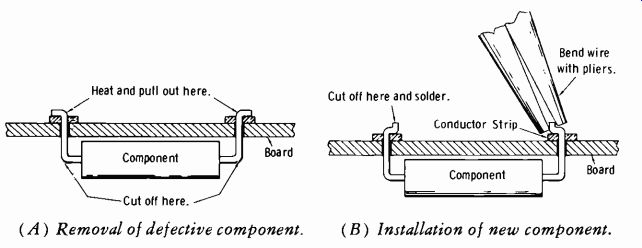

C. To remove the defective component, snip off the leads at the component side of the board (Fig. 13-10A) .

D. Using a small soldering iron (25 watts) , heat the leads and remove them from the printed-wiring side of the board. To avoid damage to the conductors, be careful not to apply too much heat or force.

E. Clean and form the leads of the new component and insert them through the holes until the component body is tight against the board.

Heat and pull out here.

Component Board Cut off here.

(A) Removal of defective component.

Bend wire with pliers.

Cut off here and solder.

Conductor Strip

Component Board

(B) Installation of new component.

Fig. 13-10. Replacement of component in printed circuit.

F. On the circuit side, grasp the component lead and bend it over in the direction of the circuit pattern.

G. Crimp the wire tightly against the board (Fig. 13-10B) , and cut off the excess component lead. Leave about 1/ c inch of wire protruding from the edge of the hole.

H. Heat the lead and apply rosin-core solder. Do not use paste or acid flux. Remove the excess rosin from the joints with alcohol.

I. Replace the circuit board, using the original hardware.

Replacement of Transistor Socket

Heat each socket terminal and pry up and straighten it with a knife blade. Pull the socket out, applying heat to the terminal leads, if it is necessary. Clean the holes free of solder. Prepare the new socket for installation as follows. Using the old socket as a model, bend the terminal leads to fit the mounting holes provided in the board. Insert the socket terminals through the holes, making sure that the socket terminals are oriented as on the previous socket. Bend the socket terminals in the direction of the circuit pattern. If it is necessary, clip off the excess length to prevent short circuits with adjacent conductors. Solder the terminals to the etched wiring.

When it is necessary to remove a transistor that is not mounted in a socket, grasp the transistor lead with a pair of long-nose pliers while un soldering. This provides a heat sink to avoid damage to the transistor from excessive heat. Use a 25-watt iron.

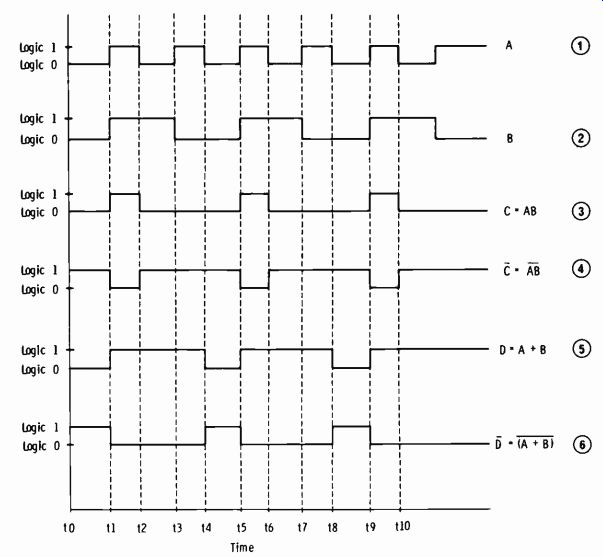

Fig. 13-11. Timing diagram.

Logic Circuitry and Integrated Circuits

Most logic circuitry today is made up in integrated circuits (ICs) .

Therefore, it is normally necessary to know how to check inputs and out puts with an oscilloscope to isolate troubles in logic circuitry where the entire chip would need replacing. Let us go through the timing diagram of Fig. 13-11 to show how it is done.

IMPORTANT NOTE: Pulses are rarely as perfectly shaped as indicated on such drawings as Fig. 13-11. In practice, there will usually be some rounding, and this may be normal. It is always desirable to scope such circuitry when it is working perfectly to ascertain the normal shape of pulses in any particular equipment.

In the timing diagram chosen, variable A (row 1) is a stream of data consisting of alternate 1's and 0's. Variable B (row 2) is composed of alternate groups of two 1's and two 0's. The remaining rows indicate the following:

Row 3: A and B combined in an AND gate. (C = AB reads "C equals A and B.")

Row 4: The complement of row 3 ( NOT or NAND circuit) .

Row 5: A and B combined in an OR gate. (D = A + B reads "D equals A or B.")

Row 6: The complement of row 5 ( NOT or NOR circuit) .

