by JOHN BASINSKI

Photography by SUSANNE BUCKLER

[John Basinski, an award-winning cabinetmaker, owns Basinski Wood Studio in Philadelphia, where he specializes in custom-built executive furniture. He is also current president of the Society of Philadelphia Woodworkers. ]

Time was when the consumer would cart a new receiver, turntable and tape deck home, pile up some cinder blocks, span them with board shelves, and the new system was ready to roll.

As the equipment has gotten more sophisticated, so has the taste of the consumers who buy it. You're probably all familiar with the inexpensive cabinetry distributed by the discounters wood-grained vinyl on a flakeboard base with all the structural integrity of a house of cards. On the following pages, I'll discuss products that seek to match the quality and styling of the audio components they house.

The major feature cited by the manufacturers covered here is the use of wood. One manufacturer calls his product "Realwood," another "Wood more." You get the picture. Wood is an alluring material, and many people feel that solid wood is superior to plywood, which is sometimes perceived as a cheap or inferior substitute. This is not at all true, and a consideration of the structure of-wood will explain why.

Wood is composed of cellulose fibers, shaped like common drinking straws, which absorb available water. Like a sponge, the walls expand when wet and contract when dry. Curiously, while the fibers expand and contract in wall thickness and diameter, they remain virtually constant in length. When live trees are cut, the lumber may contain more water than wood. Soon after being cut, the wood loses its moisture to the atmosphere until an equilibrium point is reached. During this process, sometimes misleadingly called "seasoning," moisture content will drop to an average of about 10%. A board that was 6 inches wide and 1 inch thick when "green" may shrink 1/4 inch in width and 1/16 inch in thickness but remain unchanged in length. Once dried, the wood will absorb or lose moisture in response to changes in humidity. During high summer humidity, the moisture content of the wood inside a home in the mid-Atlantic states may reach 12%; during the winter, unhumidified central heat may drop it to 7%. In the process, a solid wood table top 30 inches wide may easily expand and contract 1/8 inch.

This property presents some difficulties in dealing with solid wood. First, if a solid wood table top is firmly attached to a wood framing member whose length crosses the top's width, stress will be induced. The tendency of the top to change dimensions as humidity changes will be opposed by the dimensional stability of the framing member. The joint may fail, or the solid top may split to relieve this stress.

Joints between solid panels and framing members must be flexible enough to allow this dimensional change. Additionally, the expansion and contraction does not take place uniformly in all directions in wood. Most boards, over time, will distort or "cup" across their width. The wider the board, the greater the potential for this. The art of cabinetmaking revolves around taming and controlling these unruly traits.

Plywood offers a clever solution to dimensional stability problems-an arrangement of wood in successive layers, with the fiber or grain direction alternating between them. Strong glue bonds between the layers help the dimensional stability. Particleboard or flakeboard, sometimes used as a core between layers of wood veneer, attains stability using a different approach.

Particleboard consists of wood chips, carefully sized and manufactured, which have been mixed with glue and pressed into sheets under enormous pressure. Since there is no consistent fiber direction and the individual fibers are quite small, what little dimensional change there is occurs uniformly in all directions. The resulting panel is denser than standard, veneer-core plywood and makes a stable core resistant to denting.

The major drawback of plywood concerns its edges. Not inherently attractive, they require a veneer or solid edging for a presentable appearance.

Plywood is, however, a dimensionally stable product offering an opportunity to match patterns on its faces and achieve visual effects impossible to duplicate in one-piece or solid wood. And remember, aside from its glue content, plywood is all wood. Furniture of good quality typically combines both plywood and solids.

Using solid wood in itself doesn't assure superior quality, since the seeds of self-destruction are inherent in the material unless it's used properly. By the same token, plywood is in no way synonymous with inferior quality or longevity. Good design and quality construction depend upon carefully mating the appropriate material with a suitable method of construction.

Barzilay Company Model GR-11

Suggested Retail Price: $458.00

Address: 18737 South Reyes Ave., Compton, Cal. 90221

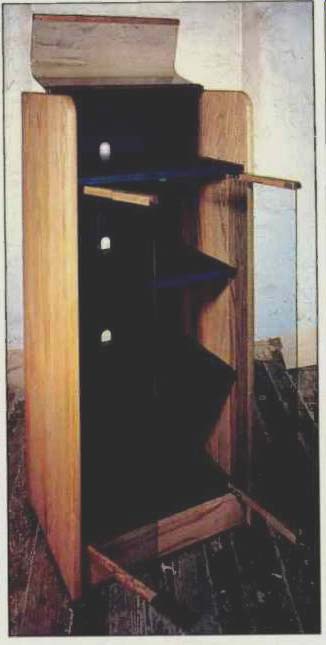

A hinged-top highboy with a friendly look, the GR-11 comes "knocked down," that is, packed flat and ready for assembly. The rectilinear form is softened by rounded corners at the top and a similarly curved, smoked-plexiglass turntable access door. It reminds me, fondly, of an old Wurlitzer jukebox.

Mirror-imaged, shaped oak pulls on the lid and doors invite touching. Side panels are glued up of narrow oak strips, with an informal, butcherblock look. The interior shelves covered in black leatherette vinyl are very low-key and focus attention outward rather than inward. All the hardware except for the piano hinge on the top is concealed. The net result is a refined appearance that's not overly slick. Like most of the units reviewed, the GR-11 sports an oiled finish. Here it's generally a "starved" or dry-looking one. Barzilay is obviously aware of this, since they include sandpaper, liquid wax, and instructions for achieving what they call a "premium quality finish." This cabinet comes in a single crate that scales in at 139 pounds. It's a load, so ask an able-bodied friend to help move it. Instructions are well-illustrated. Exploded drawings give a clear picture of the component parts and their assembly. Detailed illustrations show how to connect the knock-down fittings holding the case together, insert the record dividers provided, attach the back, install the casters, and hang the partially framed glass doors.

