by Michael B. Martin

[Michael B. Martin is a retired electroacoustics engineer who spent approximately half of his 40-year career designing consumer and professional recorders (analog and digital) and the other half in the field of magnetic recording tape. The last three years of his career were devoted to optical recording.]

Since the announcement of the Compact Disc in 1980, it has been reasonable to suppose that a CD system for recording by the consumer is under development and that sooner or later a recorder would appear on the market. However, 11 years have passed without the appearance of a completely satisfactory system. In recent years several technical papers on the subject have been published, news releases about research activity have been issued, and prototype digital audio disc (DAD) recorders have been exhibited at trade shows and reviewed by magazines. At the February 1991 Audio Engineering Society Convention in Paris, DAD recorders for professional applications were exhibited by START Lab/ Sony, Kenwood, and Yamaha from Japan as well as by Thomson and Studer from Europe.

Both erasable magneto-optical and non-erasable write-once (WORM) systems were represented but at prices beyond the normal consumer range.

For example, the Studer cost from $10,000 to $11,000, while the Yamaha was about $17,500 for the recorder plus $4,750 for a controller handling up to seven recorders. The Studer and the Yamaha produce non-erasable recordings that are claimed to be fully compatible with CD players. (Editor's Note: We published a review of the Marantz CDR-1, a $7,000 professional WORM recorder, in the March 1992 issue. The discs it records cannot be erased but they can be used in regular Compact Disc players.)

All commercially produced Compact Discs and CD players are made to standards defined by Philips and Sony, who hold the master patents. This allows them to control the licensing of other makers of CD-Audio, CD-ROM, CD-I, and CD-V and to control the licensing of makers of recorders and recording discs for all CD applications. The standards are defined in a series of five books supplied to licensees as part of a licensing procedure. Also, the CD standard is defined in the International Electrotechnical Commission (IEC) Standard BNN15-83-095, "Compact Disc Digital Audio System." The Philips/ Sony books are identified by the color of their covers: The Red Book is for CD-Audio, the Yellow Book for CD-ROM, the Green Book for CD-I, Orange Book 1 for CDR-Write/Erase or CD-MO, and Orange Book 2 for CDR WORM.

A reasonable assumption is that a disc that can be recorded by the user should be capable of meeting the same playback standards as a commercial CD and that any standard CD player should be able to play the disc after it has been recorded. The ideal medium should also be capable of being erased and re-recorded many times. In reality, the development of a medium that meets these criteria has proved to be extraordinarily difficult, and none of the systems which have been demonstrated are capable of creating a recording that can be erased and that is completely compatible with CD standards.

Most of the major companies which design and manufacture recording hardware, companies which are active in data memory and companies which make recording media for consumers and data processing, have active programs aimed at developing recording media for optical playback. It has been estimated that more than 150 companies in the world are trying, or nave tried, to solve the technical problems. Already the gross expenditure has been so great that it is doubtful whether the successful CD recording product will earn as much in its useful life; notwithstanding, success is likely to pay handsomely for the holders of the patent rights to the product technology chosen as the world standard.

CD playback standards do not apply to the use of optical discs in the data processing field other than CD-ROM. However, a high proportion of the scientific work on data processing media is applicable to blank audio discs, and it is probable that any successful consumer product will be a fallout from developments in data processing.

The Compatibility Factor

When embarking on the design and development of an audio recording system for the CD format, the question of compatibility and what this means are the first major issues to be faced. The obvious answer to the question is: To be compatible with CD, a recorded disc must be capable of playback on any standard CD player. In other words, the recorded disc must meet the same physical, optical, and digital encoding standards as a commercially produced CD. A review of the technologies by which an optical playback medium can be recorded shows quickly that the issue of playback compatibility with CDs is not simple. This article will consider compatibility at the following levels:

- Backward compatibility with all existing players and compatibility with all future players;

- Partial backward compatibility with existing players that have certain specific features;

- Forward compatibility with a modified CD playback standard, and

- Forward compatibility with a hybrid playback system.

