by JOHN ALVIN PIERCE

In August 1936, Ted Hunt, with whom I was only casually acquainted at the time, was overloaded in his efforts to finish building some remarkably advanced equipment for making phonograph records of the proceedings of the Harvard Tercentenary Celebration. Ted had induced the Tercentenary authorities to give him the financial help needed for his desired instruments by suggesting the importance of preserving for the fourth centenary celebration a complete audible record of the activities of the third.

While the idea of making such records was exciting, I suspect that Ted's greatest interest was in procuring equipment that he could use later for research purposes. He had bought professional quality turntables and other record cutting gear, and run high-quality telephone lines through the steam tunnels to connect the most important buildings with the proposed recording room in the Research Laboratory of Physics. Being dissatisfied with any of the available recording amplifiers, he began building his own to very advanced standards; it was in completing the construction of these that he was falling seriously behind a tight schedule. As was expected, there was also an uncertain amount of testing and experimental record cutting to be done before the activities began.

The Harvard Tercentenary was by far the greatest academic celebration experience, or perhaps in my lifetime. After two or three weeks of Conferences on Arts and Sciences, the formal proceedings lasted three days. It was like a glorified Commencement.

The Harvard Yard was decorated by, among other things, hundreds of white poles topped with gilded Cambridge lions. Sixty-two honorary degrees were awarded. Delegates from about 500 universities and colleges and 50 learned societies marched in the academic procession in order of the institutions' ages, beginning with al-Azhar University, founded in 970 A.D. The President of the United States was allowed a part in the festival; John Masefield, the poet laureate of England, read a poem, and musical portions were performed by the Boston Symphony Orchestra. Seats were provided for 15,000 guests in the quadrangle between the Memorial Church and the Widener Library.

This Tercentenary Theater was served by a remarkable sound system contrived and supplier by the Bell Telephone Laboratories and the Western Electric Company, allegedly at a cost of over $100,000. The Theater has been used for Commencements since 1936, and the sound reinforcement system has come down through the years surprisingly well, with only occasional modifications and replacements of equipment. The sound system for the Tercentenary was so free of distortion and so artfully supplied from loudspeakers in the trees and on surrounding buildings that most members of the audience did not realize that electronic assistance was providing what they heard. It was commonplace to hear people ask each other, "Why don't they have a public address system?" not realizing that if there hadn't been one in place, they could have heard almost nothing from their distant seats.

With such a tempting program to be recorded, it is not surprising that I volunteered and worked very hard with Ted to help complete his equipment and to learn how a recording was made. We worked day and night and, in classical fashion, completed the last changes and adjustments within the hour before the ceremonies began. From my point of view this rush had one sad effect: Ted claimed that I was the only one who could be trusted with the actual cutting of the records. I therefore spent the entire Tercentenary perched on a high stool in front of the recording turntables and saw nothing of the pageantry, although I must admit that I heard everything remarkably well.

In the weeks following the Tercentenary, we cut still more test records and learned to make optical studies of the record grooves, microscopically and in other ways. We discovered that we had, perhaps largely by accident, made records of what was then phenomenally high quality. This knowledge placed us in an intolerable position because there was no phonograph pickup in existence that could reproduce what we had recorded. Even worse, there was no pickup that could be used without damaging the records. We had had an instinctive realization of this fact, and therefore did not allow any of the Tercentenary records to be played back, with the exception of a few short sections at points where Harvard President Conant insisted on finding out exactly what expressions had been used, or where he wished to know whether certain off-microphone remarks had been picked up and recorded, as they usually had been.

Knowing the excellent quality of today's phonographs and records, it is hard to realize how bad nearly all of them were in 1936. In the preceding decade, the old mechanical reproducers had been replaced by electric pickups, amplifiers, and loudspeakers. The pickups and the amplifiers, at least, followed the old designs because they were intended to play the same records, which were, to be honest, awful. To get enough acoustical power from the record groove through a mechanical pickup, the stylus had to be pressed hard against the record. In ordinary practice, the unbalanced weight of a pickup was as much as 4 ounces. This weight rested on a needle whose point had dimensions of only a few thousandths of an inch (mils). The resulting pressure was in the range of 20,000 to 50,000 pounds per square inch, which exceeded the elastic limit of the record material. The sharp point of the usual steel needle would gouge out the groove, erasing the higher recorded frequency components, and tearing the surfaces of the record groove so that random (scratch) noise increased each time the record was played. Teddy's favorite simile was to suggest that the effect was like dragging a cannon ball along the furrow in a plowed field. To decrease the tearing effect, abrasives were added to the record material so that a new needle would be ground to fit the groove after a few revolutions of the turntable. This distributed the weight over a larger contact area so that the tearing was reduced, but it had two serious disadvantages. The larger area of contact meant that the highest frequencies could not be reproduced, and the roughness of the abrasive produced unnatural, and unwanted, noise. It was therefore common practice to limit the high frequency response of the reproducing system to about 3,500 Hz, or little more than the frequency range of an ordinary telephone circuit.