So here we have every combination fundamental to logic circuitry. If a technician understands the symbols for bistables and gate circuitry, he should know what to expect at the output of each chip for a given input or inputs. For example, he can quickly check inputs A and B to the AND gate. He must then determine the normal output as shown by row 3. For a NAND circuit, the output should be the inverted function of row 4.

As a matter of review, bear in mind that the bistable is a natural divide-by-two circuit. If the first pulse results in logic 1, a second pulse is required to result in logic 0. So to complete one output pulse, two input pulses are required. For example, if variable A (row 1 in Fig. 13-11) is the input to a bistable, variable B (row 2) would be the output. This is to say that the frequency of B is half that of A.

Digital logic circuitry becomes easy to troubleshoot with a little experience and familiarity with a particular system. Either an oscilloscope or any of the commercial IC pulsers and indicating lamps can be used. The latter permits using one probe as a pulser and another probe with an indicating lamp to show whether an output is obtained, either by half-brilliance, full brilliance, or flashing lamp for a train of pulses. Lack of lamp "turn-on" indicates low output or no output.

The important point to remember is that input conditions to a chip must be correct for the proper output condition to exist. An AND gate with four inputs must have simultaneous high levels (when high-level activation is called for) for an output to exist. One or more of these inputs might be a positive dc rather than a pulse. When a faulty chip is definitely found, the entire chip is replaced.

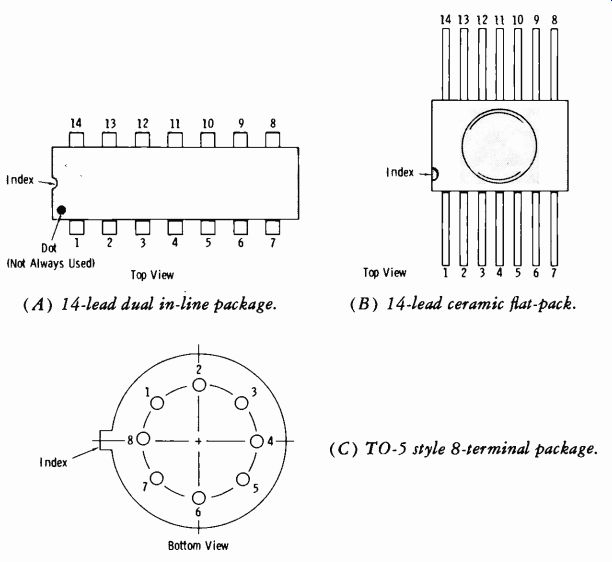

The three basic IC packages are shown in Fig. 13-12, along with their respective terminal arrangements. Figs. 13-12A and 13-12B are top views.

Note that the pin numbers increase counterclockwise around the packages as seer. from the top. There are also 16-lead packages which have 8 leads per side; pin 16 is opposite pin 1, and pin 9 is opposite pin 8.

Fig. 13-12C shows the TO-5 type of IC, for which it is conventional to show the bottom view. Note that the highest lead number is adjacent to the index tab. The numbers then run clockwise as viewed from the bottom.

This type of package may have as many as 12 terminals.

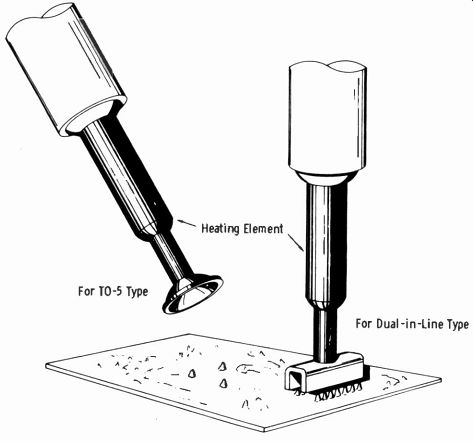

The maintenance technician must be familiar with proper techniques for replacing ICs and other components on printed circuit boards. This must be done carefully and skillfully to prevent damage. There are special tools for desoldering all IC pins at the same time (Fig. 13-13). These heated elements are placed on the pins of the IC on the wiring side of the printed board, with a special extractor clamped to the IC body to exert a "pull-away" pressure as the solder is melted. Such tools must be used with extreme caution, since IC leads are sometimes folded against the board and must be bent up before extraction can be done without damage to the boards.

(A) 14-lead dual in-line package. (B) 14-lead ceramic flat-pack.

(C) TO-5 style 8-terminal package.

Fig. 13-12. Basic integrated-circuit packages and terminal arrangements.

Fig. 13-13. Desoldering tools for integrated circuits.

Fig. 13-14. Method for desoldering components.