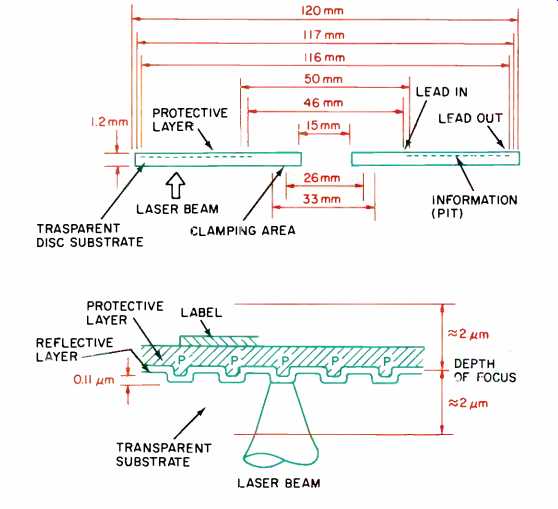

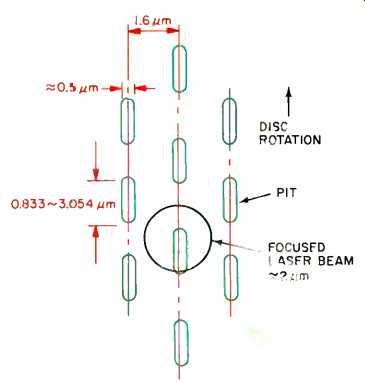

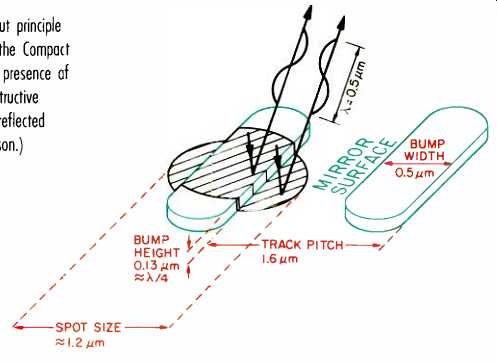

In order to be fully compatible, a recordable Compact Disc (CDR) must conform to the dimensions given in Table I and Fig. 1, and it must meet the optical requirements given in Table II. After the disc is recorded, its recorded information must have the characteristics given in Table III, and the recorded data must be compatible both with single-beam (push-pull) and with three-beam tracking systems. CD players use the binary musical information on a commercial disc to guide the playback laser head. Because the CD is read from the substrate side, the laser "sees" the data pits in the reflective surface through the substrate as a series of bumps that create a reduction in the reflected light. This reduction is caused by interference between the incident and reflected beams because the depth of the pits is one-quarter of the wavelength of the play back laser beam in polycarbonate. (See Fig. 2.) If the playback laser were to be presented with the "dimples" instead of "pimples" (that is, an information surface deformed in the opposite direction to that of a commercial CD), the half-wavelength interference would still take place and the information would be read correctly. The same situation exists with a three-beam tracking system as with the musical information, so the player would still track pits or bumps correctly; however, a push-pull single-beam tracking system depends on the phase of the tracking signals.

As a result of this phase dependency, if surface deformities were to be seen as pits and not bumps, the playback laser would track on the "land" between the data and miss the recorded information. This could be handled by a new generation of players having single-beam tracking and a switch to invert the "phase" of the tracking servo when playing CDRs--or the problem could be handled by abandoning push-pull tracking systems for CD players. This is an example of partial backwards compatibility.

The CD standard calls for the disc to have a minimum reflectance of 70%. Some of the disc technologies in development will make it difficult to achieve this comparatively high ratio of reflected-to-incident light, although 30% reflectance is readily obtained. Fortunately, the modern laser playback system can be designed to function very reliably with reflectance figures in the 20% to 30% range; this makes a realistic proposition of forward compatibility for CD players de signed to accept a lower percentage of reflectance than the present standard of 70%.

Strictly speaking, a CDR that needs a hybrid playback is not a blank CD because the technology used to read the recorded disc is not the familiar optical cancellation system; a separate playback optical system is required. The best-known example of hybrid playback occurs with magneto-optical (MO) discs; a second example is the electron trapping technology (ETT) proposed by Quantex Corp. For any non-compatible blank recording disc system to be fully successful as a commercial product, the majority of the manufacturers of CD players must agree to make players that can accommodate the system, and Philips and Sony must license the use of eight-to-fourteen modulation (EFM) encoding. Without the occurrence of these two things, the DAD system will be in direct competition with DAT and DCC; it will have the advantage of rapid random access but the probable disadvantage of higher cost.

---------------

Table I--Physical dimensions of the Compact Disc

- Disc Diameter: 12 cm (4.72 inches).

- Disc Thickness: 1.1 to 1.3 mm.

- Disc Flatness: - 0.6° (0.5 mm at rim).

- Diameter of Center Hole: 14.95 to 15.05 mm.

- Recording Diameter: Minimum, 46 mm (1.81 inches); maximum, 117 mm (4.61 inches).

- Program Diameter: Minimum, 50 mm (1.97 inches); maximum. 116 mm (4.566 inches).