The only exception to this unfortunate situation was in the case of transcription records made for distribution of radio broadcasts. These had recently been greatly improved by the Bell Telephone Laboratories and the Western Electric organization. The transcription records were in vertical cut on 16-inch lacquer-coated discs that would play for almost 30 minutes. In retrospect, it is clear that their virtues were a result of a new order of care used in their making.

Our records were cut in vinylite, without abrasive, so that they exhibited even less noise than the transcription records. Because this plastic was softer than the commercial shellac records, our records were even more subject to tearing of the grooves and wearing off of the high frequency components of the sound. The obvious direction to be taken in making a suitable pickup was to reduce the pressure on the record to the point where all stresses were below the elastic limit of the record material. This would mean that the entire mechanism would have to be very light. It was clear that the power available from a pickup would be proportional to the mass of material vibrated by the modulation of the record grooves; making the pickup light would reduce the power output. This fact did not disturb us, as good amplifiers were easy to make. We felt that even if the output should be as low as that from a microphone, we would still have a useful device.

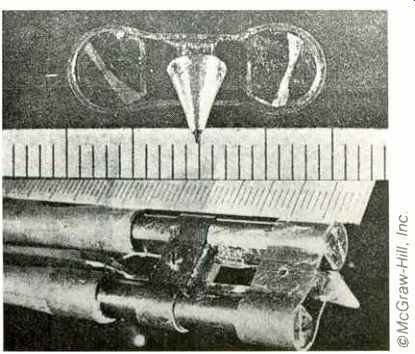

-------Head-on and top views of the HP-6A "reproducer," from

the March 1938 issue of Electronics.

We began our experimenting with a simple "hairpin" of thin phosphor-bronze ribbon. At the front, or closed end, of the hairpin, the ribbon's breadth was perpendicular to the record. This loop was coupled to a sapphire stylus by a very light aluminum cone. Lateral vibration of the stylus thus produced a rotary motion of the hairpin in a magnetic field produced by a permanent magnet, so that the front part of the hairpin was a single-turn coil and formed a small a.c. generator. The rotation of the hairpin was made easier by twisting the ribbon in the rear part, outside of the magnetic field, into the horizontal plane. A defect of this device was that the front center of the hairpin had to be supported by a block of viscous damping material to maintain the right pressure on the record, and the acoustical characteristics depended in part on the size and shape of the block of damping material. The pickup did, however, show great promise. One inconvenience was that the impedance of the generator was very small, about 0.005 ohm, so that heavy wires had to be used if the output were to be conducted very far. We solved this problem by having a small transformer that brought the impedance up to 500 ohms, and we used the transformer itself as a counterweight at the far end of the tone-arm on which the pickup was mounted.

We worked our way through many variations of this device. Each time we made a major change in the design, we raised the model number, while minor variations were accounted for by letters, in alphabetical sequence, appended to the number. By the time we graduated from the Model HP-5G to the HP-6A, we felt, that we had a pickup worth demonstrating and whose characteristics were worth publishing.

The hairpin had now become a little tube of phosphor-bronze, about 0.03 inch in diameter and with walls 0.002 inch thick. The needed flexibility toward the rear, where the hairpin was fixed, was provided by simply crushing the tube into flat strips. This construction gave us good rigidity in the "coil" part, where it was needed, and flexibility where that was essential. The electrical performance was sensational for those days, extending from 30 Hz to 18 kHz.

The power output was admittedly very low, about one-thousandth of "normal," but this did not constitute a serious problem.

One of the most fascinating features was the light "weight" on the record-about 2 grams.

This produced pressures so gentle that it was impossible to damage a record. We would astonish guests and audiences by dropping the pickup from 2 to 3 inches onto a fresh uncut disc. This would produce no visible or audible dent. An even more startling test was to place a finger on each side of the tonearm and scrub it back and forth across the grooves while a record was being played. Any other pickup would instantly ruin the record. With ours, the noise from the loudspeaker during the scrubbing was, of course, intolerable, but afterward the record continued to play with no sign of damage.

These characteristics and the tonal quality of the reproduction were quite unheard of, and we demonstrated them to any audience we could muster. Most "experts" found it hard to believe that our audiences consistently voted "No" when we inserted electrical filters to cut off the frequencies above 11 kHz. Such a result contradicted the assumption that people did not want high-frequency response-they did if distortion and noise were sufficiently reduced.

We had reached this state in November 1937 and reported our results first at the Acoustical Society meeting in Ann Arbor, Mich. Our paper on the HP-6A was published in early 1938 and drew about 200 "fan letters," a remarkable response for a scientific paper. Some of these correspondents kept us writing letters for years; in fact, I think the file was not closed until 1946.

We continued to improve our pickups until 1940; I think the last was the HP-23. We finally learned how to make them without any damping material, which in reality had been needed only to provide mechanical support or to control unwanted modes of vibration.

Although Ted and I no doubt had the ideas about what we wanted, most of the credit for these remarkably light pickups must go to Harold Benner, the elderly chief machinist at Cruft Laboratory. So far as I know, he could make anything. I remember an occasion when one of the rich young men around the lab had bought his wife a tiny Swiss watch. The works were so small that two of them could have been placed side by side on a dime without overhanging the edge. One of the watch jewels had broken, and a number of major jewelers refused to undertake repairs. Appropriately challenged, Mr. Benner took the job home, where he had a more delicate jeweler's lathe than he had at the lab, and ground and drilled a satisfactory new jewel.

Presenting a challenge was an important part of getting the best from Mr. Benner. We learned to approach delicate jobs by saying, "We don't believe it can be done, but what we really need is ...." An excellent example is the kind of cone we used in our later pickups. These were about 0.2 inch long and 0.1 inch in diameter. At the top was a narrow cylindrical section to which a thin silver band was later cemented, and there was a little button at the end into which a sapphire or diamond stylus point was inserted. Mr. Benner would start with a rod of duralumin. After boring a cylindrical and then conical hole in the end, he would cement this end to a correspondingly tapered arbor so that he could reverse the rod in his lathe. He would then turn down the outside of the cone until the remaining structure had a thickness of 0.0005 inch, except at the little bump at the end. The completed cones weighed an average of about 4 milligrams; it would have taken 7,000 of them to weigh an ounce. I must admit that occasionally one of these cones would be torn during the final cutting, but, even so, this remains one of the most remarkable examples of fine machining that I ever watched. Certainly, without Mr. Benner we could have done nothing important.

It is hard to understand the combination of flexibility and structural stiffness required in a phonograph reproducer. The acceleration in a record groove can easily reach a thousand times the acceleration due to gravity. If an automobile could tolerate such acceleration, it could reach a speed of 50 miles an hour after the first inch of travel. For a pickup to withstand such forces, the "effective mass referred to the stylus tip" must be a thousand times smaller than the "unbalanced weight on the record." For use with lateral-cut records, much of the mass of our pickups was concentrated relatively near to the axis of rotation. We could then have a total mass perhaps as large as 10 milligrams and yet achieve a "playing weight" of only 2 grams.

Our best proof of the value of light pressure on the record was a commercial Beethoven recording that we played over 2,500 times in tests and demonstrations of various pickups.

After all of this use, it still had the "gleam" of a new one. We used to annoy Briggs and Briggs, the fine music store in Harvard Square, when we went to choose a new test record. After listening to many, in an effort to select passages that were hard to reproduce accurately, we would say to the store clerk, "This one is good; now go get us a new record that has not been played." One of our finest and most difficult tests involved the "singing strings" passage in the third movement of Brahms' First Symphony.

Any pickup that could reproduce these measures without audible distortion was clearly of the first rank.

Consideration of the pickup behavior led us into a long study of the geometrical relations between the stylus tip and the record groove.

The details of this research are too complex to discuss here, but the important point is that although a groove is cut with a very sharp edged tool, we must play it back with a smooth (spherical or ellipsoidal) stylus tip. For this reason, the motion of a playback stylus is not the same as the motion of the cutting tool with which the record was made. We realized that the center of a spherical stylus traced a curve that remained at a constant distance from each of the surfaces of a record groove. If, for purposes of analysis, we took each wall of the groove as following a sine wave, the stylus would move along a path that was completely determined by the amplitude and wavelength of the sine wave and the radius of the stylus. A defined curve of this sort seemed to deserve a name. We originally called it the "Pierce-oid," partly because I had first suggested the existence of such a family of relationships, but chiefly because I made the very tedious calculations required to determine the amount of distortion produced in this way. This name seemed unduly awkward, however, and we shortened it to the "Poid" before we used the term in print. I am still occasionally pleased to find poid defined in a technical dictionary.

Ted and I came to the interesting conclusion that, in the matter of distortion, lateral-cut records had a distinct advantage over those that were made with vertical motion of the cutting stylus. Knowing, by now, the physical requirements (the right amount of stiffness, the small mass, and the capability to withstand high acceleration) for a good pickup, we were able to define the criteria for a satisfactory reproducer and to establish the kind of groove that might be used to make long-playing records. Because we could not conceive of a cutting head that could simultaneously record both vertically and laterally, we failed explicitly to predict stereo disc recording. The paper we wrote about these matters was the most important one in our collaboration. It was simultaneously published in the journals of the Acoustical Society and the Society of Motion Picture Engineers, a somewhat rare happening that was possible because the editors of both publications wanted the paper and did not feel that their membership lists overlapped too much.

We gave the subject matter of this paper verbally at several meetings of scientific societies. This became something of a road show; wherever we went, Bell Telephone Laboratories sent two or three of their engineers to try to refute our claims about the superiority of lateral recording. This was a great deal of fun because, by the time of each meeting, the opposition had thought up new arguments in favor of their excellent vertical records. As their new ideas were always presented in discussion periods after we had made our exposition, we were forced to think fast to find satisfactory counter arguments extemporaneously.

Perhaps the most interesting proof of the soundness of our work did not come until 18 years later, in 1956, when the Audio Engineering Society decided to make me an honorary member. This surprised me, as I had had no connection with audio engineering for fully 15 years. I could not resist going to the convention in New York to be awarded this honor. It turned out that when the industry was getting ready to produce stereo records, people had found the mathematical basis they needed in the 1938 Pierce and Hunt paper. I was lucky in this instance. Ted and I had a policy of alternately assuming the position of senior author, and this most important of our papers happened to fall into my share.

In the course of this work, Ted and I had secured two patents that seemed to be very sound. They were fundamental, as we claimed the physical features that would cover any phonograph pickup that could trace a groove in accordance with our teachings, and these teachings defined the criteria for satisfactory freedom from distortion and record damage.

We thought that these patents were valuable properties, but most of the industry correctly judged that we were academic types who would never know how to fight a patent suit. An exception to this general pattern was nearly provided by Columbia Records, which got far enough to offer us each $3,000 a year, for the life of our patents, for the rights. I tried hard to get Ted to accept this offer, but he had an inflated idea of the value of a patent. It had happened that, some years before, Ted had invented the electronic frequency meter. His friends at the General Radio Co. were interested in manufacturing it, and offered him his choice of two deals: $1,000 outright or a 5% royalty on whatever they sold. It did not seem that the sales would be large, and Ted chose the royalty chiefly out of friendship, not wanting the company to pay too much in case the frequency meter should not be a commercial success. Over several years, his receipts were showing some signs of reaching the thousand dollar level. By the time our phonograph patents were finally issued, the United States had entered World War II and the U.S. Navy had decided to put Ted's frequency meters into nearly every ship and shore installation. When the Columbia patent deal was being negotiated, Ted was collecting thousands from the frequency meter. This led him to feel that Columbia would pay more, but his stubborn attitude outlasted Columbia's patience. The deal collapsed, partly because Ted and I were by then both deeply involved in work for the war effort and had little time or interest for anything else. As a result, we never collected a penny on our patents.

It has always interested me that Columbia's Peter Goldmark, after the war, emerged as the "inventor" of long-playing records. Goldmark did a magnificent job of development, reducing our ideas to practice. I was to learn that this is usually a harder and much more critical part of bringing a new device before the public than is the invention of the idea, but, for a time, I sorely missed having a share of the credit. I did not then know one of Harvard President A. Lawrence Lowell's well-known aphorisms, "You may get results or you may get credit for results; you can rarely have both."

(adapted from Audio magazine, Mar. 1991; Bert Whyte)

= = = =