AES YOU LIKE IT

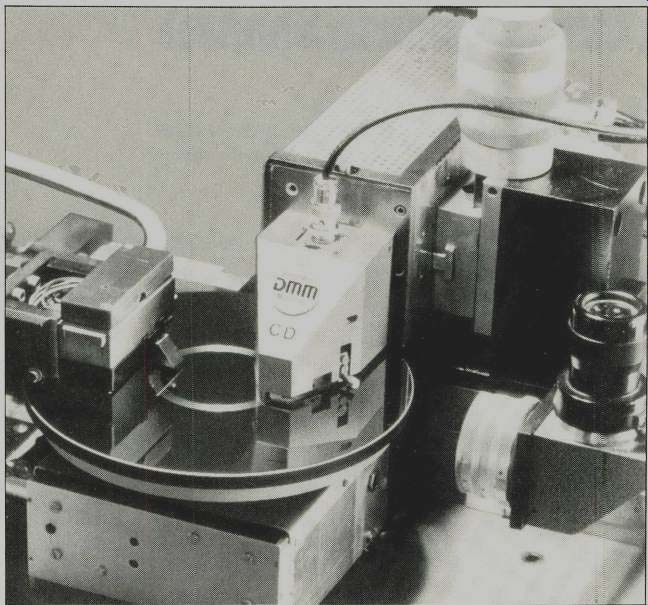

--------Master-embossing recorder used in Teldec's DMM-CD process

-------- A Teldec DMM-CD blank

After meeting elsewhere for several years, the Audio Engineering Society returned to Los Angeles for its 81st convention, November 12th through 16th. The ever-in creasing growth of professional audio necessitated two separate venues, the Los Angeles Hilton Hotel and the near by Los Angeles Convention Center.

The AES billed the convention as "The Digital/Analog Fusion: A Rainbow of Technology." A tour through the exhibits and the high quality and diversity of the technical papers soon confirmed that this slogan was most apt.

Although the convention showcased a number of important advances in audio technology, the indisputable star of this meeting was the Teldec Direct Metal Mastering process and its application to production of Compact Discs, which I described in the December 1986 issue. The technical paper on the Teldec CD system was presented by its developer, Dr. Horst Redlich, before a standing-room-only crowd. I had a chance to talk to Dr. Redlich and discuss several aspects of the DMM-CD process. In addition to what I reported in December, I elicited the following facts:

The DMM-CD Embossing Recorder uses a piezo-ceramic transducer element to drive a diamond embossing stylus which is shaped like the bow of a ship. In the CD master, a glass disc is used as the substrate. The glass disc is coated with a proprietary material which forms a separation layer only a few nanometers thick; this allows the glass disc to be removed from the met al part and reused. Upon this separation layer an evaporation process de posits approximately 300 nanometers of amorphous copper. After the copper surface has been embossed with the pits of the recording, it is electrolytically plated with a few micrometers of a precious metal, and then further plated with nickel to a thickness of 0.25 mm.

Removing the glass disc from this met al part leaves a metal "sandwich," with the recording completely protected between the copper and precious-metal layers. Obviously, this sandwich is a safe medium for storage and for shipping.

The next step in the DMM-CD process is the release of the electroplate from the sandwich. This is done by removing the separation layer and the copper layer in a ferric chloride solution, leaving the precious-metal surface on the nickel backing. Using the precious-metal part as a "father," mothers and stampers can be pre pared by electroplating-like the fathers, mothers, and stampers used in conventional record pressing. It is also possible to use this metal part directly as a stamper. However, if this is contemplated, during the sandwich pro cess rhodium should be used as the precious metal, as its hardness makes it more suitable as a stamper. Incredibly, by using the master as a stamper, it is possible to proceed from the digital tape master to the CD pressing stage within two hours! Teldec stressed that no clean room is necessary in their system and that costs are only one-third those of the usual laser photo-optical CD process. They expect to begin deliveries of DMM-CD equipment by this June.