- Diameter of Lead-In Area: 46 to 50 mm.

- Diameter of Lead-Out Area: 116 to 117 mm.

- Substrate Material: Any transparent material meeting the optical spec.

Table II--Optical system of the Compact Disc.

- Wavelength of Standard Laser: In air, 780 nm (7,800 angstroms); in substrate, 500 nm (5,000 angstroms).

- Focal Depth: ±2 Substrate: Refractive index, 1.55 at 780 nm; birefringence, <100-nm deviation from 500-nm wavelength.

- Reflectance of Metal Layer: 70% to 90% at 500 nm.

Table III--Signal format of the Compact Disc.

- Number of Channels: At normal speed, two; at twice normal speed, four.

- Quantization: 16 bit linear, concurrent on all channels.

- Sampling Frequency: 44.1 kHz.

- Channel Bit Rate: 4.3218 megabits/S.

- Data Bit Rate: 2 0338 megabits/S.

- Data-to-Channel Bit Ratio: 8 to 17.

- Error-Correction Code: CRC, with 25% redundancy.

- Modulation Systems EFM.

- Recorded Track: Spiral, inside to outside.

- Track Pitch: 1.6 p.m.

- Rotation at Constant Linear Velocity (Variable rpm): 1.2 to 1.4 m/S.

- Minimum Pit Length: At 1.2 m/S, 0.833 um; at 1.4 m/S, 0.972 p.m.

- Maximum Pit Length: At 1.2 m/S, 3.05 um; at 1.4 m/S, 3.56 p.m.

- Pit Depths 110 to 130 nm.

- Pit Width: Approximately 0.5 um

--------------

The Importance of Erasure

Several decades of consumer familiarity with magnetic recording have made the ability to erase and record again a near essential for any type of recording medium. Magnetic media can be erased an infinite number of times without loss of medium life and with no reduction in performance when recorded again. Erasure as a property of the magnetic system was not one of the principal reasons for the system's original introduction and widespread use; it was merely a useful attribute that came with the territory. Nevertheless, the freedom to erase and overwrite has been designed into all existing audio, video, and data recording systems. Life without erasing is difficult to contemplate.

The need for simple erasure is a significant problem for researchers in their quest for a medium to be used in a CD recording system. Erasable media are being researched that cover the gamut in terms of cost, new technology, and new materials. The software architecture of most data processing applications requires that at least one million erasures be possible. Fortunately, the needs of a consumer entertainment application are not as severe; the ability to erase a thousand times is usually considered adequate. (In practice it is doubtful whether more than 5% to 10% of cassettes in use today, audio or video, are erased even 100 times.) Although the ability to erase and record again is very important to both the amateur and the professional, non-erasable Write Once, Read Many (WORM) media have been developed, and systems based on them have reached the market.

WORM media present additional challenges to the designers of recorders, particularly if the recorded disc is to be compatible or partially compatible with CD. The CD standard specifies a directory or lead-in at the beginning of a recording, and the first few seconds of all CDs tell the playing equipment the number and duration of all selections on the disc and the total duration of the recording. The directory is recorded in the lead-in area shown in Fig. 1. When a CD is inserted into the player, the directory is read and the information is stored in the player's memory. If the player does not find a directory at the start of a disc, it will not operate. A CD recorder must be able to create a directory if the disc is to be used in a CD player.

Similarly, lead-out information is necessary at the end of a disc to tell the player to shut down. A full discussion of all the ramifications associated with non-erasable media is beyond the scope of this article, but a few points should be made:

- Making a copy of a complete CD is relatively simple, because with special play back electronics all directory and index information can be copied from the disc.

- Adding more "tracks" to a partially re corded disc, and updating its directory, is difficult. (Note: It is reported that some makers have solved this problem.)

- When a mistake is made during recording, an expensive blank disc may be wasted.

- Making a test recording probably means that a disc must be committed to the test.

Fig. 1--Basic dimensions of the Compact Disc, with a cutaway drawing showing

the pit structure and a laser beam track. (After Pohlmann, Principles

of Digital Audio.)

Fig. 2--The readout principle and dimensions of the Compact Disc. Note that

the presence of a bump causes destructive interference in the reflected light.

(After Watkinson.)

