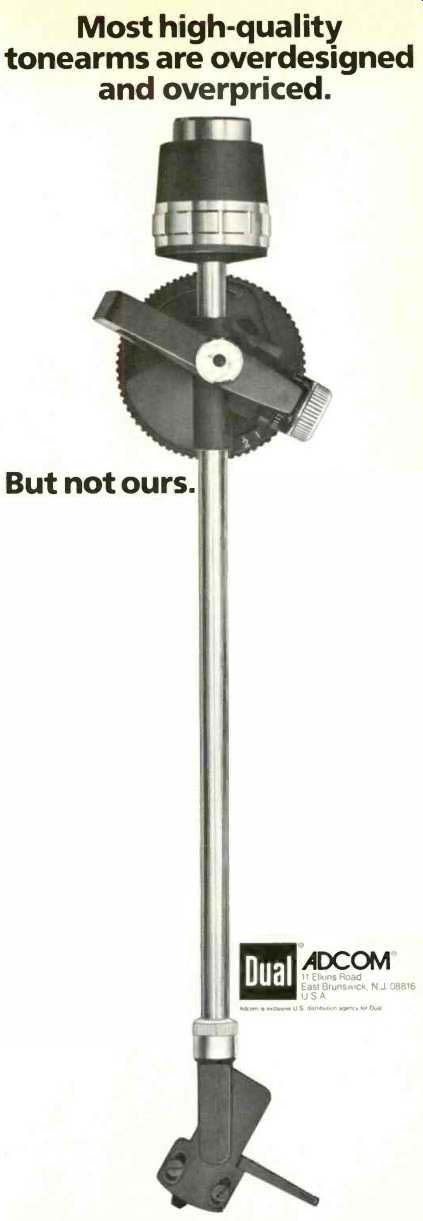

Most high-quality tonearms are overdesigned and overpriced.

But not ours.

Take a good look at those high-priced separate tone arms and you'll find most of them are designed to solve problems they created for themselves.

After all, every tonearm has the same essential job to do: let the stylus function as intended. Specifically: track the groove accurately, bring the tonearm along as the groove spirals inward from lead-in to run-out, and leave no trace of its passage on the groove.

To do that job well, a tone arm needs the right geometry, perfect balance, precise and stable settings for tracking force and anti-skating, extremely low bearing friction, and immunity to resonance and external shock.

In short, the Dual tonearm.

The straight-line tube that made everyone else go straight. (It's made of Dual's own XM300 aluminum and magnesium alloy-the best material on any tonearm for low mass, rigidity and self damping.)

The entire tonearm perfectly balanced in all planes, and suspended within a four-point gimbal on ultra low-friction bearings made and polished to aerospace standards.

Tracking force applied within 0.1 gram tolerances, and without unbalancing the tonearm the way others do--by design, no less!

And effective mass less than 7 grams with the ULM cartridge.

Contrast all this with so many of those highly-touted separate tonearms with their "Rube Goldberg" gizmos--weights, pulleys and outriggers-that may look impressive, but are really there to correct inadequacies or mistakes in the basic design.

Finally, compare the value.

Overkill tonearms like that vs. the elegant Dual tonearm.

The highest-priced less than $250--complete with turntable.

Dual / ADCOM, 11 Elkins Road, East Brunswick, N J 08816, USA

Also see:

Dual -- world's finest tonearms (Dec. 1977)

LUX PD-277 fully automatic direct-drive turntable (Aug. 1979)

(Audio magazine, Jun. 1984)

= = = =