MATTERS OF SUBSTANCE

New materials-they rule our world. If you have lived through the bulk of this century you will understand that major innovations in our jet-speed technology always begin with something new in the way of materials--either an exotic suddenly be come economically viable, like aluminum, or a substance that nature hadn't thought of but man has made, like chromium dioxide. (Or, as we'll see in a minute, MetGlas.) It is the same in audio as in other areas. Give us a new material, and we spurt forward as fast as R&D will allow.

I find it always interesting, then, to gander the latest materials all over, even those that seem totally removed from the audio arena. You never can tell; they might turn into next year's sensation. I'll admit I get much plea sure just watching the reports, and speculating. More fun than lottery numbers and about as likely to pay off.

I can remember when aluminum first appeared in the consumer world and elsewhere, after a quarter century as an expensive exotic. Quite sensational and very handsome. It revolutionized the kitchen, of course--I can still see my mother's old iron skillets and greasy, rusty frying pans, the heavy crockery and jugware, the chipped enamel, the nickel-plated counter tools with the wooden handles, red or green, that quickly split and came off. And those massive meat grinders with curved metal handles, disassembled after each grinding--a child's heaven.

Priceless antiques now, but aluminum was a huge improvement. There was duralumin too, for aircraft frames, formerly patched up out of balsa wood and steel wires. The old Graf Zeppelin used to mosey over New York every few weeks, casually, and I would glance up at it. The Hindenburg also would fly over; I saw it blow up at a distance, from Princeton, N.J. All this and more was due to the sudden abundance of one formerly scarce metal, aluminum. It came in so fast (via the electrolytic process) that we never got to agree with Europe as to how to spell it or say it. In England, they say "al-you-MIN-ium," spelled aluminium.

We haven't used much aluminum wire in audio circuitry, but about 50% of our hardware is still made of that metal. It dealt us a sidelong glance.

Plastics are another story--they make up not only a million audio parts, large and small, but our basic recording media, disc and tape. As you probably know, the first magnetic tape was solid spring steel, wound on enormous, heavyweight reels; you could "edit" these, I've heard tell, with solder and a blowtorch. Even so, this system was used very practically for delayed broadcasts. After that--still without modern tape--we went to the opposite extreme, paper tape. I remember that stuff all too well; I used it on the first home tape recorder, the Brush Sound-mirror. Just shows how much we needed the later array of plastic materials, which did not appear until after WW II, for the most part. But then the vast spread of new plastics set us up in audio for much of our later development, and don't forget such incidental items as rubber-plastic insulation on circuit wire. Did you ever work with one of the old pre-plastic household electric cords, wound with several layers of cloth insulation which came undone, unwound, and shredded into snarls? Insulated wire had been a problem since the beginning of the use of current electricity.

You never know. Usually, when one of these basic new materials appears, it is a substance looking for a use. The original promoters have ideas but they are often off the mark. Like Edison's dictating machine, out of the talking machine, which didn't get to be a mu sic machine for a long time. Usually, unexpected uses pop up and change history. Often, of course, the material itself is an accident, discovered en route to something quite different.

When I first heard of that new synthetic material, chromium dioxide, newly wrought in a fiery furnace by DuPont, I rushed right out to the introductory press conference, because this was a highly magnetic substance that could be pulverized and coated onto plastic tape. It was already being used for tapes on big old mainframe computers. So why not for audio? A chrome tape would outperform exist in a audio tape in important ways.

That event, as I remember it, was a genial farce. DuPont wasn't talking. A curious factor, corporate secrecy. Yes, chrome was being promoted for computer tapes. Was there any thought of a chromium dioxide audio tape? Polite silence. Yes, they said, we are producing computer tape, right now, with this material. Period. As bland as you please. But nobody got a word out of them, as I remember it, concerning professional and consumer audio tape. Why? Business strategy, we will suppose.

I might add that, as often happens, chrome stimulated improvements in the nonchrome tape formulations that still continue today, reducing the once considerable difference in performance to a much finer distinction. So we have both kinds still with us. And we still look for improvements. Note the same thing happening between the LP and the CD--the LP has never been finer than in these years of its competition with the CD.

In spite of digital everywhere, we continue to search almost frantically for more efficient ways to record via the magnetic medium. It is still our base, both in audio and video; only the various disc formats--the audio products "published," so to speak, with indelible ink-are nonmagnetic. But the enormous efficiency of the microchip, of the little CD with the big play, of the movie-on-a-disc, all force us to look for any possible avenue of improvement that might mean more and better magnetic recording on less tape-and we are moving. A few years ago, 8-mm video (with audio attached) seemed highly unlikely. Now it is already beginning to do what the much larger formats can do. We are holding our own, magnetically, but barely. Improvements are welcome, especially radical ones.

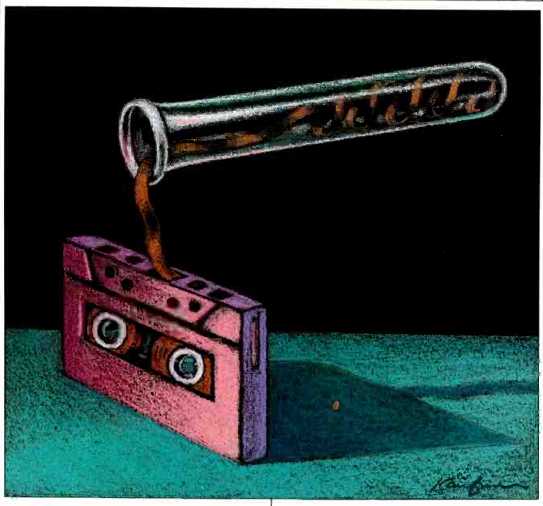

MetGlas. That may sound to you, as it did to me, like some unpleasant kind of medicine. But one look at the pictures in a fancy stockholders' brochure out of Allied Signal, the new giant combine of two major outfits, told me other wise. Did I jump in surprise! What was that? It looked like recording tape. It wasn't recording tape.

MetGlas is a wholly new form of met al alloy that apparently has never existed in nature or, until recently, via man's tricky handiwork. As the name actually implies, it is a true glass, all metal. That is, there is no regular crystalline structure, only an amorphous mix of molecules in random order. This gives the alloys--a whole family of them--some remarkable new properties. First of all, they are highly magnetic, far more so than pure iron. Second, they are produced in flat ribbon form, not in castings; they spin off a whirling wheel onto take-up reels. No, not audio or TV reels! The system is derived from Allied Signal's fiber operations, far re moved from any thought of recording.

The reels just look like TV. And the ribbons of flexible metal just look like, say, 2-inch video recording tape. A rich, reddish brown in color, obviously thin enough to wind and curl in any direction or maybe lie flat. Astonishing.

For an audio eye and a video eye, anyhow.

"Standard alloys with aligned or crystalline atomic structures," says Al lied Signal, "usually have a few missing molecules because manufacturing processes are imperfect." (Here my mind ran on the glitches and drop-outs in audio tape, and those digital errors that require the elaborate correction systems we now have in place.) "Amorphous structures, like MetGlas alloys, do not have these imperfections, so they are stronger and harder." And maybe less subject to irregularities that might foul up a magnetic re cording? That's what I would think.

Compare this to an optical lens made of absolutely uniform amorphous glass. Think of the accuracy of a telescope! That's glass for you.

MetGlas seems to be based on iron, variously alloyed. We in audio have already been able to produce a pure-iron recording tape of the standard coated sort, though not before there were actual explosions due to very rapid oxidation of the pure metal. That problem was solved, laboriously but triumphantly. Now we are looking at an amorphous alloy which is far superior to iron in its magnetic character and which features an inherent resistance to corrosion; if it could be made into a solid-metal tape, there would be no problem in that respect.

I think it is a nice speculation. The company says that MetGlas, sort of a cross between a sheet of metal and a metal foil, is "both flexible and tough." Could there not be a thin metal ribbon of it, thin enough, strong enough, to reel properly on a machine or in a cassette and to lie down flat for head contact? A tall order, I'll admit, one probably requiring much R&D and a lot of juggling of parameters. Still--it might be possible.

Keep in mind two points. First, there is no mention whatsoever of audio or video recording in Allied Signal's ac count of MetGlas. That is strictly my idea. Unless, of course, they are being cagey and not saying. The initially de scribed applications for MetGlas include, for instance, using it to make magnetic elements in large utility-type transformers. There are evidently small stamped and shaped parts of MetGlas in some new VCRs, a metal glass obviously being good for that kind of processing. (I would suppose these are magnetic elements in motors, relays, and the like.) MetGlas appears in high-speed computer printers, heat exchangers, and more-al ways as a magnetic metal alloy replacing standard formats for dramatically improved performance. This substitution market is so promising that the company figures a $6 billion world market in electrical steels might be entirely replaced by MetGlas, part for part. But a MetGlas "tape" for recording? Not a word! That's just my idea.

Second, note that this would never be a recording tape in the usual sense, a plastic base coated with magnetic material. It would be uniformly metal, all the way through. No coating, just the pure alloy. And yet maybe, even so, it could operate as a de facto tape that could meet the required specs, both mechanical and magnetic. So I am guessing. Somebody else will have to find out.

MetGlas was discovered, or invented, some 20 years ago at Allied. How ever, as with aluminum, which could not be produced in quantity when it was first isolated, MetGlas was not amenable to mass production. We are all aware that if you want small crystals you must cool fast, whether in metal or plain old ice. The faster the cooling, the finer the crystalline structure. This applies to the whole complex of metal working technology over millennia, along with bending, pounding, kneading. Quenching is the old metalworking term for quick cooling-you dunk a red-hot piece of metal in a pail of water, for instance. It follows that, to make an amorphous and non-crystalline metal, you must quench at enormous speed. How to do it? Not like the village blacksmith. That was the problem with producing MetGlas.

The new MetGlas process pours hot, liquid metal onto a wheel spinning at a tremendous rate; the metal is whirled and simultaneously cooled at one million degrees C per second, solidifying in less than a millisecond. It flies off continuously in a ribbon, to be collected on winding machines which are definitely not tape recorders, though they may look like it. That's how it is done, roughly speaking. No wonder it took a while to work up to mass production! I'd call this a 2,000-year breakthrough in metalworking technique. Beats even Bessemer.

What are the magnetic properties of MetGlas? All-important, of course, but we aren't told very much. (Maybe you could pry the specs out of the company if you tried.) Suffice it to note that MetGlas requires 70% less power to produce a given magnetic field than a conventional magnetic silicon iron. Not our usual terminology, but doesn't that say something to you? Does your hair stand on end? MetGlas, of course, must be made in a tape-like ribbon because of that instant quenching. It is inherently tape like to begin with. A thicker MetGlas wouldn't quench. Not to an amorphous state, anyhow.

Final thought: Suppose we quenched at half speed to produce billions of neat little molecule-sized magnetic domains, nicely patterned? You could tailor the structure to suit recording purposes-just maybe? Well, it's a good fantasy, anyhow.

(by: EDWARD TATNALL CANBY; adapted from Audio magazine, May 1986)

= = = =