Everywhere one looked in the exhibit area, one encountered glittering new jewels of advanced audio technology. I could fill six columns just describing these new products, but a highly selective sampling will have to suffice.

Over the past several years, you may recall, I have lamented that no manufacturer seemed to be addressing the need for a portable digital mixer that could be used for location re cording. I am happy to say that this problem has been neatly resolved with one of the most exciting new products at the convention, Yamaha's DMP-7 digital mixing processor. It measures just 18 7/8 in. W x 16 7/8 in. H x 4 7/8 in. D and weighs in at 22 pounds. The DMP 7 has A/D and D/A converters, with 16-bit quantization and a 44.1-kHz sampling rate. The processor has eight in puts and a stereo output, plus an auxiliary stereo output. The slide-type faders are motor-driven. There are three effects systems, handling such things as reverb, delay, echo, and flanging. A three-band parametric equalizer is also provided. All the effects and equalization settings can be stored in 32 memories, and the DMP-7 can be controlled from a MIDI (Musical Instrument Digital Interface). An LCD display shows the status of each channel. Yamaha states that the DMP-7 will be available in June for under $4,000, an amazingly low price for such a de vice. This could be a real boon for a great many studios. I would be particularly interested in it for location recording of classical music. About the only additional feature one might want is a means of powering it from a battery pack, permitting even more versatility.

Sony showed a prototype of a professional R-DAT portable recorder. The unit can be a.c. powered or will operate two hours on a built-in re chargeable battery. It has both 1610/1630 and AES/EBU digital interfaces. The unit also provides a 48-V phantom power supply for microphones. Maxi mum recording time is two hours on an R-DAT cassette, with 16-bit quantization, and a sampling rate of 44.1 or 48 kHz. Thus, the recorder will be suitable for mastering for CD. As is usual with R-DAT, no one at Sony would commit themselves to projected prices or de livery dates.

In fact, R-DAT was having tough sledding at the convention. The guest speaker at the awards banquet, Stan Cornyn, while admittedly a semi-official spokesman for the record manufacturers, was quite blunt in stating that "the record companies will never produce prerecorded R-DAT cassettes." Per haps Sony doesn't agree, for they gave a paper on high-speed duplication of R-DAT prerecorded cassettes (using a contact-printing process, with special high-coercivity metal mother tape and a new barium-ferrite copy tape). Al though the future of R-DAT seems a bit clouded at the moment, the idea of mating Sony's professional R-DAT recorder with the Yamaha DMP-7 is intriguing and attractive.

Sony exhibited other digital equipment of a more immediately practical nature-for example, their new PCM 3402, a two-speed DASH digital audio recorder. The unit operates at 7 1/2 and 15 ips. With 12 1/2-inch reels, 1 1/2 hours of recording is possible at 15 ips.

While razor-blade editing can be per formed, electronic editing is also possible. The machine operates at 16 bits, with selectable sampling frequencies of 44.056, 44.1, or 48 kHz. It is expected to sell for around $28,000.

Also new at Sony are the DFX-2400, a sampling-rate converter, and the K 1105, an eight-channel digital mixing system. Meant for heavy-duty studio work, the K-1105 is a much more elaborate unit than the Yamaha digital mixer and is much more expensive. Last, Sony showed the ultimate device for those who must have never-ending background music in their lives. This is the CD-006, a changer with a capacity of 60 Compact Discs, permitting one to select, in any order, from more than 1,000 cuts! It is all yours for about $3,500.

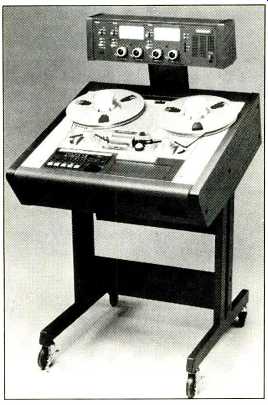

----------Studer A812 professional recorder

Studer caused quite a stir by introducing a new 24-track analog tape recorder, the A820, and quieted critics (as well as their tape noise) by offering the new Dolby SR recording system as an option. With the SR system, Studer is claiming a dynamic range of over 100 dB. The A820 incorporates many refinements and much automation, including simultaneous and automatic alignment of all 24 channels, and two digital memories for storing all the alignments for two different tape formulations. The A820 is expected to sell for $59,950 without Dolby SR. Studer also introduced a new quarter-inch analog tape recorder, the A812. This unit also incorporates many automated and microprocessor-controlled functions, including automatic tape alignment. Four tape speeds are standard, and up to 12 1/2-inch reels can be accommodated. The A812 is available now, at $9,950.

From dbx came an interesting proto type, the Professional Real-Time Analysis System, that can use music, as well as pink noise, to analyze frequency response. This will allow one to analyze the frequency response of a con cert sound system while the audience is present or to check the response of a broadcast station without taking it off the air. Using the standard 31-band, third-octave configuration, the unit has a high-resolution CRT for display, a built-in pink-noise generator, an output port for connection to a printer, and a menu-driven operating system. The company hopes it can market the system within a year, for less than $10,000.

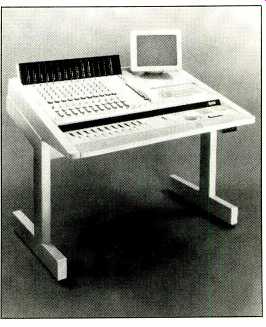

------- Lexicon's Opus work station

Lexicon created a lot of interest with its Opus unit, a random-access audio production system. The Opus can per form such functions as recording, non destructive editing, time alignment, mixing, panning, overdubbing, and signal processing, all in the digital do main. Opus offers up to eight hours of on-line random-access storage on magnetic hard disks. Up to eight events can be simultaneously recorded to or played back from the hard disks, in any combination. An optional write-once optical disc system provides archival storage and off-line re cording facilities. According to Lexicon, the first Opus units will be avail able this spring.

The Colossus four-channel digital recorder that created such a lot of interest at the New York AES convention a little more than a year ago continues to evolve. Colossus, from By the Numbers, uses a four-channel signal for mat, allowing four monophonic channels, two stereo pairs, or discrete four-channel. That signal can now be en coded on a laser videodisc, which can be played back on a videodisc player interfaced with the Colossus recorder. This system will be used to store and retrieve a very large library of digitally recorded sound effects now being prepared by Brad Miller of Mobile Fidelity Productions.

I would be remiss if I didn't mention some of the more interesting papers presented at this 81st AES convention. The redoubtable Stanley Lipshitz and John Vanderkooy gave everyone the lowdown on "Digital Dither" (AES Pre print No. 2412), while the good Dr. Floyd Toole held forth on "The Perception of Sound Colorations Due to Resonances in Loudspeakers and Other Audio Components" (Preprint No. 2406). You may get some great ideas on room treatment by reading how "New Types of Acoustical Materials Simplify Room Designs," by Peter D'Antonio of RPG Diffusor Systems (Preprint No. 2365).

Last, but hardly least, my dear friend and colleague, Associate Editor B. V. Pisha, was made a Fellow of the AES at this convention, in recognition of his contributions to the testing and evaluation of audio components.

(Editor's Note: I am extremely proud to state that B. V. Pisha becomes the sixth person associated with Audio to be recognized as a Fellow of the Audio Engineering Society. Previously, C. G. McProud, the late founder of this magazine; Associate Editors Edward Tatnall Canby and Bert Whyte; Senior Edi tor Richard C. Heyser, and Contributing Editor John M. Eargle have been so honored. In addition, Richard C. Heyser is now President-Elect of the AES. -E.P.)

(adapted from Audio magazine, Feb. 1987; Bert Whyte)

= = = =