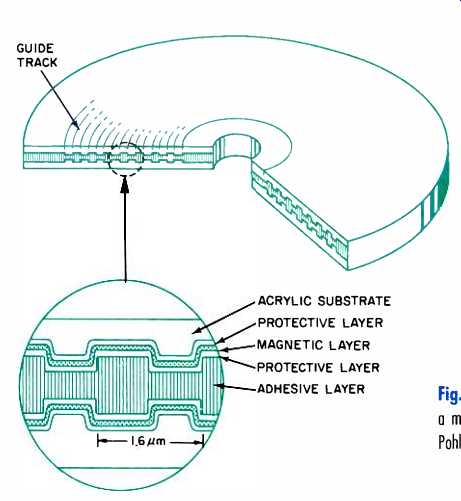

Fig. 3--A cutaway drawing of a magneto-optical disc. (After Pohlmann, Principles....)

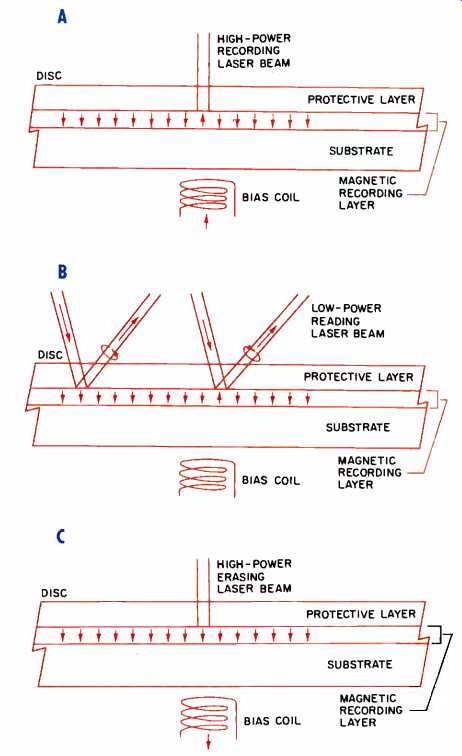

Fig.

4--Magneto-optical (MO) recording principles: A laser beam heats the medium

while magnetic recording is induced by the bias coil (A); data is read

by shining a laser beam on the surface and observing the rotation in the

plane of polarization of the reflected light (B), and data is erased by

heating the medium and reversing the bias field (C). (After Pohlmann)

Competing Technologies

The systems to be considered here are based on media which use one of the following technologies: Magneto-optical, phase change, or dye polymer. In addition to significant problems with materials, manufacturing technique, and fragility of the finished product, each of these technologies has a major drawback associated with either CD compatibility, erasure, or both. An MO recording requires a sophisticated playback head that bears little relation to the laser head of a normal CD player. Dye-polymer recordings cannot be erased, are limited in the number of erasures which can be made before the medium fails, or have limited compatibility with the CD standard. Phase-change media need a playback system with a higher sensitivity than standard, and some changes in phase are not reversible and do not permit erasure. I will not be discussing the Quantex electron trapping technology because the medium needs a low-power blue laser for playback. Semiconductor laser diodes that emit a blue beam will not be available for several years, so the system has not been demonstrated.

The magneto-optical (MO) approach to the problem of developing a consumer CDR system is the only one known to have the property of infinite erasure and overwrite capability. This makes it very attractive to the data processing community, which is not concerned with CD compatibility. The MO discs are comparatively expensive to make and can be fragile during use and in transit. Figure 3 shows a typical structure of an MO disc. Magneto-optical recording is not optical recording in the strict sense; a more correct description is heat-assisted magnetic recording. Full compatibility with CD is impossible, and the systems that have been announced and demonstrated are only for ward compatible in that they use EFM en coding for the audio. The use of EFM permits an MO recording to be played back and decoded by the standard electronics of a CD playback chain. It also brings MO under the umbrella of the Philips/Sony patents.

Magneto-optical recording depends on a phenomenon known as the Curie effect. A thermomagnetic property of all magnetic materials is that when they are heated above a certain temperature, they become nonmagnetic; this temperature is the Curie point of the particular material. If a material at a temperature above its Curie point is cooled in the presence of a magnetic field, it becomes magnetized to saturation in the same direction as the applied field and remains magnetized until it is reheated in a neutral magnetic field or is exposed to an erasing field of sufficient strength.

An MO disc is coated with a thin layer of material that has a comparatively low Curie point. Compounds of rare earths, such as terbium and gadolinium alloyed with iron and bismuth, have been used and can be very expensive. To make a recording, the disc is rotated in a constant magnetic field that is perpendicular to the disc surface. (See Fig. 4A.) The field will not be strong enough to magnetize the coating unless the surface temperature is raised above the Curie point.

The beam of a laser diode is focused to the smallest possible spot at the active layer of the disc, and the heat generated by the energy concentrated in the light spot raises the temperature of the magnetic material above the Curie point. As the disc rotates and the laser is turned off, the hot spot cools (passing the Curie point), and the magnetic layer is magnetized locally throughout its depth.

Thus, by modulating the laser, a perpendicularly polarized magnetic recording is created. When a single magneto-optic layer is used in conjunction with a modulated laser, the recording of new information must be preceded by a separate erase step. (See Fig. 4C.) Normally this will require a delay of one revolution of the disc, during which era sure is achieved by unidirectional magnetization of a track before rerecording. One method of overcoming this disadvantage is the use of complex magnetic layers. A pro posed method of achieving overwriting (one step rerecording) is to use a field-controlling magnetic layer as the bottom coating on the disc and depositing the magneto-optic memory layer on top of it. A second method, used in the Thomson recorder, modulates the magnetic field with the signal and heats the MO layer with a laser of constant intensity for both recording and erasure, thus making an overwriting action possible.

Diffraction within a light beam puts a lower limit on the diameter of the spot to which the beam can be focused. Because diffraction is a function of the wavelength of light, short-wavelength laser beams can be focused to smaller spots than can long-wavelength la ser beams. However, the size of a diffraction-limited spot achievable with practical laser diodes results in magnetization of a much smaller area than is possible with any conventional magnetic head. As a result, MO discs are capable of data densities several orders of magnitude greater than those realized with either longitudinal or vertical magnetic systems. Typical laser diodes used for recording emit in the near infrared and have wavelengths of 780 to 840 nanometers (nm). Visible-red diodes with a wavelength of about 640 nm will be used in the near future.

They will permit a smaller spot than do the near-IR diodes, which will make it possible to record higher data densities. Red laser diodes are available now, but as yet the beam quality of production diodes is not good enough for precision recording; precision di odes are in the laboratories of several semi conductor makers.

Playback of an MO disc makes use of a phenomenon known as the polar Kerr effect, which is a rotation of the plane of polarization of light due to a magnetic field. The direction of rotation of the plane depends on the direction of the magnetization of the layer. To read an MO disc recorded with digital information, a polarized laser beam is focused onto the information track, and the angle between the polarization plane of the reflected beam and the polarization plane of the incident beam is detected. As the incident beam passes each magnetic reversal, the polarization plane or the reflected beam will flip from one side of the plane of polarization of the impinging beam to the other. Detection of this angular shift makes it possible to read the recorded information. The power of the laser used for reading the information is low and does not heat the recorded layer, which ensures that the playback operation has no influence on the recorded information. Because the magnitude of the Kerr rotation is minuscule (usually less than 0.5°), a sophisticated optical playback head is necessary to achieve a satisfactory signal-to-noise ratio.

Another difficulty is that compounds magnetically suited to MO applications tend to corrode very rapidly in air. To protect the active layer from corrosion, either a disc is coated with an impervious layer or an hermetically sealed cavity construction is used.

Either method of protection may result in a disc thicker than the maximum of 1.3 mm in the CD specification, though this may be unimportant with a forward-compatible system. A pinhole can easily be made in a thin protective layer, thus making a point where corrosion can start. The cavity in a sandwich disc may be mechanically susceptible to a reduction in external air pressure, so shipping magneto-optical discs via airfreight might be a problem if the airplane hold is not adequately pressurized.

In Part II of this article, I will discuss two other competing technologies (phase change and dye polymer), the interrelation ship of CDR hardware and software, and recorder tracking.

Bibliography

For further information, the following books are recommended. They were of great assistance to me in the preparation of this article and are very valuable for the extensive reference bibliographies given in each.

-M.B.M.

1. Pohlmann, Ken C., Principles of Digital Audio, Second Edition, Howard W. Sams & Co. (Indianapolis, Ind., 1989).

2. Pohlmann, Ken C., The Compact Disc: A Handbook of Theory and Use, A-R Editions (Madison, Wisc., 1989).

3. Watkinson, John, The Art of Digital Audio. Focal Press (London, England and Boston, Mass., 1988).

4. Mee, C. Denis and Eric D. Daniel, editors. Magnetic Recording, Volume Ill: Video, Audio, and Instrumentation Recording, Chapter 6, "Magneto optical Recording" by Dan S. Bloomberg and G. A. Neville Connell, McGraw-Hill (New York, N.Y., 1987).

(adapted from Audio magazine, Jun. 1992 )

Next: Recordable CD: Promises & Problems (part 2) (Jul. 1992)

Also see: Link |

Marantz CDR-1 Professional CD Recorder (Equip. Profile, Apr. 1992)

A New Type of Speaker-- A Sphere of Sound (Jun. 1992)

= = = =