Generally excellent, the only shortcoming I find with the directions is a failure to list together the tools needed for assembly. These tools include a slotted screwdriver to open the crate, a #2 (medium) Phillips screwdriver, an adjustable wrench to tighten the caster stems, and a drill with a 5/64-inch bit or an awl to make pilot holes for some of the attaching screws. (To speed assembly, I used an electric screwdriver.) Finally, a mallet or hammer is needed to install record dividers.

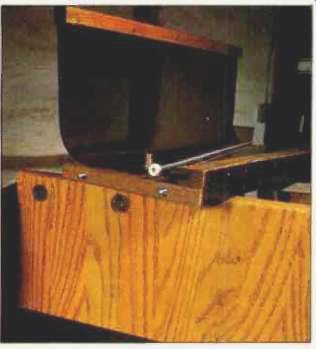

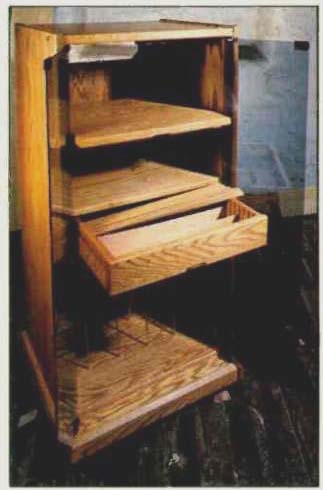

Assembly took two people half an hour. The knock-down (KD) fittings shown with the disassembled top in the detail photo, fit well and lock securely. One shelf at a time can be positioned and tightened to the first side, but four shelves need to be aligned simultaneously to fit the other side. Screwdriver in hand, this called for two more hands than I have (nobody's perfect), so a helper is necessary. The back is in four sections and requires some finagling to insure that the case is squared up and held in position while pilot holes are spotted and drilled for the attaching screws.

This is a nuisance, and I had my helper hold the unit square while I drove home the screws with an electric screw-gun, obviating pilot holes. If Barzilay provided a recess for the back and pre-drilled the holes, this would be a breeze and the finished assembly would be more attractive.

Mounting the doors was easier than on any other cabinet requiring it. Both doors are trimmed top and bottom with oak strips which combine shaped pulls, magnetic catches, and pre mounted and threaded inserts for hinge attachment. Nicely done.

Once assembled, the GR-11 stands 51 1/4 inches high, tallest of the units reviewed. While one might expect a KD unit so tall to be less than Gibraltar like, this one's good and solid. Fixing the sides together at four levels and affixing the back produces a cabinet with good resistance to both lateral racking and circular twisting, normal stresses for a caster-equipped unit.

Barzilay clearly intends the top compartment for a turntable, and the hinged lid gives access to the front and half of the top of the compartment.

The turntable shelf's height of 42 3/4 inches is comfortable for the average adult. A light with adjustable reflector is supplied, but I don't find it especially attractive. Given the ample access, I'd probably omit installing it if the unit were mine. All shelves have usable dimensions of 21 inches wide x 16 inches deep, and the turntable compartment has 7 1/2 inches of available height. It'll take most, if not all, turntables and changers.

In the lower compartment, one fixed and two adjustable shelves provide additional equipment platforms. The fixed shelf is set 13 inches above the bottom to provide record storage, and there's 23 inches of usable vertical space for three pieces of equipment.

Owners of open-reel tape decks will find that the GR-11, like all other cabinets reviewed, will probably accept reel-to-reel decks only in the horizontal position; 10-inch reel units probably won't fit. This is the one drawback of the hinged-top design, since an unusually large piece of equipment can't be placed on top. Cassette-deck owners should find the shelves ample for their equipment, though. Owners of wide components should note that the glass doors limit horizontal clearance to 18 inches, so such equipment should be placed inside the cabinet before door installation. Shelves adjust on 2-inch centers, with recesses in the undersides of the edges to receive 1/8-inch steel pins. The pins are sturdy, fit nicely, adjust easily, and are invisible when installed. They do, however, position the shelves flush against the back, which has only one slot for ventilation and wiring. Owners of hefty amps (especially Class-A models) might do well to make additional holes for heat dissipation. Recessed casters raise the unit only 1/4 inch off the floor, which is visually appealing but does restrict mobility on thickly carpeted floors a bit.

Pins on Barzilay lid engage holes in cabinet sides. Threaded

rod is Naiad's compression fitting.

The GR-11 is one of three units surveyed with solid oak side panels. At a thickness of 1 inch, Barzilay's are the heaviest, and they're glued up of strips no wider than 2 1/2 inches. These two facts are likely to ensure that they'll be stable and reliable, and Barzilay treats the panels with a chemical stabilizer to prevent end-checking and splitting.

Both fixed and adjustable shelves are flakeboard, covered with black-vinyl leatherette on the top and front edge.

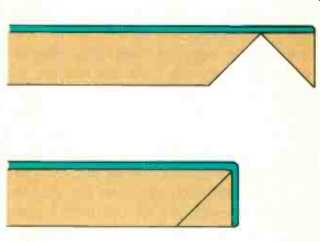

As I pointed out in the introduction, improper joinery between a composite material like this and solid panels can cause trouble. Using knock-down fittings, as done here, is a very appropriate method since KD fittings hold firmly (but not immovably) and allow for expansion and contraction in the solid panels. Proponents of the all-wood look may object to vinyl-covered shelves, but while their edges may damage more easily than solid oak ones, vinyl is certainly an easy surface to clean. These shelves are produced by a process called miter folding, where a V-shaped piece is removed from the core. The vinyl covering then acts as a hinge, and the remaining piece is folded over and glued. From a consumer's point of view, this assures a heavier than usual vinyl because the process demands it.

