Most of us are familiar with the founding fathers of high fidelity. Pioneers

like Avery Fisher, Rudy Bozak, Frank McIntosh, H.H. Scott, Walter Stanton and

others, whose dedication to the quest for high-quality sound reproduction resulted

in their manufacturing the first hi-fi audio components for the consumer market.

Needless to say, this fledgling activity in the consumer hi-fi market was complemented by parallel developments in the fields of professional audio and re cording. There were pioneers in both these fields as well, but within the relatively circumscribed world of profession al audio, few people achieved high visibility and their accomplishments have largely gone unrecognized.

One of the most gifted of those early pioneers in professional audio is Milton T. (Bill) Putnam, currently Chairman of the Board of United Recording Corp. in Hollywood, California. URC encompasses United/Western Studios, Coast Recorders, Teletronix, and its manufacturing arm UREI (United Recording Electronics Industries).

Bill Putnam founded Universal Recorders and built his own studios in Chicago in 1946. It must be remembered that in those days, most recording studios were constructed with only rudimentary knowledge and little application of acoustic treatment. Typical studios of 15,000 to 35,000 cubic feet used draping and perforated acoustic panels, quite often applied directly to boundary surfaces with no provision for air space be hind them. Some used rock-wool batts behind perforated Celotex. For the most part, there was inadequate low-frequency absorption with the ratio of indirect-to-direct sound in the low-frequency instruments causing a distinct lack of separation and presence and an unpleasant coloration of the sound. Add to this the fact that the off-axis response of many micro phones (even bidirectional or cardioid types) caused time-related and spectral colorations of a signal arriving after the direct sound. Of course, at the low frequencies below 125 Hz, all the directional mikes became virtually omni-directional, further contributing to the muddiness of the sound.

In marked contrast to this common studio environment, Bill Putnam's studio at Universal Recorders was constructed with the specific goal of increasing instrumental separation, and he accomplished this by lowering the overall reverberation time, with particular attention to substantial absorption of the low frequencies. To this end, diaphragmatic panels in convex splays were used, and the thickness of rock-wool batts behind perforated panels was increased by fur ring out frames for greater depth. Separation screens and rugs were used for absorption of higher frequency reflections.

An early type of absorptive roll-around isolation vocal booth was used, which also was occasionally used for a drum set--a fore runner of today's drum cage. A roll-around band shell was constructed with interior poly-cylindrical diffusers to pre vent focusing, especially of strings. Instrumental positioning and mike placement in the studio were radically altered from the hand-me-down practices of early broadcasting and recording, with a view towards more separation and definition. (Remember, this was before the days of multi-track and overdubbing.) Having achieved better instrumental separation by lowering studio reverb time, Bill did not want a dead or dry overall sound, so he experimented with feeding his output signal to various types of reverberation rooms. (Note that this was before electronic echo chambers.) Bill was looking for a reverberation room which had a smooth decay, would eliminate periodicity, and have low coloration. Bill experimented with delaying the signal sent to the reverb room to more effectively simulate early sound. He realized the importance of the control room in his studio, and it was acoustically treated. This led to measuring monitor-speaker response in the room and even some attempts at room/speaker equalization.

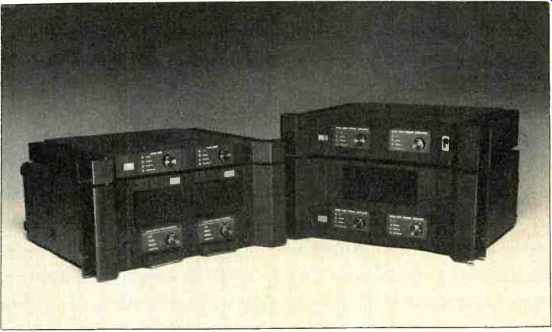

Above: UREI's power amplifiers, Models 6150, 6500, 6250 and 6400.

Because of all the factors in studio design and recording practices Bill had incorporated into his Universal Recorders studios, he developed a distinctive and easily recognized high-quality sound which generated considerable business.

In the early and mid-fifties, the advent of exotic high-quality condenser microphones such as the Telefunken U-47, along with greatly improved mono feed back cutterheads such as the Westrex 2B and Grampian, resulted in rapid advances in the quality of recordings. Bill Putnam adopted these and other aids to high-quality mastering, and in competition with several other studios, the "Hi-Fi Spectacular" record was a new specialty product for what was called the audiophile market! Imagine that, way back in 1955! As tape recorders and tape formulations improved, permitting greatly extended high-frequency response, the battle to produce even more spectacular hi-fi records intensified. In 1955, Bill managed some neat technical one-upmanship by recording at 30 inches per second and mastering the tapes at half speed. Shades of Mobile Fidelity back then! I had the pleasure of meeting Bill Putnam in 1951 in Chicago, where I was in technical sales and served as music di rector for Magnecord, one of the pioneer manufacturers of tape recorders. This is where stereophonic sound enters the picture. I had been recording in stereo for some time, and Bill had been experimenting with stereo too. The Magnecord stereo recorder used a staggered head configuration which gave adequate stereo separation but also caused certain problems. Bill recorded some stereo in this format. Ever the innovator, in 1954, in cooperation with the Pentron Corp. of Chicago, he used a recorder with eight channels on standard quarter-inch tape in a staggered head configuration to record an instrumental group. In the eight-channel playback, eight loud speakers were arrayed in the listening room in the same positions in which the instruments had originally been recorded.

Portents of a future as yet unrealized. In 1958, Bill Putnam moved to Hollywood, California, formed United Recorders and constructed the first purpose built studio for stereophonic recording.

The studio was an amalgam of Bill's original ideas, with important new acoustic design work by Michael Rettinger. In later revisions, the Time Delay Spectrometry (TDS) measurement system of Audio's own Richard Heyser was extensively employed, as were some of Don Davis' pioneering ideas on room equalization. John Eargle contributed new data on monitor speaker response in acoustically treated control rooms. Bill Putnam and Ed Long (a frequent contributor to Audio) collaborated on a joint R&D pro gram to upgrade the quality of monitor speakers. The result was a speaker which was designated a "Time Aligned" studio monitor. The technique takes into consideration the time (phase) response of the speaker, and by proprietary de sign of the crossover network and the placement of the loudspeaker driver elements, the system is said to be "Time Aligned" and free of group time-delay anomalies. In essence, there is near-perfect alignment of the frequency components in a complex transient waveform'.

Bill Putnam had formed a company -- United Recording Electronics Indus tries, UREI--to manufacture specialized equipment for the professional re cording market, and the new "Time Aligned" studio monitor was to be built at this facility. UREI has been in existence for some years now and is one of the most successful of Bill's companies.

I have used a number of UREI's more exotic products, and when I was invited to visit their new plant, I gladly accepted.

The UREI plant is a modern one-story building in Sun Valley, one of those pleasant little towns in the San Fernando Valley, and just a short drive to the United Recording studios in Hollywood.

DeWitt "Bud" Morris, President of UREI, is an old friend. He's an easygoing and genial man, but nonetheless runs a tight ship at UREI, aided by Brad Plunkett, Chief Engineer, and Ray Combs, V.P.

Work flow is very well organized, beginning with in-house testing of incoming parts, then sub-assembly build-up and unit fabrication on various dedicated technology assembly lines. While vendors supply many parts, whenever possible and economically feasible, UREI makes their own. For example, most transformers and certain coils are made on the premises. UREI is subject to the same inordinately long delivery times on parts as most companies these days, but they invest heavily in quantity buying and as a consequence are usually in a strong inventory position. Thus, most of the equipment they make is readily available from stock.

In addition to a well-equipped R&D lab, a modern test lab monitors quality-control procedures. Fortunately, subjective testing of many UREI products is given high priority and is carried out in a purpose-built, acoustically treated listening room. Currently UREI is producing a new generation of "Time Aligned" monitor speakers, the 811 A (single 15-in. woofer with exponential HF horn), the 813A (same as 811 A with addition of another 15-in. woofer in a large enclosure), and 815A (same as 811 A with two 15-in. woofers in a still larger enclosure). The HF horns are newly designed for improved frequency response and dispersion characteristics. The "Time Aligned" crossover network has been redesigned for more power transfer to the speaker driver.

UREI is now heavily committed to amplifier production. Their big brute, Model 6500, was introduced at the May, 1980 AES Convention, and I described it in the August, 1980 issue of Audio. At the November, 1980 New York AES, the 6500 was joined by the 255 W/channel Model 6400, the 150 W/channel Model 6250, and a slim-line design, only 1 3/4-in. high, the Model 6150 with 76 W/channel. All of these units are 19-in. rack-mountable and are of highly rugged construction.

UREI continues to produce such specialized items for professional recording as limiters and compressors and various types of equalizers and filters. A new electronic crossover is currently in the works, and UREI still makes their invaluable Model 200 XY plotter and recorder with the Model 2000 frequency response module, the Model 2010 level and frequency detector module, and the new Model 21 warble generator for room measurements. When I was visiting the UREI plant, a huge new Neve mixing console with the Necam automated mix-down feature was undergoing tests prior to installation in Bill's studio at United Recorders.

Over the years, Bill Putnam has al ways tried to stay just a bit ahead of cur rent recording technology. His early experiments with time delay and subsequent manufacture of the Cooper Time Cube is an example, as was his issuing of four-channel matrix evaluation test records. Bill's quadraphonic recordings of the late Stan Kenton and his orchestra are among the very best ever done in this medium. Today Bill Putnam continues in his pursuit of recording excellence, and his UREI company translates many of his ideas into products that find favor in professional audio.

-----------

(Source: Audio magazine, Mar. 1981; Bert Whyte )

= = = =