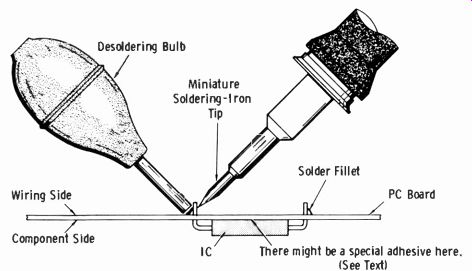

The preferred method is shown in Fig. 13-14. The procedure is as follows:

1. With the soldering-iron tip applied, squeeze the desoldering bulb and hold its tip at an angle of approximately 45° against the solder fillet of the lead of the component to be removed.

2. As the solder melts, release the bulb quickly to draw solder away while continuing to hold the soldering-iron tip against the lead. All solder must be removed from each lead. If the lead is bent against the board, pry it up and repeat the procedure until all solder is removed from the lead.

Caution: When the soldering bulb is released to draw in air (and solder) , do not remove the soldering iron from the lead. If the iron s removed during this operation, air will cool the joint enough to prevent clean removal of the solder.

3. Repeat the procedure for each of the remaining leads. Note the position of the index (dot, notch, or tab) if the replaced component is an IC. Make certain that all leads are free and clean of burrs; then re move the component. NOTE: Some manufacturers hold flat-packs in place by a small drop of special adhesive which remains flexible and will part with a small amount of pressure. The residue of adhesive from the old flat-pack should be sufficient to hold the new one in place before soldering.

4. Carefully inspect the holes in the board to insure freedom from excess solder or burrs which would prevent insertion of the replacement component. Remove burrs if necessary by gently reaming the holes with a sharp instrument such as a pick or soldering aid.

5. Bend the lead of the new component to correspond with those of the one removed. Place it on the component side of the board, making certain that the orienting dot, notch, or tap is in the same position as the one removed (step 3) .

6. Insert the leads through the holes and press the component to the board. Do not trim the leads yet.

7. Solder the leads to the wiring eyelets or pads; use small-diameter solder to minimize the possibility of solder bridges between leads.

Then clip the leads close to the board. Carefully inspect all work after the last lead is soldered to make certain that no solder bridges exist between any leads.

IMPORTANT NOTE: Examine the instruction book for any particular equipment for special instructions regarding component replacement.

A word of advice: This text can serve only to introduce the reader to logic circuitry. In broadcast systems, great numbers of such circuits are being used in computer-type remote controls, signal generators and monitoring systems, station-break automatic switching systems, etc. The information presented in this guide is written as a basic discussion that should remain valid with future advances in logic circuitry. Since a full-length book would be required to cover broadcast-system applications alone, the maintenance technician-engineer must undertake a training program on his own to re main competent in his field.

Amplifier Distortion Checks

It is good maintenance practice to run overall noise and distortion checks from the microphone input to the transmitter output at periodic intervals.

If the maintenance personnel are divided between the studio and transmitter, the prevailing practice is to carry out this procedure separately for the studio and transmitter equipment. This is usually done in the intervals be tween the required proofs-of-performance in order to be ready for the official proof-of-performance run. The FCC requires a harmonic-distortion measurement. Detailed procedures are outlined in Section 14, since the transmitter is involved in the FCC requirement. When the run is made only at the studio, the noise-distortion meter is terminated by the line output of the studio. When excessive noise and/or distortion results, the audio oscillator is fed first to the line-amplifier input and then into preceding amplifier stages until the source of the defect is isolated. (Use the proper input level to the amplifier.)

Since harmonic-distortion measurements are required by the FCC, this type of measuring equipment must be on hand or available to the station.

For studio use, however, more and more engineers are considering the use of intermodulation-distortion measurements to maintain a tighter and more definite control over studio amplifiers and transducers. This is covered in Section 13-13.

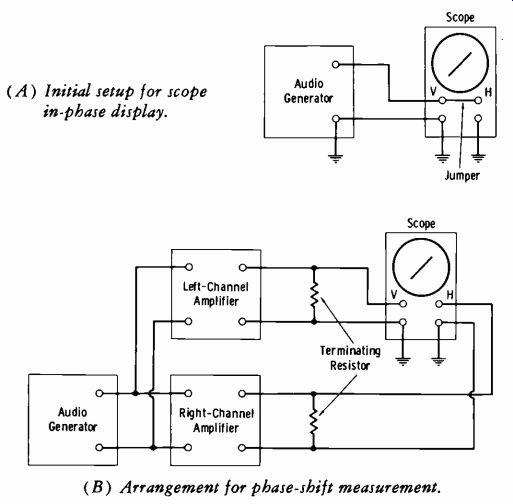

(A) Initial setup for scope in-phase display.

(B) Arrangement for phase-shift measurement.

Fig. 13-15. Method of measuring phase shift between stereo channels.

13-8. PHASING THE STEREO SYSTEM

A good audio oscillator of the type used in the station proof-of-performance runs and an oscilloscope provide the most convenient method of measuring the phase conditions. The technique is based primarily on that out lined previously for checking microphone phasing. The procedure is as follows:

1. Connect the audio generator (adjusted to 1000 Hz) to the vertical input of the scope. Run a jumper wire from the vertical to the horizontal input (Fig. 13-15A).

2. Adjust the horizontal and vertical gains of the scope so that a line slants from the lower left to the upper right of the screen. This is obviously the in-phase condition, since a common source is employed.

If the vertical and horizontal amplifiers of the scope have a different number of phase reversals, the in-phase trace will be from the lower right to the upper left. A small difference in gains will not upset the accuracy of the reading. However, if an ellipse occurs (indicating phase distortion in the scope itself), it will be necessary to connect directly to the x- and y-deflection plates, through suitable (and identical-value) capacitors.

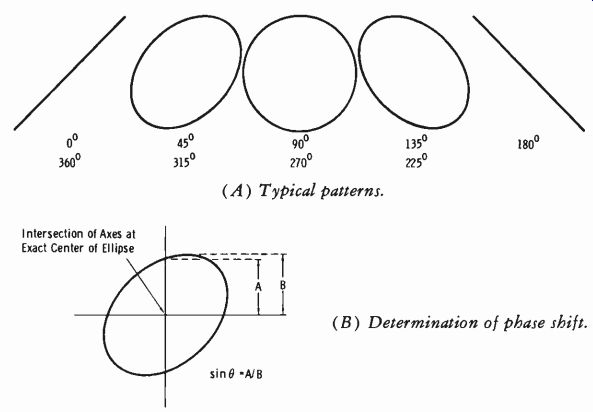

(A) Typical patterns.

Intersection of Axes at Exact Center of Ellipse

(B) Determination of phase shift.

Fig. 13-16. Scope displays in phase-shift measurement.

3. In the following discussion it is assumed that the in-phase trace is as illustrated in Fig. 13-15A, as is common with nearly all modern oscilloscopes. Now connect the line outputs of the left and right channels to the scope as shown by Fig. 13-15B. Adjust the respective levels to obtain the same sine-wave amplitudes used in step 1. Fig. 13-16A illustrates the basic phase-shift displays. If the 180° phase reversal is indicated, this means that a "turnover" in interconnecting wiring has occurred or that unlike amplifiers are employed. It is then necessary to proceed back toward the generator input until this discrepancy is isolated.

4. Fig. 13-16B indicates the method of measuring the phase angle. Ad just the centering so that the intersection of the x- and y-axis lines is at the exact center of the ellipse. For example, if A is 1.5 divisions and B is 2 divisions, 1.5/2 = 0.75, and sin O = 0.75. From a table of sines, it is found that the angle whose sine is 0.75 is 48.6 degrees.

An alternate method is as follows. Measure the amplitudes of the two voltages individually. For example, adjust each channel for an output of 1 volt, a convenient value for a 600-ohm load. Then measure the sum of the two voltages. A zero-degree phase difference will result in 2 volts. A 180° phase difference will result in zero volts (complete cancellation). A 90° difference results in 1.4 volts, etc. This method is less accurate than the preceding one, but normally it is only important to ascertain that no phase turnover has occurred or that an excessive amount of phase distortion is not present.

Speakers must also be properly in phase. The most convenient and accurate method of checking speaker phasing is to connect a sensitive dc meter across the voice-coil transformer and note the polarity of meter deflection when the cone is pushed rapidly downward. All speaker connections are then made to achieve a like polarity of deflection. When the same make and model of speaker is employed throughout, it normally is only necessary to connect all color-coded leads in an identical fashion.

13-9. REEL TO REEL AND CARTRIDGE TAPE RECORDERS

There are a large number of different makes of commercial tape recorders. Although these machines embrace a wide variety of physical and electrical designs, the major troubles encountered by the operator have characteristics common to all makes. Some of the usual sources of trouble will be discussed here for the guidance of the user of commercial tape recorders.

Distortion

Distortion is the most commonly encountered trouble and probably has a larger number of causes than any other characteristic. There are three general types of distortion that are distinguished easily by the average listener. They are as follows:

1. Unintelligible speech and extreme lack of bass. This symptom is most likely caused (assuming that the audio amplifier and microphone are normal) by a complete loss of the supersonic bias to the recording head. Check all components in the bias oscillator-amplifier circuit.

Check also for loose connections, and check the bias winding on the recording head.

2.. Low output, muffled sound. Again assuming that the audio amplifier is normal, this trouble is usually traced to an accumulation of tape-coating residue, dirt, dust, or foreign matter on the pole pieces of the recording head. Clean them thoroughly. This should be a regular part of the maintenance schedule on high-quality magnetic recorders.

Check the head alignment as outlined later.

3. Little or no output, mushy sound. This trouble can have the same causes just described; however, it is most likely an indication of a faulty component part in the audio amplifier or switching system.

Check them in the orthodox manner. Keep heads clean by the application of isopropyl alcohol. Clean the capstan and the pinch roller with the same chemical. Follow the manufacturer's instructions on lubrication at the indicated intervals. Be sure to keep the heads de magnetized by using a small "wand" type demagnetizer.

Measurement of Harmonic Distortion

Manufacturers sometimes specify the percent of third-harmonic distortion in their system, since this is the most prevalent type of magnetic-tape distortion. It is desirable to measure the amount of third-harmonic distortion at normal signal input levels. In determining the maximum permissible recording level which can be used in the recorder, or in evaluating different tapes, this is an important consideration. It is desirable to operate the recorder at the highest possible recording level without exceeding the distortion limits.

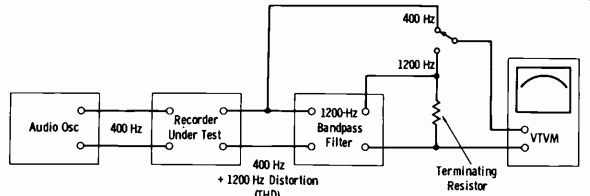

The following method of measurement is suggested by the 3M Company, makers of Scotch brand recording tapes. The third harmonic is separated from the fundamental sine-wave frequency by a filter and directly measured with a vtvm (Fig. 13-17) .

The equipment required is an audio oscillator that provides a good wave-shape (normally the one used by the station for proof-of-performance runs), a vacuum-tube voltmeter, and a bandpass filter. Since it is customary to measure distortion at 400 Hz, a 1200-Hz filter is ideal. However, the more common 1000-Hz or 5000-Hz filters can easily be substituted if the test frequency is suitably adjusted. The filter should have a rejection of at least 60 dB at the fundamental test frequency if the highest accuracy is to be obtained.

Fig. 13-17. Method of measuring third-harmonic distortion.

Before the test is made, it is necessary to calibrate the system. This takes into account the insertion loss of the filter. Since the input termination affects this value, it is best to calibrate the filter from the actual recorder under test. To do this, the filter is disconnected, and the output level of the recorder is checked at 400 Hz and 1200 Hz to determine if it is the same at these frequencies. If it is not, the input to the recorder must be re adjusted at one of the frequencies to compensate for the discrepancy. The filter is then connected to the recorder, and a level reading is taken at the input to the filter with a 400-Hz input to the recorder and at the output of the filter with a 1200-Hz input to the recorder. (If it is necessary, the input level to the recorder must be readjusted as previously explained.) The difference between these readings in decibels is the insertion loss of the filter.

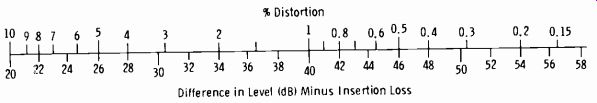

In making the actual test, the 400-Hz signal is fed through the recorder, and level readings are taken at both the input and output of the filter. The difference between these readings in dB minus the insertion loss of the filter is the true ratio between the signal and the third-order harmonic component. This can be converted to percent by reference to the alignment chart (Fig. 13-18) .

Difference in Level (48) Minus Insertion Loss

Fig. 13-18. Chart for converting decibels to percent distortion.

Once a particular system is calibrated and the insertion loss is known, this step need not be repeated in subsequent tests. With a little practice, distortion measurements can be made very quickly. All that is necessary is to patch in the oscillator, filter, and voltmeter and make two quick readings.

When distortion measurements are made not using the third-harmonic bandpass filter, the measurement is termed total harmonic distortion (thd).

Normally, thd should be less than 2 percent over the frequency range of 50 Hz to 15 kHz.

