Disk drives came into being as random-access file-storage devices for digital computers. They were prominent in early experiments with digital audio, but their cost at that time was too great in comparison to emerging tape technology. However, the explosion in personal computers has fuelled demand for low-cost high-density magnetic disk drives and the rapid access offered is increasingly finding applications in digital audio. Optical and magneto-optic (MO) disks are considered in Section 12.

FIG. 1 The rotating store concept. Data on the rotating circular

track are repeatedly presented to the head.

1. Types of disk drive

Once the operating speed of computers began to take strides forward, it became evident that a single processor could be made to jump between several different programs so fast that they all appeared to be executing simultaneously, a process known as multiprogramming.

Computer memory is designed for speed and remains more expensive than other types of mass storage, and so it has never been practicable to store every program or data file necessary within the computer memory. In practice some kind of storage medium is necessary where only programs which are running or are about to run are in the memory, and the remainder are stored on the medium. Punched cards, paper tape and magnetic tape are all computer media, but suffer from the same disadvantage of slow access. The disk drive was developed specifically to offer rapid random access to stored data. FIG. 1 shows that, in a magnetic disk drive, the data are recorded on a circular track. In floppy disks, the magnetic medium is flexible, and the head touches it. This restricts the rotational speed. In hard-disk drives, the disk rotates at several thousand rev/min so that the head-to-disk speed is of the order of one hundred miles per hour. At this speed no contact can be tolerated, and the head flies on a boundary layer of air turning with the disk at a height measured in microinches. The longest time it is necessary to wait to access a given data block is a few milliseconds. To increase the storage capacity of the drive without a proportional increase in cost, many concentric tracks are recorded on the disk surface, and the head is mounted on a positioner which can rapidly bring the head to any desired track. Such a machine is termed a moving-head disk drive. The positioner was usually designed so that it could remove the heads away from the disk completely, which could thus be exchanged. The exchangeable-pack moving-head disk drive became the standard for mainframe and minicomputers for a long time, and usually at least two were furnished so that important data could be 'backed up' or copied to a second disk for safe keeping.

Later came the so-called Winchester technology disks, where the disk and positioner formed a sealed unit which allowed increased storage capacity but precluded exchange of the disk pack. This led to the development of high-speed tape drives which could be used as security backup storage.

Disk drive development has been phenomenally rapid. The first flying head disks were about 3 feet across. Subsequently disk sizes of 14, 8, 5 1/4, 3 1/2 and 1 3/4 inches were developed. Despite the reduction in size, the storage capacity is not compromised because the recording density has increased and continues to increase. In fact there is an advantage in making a drive smaller because the moving parts are then lighter and travel a shorter distance, improving access time.

Disk drives are devices which have distinctive characteristics distinguishing them from other media. These will all be explained in this section, after which it will become clear how these useful devices can be used in digital audio applications.

2. Disk terminology

In all technologies there are specialist terms, and those relating to disks will be explained here. FIG. 2 shows a typical multiplatter disk pack in conceptual form. Given a particular set of coordinates (cylinder, head, sector), known as a disk physical address, one unique data block is defined. A common block capacity is 512 bytes. The subdivision into sectors is sometimes omitted for special applications. FIG. 3 introduces the essential subsystems of a disk drive which will be discussed.

FIG. 2 Disk terminology. Surface: one side of a platter. Track: path

described on a surface by a fixed head. Cylinder: imaginary shape intersecting

all surfaces at tracks of the same radius. Sector: angular subdivision

of pack. Block: that part of a track within one sector. Each block has

a unique cylinder, head and sector address.

FIG. 3 The main subsystems of a typical disk drive.

3. Structure of disk

The floppy disk is actually made using tape technology, and will be discussed later. Rigid disks are made from aluminum alloy. Magnetic oxide types use an aluminum oxide substrate, or undercoat, giving a flat surface to which the oxide binder can adhere. Later metallic disks are electroplated with the magnetic medium. In both cases the surface finish must be extremely good owing to the very small flying height of the head.

FIG. 4 (a) Typical construction of multiplatter exchangeable pack. (b)

the hold-down screw A is fully engaged with the lockshaft B, and the

pin C lifts the ramp D, retracting the balls E. In (c) the hold-down

screw is withdrawn from the lockshaft, which retracts, causing the ramp

to force the balls into engagement with the cover F. The lockshaft often

operates a switch to inform the logic that a pack is present (G).

FIG. 4 shows a cross-section of a typical multiplatter disk pack. As the head-to-disk speed and recording density are functions of track radius, the data are confined to the outer areas of the disks to minimize the change in these parameters. As a result, the center of the pack is often an empty well. In fixed (i.e. non-interchangeable) disks the drive motor is often installed in the center well. Removable packs usually seat on a taper to ensure concentricity and elaborate fixing mechanisms are needed on large packs to prevent the pack from working loose in operation. Smaller packs are held to the spindle by a permanent magnet, and a lever mechanism is incorporated into the cartridge to assist their removal.

4. Principle of flying head

Disk drives permanently sacrifice storage density in order to offer rapid access. The use of a flying head with a deliberate air gap between it and the medium is necessary because of the high medium speed, but this causes a severe separation loss which restricts the linear density available.

The air gap must be accurately maintained, and consequently the head is of low mass and is mounted flexibly.

The aerohydrodynamic part of the head is known as the slipper; it is designed to provide lift from the boundary layer which changes rapidly with changes in flying height. It is not initially obvious that the difficulty with disk heads is not making them fly, but making them fly close enough to the disk surface. The boundary layer travelling at the disk surface has the same speed as the disk, but as height increases, it slows down due to drag from the surrounding air. As the lift is a function of relative air speed, the closer the slipper comes to the disk, the greater the lift will be.

The slipper is therefore mounted at the end of a rigid cantilever sprung towards the medium. The force with which the head is pressed towards the disk by the spring is equal to the lift at the designed flying height.

Because of the spring, the head may rise and fall over small warps in the disk. It would be virtually impossible to manufacture disks flat enough to dispensed with this feature. As the slipper negotiates a warp it will pitch and roll in addition to rising and falling, but it must be prevented from yawing, as this would cause an azimuth error. Downthrust is applied to the aerodynamic center by a spherical thrust button, and the required degrees of freedom are supplied by a thin flexible gimbal. The slipper has to bleed away surplus air in order to approach close enough to the disk, and holes or grooves are usually provided for this purpose in the same way that pinch rollers on some tape decks have grooves to prevent tape slip.

In exchangeable-pack drives, there will be a ramp on the side of the cantilever which engages a fixed block when the heads are retracted in order to lift them away from the disk surface.

5. Reading and writing

FIG. 5 shows how disk heads are made. The magnetic circuit of disk heads was originally assembled from discrete magnetic elements. As the gap and flying height became smaller to increase linear recording density, the slipper was made from ferrite, and became part of the magnetic circuit. This was completed by a small C-shaped ferrite piece which carried the coil. In thin-film heads, the magnetic circuit and coil are both formed by deposition on a substrate which becomes the rear of the slipper.

FIG. 5 (a) Winchester head construction showing large air bleed grooves.

(b) Close-up of slipper showing magnetic circuit on trailing edge. (c)

Thin-film head is fabricated on the end of the slipper using microcircuit

technology.

In a moving-head device it is not practicable to position separate erase, record and playback heads accurately. Erase is by overwriting, and reading and writing are carried out by the same head. The presence of the air film causes severe separation loss, and peak shift distortion is a major problem. The flying height of the head varies with the radius of the disk track, and it is difficult to provide accurate equalization of the replay channel because of this. The write current is often controlled as a function of track radius so that the changing reluctance of the air gap does not change the resulting record flux. Automatic gain control (AGC) is used on replay to compensate for changes in signal amplitude from the head.

Equalization may be used on recording in the form of pre-compensation, which moves recorded transitions in such a way as to oppose the effects of peak shift in addition to any replay equalization used. This was discussed in Section 6, which also introduced digital channel coding.

Early disks used FM coding, which was easy to decode but had a poor density ratio. The invention of MFM revolutionized hard disks, and was at one time universal. Further progress led to run-length-limited codes such as 2/3 and 2/7 which had a high density ratio without sacrificing the large jitter window necessary to reject peak-shift distortion. Partial response is also suited to disks, but is not yet in common use.

FIG. 6 Representative head matrix.

Typical drives have several heads, but with the exception of special purpose parallel-transfer machines for digital video or instrumentation work, only one head will be active at any one time, which means that the read and write circuitry can be shared between the heads. FIG. 6 shows that in one approach the center-tapped heads are isolated by connecting the center tap to a negative voltage, which reverse-biases the matrix diodes. The center tap of the selected head is made positive. When reading, a small current flows through both halves of the head winding, as the diodes are forward-biased. Opposing currents in the head cancel, but read signals due to transitions on the medium can pass through the forward-biased diodes to become differential signals on the matrix bus.

During writing, the current from the write generator passes alternately through the two halves of the head coil. Further isolation is necessary to prevent the write-current-induced voltages from destroying the read preamplifier input. Alternatively, FET analog switches may be used for head selection.

The read channel usually incorporates AGC, which will be overridden by the control logic between data blocks in order to search for address marks, which are short unmodulated areas of track. As a block preamble is entered, the AGC will be enabled to allow a rapid gain adjustment.

The high bit rates of disk drives, due to the speed of the medium, mean that peak detection in the replay channel is usually by differentiation. The detected peaks are then fed to the data separator.

6. Moving the heads

The servo system required to move the heads rapidly between tracks, and yet hold them in place accurately for data transfer, is a fascinating and complex piece of engineering.

In exchangeable pack drives, the disk positioner moves on a straight axis which passes through the spindle. The head carriage will usually have preloaded ball races which run on rails mounted on the bed of the machine, although some drives use plain sintered bushes sliding on polished rods.

Motive power on early disk drives was hydraulic, but this soon gave way to moving-coil drive, because of the small moving mass which this technique permits. Another possibility is a coarse-threaded shaft or leadscrew which engages with a nut on the carriage. In very low-cost drives, the motor will be a stepping motor, and the positions of the tracks will be determined by the natural detents of the stepping motor. This has an advantage for portable drives, because a stepping motor will remain detented without power whereas moving-coil actuators require power to stay on track.

When a drive is track-following, it is said to be detented, in fine mode or in linear mode depending on the manufacturer. When a drive is seeking from one track to another, it can be described as being in coarse mode or velocity mode. These are the two major operating modes of the servo.

With the exception of stepping-motor-driven carriages, the servo system needs positional feedback from a transducer of some kind. The purpose of the transducer will be one or more of the following:

1. To count the number of cylinders crossed during a seek.

2. To generate a signal proportional to carriage velocity.

3. To generate a position error proportional to the distance from the center of the desired track.

Sometimes the same transducer is used for all of these, and so transducers are best classified by their operating principle rather than by their function in a particular drive.

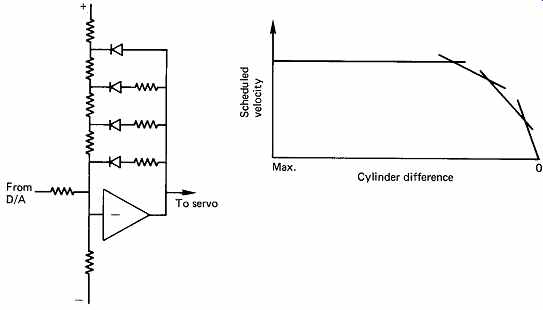

FIG. 7 Control of carriage velocity by cylinder difference. The cylinder

difference is loaded into the difference counter A. A digital-to-analog

convertor generates an analog voltage from the cylinder difference, known

as the scheduled velocity. This is compared with the actual velocity from

the transducer B in order to generate the velocity error which drives the

servo amplifier C.

The simplest transducer is the magnetic moving-coil type, with its complementary equivalent, the moving-magnet type. Both generate a voltage proportional to velocity, and can give no positional information, but no precise alignment other than a working clearance is necessary.

These devices are usually called tachos and should not be confused with burritos.

Optical transducers have also been used. These consist of gratings, one fixed on the machine base, and one on the carriage. The relative position of the two controls the amount of light which can shine through onto a sensor.

FIG. 8 In the simple arrangement in (a) the dissipation in the positioner

is continuous, causing a heating problem. The effect of limiting the scheduled

velocity above a certain cylinder difference is apparent in (b) where heavy

positioner current only flows during acceleration and deceleration. During

the plateau of the velocity profile, only enough current to overcome friction

is necessary. The curvature of the acceleration slope is due to the back

EMF of the positioner motor.

7. Controlling a seek

A seek is a process where the positioner moves from one cylinder to another. The speed with which a seek can be completed is a major factor in determining the access time of the drive. The main parameter controlling the carriage during a seek is the cylinder difference, which is obtained by subtracting the current cylinder address from the desired cylinder address. The cylinder difference will be a signed binary number representing the number of cylinders to be crossed to reach the target, direction being indicated by the sign. The cylinder difference is loaded into a counter which is decremented each time a cylinder is crossed. The counter drives a DAC which generates an analog voltage proportional to the cylinder difference. As FIG. 7 shows, this voltage, known as the scheduled velocity, is compared with the output of the carriage-velocity tacho. Any difference between the two results in a velocity error which drives the carriage to cancel the error. As the carriage approaches the target cylinder, the cylinder difference becomes smaller, with the result that the run-in to the target is critically damped to eliminate overshoot.

FIG. 8(a) shows graphs of scheduled velocity, actual velocity and motor current with respect to cylinder difference during a seek. In the first half of the seek, the actual velocity is less than the scheduled velocity, causing a large velocity error which saturates the amplifier and provides maximum carriage acceleration. In the second half of the graphs, the scheduled velocity is falling below the actual velocity, generating a negative velocity error which drives a reverse current through the motor to slow the carriage down. The scheduled deceleration slope can clearly not be steeper than the saturated acceleration slope. Areas A and B on the graph will be about equal, as the kinetic energy put into the carriage has to be taken out. The current through the motor is continuous, and would result in a heating problem, so to counter this, the DAC is made non linear so that above a certain cylinder difference no increase in scheduled velocity will occur. This results in the graph of FIG. 8(b). The actual velocity graph is called a velocity profile. It consists of three regions: acceleration, where the system is saturated; a constant velocity plateau, where the only power needed is to overcome friction; and the scheduled run-in to the desired cylinder. Dissipation is only significant in the first and last regions.

A consequence of the critically damped run-in to the target cylinder is that short seeks are slow. Sometimes further non-linearity is introduced into the velocity scheduler to speed up short seeks. The velocity profile becomes a piecewise linear approximation to a curve by using non-linear feedback. FIG. 9 shows the principle of an early analog shaper or profile generator. Later machines compute the curve in microprocessor software or use a PROM look-up table.

In small disk drives the amplifier may be linear in all modes of operation, resembling an audio power amplifier. Larger units may employ pulse-width-modulated drive to reduce dissipation, or even switched-mode amplifiers with inductive flywheel circuits. These switching systems can generate appreciable electromagnetic radiation, but this is of no consequence as they are only active during a seek. In track following mode, the amplifier reverts to linear mode; hence the use of the term linear to mean track-following mode.

The input of the servo amplifier normally has a number of analog switches which select the appropriate signals according to the mode of the servo. As the output of the position transducer is a triangle or sine wave, the sense of the position feedback has to be inverted on odd numbered cylinders, to allow detenting on the negative slope. Sometimes a separate transducer is used for head retraction only. A typical system is shown in FIG. 10.

FIG. 9 The use of voltage-dependent feedback around an operational

amplifier permits a piecewise linear approximation to a curved velocity

profile. This has the effect of speeding up short seeks without causing

a dissipation problem on long seeks. The circuit is referred to as a shaper.

FIG. 10 A typical servo amplifier input stage. In velocity mode the shaper

and the velocity transducer drive the error amp. In track-following mode

the position error is the only input.

8. Rotation

The rotation subsystems of disk drives will now be covered. The track following accuracy of a drive positioner will be impaired if there is bearing run-out, and so the spindle bearings are made to a high degree of precision. On early drives, squirrel-cage induction motors were used, driving the spindle through a belt. As recording density has increased, the size of drives has come down, and today brushless DC motors with integral speed control are universal.

In order to control reading and writing, the drive control circuitry needs to know which cylinder the heads are on, and which sector is currently under the head. Sector information in early drives was obtained from a sensor which detects slots cut in the hub of the disk. These can be optical, variable reluctance or eddy-current devices. Pulses from the transducer increment the sector counter, which is reset by a double slot once per revolution. The desired sector address is loaded into a register, which is compared with the sector counter. When the two match, the desired sector has been found. This process is referred to as a search, and usually takes place after a seek. Having found the correct physical place on the disk, the next step is to read the header associated with the data block to confirm that the disk address contained there is the same as the desired address.

Rotation of a disk pack at speed results in heat build-up through air resistance. This heat must be carried away. A further important factor with exchangeable pack drives is to keep the disk area free from contaminants which might lodge between the head and the disk and cause the destructive phenomenon known as a head crash, where debris builds up on the head until it ploughs the disk surface.

9. Servo-surface disks

One of the major problems to be overcome in the development of high density disk drives was that of keeping the heads on track despite changes of temperature. The very narrow tracks used in digital recording have similar dimensions to the amount a disk will expand as it warms up.

The cantilevers and the drive base all expand and contract, conspiring with thermal drift in the cylinder transducer to limit track pitch. The breakthrough in disk density came with the introduction of the servo surface drive. The position error in a servo-surface drive is derived from a head reading the disk itself. This virtually eliminates thermal effects on head positioning and allows great increases in storage density.

In a multiplatter drive, one surface of the pack holds servo information which is read by the servo head. In a ten-platter pack this means that 5 per cent of the medium area is lost, but this is unimportant since the increase in density allowed is enormous. Using one side of a single platter cartridge for servo information would be unacceptable as it represents 50 per cent of the medium area, so in this case the servo information can be interleaved with sectors on the data surfaces. This is known as an embedded-servo technique. These two approaches are contrasted in FIG. 11.

The servo surface is written at the time of disk pack manufacture, and the disk drive can only read it. Writing the servo surface has nothing to do with disk formatting, which affects the data storage areas only.

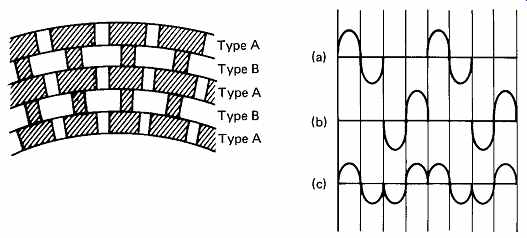

The key to the operation of the servo surface is the special magnetic pattern recorded on it. In a typical servo surface, recorded pairs of transitions, known as dibits, are separated by a space. FIG. 12 shows that there are two kinds of track. On an A track, the first transition of the pair will cause a positive pulse on reading, whereas on a B track, the first pulse will be negative. In addition the A-track dibits are shifted by one half cycle with respect to the B-track dibits. The width of the magnetic circuit in the servo head is equal to the width of a servo track. During track following, the correct position for the servo head is with half of each type of track beneath it. The read/write heads will then be centered on their respective data tracks. FIG. 13 illustrates this relationship.

FIG. 11 In a multiplatter disk pack, one surface is dedicated to

servo information.

In a single platter, the servo information is embedded in the data on the same surfaces.

FIG. 12 The servo surface is divided into two types of track, A and

B, which are out of phase by 180° and are recorded with reverse polarity

with respect to one another.

Waveform (a) results when the servo head is entirely above a type A track, and waveform (b) results from reading solely a type B track. When the servo head is correctly positioned with one-half of its magnetic circuit over each track, waveform (c) results.

FIG. 13 When the servo head is straddling two servo tracks, the data

heads are correctly aligned with their respective tracks.

The amplitude of dibits from A tracks with respect to the amplitude of dibits from B tracks depends on the relative areas of the servo head which are exposed to the respective tracks. As the servo head has only one magnetic circuit, it will generate a composite signal whose components will change differentially as the position of the servo head changes.

FIG. 14 shows several composite waveforms obtained at different positions of the servo head. The composite waveform is processed by using the first positive and negative pulses to generate a clock. From this clock are derived sampling signals which permit only the second positive and second negative pulses to pass. The resultant waveform has a DC component which after filtering gives a voltage proportional to the distance from the center of the data tracks. The position error reaches a maximum when the servo head is entirely above one type of servo track, and further movement causes it to fall. The next time the position error falls to zero will be at the centerline of the adjacent cylinder.

FIG. 14 Waveforms resulting from several positions of the servo head

with respect to the disk. At (a) and (b) are the two components of the

waveforms, whose relative amplitudes are controlled by the relative areas

of the servo head exposed to the two types of servo track. Because the

servo head has only one magnetic circuit, these waveforms are not observed

in practice, but are summed together, resulting in the composite waveforms

shown at (c). By comparing the magnitudes of the second positive and second

negative peaks in the composite waveforms, a position error signal is generated,

as shown at (d).

Cylinders with even addresses (LSB = 0) will be those where the servo head is detented between an A track and a B track. Cylinders with odd addresses will be those where the head is between a B track and an A track. It can be seen from FIG. 14 that the sense of the position error becomes reversed on every other cylinder. Accordingly, an invertor has to be switched into the track-following feedback loop in order to detent on odd cylinders. This inversion is controlled by the LSB of the desired cylinder address supplied at the beginning of a seek, such that the sense of the feedback will be correct when the heads arrive at the target cylinder.

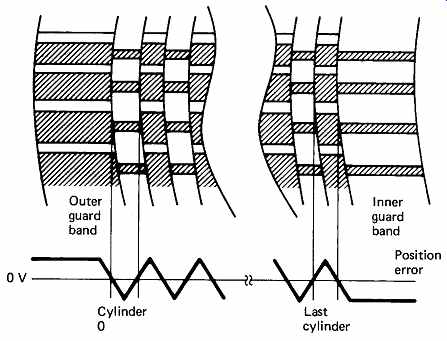

Seeking across the servo surface results in the position-error signal rising and falling in a sawtooth. This waveform can be used to count down the cylinder difference counter which controls the seek. As with any cyclic transducer there is the problem of finding the absolute position. This difficulty is overcome by making all servo tracks outside cylinder 0 type A, and all servo tracks inside the innermost cylinder type B. These areas of identical track are called guard bands, and FIG. 15 shows the relationship between the position error and the guard bands.

During a head load, the servo head generates a constant maximum positive position error in the outer guard band. This drives the carriage forward until the position error first falls to zero. This, by definition, is cylinder zero. Some drives, however, load by driving the heads across the surface until the inner guard band is found, and then perform a full length reverse seek to cylinder zero.

FIG. 15 The working area of the servo surface is defined by the inner

and outer guard bands, in which the position error reaches its maximum

value.

10. Soft sectoring

It has been seen that a position error and a cylinder count can be derived from the servo surface, eliminating the cylinder transducer. The carriage velocity could also be derived from the slope of the position error, but there would then be no velocity feedback in the guard bands or during retraction, and so some form of velocity transducer is still necessary.

As there are exactly the same number of dibits or tribits on every track, it is possible to describe the rotational position of the disk simply by counting them. All that is needed is a unique pattern of missing dibits once per revolution to act as an index point, and the sector transducer can also be eliminated.

Unlike the read-data circuits, the servo-head circuits are active during a seek as well as when track-following, and have to be protected against interference from switched-mode positioner drivers. The main problem is detecting index, where noise could cause a 'missing' dibit to be masked.

There are two solutions available: a preamplifier can be built into the servo head cantilever, or driver switching can be inhibited when index is expected.

The advantage of deriving the sector count from the servo surface is that the number of sectors on the disk can be varied. Any number of sectors can be accommodated by feeding the dibit-rate signal through a programmable divider, so the same disk and drive can be used in numerous different applications.

In a non-servo-surface disk, the write clock is usually derived from a crystal oscillator. As the disk speed can vary owing to supply fluctuations, a tolerance gap has to be left at the end of each block to cater for the highest anticipated speed, to prevent overrun into the next block on a write. In a servo-surface drive, the write clock is obtained by multiplying the dibit rate signal with a phase-locked loop. The write clock is then always proportional to disk speed, and recording density will be constant.

Most servo-surface drives have an offset facility, where a register written by the controller drives a DAC which injects a small voltage into the track following loop. The action of the servo is such that the heads move off track until the position error is equal and opposite to the injected voltage.

The position of the heads above the track can thus be program-controlled.

Offset is only employed on reading if it is suspected that the pack in the drive has been written by a different drive with non-standard alignment. A write function will cancel the offset.

11. Winchester technology

In order to offer extremely high capacity per spindle, which reduces the cost per bit, a disk drive must have very narrow tracks placed close together, and must use very short recorded wavelengths, which implies that the flying height of the heads must be small. The so-called Winchester technology is one approach to high storage density. The technology was developed by IBM, and the name came about because the model number of the development drive was the same as that of the famous rifle.

Reduction in flying height magnifies the problem of providing a contaminant-free environment. A conventional disk is well protected whilst inside the drive, but outside the drive the effects of contamination become intolerable.

In exchangeable-pack drives, there is a real limit to the track pitch that can be achieved because of the difficulty or cost of engineering head alignment mechanisms to make the necessary minute adjustments to give interchange compatibility.

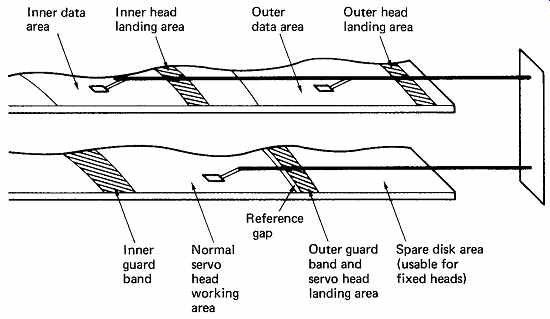

The essence of Winchester technology is that each disk pack has its own set of read/write and servo heads, with an integral positioner. The whole is protected by a dust-free enclosure, and the unit is referred to as a head disk assembly, or HDA.

As the HDA contains its own heads, compatibility problems do not exist, and no head alignment is necessary or provided for. It is thus possible to reduce track pitch considerably compared with exchangeable pack drives. The sealed environment ensures complete cleanliness which permits a reduction in flying height without loss of reliability, and hence leads to an increased linear density. If the rotational speed is maintained, this can also result in an increase in data transfer rate.

The HDA is completely sealed, but some have a small filtered port to equalize pressure. Into this sealed volume of air, the drive motor delivers the majority of its power output. The resulting heat is dissipated by fins on the HDA casing. Some HDAs are filled with helium which significantly reduces drag and heat build-up.

An exchangeable-pack drive must retract the heads to facilitate pack removal. With Winchester technology this is not necessary. An area of the disk surface is reserved as a landing strip for the heads. The disk surface is lubricated, and the heads are designed to withstand landing and take off without damage. Winchester heads have very large air-bleed grooves to allow low flying height with a much smaller downthrust from the cantilever, and so they exert less force on the disk surface during contact.

When the term parking is used in the context of Winchester technology, it refers to the positioning of the heads over the landing area.

Disk rotation must be started and stopped quickly to minimize the length of time the heads slide over the medium. A powerful motor will accelerate the pack quickly. Eddy-current braking cannot be used, since a power failure would allow the unbraked disk to stop only after a prolonged head-contact period. A failsafe mechanical brake is used, which is applied by a spring and released with a solenoid.

A major advantage of contact start/stop is that more than one head can be used on each surface if retraction is not needed. This leads to two gains: first, the travel of the positioner is reduced in proportion to the number of heads per surface, reducing access time; and, second, more data can be transferred at a given detented carriage position before a seek to the next cylinder becomes necessary. This increases the speed of long transfers. FIG. 16 illustrates the relationships of the heads in such a system.

FIG. 16 When more than one head is used per surface, the positioner

still only requires one servo head. This is often arranged to be equidistant

from the read/write heads for thermal stability.

12. Servo-surface Winchester drives

With contact start/stop, the servo head is always on the servo surface, and it can be used for all the transducer functions needed by the drive.

FIG. 17 To generate a velocity signal, the position error from the servo head

is differentiated and rectified.

FIG. 17 shows the position-error signal during a seek. The signal rises and falls as servo tracks are crossed, and the slope of the signal is proportional to positioner velocity. The position-error signal is differentiated and rectified to give a velocity feedback signal. Owing to the cyclic nature of the position-error signal, the velocity signal derived from it has troughs where the derivative becomes zero at the peaks. These cannot be filtered out, as the signal is in a servo loop, and the filter would introduce an additional lag. The troughs would, however, be interpreted by the servo driver as massive momentary velocity errors which might overload the amplifier. The solution which can be adopted is to use a signal obtained by integrating the positioner-motor current which is selected when there is a trough in the differentiated position-error signal.

In order to make velocity feedback available over the entire servo surface, the conventional guard-band approach cannot be used since it results in steady position errors in the guard bands. In contact start/stop drives, the servo head must be capable of detenting in a guard band for the purpose of landing on shutdown.

FIG. 18 This type of servo surface pattern has a second pulse which

may be omitted to act as a data bit. This is used to detect the guard bands

and index.

FIG. 19 (a) Conventional guard band. (b) Winchester guard band, showing

the plateau in the position error, known as the reference gap, which is

used to locate cylinder 0.

A modification to the usual servo surface is used in Winchester drives, one implementation of which is shown in FIG. 18, where it will be seen that there are extra transitions, identical in both types of track, along with the familiar dibits. The repeating set of transitions is known as a frame, in which the first dibit is used for synchronization, and a phase locked oscillator is made to run at a multiple of the sync signal rate. The PLO is used as a reference for the write clock, as well as to generate sampling pulses to extract a position error from the composite waveform and to provide a window for the second dibit in the frame, which may or may not be present. Each frame thus contains one data bit, and successive frames are read to build up a pattern in a shift register. The parallel output of the shift register is examined by a decoder which recognizes a number of unique patterns. In the guard bands, the decoder will repeatedly recognize the guard band code as the disk revolves. An index is generated in the same way, by recognizing a different pattern. In a contact start/stop drive, the frequency of index detection is used to monitor pack speed in order to dispense with a separate transducer. This does mean, however, that it must be possible to detect index everywhere, and for this reason, index is still recorded in the guard bands by replacing the guard-band code with index code once per revolution.

A consequence of deriving velocity information from the servo surface is that the location of cylinder zero is made more difficult, as there is no longer a continuous maximum position error in the guard band. A common solution is to adopt a much smaller area of continuous position error known as a reference gap; this is typically three servo tracks wide.

In the reference gap and for several tracks outside it, there is an unique reference gap code recorded in the frame-data bits. FIG. 19 shows the position error which is generated as the positioner crosses this area of the disk, and shows the plateau in the position-error signal due to the reference gap. During head loading, which in this context means positioning from the parking area to cylinder zero, the heads move slowly inwards. When the reference code is detected, positioner velocity is reduced, and the position error is sampled. When successive position error samples are the same, the head must be on the position-error plateau, and if the servo is put into track-following mode, it will automatically detent on cylinder zero, since this is the first place that the position error falls to zero.

13. Rotary positioners

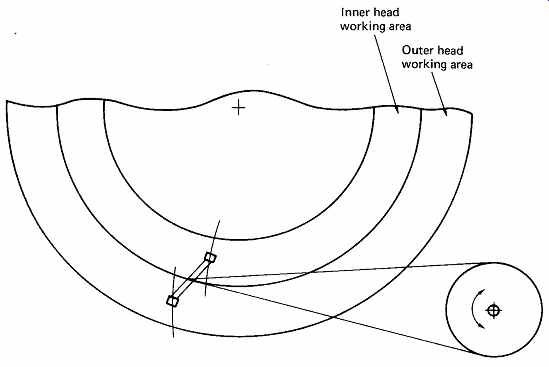

FIG. 20 A rotary positioner with two heads per surface. The tolerances

involved in the spacing between the heads and the axis of rotation mean

that each arm records data in a unique position. Those data can only be

read back by the same heads, which rules out the use of a rotary positioner

in exchangeable-pack drives. In a head disk assembly the problem of compatibility

does not arise.

FIG. 21 Head disk assembly with a rotary positioner. The adoption

of this technique allows a very compact structure.

FIG. 20 shows that rotary positioners are feasible in Winchester drives; they cannot be used in exchangeable-pack drives because of interchange problems. There are some advantages to a rotary positioner. It can be placed in the corner of a compact HDA allowing smaller overall size. The manufacturing cost will be less than a linear positioner because fewer bearings and precision bars are needed. Significantly, a rotary positioner can be made faster since its inertia is smaller. With a linear positioner all parts move at the same speed. In a rotary positioner, only the heads move at full speed, as the parts closer to the shaft must move more slowly. FIG. 21 shows a typical HDA with a rotary positioner.

The principle of many rotary positioners is exactly that of a moving-coil ammeter, where current is converted directly into torque. Alternatively various configurations of electric motor or stepping motor can be used with band or wire drive.

One disadvantage of rotary positioners is that there is a component of windage on the heads which tends to pull the positioner in towards the spindle. In linear positioners windage is at right angles to motion and can be neglected. Windage can be overcome in rotary positioners by feeding the current cylinder address to a ROM which sends a code to a DAC. This produces an offset voltage which is fed to the positioner driver to generate a torque which balances the windage whatever the position of the heads.

When extremely small track spacing is contemplated, it cannot be assumed that all the heads will track the servo head due to temperature gradients. In this case the embedded-servo approach must be used, where each head has its own alignment patterns. The servo surface is often retained in such drives to allow coarse positioning, velocity feedback and index and write-clock generation, in addition to locating the guard bands for landing the heads.

Winchester drives have been made with massive capacity, but the problem of backup is then magnified, and the general trend has been for the physical size of the drive to come down as the storage density increases in order to improve access time. Very small Winchester disk drives are now available which plug into standard integrated circuit sockets. These are competing with RAM for memory applications where non-volatility is important. cont.>>