Barzilay is one of the oldest manufacturers of consumer-electronics cabinetry in the business. The GR-11 demonstrates this experience by combining a pleasant appearance with spaciousness, flexibility, and intelligent engineering. It's a very competent offering, and a good value.

Barzilay's shelves are made by miter folding. The core is

scored, then folded, using the vinyl covering as a hinge.

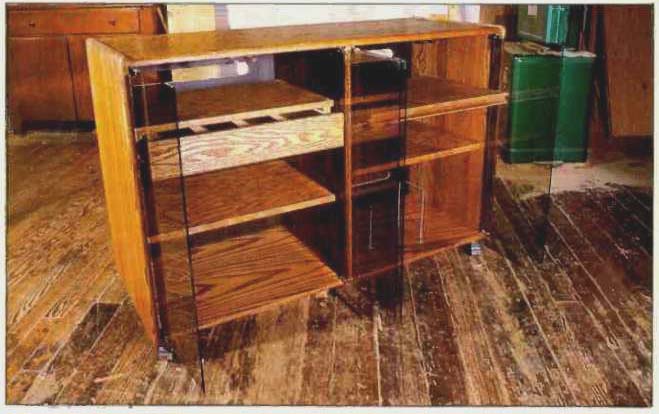

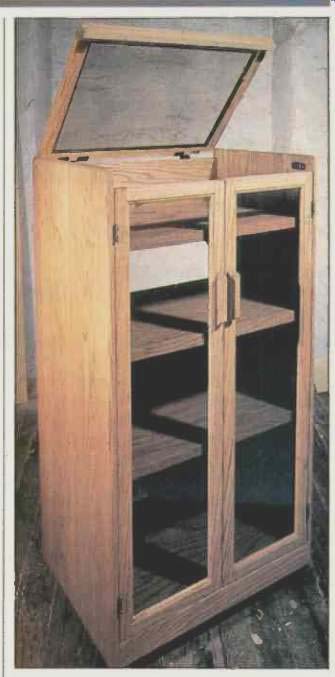

Custom Woodwork & Design: Woodmore Lowboy Model KD 600

Suggested Retail Price: $475.00 Accessories Reviewed: Audio-cassette drawer, $70.00; turntable slide-out shelf, $70.00; stacking frames, $60.00 (kit)

Address: 7447 South Sayre Ave., Bedford Park, III. 60638

Custom Woodwork & Design's Woodmore lowboy has a very contemporary look, with uncluttered lines and frameless smoked-glass doors accentuated by chrome hardware. An oak center divider and two pairs of doors provide a rhythmic vertical counterpoint to a horizontal profile, and its essentially boxy quality is softened nicely by rounded edges on the top, bottom and end panels_ Door hardware is similar to that used by Lepper and Naiad, but here it's well-finished chrome. Even the casters have chrome-metal hoods.

(Other cabinets have all-plastic casters.) The KD 600's finish, a dark oak stain under a well-rubbed penetrating oil and wax coating, is very well done; excellent quality.

The unit comes knocked down in a single crate which weighs in at 120 pounds, so proud owners should have a strong friend handy to help cart it home. Accessories are separately packed and quite manageable. Instructions are well illustrated and clear, but if you're prone to anxiety attacks when faced with the prospect of assembling a bicycle, this cabinet could give you a case of hives. Twenty-four different types of parts are used in assembly, which took me about an hour and a half to complete. In fairness to CWD, I should point out that all really sturdy knock-down units suffer this problem to varying degrees. Pre-assembled cabinets are expensive to ship, but the manufacturer and, ultimately, the consumer save money when the knock-down approach is used. The problem is in designing a piece that is demountable and is solid when assembled, yet can be put together successfully by untrained people. Although CWD has done an excellent job of designing for solidity, the trade-off is an assembly procedure which, frankly, will be difficult for some. For them, I'd recommend dealer assembly.

Tools required include #1 (small) and #2 (medium) Phillips screwdrivers, a large slotted driver, a mallet, and a bar of soap or candle stub. A Yankee-type ratchet screwdriver or electric screwdriver with a #1 Phillips tip is very handy for installing the back. The basic case assembles with knockdown fittings which consist of metal dowels that screw into pre-mounted inserts in one panel. The dowels then slide into pre-drilled holes in the mating panel, where they are engaged by metal cams. After tightening with a flat bladed screwdriver, the metal discs are covered with color-coordinated plastic. The side panels are solid oak and, as solid panels are occasionally wont to do, arrived slightly cupped across their width. I had to bend the metal dowels gently with a hammer to align them with their mating holes, but, once aligned, they pulled everything together firmly and flat. Two record dividers also fit snugly, and in tapping the first end home I inadvertently drove it through the bottom. Chastened and determined to be careful, I nonetheless managed to repeat the error on the other divider. After repairing the admittedly invisible damage, I avoided a repeat performance by enlarging the holes slightly with a 13/64-inch drill.

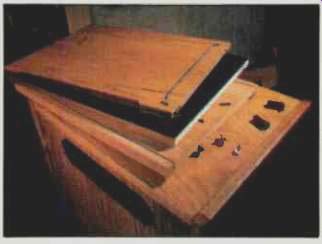

The back rests in a recess. Positioning is simple, but pilot holes are not pre drilled for it. Lubricating the screws with soap or candle wax makes them easier to drive, but a ratchet-type screwdriver simplifies the job considerably. The glass doors mount with pivot hinges which attach to the unframed glass by compression screws. They mount easily but require some fiddling to align properly.

