According to the EIA, 1970 marks the Golden Anniversary of the Consumer Electronic Industry. It is true that the loudspeaker and phonograph were invented long ago in the eighteen-seventies and radio not so many years after, but 1920 was the year in which broadcasting began and when radio receivers were on sale. This was three years after Radio magazine (later to become AUDIO) was founded. The change in name took place in 1947, the year that saw the invention of the transistor which has caused such a revolution in electronics. Stereo made its debut-at least commercially-in 1958, and now interest is centered on 4-channel sound. At the Consumer Electronic Show, the great majority of exhibitors in the audio field will be demonstrating some kind of quadraphonics using reel-to-reel and 8-track tape, disks, and FM with internal `transmitters'. No doubt we will have a standard system before very long but this must be said: whatever system is adopted for FM and disk, matrix, multiplex, psycho-acoustic, synthetic, or what have you-the results must be comparable with that obtainable from the best quadraphonic tapes. I said best deliberately because some of the alleged 4-channel tapes were made by the simple expedient of ‘mixing down' from the original 16-track recordings.

--If you could examine the groove( s) of a modern stereo record under a high-power microscope you would be astonished at the complexity of the waveforms cut-or rather pressed into the vinyl.

Furthermore, if you could see the whole series of processes involved, from the studio to the finished product you would realize what a near-miracle of mass production the phono record really is. . . . That said, it must be conceded that we do get a fair number of complaints about disk quality--some justified, some not. Here are extracts from a recent letter written by David Grossman of New York "... I think it is time someone exposed the negligence of the record industry and began a campaign for an up-to-par product.... I have an Empire 999 cartridge and take meticulous care of my records in spite of the inferior quality of the disks on sale. Looking over my collection, I find less than a quarter of the disks are properly made.

The remaining records feature a great number of defects including off-center holes, thin flimsy disks, inferior pressings, and surface scratches." Now some of these troubles might originate with poor storage or careless handling at the dealer's but many are certainly due to poor quality control.

Other letters complain about indifferent sound reproduction and here the record reviews can often save money being wasted. I discussed this problem with Douglas Sax of a Hollywood mastering studio on a recent visit there and Douglas, who is a perfectionist, had an interesting suggestion to make ( That is-when I finally got him away from his Scully!) The proposal was to form a committee of those concerned-the makers of cartridges, turntables, and so on-to judge records and then give a Seal of Approval to those surviving the tests. Trouble is, even if the idea worked and we had a hard-working, altruistic committee happily engaged in awarding Gold Seals-it would still leave the problem of variations in pressings, off center holes, and other faults to plague us.

The record companies may not get that many complaints because a high proportion of the records sold feature rock music of some kind or other and eccentricity and warps might even improve the sound. After all, rock ‘musicians' often introduce electrical distortion when recording. One device for creating this distortion is advertised as giving 'that dirty sound reminiscent of overloading in early tube amplifiers'! So now you know ....

--I hope most readers will have noticed the increased space given over to equipment profiles.

Pictures and diagrams are larger and more technical information is given-although this may mean fewer products are reviewed. We get letters from time to time asking 'why do we not review this receiver or that speaker'. It is not always a question of space-some manufacturers, like McIntosh, just cannot make enough of their products and so they would rather not have a review now.

Nothing we can do about it!

--The New York Audio Society is holding a meeting on July 29 and the main feature will be a demonstration of TDK cassettes by representatives of that company. A film will also be shown and it is said `there might be some surprises' ( surely not those films?). The venue is the Dragonseed restaurant on 37th Avenue at Jackson Heights, and the time: 8 p.m.

-G.W.T.

================

ADs:

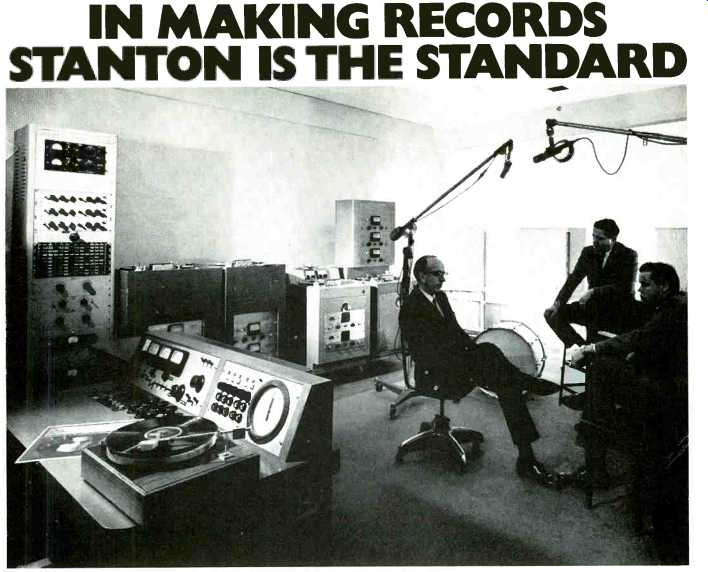

IN MAKING RECORDS STANTON IS THE STANDARD

Whatever your requirements for recording and playback, Stanton's Series 681 cartridges are the calibration standard. And there is a 681 model engineered specifically for each of these critical applications.

The Stanton 681A-For Cutting Head Calibration With Stanton's Model 681A, cutting heads can be accurately calibrated with the cartridge, for it has been primarily designed as a calibration standard in recording system checkouts for linearity and equalization. Frequency response is factory calibrated to the most rigid tolerances and the flattest possible response is assured for precise alignment of recording channels. Implicit in this kind of stability and constancy is a reliability factor unmatched by any other cartridge for this application.

The Stanton 681 EE-For Critical Listening In critical playback auditioning, whether a pre-production disc sample sounds too "dead" or "bright" is largely a matter of cartridge selection.

Here too, Stanton provides the evaluation standard in its model 681EE. In this application, the Stanton 681EE offers the highest obtainable audio quality in the present state of the art. It is designed for low distortion tracking with minimum stylus force, regardless of the recorded velocity or the distance of the groove from the disc center. High compliance,. low mass and low pressure assure perfect safety even on irreplaceable records.

All Stanton Calibration Standard cartridges are guaranteed to meet the specifications with exacting limits. Their warranty comes packed with each unit--the calibration test results for that individual cartridge.

For complete information and specifications write:

Stanton Magnetics, Inc., Terminal Drive, Plainview, L.I., New York.

Stanton

---------------------

---------------------

= = = =

(Source: Audio magazine.)

Also see: Editor's Review (Sept 1970)