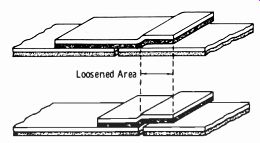

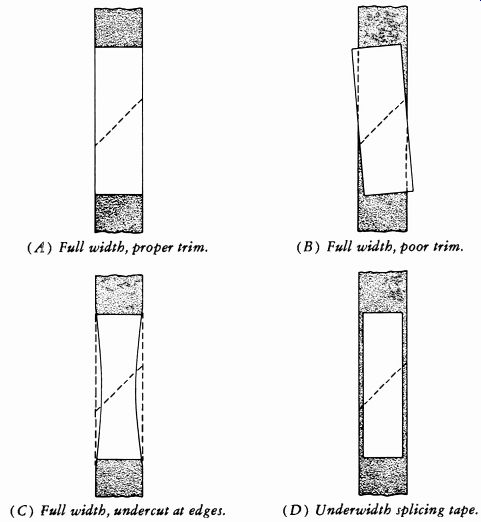

Head Alignment and Loss of High Frequencies

If the reproducing gap is not parallel to the recorded poles on the tape, a serious loss of high frequencies may result. An attempt is made to align the head gaps on all recording machines exactly perpendicular to the tape so that tapes made on one machine can be played on any other machine in the station. This alignment is accomplished by rotating the head for the maximum output from an alignment tape on which a steady high-frequency signal has been recorded using a carefully aligned head. In making this adjustment, the extreme sensitivity of these high-frequency ,signals to alignment becomes immediately apparent. For example, in a full-width (1/4") recording of 1-mil wavelength, a misalignment of only 8 minutes of arc can reduce the output by about 6 dB.

An equally crucial problem in obtaining good frequency response is that of maintaining intimate contact between the tape and the head gap. In playing a low-frequency signal, a separation of one or two mils does not appreciably affect the level, but at a high frequency of, say, 1-mil wave length, even a half-mil spacing results in a drop of more than 20 dB. It is apparent that any loss of contact between head and tape, however slight, has a profound effect on the high-frequency output. Therefore, always check the pressure pads and tensions to be certain that the tape is held in intimate contact with the heads. Be sure the heads are clean.

In playing a tape recording that was made on a different machine, head misalignment may be suspected, but one may not wish to disturb the head adjustment to verify this. In this case, the skew effect can be used to ad vantage because a deflection of the tape from its normal path across the head has the same effect as rotating the head. If, after carefully deflecting the tape a small amount in each direction, it is found that the greatest high-frequency output corresponds to the normal tape path, the head is correctly aligned. This test may be made on almost any kind of a recording, since the ear can readily distinguish the presence of high-frequency components in program material.

In case the highs can be improved by deflection of the tape ( indicating misalignment) , either the head used to make the recording or the one on the playback machine may be at fault. Regardless of the origin of the mis alignment, optimum reproduction of this particular tape may be obtained by readjusting the playback head. After playing this tape, the machine should be rechecked with an alignment tape, and, if necessary, readjusted.

In summarizing these points, the following check list is suggested for locating the cause of poor high-frequency response due to head problems:

1. Check azimuth alignment with an alignment tape.

2. Check for tape skewing which seems to occur simultaneously with amplitude fluctuations.

3. Check to be sure the head meets the tape squarely.

4. Check for stability of the tape path in its guides.

5. Check for foreign deposits, nicks, or gouges on the head surface.

6. Check for 'breakthrough" in the head gap. A magnifying glass or microscope is helpful.

7. Check for uneven wear.

8. Replace the head if necessary.

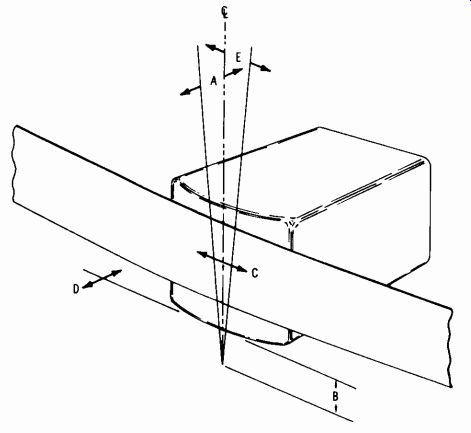

Fig. 13-19 illustrates the five basic adjustments in correctly positioning a recorder head. Note that two of these positioning adjustments, A and B, are concerned with the tape centerline. Ideally, the centerline of each component which is in direct contact with the tape should maintain an unvarying reference plane. Failure to do so results in bending of tape edges, tape skewing on a tangent from the normal path, azimuth error, and excessive friction.

----------------

A. Tilt, in which the face of the head must be simultaneously tangent to the same degree with both edges of the tape and without distortion of either of the latter.

B. Height, in which the gap width dimension is centered on the standard track location.

C. Tangency assures that the tape contacts the portion of the head face containing the head gap.

D. Contact, head position into or away from the tape to assure proper contact pressure between head and tape ("wrap"). Not as critical with machines employing pressure pads at the heads.

E. Azimuth or skew, in which width dimension (corresponds to track width) of gap is exactly 90° with tape edge.

Courtesy 3M Co.

Fig. 13-19. Orientation in head adjustment planes.

------------------

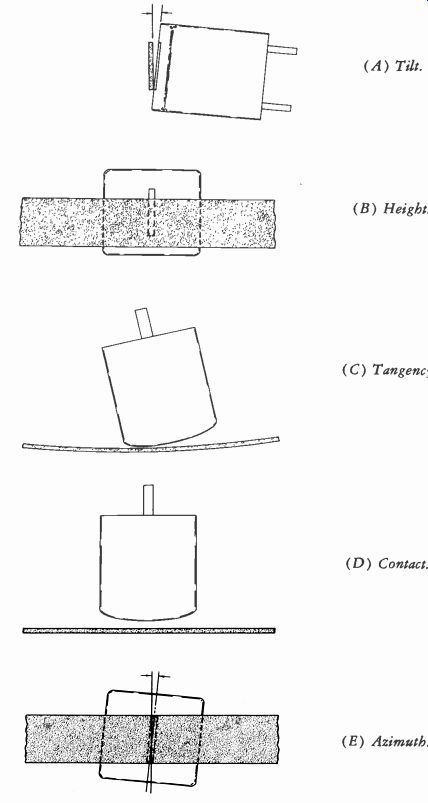

Fig. 13-20 shows the details of the corresponding characteristics in Fig. 13-19. These may be outlined briefly as follows:

A. Tilt. Designated as arc A in Fig. 13-19; must establish a true vertical position for the face of the head. Fig. 13-20A shows the exaggerated condition. If the head tilts even slightly, uneven tension results across the entire width of the tape. Intimate contact between tape and head is lost, and the tape can be caused to skew away from the centerline.

B. Height. Improper head height is particularly disturbing on multiple-track recordings due to noise, cross talk, and loss of signal.

C. Tangency. Characteristics A and B above have established the tape centerline path. Tangency (arc C of Fig. 13-19) squares the record and playback gaps to the tape surface. Even a slight error in tangency can cause high-frequency loss, and a high sensitivity to dropouts caused by slight contamination on the tape or head.

D. Contact. Proper contact is assured by a slight "wrap" in the path of the tape as it passes over the head. Contact is very important for good high-frequency response. When pressure pads are used, they should be inspected for signs of wear or damage.

E. Azimuth. The reproducing gap of the playback head must be exactly parallel to the recorded poles on the tape. Thus for compatibility and interchangeability, the record and playback heads must be adjusted so that the gaps are exactly perpendicular to the centerline of the tape path. An alignment test tape must be used for this adjustment.

The 3M Company furnishes the following hints for this alignment procedure:

(A) Tilt. (B) Height. (C) Tangency. (D) Contact. (E) Azimuth.

Fig. 13-20. Details of head adjustment planes.

When an alignment tape is used to check azimuth, a variety of methods can be employed, the simplest being deliberately to skew the tape across the head while checking the output. If the output, as indicated by the signal level meter (or the playback volume), is highest with normal tape alignment across the head, it can be assumed that azimuth is correct. If the output signal level increases while the tape is intentionally skewed, the azimuth should be readjusted. The head should be realigned to yield maxi mum output. In the case of separate record and playback heads, the play back head should be peaked according to the output signal level determined while using the prerecorded alignment tape. The record-head azimuth should then be peaked by recording on a blank tape and playing back through the correctly positioned playback head. Only a studio-prepared prerecorded tape should be used for an azimuth test.

While checking head azimuth, it is also good practice to inspect the pressure pad (if used) for wear. If a pad which has become worn does not properly position itself against the tape, it will have a tendency to skew the tape out of alignment with the head gap, giving the same effect as in correct head azimuth. If the pressure pad shows signs of a wear-created channel, it should be replaced.

Stereo Phase Problems in Tape Equipment

Proper head alignment is extremely critical in stereo tape decks, because phase shifts between channels can result either from azimuth misalignment between the record and playback heads, or from a different skewing of the tape during the record and playback functions. This emphasizes that compatibility and interchangeability are much harder to obtain for stereo tapes than for mono tapes.

This type of distortion is most evident when a stereo tape which exhibits the problem is reproduced on a monophonic receiver. Bear in mind that a monophonic receiver essentially reproduces the sum of the two channels.

Phase shifts between the two channels, which will differ with frequency, result in partial cancellation and reinforcement over the gamut of frequencies being reproduced. The net sum in this case can have a disastrous effect on the quality of the reproduced sound. This means that the stereo trans mission is no longer compatible with monophonic reproduction when such errors exist.

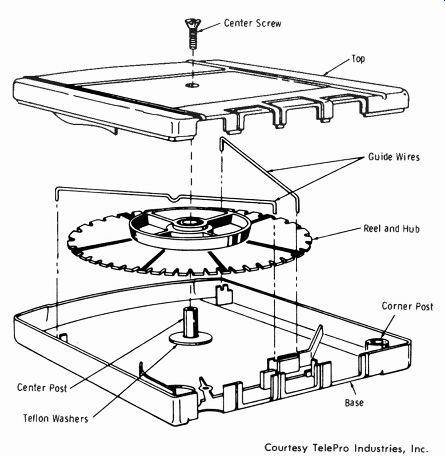

Center Screw Center Post Teflon Washers Top Guide Wires Reel and Hub Corner Post Bdr Courtesy TelePro Industries, Inc.

Fig. 13-21. Exploded view of tape cartridge.

For reel-to-reel stereo tape recorders, a very precise azimuth adjustment is required. Cartridge stereo systems have an additional problem in that all of the earlier cartridges did not provide for a tape-guide height adjustment, and the arrangement of the tape path allowed considerable "creeping" up the guide posts. More recent tape cartridges have provided adjustable guide height (as well as head adjustments), and some have an additional guide post prior to the original input guide so that the tape enters its final path across the head in a more rigid and flutter-free state, with a standardized tension.

A good way to align the stereo head is to use a full-track monophonic alignment tape. This allows precise alignment of the two-head stereo assembly for equal amplitude and identical phase from the two tracks at the reference frequency on the tape. A scope with identical horizontal and vertical amplifiers can be used, as described in Section 13-8 for phasing the stereo system.

The Tape Cartridge

Servicing the automatic tape cartridge is necessary when the tape in the cartridge has become too tight, too loose, looped, or ridged. Telepro Indus tries, Inc., maker of the Fidelipac cartridge, recommends the following servicing techniques for each type of problem.

Tight Tape--One cause of tape tightening is the gradual wearing away of the graphite lubricant of the tape. When this occurs, the tape cannot slide on itself and will tighten to the extent that the reel will not turn and the tape may be torn or damaged. This problem can be corrected before the tape freezes or damages itself if periodic visual checks are made of the magazines. Just prior to the tightening up of the tape, it is possible to predict its failure by the very shiny appearance of the tape.

When this condition appears, it is possible for the tape to be relubricated temporarily with a flake graphite, such as Dixon's No. 635 flake graphite. To apply the graphite, remove the top cover of the magazine (Fig. 13-21) , and with the top cover off, insert the magazine into a slow-speed player, preferably one operating at 1 7/8 in/s. Place a small amount of graphite between the two guide wires near the front of the cartridge or next to the guide wire at the rear left of the cartridge. Note that the graphite tends to spread itself somewhat uniformly over the entire surface of the reel of tape.

If the tape is allowed to run long enough, the majority of the flake graphite will work itself between each turn of tape and eventually imbed itself either on the oxide-coated side or on the lubricated side of the tape.

If the tape accepts the graphite lubricant, the eye, or large opening in the tape, will gradually move to the outside of the reel of tape and disappear.

Then it will slowly reappear close to the hub if the magazine is permitted to run longer.

If the eye maintains a position near the hub, the tape will have a relatively long life. If the eye moves to the outside of the reel of tape, reap pears near the hub and again moves to the outside, then no amount of graphite lubricating can salvage the tape. In these cases, it is best to scrap the tape and begin with a fresh reel of tape.

Tape tightening can also be caused by improper placement of the guide wires in the Fidelipac Model B and C cartridges. If the guide wires are allowed to rub against the hub of the reel, the reel will turn slower than normal. At the same time, the tape, which is being pulled from the center of the hub at a faster rate than the turning of the hub, will gradually tighten around the hub and stop the turning of the reel. This can be seen by watching the magazine in operation. If the guide wires are touching the hub, you will note that the hub does not turn freely, but turns with a slight jerky motion. Another way of noting this is to observe that portion of the hub which extends above the reel of tape. If the wire is touching, you will note a white mark drawn around the top edge of the hub by a wire guide. To correct this, bend the guide wire away from the hub very slightly, just enough to clear.

The same difficulty may be encountered if the reel is warped enough to touch the base each time it makes a revolution. If either the lid or base is even slightly warped, tightening of the tape may again be introduced. Prior to assembly, visually check the cartridge for warping.

Failure of the brake to release the reel completely may cause the tape to tighten up also. When the pinch roller engages the brake, which in turn releases the reel, there should be a space of approximately 1/16 inch between the edge of the reel and the brake. When the cartridge has been removed from the instrument, the brake should spring back and rest against the reel, thereby preventing it from turning during handling.