Once assembled, this cabinet is a rock. The 1/2-inch thick back screws firmly into place and makes the rectangular geometry rigid. A fifth caster, placed under the very center of the unit, prevents any tendency to sag in the middle. The doors use magnetic touch latches and pop open when a chrome strike is pushed. They work nicely. The four shelves adjust on 1 1/4 inch centers on 1/8-inch wire frames that plug into matching sets of holes in the cabinet sides. A slot in the edge of the shelf receives the frames, so they are invisible when installed. The mounting holes are small and unobtrusive. Since shelves must be installed before mounting the glass doors with this system, plan your configuration carefully at this step.

The Woodmore lowboy also has solid oak end panels, which are glued up of strips averaging 3 inches wide, and the manufacturer stress-tests each panel before shipping. Like Barzilay, CWD uses both particleboard cores in shelves and KD fittings that should allow adequate flexibility for dimensional changes in the solid side panels. Top, bottom, and shelves have solid oak front edges, which will wear very well.

Oak veneer encases the edging top and bottom, so the shelves appear to be solid oak. Nice touch, and it doubly ensures the structural integrity of the joint between shelf and edging. My one complaint about CWD's materials is their use of rotary-cut veneers for the top of the cabinet. Rotary cutting is the process a pencil sharpener uses, peeling off thin continuous slices from a log. When veneer is cut this way, the grain or figure pattern is coarse and wild looking.

Adjustable shelves measure 16 1/4 inches deep x 22 1/2 inches wide, and the two interior compartments offer a total of 55 inches of shelf height. If space on top is included, this lowboy offers as much as twice the usable space on twice as many shelves as any of the upright models. All save gargantuan turntables will fit inside, and an accessory slide-out shelf for this purpose was supplied with the unit reviewed. The accessory shelf suffers from a design flaw: When the sliding part was pulled out, the supposedly fixed base slid on its wire mounts until it collided with the glass doors. Shimming with wood veneer could wedge the base into position, or a 5/8-inch-long wood screw could trap the back mount; neither were provided. I'd put a turntable on top anyway, at a more comfortable working height. Virtually all cassette decks will fit inside, and the accessory cassette-storage drawer is quite satisfactory. It runs smoothly on full-extension ball-bearing slides, with dividers to separate rows of cassettes. Reel-to-reel fans can place large decks on top of the cabinet. Six large openings in the back provide good ventilation, and the shelves stop 1 inch from the back to allow both air circulation and wireways within the cabinet. Given the space in the KD 600, I'm a bit surprised CWD only provides record dividers for one side, but an extra pair can be purchased separately. Another option is a pair of oak frames in kit form to replace casters and allow two units to be stacked. At $60, this kit seems overpriced to me; consisting of eight pieces of prefinished oak and some drywall screws for mounting, it omits leveling feet, which I consider mandatory for fixed installation. A leveling base for three or more units is available, as is a videocassette drawer, a video-game drawer, and even a wine rack.

The KD 600 is an unusually well designed, spacious, and well-finished cabinet. But why waffle; assembly's a pain. Yet, though suffering from a few relatively minor flaws, it nonetheless offers the best value of the units reviewed.

Raymond Lepper Works Xylophile Model XP 48

Suggested Retail Price: $625.00

Accessories Reviewed: Sliding turntable shelf, $97.50; audio-cassette drawer, $97.50; interior light, $18.80

Address: 2269 Old Middlefield Way, Mountain View, Cal. 94040

Model XP 48 is a no-nonsense, rectilinear highboy featuring smoked-glass doors and very low-key black hardware. This unit is neither high-tech nor designer chic, and its understated functional lines will harmonize with most environments. An extended base platform supports side and top panels of oak veneered particleboard. These panels are 1-inch thick and have chamfered, solid-oak edges. Veneer patterns are nicely book-matched and centered, and both side panels are pattern matched. Casters lift the platform base 1 3/4 inches off the floor; this gives an odd, levitated look to the cabinet, so I would be inclined to remove them. The XP 48 has a medium-dark oak finish which I'd rate best in show. Lepper uses Watco oil finishes, like many other manufacturers, but the company carefully and very thoroughly sands and rubs to produce an exquisite surface.

Lepper packs the XP 48 knocked down in a single crate weighing 100 pounds and requiring two people to transport. Accessories are individually packed in comfortable sizes and weights. Instructions are well illustrated but have been updated by an addenda sheet which I found distracting and potentially troublesome. The type of hinge detailed in the original instruction sheet has been changed, and following the original instructions without noting the addenda could result in broken glass doors. Lepper goes to the trouble of providing all the tools needed for assembly as well as a container of finish for touch-up purposes. They do themselves a disservice by not reprinting their directions.

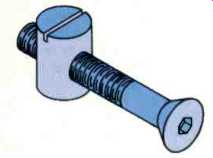

A screwdriver and pliers are needed to open the crate. These are the only tools you'll need to supply, for Lepper provides a #1 Phillips screwdriver and two Allen wrenches. Assembly took me 11/4 hours. This unit is a bit simpler to assemble than the CWD Woodmore lowboy, but since it was the first unit I put together, my progress was slower than with subsequent cabinets. This was partly because of curiosity. As I was screwing the casters to the base, I noticed some screw heads in the top that didn't seem tight. Grabbing a flat bladed screwdriver, I began turning them, against no apparent resistance. I scanned the directions and soon realized these were anchor points for the knock-down fittings, and that I had now misaligned them. The system itself consists of pre-inserted rods with threaded holes and countersunk mating bolts (see sketch), which are very unobtrusive, extremely strong and easy to assemble.

Bolt and rod used to anchor the XP 48's knock-down fittings.

Lepper uses composite materials in the XP 48. Side and top panels are 1 inch thick, composed of'/ 3/4-inch particleboard core banded with-inch solid oak, and veneered with matched oak skins. The panels are massive, attractive, and structurally stable. Solid edging is encapsulated between the outer veneers for extra strength, avoiding the visual distraction of typical, "glued-on" edging. The shelves are of veneer core plywood with solid front edges.

Lepper uses a premium 9-ply panel instead of the 7-ply construction of less expensive plywoods. The back is 1/2 inch oak-veneer plywood, finished to match the cabinet front and back. In short, premium materials are used.

Material selection mates with thoughtfully conceived engineering. The knock-down fittings work on a compression principle, and the fittings all mount in particle-core panels which have excellent resistance to compression crushing. Veneer plywood shelves are light but strong. Lepper, alone among the makers of KD units reviewed here, has very carefully designed a highly versatile system around his adjustable shelving hardware, using it for accessory slides and drawers as well as for shelves. However, he apparently presumes that the cabinet won't be reconfigured often, for one must remove and remount the doors to adjust shelf positions.

From top: Lepper/CWD system, Naiad shell with Naiad/Barzilay

support pins, Sonrise shelf and pins, Lepper/CWD/Sonrise door hinge pins,

and Lepper KD fitting.

The cabinet normally comes with three shelves. Two mount with the same type of 1/8-inch wire-frame base as CWD uses. But the third mounts between cleverly designed brackets which screw into the adjusting holes, designed so the shelf locks snugly to them. This helps keep the cabinet sides from bowing and assures a very positive, snug fit for the adjustable shelves as well as for the back. Furthermore, the shelves can be quickly, easily and solidly screwed to the back, where there are holes level with each set of adjustment holes; mating pilot holes are drilled into each shelf.

The accessory turntable-slide mounts between a shelf (resting on wire brackets) and the slightly smaller platform bearing the turntable. Only the platform slides out; the shelf stays in place when the slide is extended.

The accessory cassette drawer runs on oak guides that can be screwed into any set of adjusting holes. The drawer holds up to 68 cassettes, with dividers to keep the tapes from falling over when the drawer is opened or closed. The wood at the front bearing edge of the right-hand drawer guide was crumbly with decay, and would wear out quickly-but that was a lonely quality-control slip.

Oversize, stable base of XP 48 has reinforced caster

mounts.

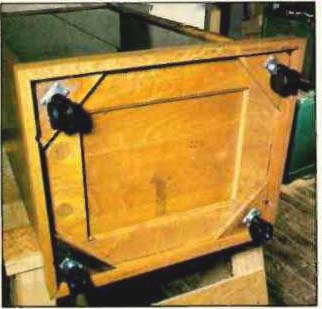

The base of the unit, seen in the photo (next page), also deserves a word. First, it's very well structured. A tongue-and-groove-joined subframe is glued together, reinforced with triangular corner blocks, then stapled and glued to the oak plywood base panel.

A solid oak skirt with mitered corners thus has a gluing surface 2 1/4 inches wide at each corner for maximum strength. Second, Lepper provides for both vertical and horizontal bolts between the base and cabinet sides, for extra-rigid connection. Finally, the base is both wider and deeper than the cabinet itself. Since all highboy units are inherently top-heavy, this extended footprint improves the cabinet's stability. Some may have aesthetic complaints about the visual look of the base, but structurally it's a rock.

Fixed-top design offers four usable component platforms plus record storage (four record dividers are provided). Interior shelves measure 21 inches wide x 16 inches deep, with a 193/4-inch clearance between glass doors when open. The three standard shelves in the cabinet offer 393/4 inches of usable interior height. When the turntable slide and cassette drawer are installed, this drops to 34 1/4 inches of headspace. Ventilation comes from three large openings in the back, and cutouts at the backs of the shelves provide for interior air circulation or wire routing. Lepper thoughtfully provides adhesive anchors for cables as well as cable ties.

The Lepper Works XP 48 is a well designed, solidly structured, and beautifully finished cabinet. With a suggested retail price of $625.00, it clearly is not intended for a mass market. On the other hand, given the high levels of engineering and execution, I'd say Mr. Lepper has earned his price.

Naiad Products Profile 47OR

Suggested Retail Price: $349.95

Address: P.O. Box 1840, 121 Roy Blvd., Brantford, Ont. N3T 5W4, Canada

Naiad's Profile 470R offers a flat-out high-tech look in a knockdown, highboy format. Also available in natural oak, the reviewed unit features walnut-veneer sides, a black-vinyl fixed top with walnut accents, walnut-edged black-vinyl adjustable shelves, and the ubiquitous smoked-glass frameless doors. Darth Vader's got nothing on this cabinet. Even the shelf pins and record dividers are black. Side-panel veneers are book-matched walnut, nicely centered and unobtrusively oiled.

Packaged in an 80-pound carton, the 470R is among the more manageable units sampled. Instructions begin with an exploded drawing, concisely demonstrating the overall assembly, and a list of the required tools thoughtfully follows. This list includes a small slot screwdriver, a #2 Phillips screwdriver, and a 5/32-inch Allen wrench (supplied). The company fails to mention a mallet or hammer to install record dividers, and I found an electric screw-gun (or ratchet-type screwdriver) with a #2 Phillips tip useful when installing the back. Assembly is straightforward and took two people 25 minutes. (By this time I was getting proficient.) Threaded rods and brass end fittings compress top and bottom between side panels. This works well, but lacks positive positioning references for the top and bottom. I discovered this while installing the glass doors, which use the same compression-type pivot hinges as CWD and Lepper. The doors wouldn't fit on the right side, and we had to loosen and reposition the top. Then we discovered that two of the four sockets for the hinge pivots were missing. The back is of 1/8-inch masonite pieces, which overlay the sides and lack pilot holes for attaching screws. By now the electric screwgun was warmed up, but the lack of pilot holes was still a nuisance.

All the panels in the 470R are 3/4-inch thick, with a particleboard core. Given particleboard's good resistance to compression, the compression-type assembly system, together with the fixed back, produces a unit of adequate if not overwhelming solidity. Side panels feature plain-sliced walnut veneers on both sides, with walnut-veneer edge banding. While adequate, this type of edging does not suffer abuse well. All horizontal panels are black leatherette vinyl (one side) over a particleboard core, with solid walnut accents on the fixed top and bottom shelves. Adjustable shelves (three are provided) are also vinyl-clad on top, with walnut-veneer front edges. These are attractive and easily cleaned, and since the shelves are behind glass, veneer edging is more appropriate here. Adjustments are made by positioning '/8-inch steel pins in pre-drilled holes in the sides. As in the Barzilay, these pins are sturdy, well-fitted and easy to readjust. But Naiad's shelves, unlike Barzilay's, sit directly on top of the pins, which are thus visible.

Interior space is ample, with shelves measuring 16 inches deep x 21 3/4 inches wide. There is 35 3/8 inches of usable interior height. Clearance through the doors, at 20 3/4 inches, is generous. The fixed-top design is clearly intended for a turntable, though no turntable slides or interior lights are offered for this cabinet. Interior configuration is very flexible and easily changed without removing and remounting the doors. Most components, save vertical reel-to-reel tape decks, should fit. A large opening in the top section of the back provides good ventilation and easy wiring access. The 470R comes without casters; although a casterless cabinet is more stable than its mobile cousins, access to the back becomes more arduous, so be forewarned. Door catches are magnetic touch latches, similar to both CWD's and Lepper's. I preferred Naiad's black latches to Lepper's, because the magnets are shaped so as not to chip the paint on the catches, as Lepper's tend to do. Three black-wire record dividers tap into pre-drilled holes in the bottom shelf and round out the hardware.

With a suggested retail price of $349.95, the Profile 470R is at least $100 less than any other model reviewed. For the price, Naiad produces a cleanly styled, nicely finished, functional unit. Frills like drawers, slides, and lights have been omitted. But for roominess, accessibility, ventilation and flexibility, this cabinet is the equal of any of the others. While not a timeless example of the cabinetmaker's art, the Profile 470R is competent, well designed, and suitable to many requirements.

Sonrise Audio Systems: Crestwood Model SK 3 GT

Suggested Retail Price: $496.00

Address: 13622 NE 20th St., Suite F, Bellevue, Wash. 98005, USA

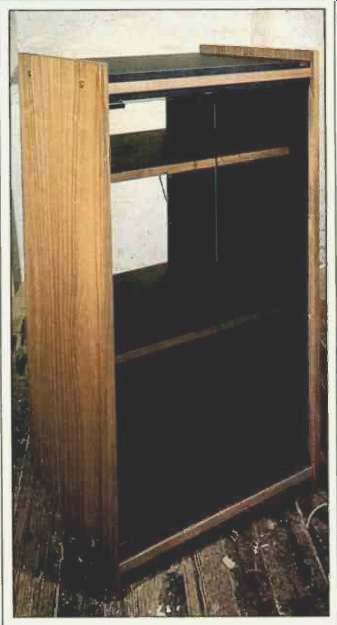

The glass-topped Crestwood is a fully assembled, hinged-top highboy with several likable features. Visually, it's a pleasant compromise between the severe sleekness of some units and the slightly overfed chunkiness of others. Solid oak-framed top and front doors lend a homey softness, while the flat-panel style keeps the look clean. Sonrise has clearly worked hard to produce an appealing product with an emphasis on craftsmanship, which in many ways is outstanding. Unfortunately, a series of design shortcomings hampers the effort.

The cabinet comes pre-assembled in an 86-pound crate. Setup requires opening the crate with a knife, attaching molded wood handles to the pre hung doors with a #2 Phillips screwdriver, adjusting the spring tension for the top with the same tool, and plugging the adjustable shelf pins into the desired positions. Two sets of instructions are enclosed on separate cards.

The first clearly and concisely details the procedure for fine-tuning the tension of the spring that holds the lid open and keeps it from slamming when you close it. The second card details maintenance procedures for the solid-oak side panels. Sonrise points out, quite correctly, that the solid side panels will adjust to local temperature and humidity conditions for a period of time, and very wisely recommends periodic application of oil finish during this time to prevent splitting.

This is good advice and should be followed. Unfortunately, Sonrise does not provide the oil. They recommend tung oil which, like boiled linseed oil, is used in many penetrating oil finishes.

Any oil finish (such as Watco, Waterlox, Minwax and Tungseal) is an adequate alternative. I don't mean to belabor the subject, but keeping the wood properly oiled is important.

While Barzilay and CWD also employ solid panels, the Sonrise panels are inherently more susceptible to distortion from changes in temperature and humidity. Sonrise uses relatively wide boards (only three boards for each 16 1/2-inch panel), and this gives the panels visual appeal. On the other hand, the wider the boards, the more likely they are to warp. At 11/16-inch thick, they are also thinner than Barzilay's or CWD's, and thin panels warp more easily. Maintenance oiling helps keep this to a minimum, and a conscientious maker will facilitate that maintenance.

Sonrise emphasizes craftsmanship, and their craftsmen do a good job.

Grain patterns in the solid side panels are nicely matched. Shelves are 9-ply, veneer-core oak plywood with plain sliced face veneers (good stuff) generously edged with solid oak. Front doors are oak framed, and the adjacent center frame members of each door are cut from the same board. This is a pleasing touch because the pronounced grain pattern is continuous between the two frames, a clear sign that an unusual amount of care went into assembly. The hinged top features pleasantly sculpted finger grips which I find very attractive. Solid-oak door handles are pleasing and visually unobtrusive. Slots carved in the sides allow the lower back to be removed for access without tools.

The potential is here for a really outstanding unit, but it's less than fully realized. My biggest complaint focuses on the back. While this may seem an odd place for concern, the Crestwood is more susceptible than the other cabinets to "racking." That is, its shape changes from a rectangle to a bit of a parallelogram when the cabinet is moved on its casters. The doors have a tendency to pop open. And even when the cabinet is at rest, nudging it changes the spacing between the carefully hung doors and the case.

All these symptoms could be cured by one easy change in the design: Replace the removable, partial back with a full-length, fixed back. The only diagonal bracing in the back is a 6 inch fixed piece at the top; it's not enough. To stiffen the unit, Sonrise has fixed a shelf 13 3/8 inches from the bottom, allowing record storage.

Since solid side panels are joined to plywood shelves, they are screwed but not glued, which allows inevitable dimensional change to take place peacefully but adds little to lateral stability. And since both the bottom and top shelves are fixed, they limit the interior configuration's flexibility. Only one adjustable shelf is provided for the 18 7/8 inches of space between the two fixed shelves. The defined space is more than required for two components, but probably not quite enough for three. If Sonrise gave the cabinet a fixed back for lateral stability, the lower fixed shelf could be made adjustable, and four equipment platforms would then be feasible. Sometimes small things mean a lot.

Sonrise recommends using the top shelf for either a turntable or a VCR. All shelves measure 22 inches wide x 14 7/8 inches deep, and the top shelf has 5 1/4 inches of usable height. This should be adequate for many turntables, but record changers and larger VCRs may not fit. An accessory slide out shelf for the lower compartment ($45, not reviewed) is available if this is a problem. The top compartment is eminently accessible through the hinged top and front doors. A wireway is provided through the back. The partial back does allow excellent ventilation and easy wiring access in the lower compartment. Drawers for (audio or video) cassette storage are additional options ($70 each, not reviewed). The full length of the cabinet is accessible since regular pin hinges are used for the doors. One of the hinges was slightly loose, probably from indelicate handling during shipping. It would've been an easy matter to retighten, except the hinges are mounted with Robertson-head screws, which require a special square-headed screwdriver.

(Every once in a great while, even / don't have the right tool.) Casters are garden-variety, brown-plastic hooded wheel types. Catches are magnetic and could be a shade stronger to keep the doors closed when the unit is rolled around. Although a lower compartment is designed for record storage, no dividers are provided; use bookends if you can't fill the compartment. Shelf pins are tan plastic and are serviceable, if somewhat bulky.

The essence of craftsmanship is attention to detail. Sonrise illustrates this well with its matching of materials in doors and side panels. This is why I'm a bit mystified at their finish. After taking the trouble to carefully match grains, plug screwholes with oak plugs, and individually hang and true doors, they finish the cabinet with what appears to be a single coat of pigmented oil finish. The result, while adequate, has dry patches and random splotchiness where excess stain has bled out of the open grain of the oak. With a light sanding followed by another coat of oil, this cabinet would sing.

I really like the looks of the Crestwood. An unusual amount of care has been taken in making it, and I'd love to be able to rave about it. Sonrise has gone 95% of the way toward producing an outstanding product. Now, if they'd just take care of that last 5%... .

EL Manufacturing: Realwood Model 2001

Suggested Retail Price: $700.00

Address: 215 South Tyler St., Dallas, Tex. 75208

Unlike the other units, the Real wood 2001 specifically dedicates half its space to video components, with flexible audio-component space in the remaining half. Also unique is the combination fixed/hinged top of this fully assembled lowboy. Half of the top is hinged to provide enclosed storage with both top and front access, while the other half can be used as an additional platform for large or frequently used components. The 2001 has a medium-dark walnut finish on oak; the Realwood Model 2000 has a natural-oak finish.

The styling is reminiscent of traditional-country kitchen cabinetry. Doors are oak-framed, overlay types with clear glass in place of raised panels.

The drawers appear to have solid oak-, sides, assembled with glue and staples, and have attached oak fronts with beveled edges. Hinges and knobs are kitchen-cabinet standbys. If you like the look of a traditional kitchen, this is your cabinet. It arrives pre-assembled, in a carton 30 inches high x 50 inches long x 21 inches deep, and tips the scale at 120 pounds. Final assembly is duck soup. Uncrate by slitting the tape on the cardboard shipping box, slide the box off, then use a slot screwdriver to remove the knobs inside the doors and drawers and install them on the outside. Unwrap the two adjustable shelves, plug in the adjusting pins, and you're all set. I only review this in detail because the manufacturer provides no owner's manual or other information whatsoever. Thinking that a brochure might have been omitted by oversight, I checked with EL Manufacturing and was told that assembly is so straightforward they felt no explanation was necessary. As their finish requires no routine maintenance, they make no mention of any. Fair enough, but omission of maintenance, adjustment, and warranty information left the impression that I'd just taken in a foundling.

Real-wood models are made of just that-no vinyl here. Like most commercial furniture, the 2001 is made of a variety of materials. Tops are rotary-cut oak plywood, with a characteristically coarse grain pattern, edged with wide strips of 3/4-inch-thick oak, shaped along the perimeter. Case parts are oak plywood, chosen for dimensional stability. Face frames are oak solids, glued and screwed together. Such frames are rugged and resist damage well. Door frames are oak solids, joined with glue and self-clamping metal fasteners. Clear door glass is set in brown silicone rubber for cushioning and to lend an attractive appearance. In line with standard practice, drawer bottoms are'/4-inch oak plywood, as is the case back. Adjustable shelves are 3 inch oak plywood with oak veneer edging. I noticed that veneer was chipped out on the underside ends of the shelves, indicating either improper sawblade selection by the manufacturer or poor glue-line quality from their plywood supplier. Since some other units surveyed had unfinished or mismatched undersides, it would be unfair to be too critical of this minor flaw.

The cabinet itself is exceptionally solid. Joinery is generally more than adequate. Door frames, although joined with metal plates that I instinctively distrust, should hold up well. Because the door glass has been literally glued in place, it becomes a structural part of the door assembly, reinforcing it. Construction of the drawers is standard industry practice, which holds up well in use, and they run on full-extension ball-bearing slides which are convenient and hefty. The top operates on spring-loaded hinges which can be adjusted to hold the top open for easy access. A glass door folds down to give unobstructed access to the front of this compartment as well. The other glass doors mount on antique-finished hinges to hold doors fully open, and use spring tension to hold doors closed, obviating catches. Knobs are die-cast and antique finished. No casters are supplied.

The 2001's configuration has some unavoidable limitations. The left side, with a top platform accessed from top and front, offers a shelf 23 inches wide x 15 inches deep, with headroom of 9 1/4 inches. The 15-inch depth in itself will not accommodate the largest turntables or VCRs, and the hinges for the front access door further restrict usable depth to 14 1/4 inches. Potential buyers should check this carefully against current or anticipated components. I don't mention tape decks because the two drawers beneath this compartment measure 19 inches wide, 12 1/4 inches deep, and 6 3/8 inches high. They're too big for efficient storage of audio cassettes and too small for 7or 10inch reels. Clearly ticketed for videocassettes, the drawers hold up to 40 each, but have no dividers to keep your cassettes from clattering around when the drawer is opened and closed. An alternative design offers record storage in place of these two drawers. Tape fanciers, though, won't find the 2001 their best choice.

The right side of the cabinet offers more options in equipment placement. A fixed top offers a convenient turntable platform; at 25 inches wide x 17 inches deep, it will house most anything this side of a Lincoln. The cabinet's traditional design places some constraints on utilizing all the interior space. Two interior shelves measure 14 7/8 inches deep and 22-9/16 inches wide, and adjust easily on 1 1/2-inch centers by use of well-fitting metal pins. Face framing, while contributing to the structural strength of the cabinet, reduces accessible width to 19 3/4 inches and accessible height to 22 inches, if both adjustable shelves are used.

Storing records inside may leave room for only one component. The wood framing of the doors visually cuts enclosed components in half, and the clear glass accentuates this. Owners of infrared remote-controlled components should check sensor positions to avoid blocking by wood frames. Interior ventilation is very good, provided by generous openings in the back.

Unlike all other companies discussed here, EL Manufacturing does not use penetrating-oil finishes. Instead, they use a more typical furniture-industry system of a wiping stain, protected by a sprayed synthetic lacquer-type finish. Environmental-protection statutes now require many firms to replace older, solvent-based finishes with water-based alternatives, and EL has complied. Modern water-based finishes have demonstrated excellent durability, with water and alcohol resistance, but from a manufacturer's point of view, their biggest drawback is extended drying times compared to their solvent-based predecessors. The longer the drying time, the greater the likelihood of stray dust particles being incorporated in the finish as small nibs or bumps. To overcome this problem, some manufacturers bake the finish to accelerate drying while others rub out (sand out, really) the offending flaws.

The literature about Realwood proclaims a hand-rubbed finish. The two units I examined, with numerous surface imperfections, clearly had not received this treatment. The finishes are acceptable commercial quality. They'll provide tough, low-maintenance protection superior in a number of ways to the oil finishes used by the other manufacturers. But this is the most expensive cabinet of the lot. The gentleman is solidly built, but he needs a more finely tailored coat.

EL Manufacturing Realwood Model 2090 Video Cart

Suggested Retail Price: $200.00

Styling, construction, materials and finish of the 2090 are similar to the 2001, its mate in the Real wood media-center product line.

This model is a caster-equipped platform for a television, with an enclosed, slide-out shelf to accommodate a VCR. Overall dimensions are 16 inches deep x 25 inches long, and the unit stands 18 inches tall. The enclosed shelf measures 14 3/4 inches deep x 23 1/2 inches long, with usable headspace of 9 1/4 inches. Solidly structured, it rolls easily on four dark-brown plastic casters. The slide-out shelf operates smoothly on a ball-bearing slide, but lack of proper cushioning left the front corners of the shelf scarred from its journey. The fit of shelf through door opening is tight, as the shelf hits the doors unless they're opened fully. An ample, T-shaped cutout in the 1/4-inch plywood back provides ventilation and wiring access.

Though lacking in tape storage, the 2090 could be a handy unit for the videophile. The Realwood modular concept offers a variety of largely single-purpose units with a strong video focus to allow custom tailoring a system. The audiophile who updates equipment on a regular basis may find this approach lacks flexibility once he owns specific units.

As the dust settles, one impression lingers. Technology in the furniture business looms larger all the time, as labor and material costs increase. One of its most notable impacts has been in finishing, where huge efforts have succeeded in enhancing cheap materials. Many manufacturers are thus able to mix injection-molded plastics, any number of woods and carefully engineered, machined-flakeboard components into products that look like well-finished solid wood-all due to a few thousandths of an inch of high-tech coatings. Without exception, the manufacturers reviewed have shunned this approach. They all use low-tech finishes that straightforwardly present honest materials. The results, to be sure, are varied and I've been pretty tough in my criticism. Still, I come away impressed with the overall effort.

(Adapted from: Audio magazine, April 1983)

Also see: