MANUFACTURER'S SPECIFICATIONS:

Drive System: Belt.

Motor Type: 24-pole synchronous, 300 rpm.

Speeds: 33 1/3 and 45 rpm.

Speed Accuracy: 0.1%.

Wow & Flutter: 0.05%.

Rumble: -75 dB, DIN weighted.

Dimensions: 17 1/2 in. W x 13 3/4 in. D x 5 1/2 in. H (445 mm x 349 mm x 140 mm); height with lid open, 15 3/4 in. (400 mm).

Shipping Weight: 17.6 lbs. (8 kg), including arm.

Price: $425; $575 with Linn Basik arm.

Company Address: c/o Audiophile Systems, 8709 Castle Park Dr., Indianapolis, Ind. 46256.

For years we heard most experts tell us that the loud speaker was the weakest link in the sound reproduction chain. Other experts told us that the cartridge was the most important element to consider when buying a system. When Ivor Tiefenbrun of Linn Products Co. began to demonstrate that the seemingly unobtrusive turntable could also color reproduced sound, most experts were skeptical at first. He set up demonstrations and compared the Linn Sondek LP-12 with other turntables of the day, and the coloration caused by these turntables was apparent-but only be cause it was absent in the LP-12. I think that Tiefenbrun can be credited with focusing, in recent years, more attention on the turntable.

---------------

MEASURED DATA

This data has been updated from that which appeared in Audio's original Profile for the LP-12 (November 1983).

**Measured with the B & K 2010 test record, whose 3,150-Hz tone may not be exact.

Accurate measurement not possible because of the turntable's low Q.

-------------

I am sure there are still many audio readers who wonder why such a fuss is made about turntables. Even the editor of this magazine admitted to me that he had been a bit skeptical about the relative emphasis to be assigned to turntables, until a recent demonstration at which we both were present.

For Linn Products and Ivor Tiefenbrun in particular, it must have been difficult to decide to bring out a turntable which would be lower in cost than the LP-12. How could this be achieved? What could be done to make the turntable less expensive without seriously compromising its quality? One thing which helped to allow a lower cost turntable even to be considered was the fact that the LP-12 has undergone a series of significant improvements since its introduction.

Therefore, Linn set out to produce a turntable which provided a level of performance at least equal to that of the original LP-12. Another goal was that the new turntable should be" audibly better than other, competitively priced turntables.

Thus the Axis was born. While many other companies appear to build turntables for different price points, the price of the Axis was determined by the cost necessary to produce a specified level of quality. Some insiders know that Linn has aborted. at least a couple of times, the introduction of designs which didn't quite meet their goals.

First Impressions

Whenever I receive an audio product to test, I form certain impressions as I set it up and adjust it. Sometimes the high level of performance of a product overcomes the negative feelings initially generated during a difficult setup. Other times, the appearance of a product causes a positive or negative prejudgment. In the case of the Linn Axis turntable, there were some things which tended to make me think that it would provide a lower level of performance than it actually did provide. After testing a number of difficult-to-set-up turntables which provided excellent performance, setting up the Linn Axis was so easy that I naturally thought, "How can a turntable that is this easy to set up be capable of great performance?" The simple styling and light weight also contributed to this false impression. The Axis weighs only about 17V pounds with the arm, detachable line cord, and phono cable included. I always attempt to keep an open mind when I evaluate any product, but the fact that I rely on the aural judgments of a listening panel helps considerably. In the case of the Axis, it was invaluable.

Features

Because of its similarities to the Sondek LP-12 turntable, which was evaluated in the November 1983 issue of Audio, it seemed logical to me that I should compare the Axis to it, looking at each major part one by one. The spindle and its associated thrust-plate bearing have always been considered by Linn to be the principal feature of any turntable, and they have lavished attention on these parts, machining and polishing them to a degree never even considered by most turntable manufacturers. Rather than go into detail here about the specific operations, I will say only that I have never seen anything comparable-except in the aerospace industry.

Fig. 1 -Computer plot of wow-and-flutter spectrum, from 0 to 100 Hz. The

major output at 0.56 Hz is related to the rotational

Fig. 2-Speed drift over 42-S period.

Fig. 3-Speed stability referenced to 3,150-Hz test tone on B & K 2010

test record. The tone may be a bit high (see text); speed stability is

excellent.

The spindle on the Axis turntable is less complicated than that of the LP-12, but the tip and the sides, which rotate against the thrust plate and well bearings, are machined and polished to the same degree of perfection. Linn engineers have found a way to eliminate some of the 14 steps necessary in manufacturing the LP-12 spindle, by simplifying the way the Axis spindle is attached to the turntable platter. Both spindles are made from hardened steel. Rather than using a separate ball bearing, as some other turntables do, they are machined to a conical shape with a precision radius at the end. The advantage of this technique is that instead of having a flat spindle bottom rotating on a ball which then rotates against a flat thrust plate, only the tip of the spindle rotates on the thrust plate. This means that the spindle tip must be perfectly centered so that it does a perfect pirouette on the thrust plate, rather than engraving a circle. The thrust plate, also made of hardened steel, is lapped and polished to a mirror finish. Such precision ensures that rotationally related vibration, which would color the reproduced sound, is reduced to an insignificant level.

The two-piece platter of the Axis is aluminum rather than the more costly Mazak alloy used on the LP-12. Both parts of the Axis platter are gravity cast and then machined, as is the LP-12 platter. The outer platter, 11 3/4 inches in diameter, rests upon an inner platter which is 6 3/8 inches in diameter.

Both are covered by a felt record mat. The precision-ground, 3/16-inch-wide, flat neoprene drive belt is looped around the inner platter and an aluminum pulley which is mounted on the motor. The motor, a 24-pole a.c. type made to order by Philips, runs at 300 rpm. This allows Linn to machine a large-diameter pulley and press-fit it to the motor shaft. The motor's 300-rpm speed is equivalent to 5 Hz; this low frequency, which is below the useful audio range, is much easier to filter out than the 30-Hz vibration which is produced by a four-pole a.c. motor running at 1,800 rpm.

While the main platform of the LP-12 is stainless steel with a separate wood mounting board for the tonearm, the Axis uses a high-density, 1/2-inch-thick fiberboard material which has a laminate veneer on both sides to eliminate any tendency to warp. This base is less expensive to produce than the LP-12's, and probably does change the character of the reproduced sound; the question is whether the change is acceptable as a trade-off to achieve a lower cost. The visible side of the platform is dark gray laminate.

The turntable base, made of particleboard with a vinyl laminate veneer, is constructed using V-groove, fold-up techniques. The vinyl veneer is black with a wood-grain pattern. This base is obviously less expensive than the selected hardwood base of the LP-12.

Rather than employing the usual springs-with-damping type of suspension system, the Linn Axis uses three silicone-rubber mounts which act as springs with inherent damping. These are custom designed and molded and I have never seen anything like them on any other turntable.

Each is cleverly designed as one long part, and together they act as the suspension of the turntable/tonearm platform and as feet for the base. Each mount consists of two thick walled rubber tubes, connected by a thin rubber diaphragm, all parts of a single molding. The large, tubular bottom section has a 2 3/4-inch outer diameter and a 2-inch inner diameter, and projects 1/2 inch below the base to form the foot. This section is crowned by a molded-on metal flange ring, which is held to the base by four screws. The large tube is closed at the top by the molded-in diaphragm, to which the smaller tube, with an outer diameter of 1 1/8 inches, is joined. This tube, which is about 1% inches high, supports the platform on which the arm and platter are mounted. The rubber diaphragm allows for up-and-down motion of this platform while limiting any tendency to rock or sway. Rocking and swaying are further limited by a bolt that passes through the upper tube, through a 3 1/2-inch-diameter washer below the platform, into a captive nut.

The output is extremely low, except for that which is caused by the arm cartridge resonance.

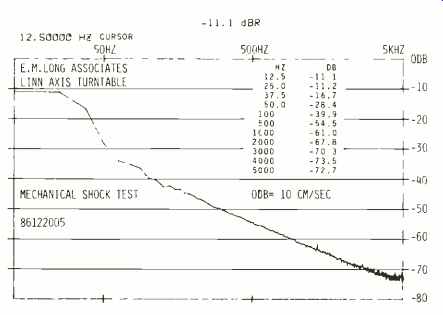

Fig. 5 Output vs. time for mechanical shock applied to edge of a stationary

record, with stylus resting in groove.

The felt mat causes a very smooth decay.

Fig. 6-Spectrum of output caused by a series of mechanical impulses applied

to edge of stationary record, with stylus resting in groove.

By molding each foot/suspension part as one continuous piece of the same material, three things are accomplished.

First, energy transmitted from the turntable/tonearm platform to the surface upon which the turntable rests flows through the material with no change in velocity, which could result in reflection of energy back to the platform. Second, using one solid part reduces the chance for assembly errors and possible misadjustment. Third, the parts and assembly-time costs are reduced significantly.

The tonearm mounts directly to the platform. The bottom of the base has a hole and slot, in the shape of a keyhole, to allow the exit of the tonearm phono leads. The turntable can be supplied without a tonearm or with the Linn Basik LXV.

The unit that I tested had the Basik LVX tonearm and a Linn K9 moving-magnet cartridge. The a.c. power cord is an IEC standard detachable type with a separate three-pin plug; it is 2 meters (6/2 feet) long. It appears that a simple wiring change on the circuit board will allow either 110- or 220-V operation. I am not sure about the motor speed for 50- or 60-Hz operation, but I assume the electronic circuitry provides for this.

The most obvious feature of the Axis-and the one which most clearly indicates that Linn is not just out to make a "cheap" turntable-is the large, 11-fin heat-sink which projects 3/4 inch from the rear of the base. This heat-sink is for the two Class-A amplifiers which are used to drive the motor coils. Seeing this heat-sink makes an inquisitive person like myself want to get inside the turntable to see what is going on. Well, I wasn't disappointed; there is a large p.c. board with many parts, including seven ICs and four transistors.

There are also four power transistors mounted on the heat-sink and connected to the p.c. board. This circuitry is designed to provide clean a.c. power to the motor and to allow both 33 1/3- and 45-rpm speeds. A unique feature of the electronic circuitry is that it provides 110 V for starting and about 20 V for steady operation, thus reducing the hum and vibration produced by the motor. Pressing the button on the left front of the base lights a red LED and causes the turntable platter to rotate at 33 /3 rpm. Holding the button down for 2 S causes a green LED to light and changes the speed to 45 rpm.

The Axis is very light, as I mentioned before, so finding a place for it will not be the problem it is for some of the heavyweight turntables I have tested. A clearance of 16 inches between the shelf upon which the turntable is placed and the shelf above is necessary to allow the lid to remain open on its spring-loaded hinges. The shelf should be about 16 inches deep.

Measurements and Listening Tests

The listening panel auditioned the Linn Axis as compared to my reference system, and their comments apply to that comparison, but I also had a chance to hear the Axis alongside a recent version of the Sondek LP-12. The LP-12 has an advantage over the Axis in terms of musical clarity and articulation of detail. In the Measured Data table, for comparison purposes, I have included data for the LP-12 (based on my original 1983 measurements) along with the data for the Axis. (As originally published, some of the LP-12 measurements were in error; they have been corrected here.) I have always felt that the raw data shown in the Figures is much more valuable than single numbers for such things as wow and flutter and rumble. Comparing the graphs of the original report with the graphs in this report can be useful, but I wish I had been able to run tests on a recent Linn Sondek LP-12.

Figure 1 shows the wow-and-flutter spectrum in the range from 0 to 100 Hz when reproducing the 3,150-Hz tone on the B & K 2010 test record. The system was calibrated so that a 1% modulation of the test signal produced an output at the top of the scale. Each division represents 10 dB, so 10 dB down represents 0.316%, - 20 dB is 0.1%, and so on to the bottom, which is -80 dB or 0.0001%. (Figure 1 of the LP-12 is calibrated to show 3% at the top of the scale, so you will have to make a visual adjustment if you compare it to Fig. 1 here.) The major output is at the rotational-speed related frequency of 0.56 Hz, with some additional output in a broad range around the tonearm/cartridge resonance, which was about 8.75 Hz. Piano recordings seem to be the most revealing of wow and flutter, and the Axis elicited no adverse comments by the listening panel when reproducing them.

Figure 2 shows the drift in speed over a 42-S interval with the Axis running at 33 1/3 rpm. The cyclical speed variation is related to the rotational speed of the turntable platter and is within ±0.18%. The overall drift over the 42-S period shows a variation of only ±0.11%. This is better than other, higher priced turntables that I have measured, but the jaggedness means that the speed is not changing in a smooth manner. I don't think this effect was discernible when the Axis was compared to the reference system, since I found no comments by the listening panel which I could correlate to it.

Figure 3 analyzes changes in speed in another way. The spectrum shown is due to the frequency variation of the 3,150-Hz test tone, graphed with a Nicolet 660-2D Fast Fourier Transform (FFT) analyzer in zoom mode with a window 80 Hz wide. The data was taken over 16 samples with the Axis running at 33 1/3 rpm. The cursor was set at 3,158 Hz because either the Axis is 0.254% fast or the tone on the B & K 2010 test record is not precisely 3,150 Hz.

Comparing this data with data on other turntables that I have tested, I have to say that it shows excellent speed stability. This was an advantage during the listening tests, when I would synchronize the reference turntable with the Axis to allow simultaneous playing of copies of the same record on both. The Axis stayed synchronized with the reference turntable over the whole side of an LP. Very nice.

Figure 4 shows the rumble spectrum for the Axis; except for what is contributed by the tonearm/cartridge resonance, the output is extremely low. If the Q of the tonearm/cartridge resonance were lower, then the rumble would be reduced considerably. In any case, the contribution to the total rumble caused by the turntable is negligible. I am certain that this is due to the precision polish of the shaft and its bearings, and the main bearing and its thrust plate.

While other turntable manufacturers have implemented various methods of removing internally reflected or delayed energy from records, Linn has continued using a simple felt mat on the Sondek LP-12. The same felt mat is supplied with the Axis. The output caused by a mechanical impact to the edge of a stationary record (Fig. 5) shows a sharp rise with a smooth decay of energy. The total time window is 2.05 S.

(For those of you comparing this with Fig. 6 of the LP-12 report, I noticed that the caption on the latter says the time window is 0.205 S. This is incorrect; it should say 2.05 S.) This curve for decay versus time is very distinctive, and have seen it only when a felt mat is used. The only comments made by listening panel members which I could correlate to the felt mat were that certain instruments such as trumpet and violins were brighter, and that individual piano notes during staccato passages were not as clearly defined on the Axis as on the reference turntable.

Figure 6 shows the spectrum of the output caused by 16 mechanical impulses like that of Fig. 5. The value of such a spectral analysis is in the fact that peaks and dips can be seen even though the impulse in Fig. 5 might not indicate that they are present. The energy which appears in the spectrum between 11.25 and 28 kHz might be related to panel members' comments about brightness in the sound. It should be emphasized that these comments were made when comparing the sound with that produced using the reference turntable.

Fig. 7 Output vs. time for mechanical shock applied to heavy platform on

which the turntable rested. Isolation was impressive.

Fig. 8-Spectrum (to 5 kHz) of the vibrations caused by mechanical shock

applied to platform supporting the turntable.

Fig. 9-Spectrum (to 100 Hz) of the vibrations from a 100 dB SPL acoustic

field at the surface of a record.

Stylus is resting in a groove near the middle of the record.

I was able to listen to a large number of recordings using the Axis over long periods of time. I do this with all the turntables that I test to check for "listening fatigue." The Axis passed this test easily.

Figures 7 and 8 show the reaction of the Axis to a mechanical shock applied to the heavy platform upon which the turntable rested. The isolation was impressive, and remained so during numerous repetitions of this test.

Figure 9 shows the spectrum of the output generated by a slow sweep of frequencies from 20 to 100 Hz, which produces an acoustical level of 100 dB SPL at the surface of a record on the turntable. I am not sure what produced the sharp increase in output at 12.75 Hz, and I don't want to speculate. There was nothing strange in the sound during any listening tests which I could correlate with this 12.75-Hz output. The output at higher frequencies, up to 100 Hz, is similar to that seen in other reports, and shows that the Axis has good isolation from external sound fields.

Conclusions It is apparent that both Linn Products Co. and its U.S. distributor, Audiophile Systems, are dedicated to the enjoyment of reproduced music via records. I think the Axis is a very good turntable, especially when its price is considered, and anyone thinking of purchasing a turntable should audition it. In fact, if Audio had a "best buy" rating I would vote that it be awarded to the Axis, because of its combination of high performance and low cost.

--Edward M. Long

(adapted from Audio magazine, May 1987)

= = = =

Also see: