JBL introduces The Titanium Series. To tell the truth.

For some loudspeaker manufacturers, the passing of the seasons is heralded by the passing of the speakers. Last year's glittering "technological triumph" is consigned to the dustbin to make way for this year's glittering "technological triumph." Buzzwords replace true breakthroughs, as the unwary music lover is promised space age answers to age old needs: Beautiful music, reliable equipment. Lately, the carrot being dangled in front of would-be loudspeaker purchasers is "digital ready" Enticing? Without a doubt. New? Assuredly not.

For more than forty years, JBL has persevered in the design and development of precision loudspeakers-loudspeakers capable of translating the fullest range of electro-acoustical impulses into the most accurate sound. In a word, JBL loudspeakers were "digital ready" long before digital was ready. This unwavering homage to accuracy, coupled with granite-like durability, has made JBL loudspeakers the overwhelming first choice among professional recording studios, recording engineers, and professional musicians, as well.

Why then the introduction of a new line of JBL loudspeakers? Because in our constant search for greater accuracy, greater neutrality, greater reliability, we have developed new techniques, new materials, new components, and new designs that afford a truly significant improvement, to satisfy the most demanding audiophile. The new Ti series is not another glittering "technological triumph." It is a true breakthrough.

Beginning with computer optimization of design and componentry, through to the unique new pure titanium dome high frequency transducer, the Ti series represents the finest JBL loudspeakers ever made, and the new benchmark for musical accuracy. Titanium tells the truth.

1,000 Gs ACCELERATION

The basic notes for most music and voice occur in the middle and lower frequencies.

And yet, it is the higher frequencies that provide the character that separates, let us say, a high C on a piano from a high C on an oboe. The fundamental character of musical instruments is often defined by these higher, sometimes unheard, frequencies. As a result, the reproduction of the music from a particular instrument is often determined by the high frequency element in a speaker system. In this regard, the JBL Ti series is without peer.

To reproduce these higher frequencies accurately, a driver (in this case. a one-inch dome) must travel over exceedingly small distances at enormously fast speeds. That rapid back and forth movement creates forces as great as 1,000 Gs, a thousand times the force of gravity.

The driver must be light enough in its mass to respond instantly to musical transients. Yet it must be strong enough to endure crushing force. For this purpose, JBL has selected titanium.

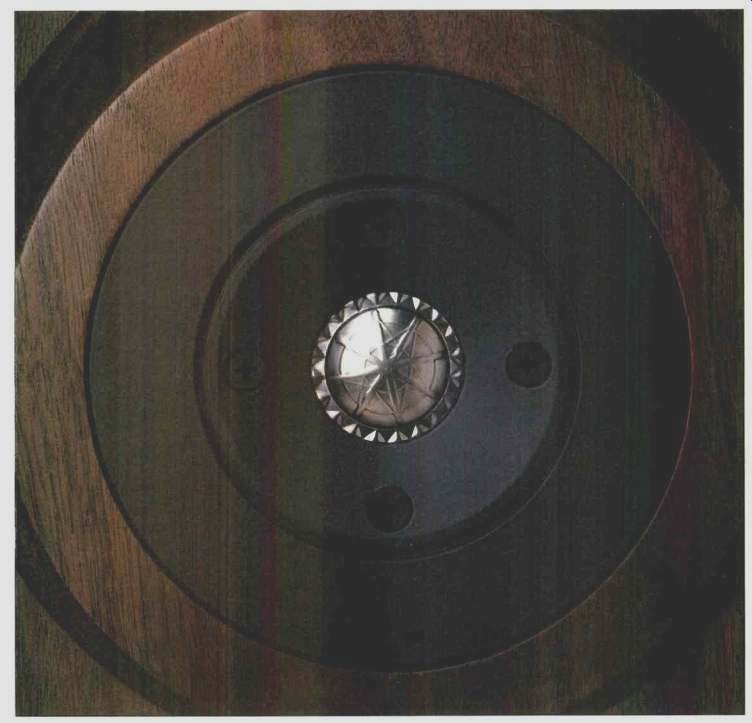

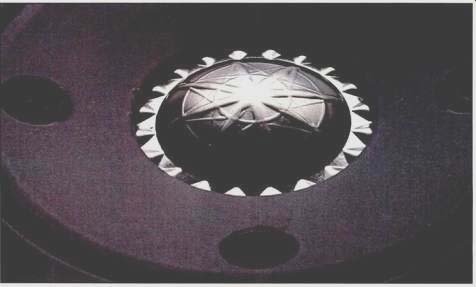

Titanium has an extremely high strength-to-weight ratio. But until recently, it could not be fabricated thin enough, light enough, to produce a dome. JBL solved that by developing a unique process that swirls compressed nitrogen gas against a film of titanium, only 25 microns thick-thinner than a human hair. The process forms the dome perfectly and without causing stress fractures.

Being that thin, however, made the dome subject to deformation. And so we solved that problem by creating an intricate network of ribs modeled directly into the dome. This ribbing increases the structural rigidity without increasing the thickness. And so, a 25 micron-thick dome can be as strong as one that is 250 microns thick.

The final dome is capable of responding faster, more precisely, and more often with no material fatigue. The sound is unstrained, clear, clean.

A LESSON LEARNED FROM ORIGAMI

A further inspection of the new titanium dome driver reveals not only a network of ribbing embossed into the dome, but also a pattern of diamond shaped creases or folds surrounding the dome. Although these are admittedly attractive, the specific designs are by no means a decoration.

Every driver has its resonant frequencies. In general, the resonant frequencies of the dome itself are different from the resonant frequencies of the surround, but both can be excited by the input signal to produce uncontrolled response. What is heard is tonal distortion and strain. The objective is to control the response of these resonant frequencies.

Typically other manufacturers have dealt with the problem by using a soft dome and half roll surround. The resonances are controlled by high internal damping, but the sacrifice is often a softening or blurring of transient detail.

By using a hard metal dome and surround, we have retained the transparent transient detail. And by the pattern of ribbing in the dome that adds strength tenfold, we have also shifted the resonant frequencies of the dome to well above the 20,000 Hz limit of audibility. The dome pattern and the diamond pattern on the surround were conceptualized at JBL but owe their existence to the lessons learned from the Japanese art of paper folding--Origami. By creasing or folding the metal in various ways, the weight remains unchanged, but the stiffness can be concentrated rather than spread evenly. This in turn permits independent control of first and second resonances. The first is now below the operating range of the dome, and the second is shifted to a point below 30.000 Hz.

The result for music lovers is a high frequency response that is flat to 27000 Hz and absolutely smooth, effortless, and neutral in sound character through the critical range of 3,000 to 20,000 Hz.

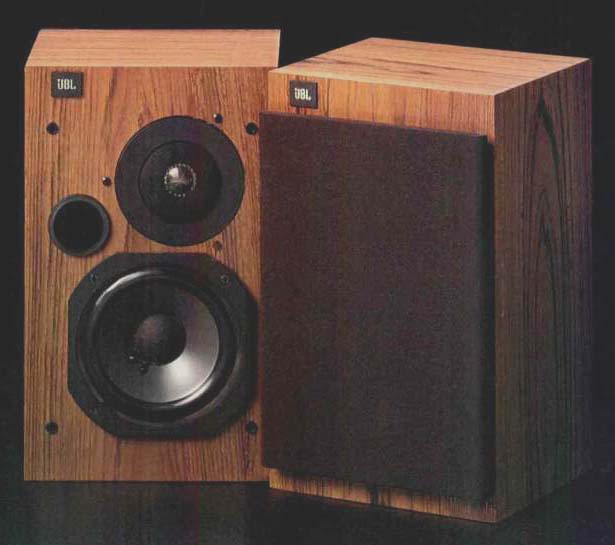

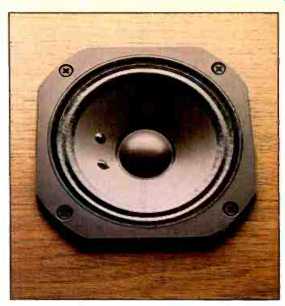

18 Ti

Two-way system designed for optimum performance when placed on bookshelf. When free-standing in a room and placed on speaker pedestals, the effect of bass rolloff; is ideal for use with subwoofer. Features 1 inch HF diver. 6 1/2 inch LF driver, 5-way gold binding posts, floating grilles, and oiled teak finish.

TITANIUM, POLYPROPYLENE, AND AOUAPLAS

While titanium has proven to be the most satisfactory material for reproducing the higher frequencies, at higher power levels, without fear of break-up, the engineers at JBL examined a wide spectrum of other materials for use in the mid- and low frequency transducers in all the new Ti loudspeaker systems. And as a consequence, you will note that each of the various individual transducers makes use of a separate material best suited to the intended function.

The new midrange unit has been in development some years now, and the final cone material selected is specially derived polypropylene-surprisingly for some who believed that JBL was reluctant to use this material. In truth, we have long recognized that polypropylene provides high internal damping for smooth response, but this virtue was far outweighed by the fact that commonly used polypropylene offered poor stiffness-to mass ratio. This resulted in a softened impulse response, and a tendency to compress or distort under high power input.

The grey polymer cone used in the Ti series midrange transducer employs a secondary filler material that markedly improves stiffness, yet retains the same internal damping effect. The result is a midrange that is smooth, uncolored, excellent on transients, and resistant to the distorting effects of high power. Accurate and uncommonly strong.

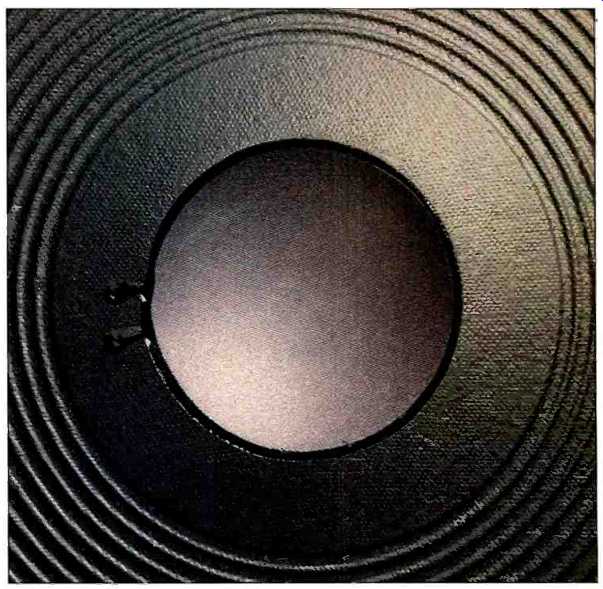

The lower frequencies are handled by transducers whose cone material is constructed of fiber and aquaplas laminate.

This composite is not new to JBL, but has been used successfully for the past several years in other JBL low-frequency drivers.

The material has proven to have the optimal combination of internal damping and strength through the assigned frequency range. With excursions as great as 5/8" these low frequency drivers exhibit linearity to within 10%, and the smoothest natural high-frequency roll-off of any such drivers we know.

By this selective use of materials to satisfy the frequency ranges and engineering objectives, we have been able to generate the most accurate signals, with utmost reliability.

120 Ti

Three-way system supplied in mirror imaged

pairs and designed for optimum performance when free-standing in a room

and placed on speaker pedestals. Features 1 inch HF driver. 5 inch midrange.

12 inch LF driver. 2-position switch level controls (fixed attenuators

introduce no distortion) for midrange and LF drivers. 5-way gold binding

posts, floating grilles, and oiled teak finish.

THE SYSTEM IS GREATER THAN THE SUM OF ITS PARTS

Under test conditions, and within the precise limits of their assigned frequency ranges, each of the Ti series transducers is impeccable. But it is the critical function of the dividing network to distribute the various frequencies to those respective drivers, and in so doing "orchestrate" the interaction that changes exceptional components into exceptional music.

The dividing networks of the Ti series loudspeakers are multi-element and quite complex, making use of conjugate circuits that cause the varying impedances of the separate transducers to appear relatively smooth, for better matching and smoother transitions.

Another unusual aspect is the use of bypass capacitors, a technique commonly seen only in advanced electronics design.

These smaller value elements correct for some of the nonlinear effects which exist in the larger network capacitors.

The resulting systems afford the listener smooth response and effortless transitions from the deepest pipe organ fundamentals to the clear open air at 27,000 Hz.

A CABINET IS NOT A BOX

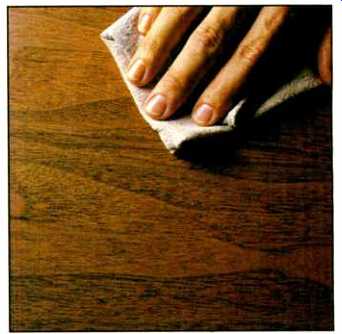

As distinguished as the sound is, so too the cabinetry of the Ti series. Designed to satisfy both sonic and esthetic criteria, the cabinets represent the combined efforts of computer optimization, old world craftsmanship, and critical listening.

Each of the loudspeaker systems is contained within space and materials that are in themselves an essential component. The inner size is determined by component needs and the computer models. The space is then surrounded, if you will, by a material that is sufficiently rigid not to add any of its own harmonics. In this case, we use 3/4 inch extra-high-density compressed wood, internally cross-braced.

The components are carefully located on the front baffle of the cabinet to minimize distortion, aid in dispersion, and enhance stereo imaging.

Two more characteristic JBL features of the Ti series are the fine carpentry

and cabinetry skills that are apparent. Carefully selected and matched

veneers are skillfully applied to front, sides and top for an appearance

that is both classic and contemporary and more than holds its own alongside

the finest furniture likely to be found in anyone's listening room.

The final touch is the floating grille for less obstruction and interference,

better dispersion.

240 Ti

Three-way system supplied in mirror imaged pairs, and designed for optimum

performance when free-standing away from walls and corners Low frequency

driver is precise height from floor to give best balanced bass response

Features 1 inch HF driver. 5 inch midrange. 14 inch LF driver. 2-position

switch level controls (fixed attenuators introduce no distortion) for

midrange and HF drivers. 5-way gold binding posts, floating grilles,

and Oiled teak finish

OVERBUILDING IS A JBL WAY OF LIFE

Wherever you choose to look at any or the Ti series loudspeakers, internally or externally, you will see ample evidence of JBL's continuing commitment to utmost reliability. Without this, there can be no confidence in the accuracy and musical purity of any loudspeakers.

On the 44 acres of college-like setting in Northridge, California, a team of computer specialists, transducer engineers, structural engineers, model makers, cabinet makers, tool and die makers, assemblers, every one of them, is imbued with one overriding concern. Building the best. Nothing less.

The selection of titanium for the high frequency drivers spurred a search for new methods to mold it, new techniques for strengthening it to be sure it performed and performed and performed.

The selection of polypropylene, long after other manufacturers had endorsed the use of less reliable composites, testifies not to caution, but to conviction.

The low frequency drivers employ JBL's unique SFG (Symmetrical Field Geometry) magnetic structure, which reduces second harmonic distortion below 100 Hz. The magnets themselves are substantially heavier than those typically found in loudspeakers.

These drivers also have voice coils formed from flat wire wound on edge, a design which packs more wire into the voice coil gap for better transient response and improved power handling.

Internal connections in the Ti series are made with thick, heavy gauge audiophile cable, instead of conventional thin wire, and all connections are hard wired. This construction contributes to better current transfer and lower distortion. Additionally, there are no L-pads in the signal path. Mid and high-frequency level adjustments in the three-way models are made via fixed attenuators, switch-selectable. In the 250Ti, the fixed attenuators are selected through bus bars.

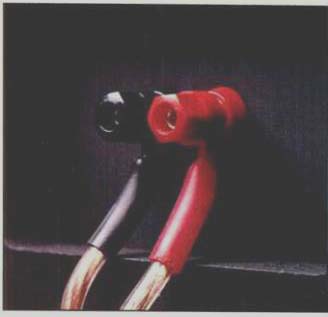

The external connections to the Ti series are made through five-way

gold binding posts, for multiple options and cleaner linkage.

Even the back of the cabinet, finished in black, shows the same high degree of craftsmanship as the other surfaces. Perhaps not really necessary, but a reassuring sign that all aspects are built with care.

WHEN DO WE STOP TESTING?

The search for musical truth is ongoing with musicians as well as for JBL. But for the moment at least, and for the foreseeable future, the Ti series represents the most ambitious of the JBL achievements and the most accurate loudspeakers available to the most demanding audiophiles and music lovers.

The actual testing for this series began years ago, with the search for new materials and new designs that could better meet the needs of recording studio professionals. In studios, every detail, every note, every nuance of the recorded music must be played back at high volume in an endless examination by recording engineers. Before the music is finally committed to tape master and then records, cassettes, or digital compact discs, it must be heard clearly and precisely. The loudspeakers must be not only precise, but also unvarying in that precision.

One of the first steps was the development of the titanium compression driver by JBL. Further refinements to various components occurred in the ensuing years. In fact, the primary elements of the Ti series were tested in field and laboratory situations for more than five years.

Those qualities of uncanny accuracy, virtually non-existent distortion, smooth response, and wide dynamic range, which took years to develop, can be enjoyed now. And because the Ti series is made by JBL, you can be assured that those qualities will remain pleasing for years to come. And that is the final test.

250 Ti

Finest expression of JBL product philosophy, this is a no compromise

four-way system supplied in mirror imaged pairs Designed for optimum

performance when free-standing away from walls and corners Lo frequency

driver is precise height from floor to give best balanced bass response

Special pyramidal enclosure provides optimum baffle width for each driver

to minimize diffraction effects, further improve imaging Features 1 inch

HF driver, 5 inch midrange. 8 inch lower midrange. 14 inch LF driver,

special level control for HF and midrange and lower midrange drivers

incorporate fixed attenuators in the form of bus bars. 5-way gold binding

posts, floating grilles, and oiled teak finish.

JBL Titanium Series Loudspeakers Are Available At Selected Audio Salons.

JBL / harman international. 8500 Balboa Blvd. P.O. Box 2200. Northridge, California 91329, USA. Telephone: (818) 893-8411

(Adapted from Audio magazine, Aug. 1985)

Also see:

JBL Ti Series Loudspeakers (Auricle, Aug. 1985)

Link | --JBL L150 speaker system (ad, Aug. 1979)

JBL L166 speaker system (ad, Dec. 1976)

JBL -- SFG technology (ad, Mar. 1981)

= = = =