MANUFACTURER'S SPECIFICATIONS:

Speeds: 33 1/3, 45.

Platter Diameter: 13 in.

Material: Aluminum.

Weight: 3.86 lbs.

Motor: 20-pole rotor, 15-pole stator, ultra-low-speed d.c. brushless motor.

Variable Pitch Control: ± 5%.

Wow and Flutter: Less than .03% weighted r.m.s.

Rumble: Better than-65 dB (DIN A),-70 dB (DIN B).

Dimensions: 17 13/16 in. W, 13 57/64 in. D, 7 3/32 in. H.

Weight: 22.1 lbs. (with dust cover).

Price: $279.95.

TONEARM SECTION: Direct-reading stylus-force adjustment, static-balanced type, universal head shell, anti-skating device.

Effective length: 8 21/32 in.

Overhang: 35/64 in.

Stylus force: 0.4 grams.

Arm Resonance: 10 Hz.

Tracking Error Angle: Within ± 2.0 deg.

This is a beautiful instrument. Anyone who has any interest in mechanical devices would derive considerable pleasure in inspecting it to say nothing about connecting it up to his stereo system or even to a CD-4 installation, since it is already provided with low-capacitance leads in readiness for discrete four channel applications. The measured capacitance is 70 pF, which is exceptionally low.

The motor itself is an interesting device-no commutator, and a speed selectable by a switch to either 33 1/3 or 45 rpm so as to drive the turntable directly without the need for any speed-reducing drives which were almost universal a year ago--no belt, no idler, no mechanical movement to change speeds. The speed is controlled by an electronic circuit, and although adjustable over a range of ± 5%, it remains exactly where it is put with no dependence on line frequency or, within limits, on line voltage.

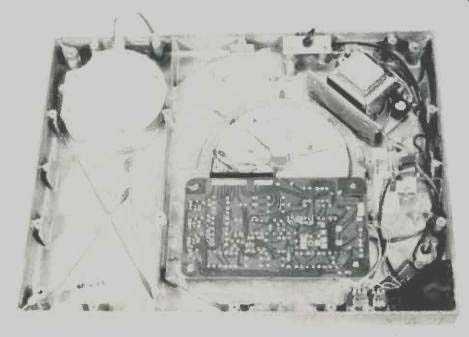

Fig. 1--Underside of chassis with protective molded plastic cover removed.

Fig. 2--Close-up of arm mounting showing balance and stylus-force adjusting

knob, cue control, anti-skating control, and arm lock.

The cast chassis is relatively heavy, and is mounted on four "audio insulated" legs which combine springs and damping material for the insulation, and yet may be rotated to adjust leveling of the platter. The large platter--13-in.--extends beyond the record area to provide the stroboscope markings: four rows of die-cast "dots" for both 50and 60-Hz line frequency for the two speeds. The mat is molded rubber, attractively ribbed, and of the full diameter of LP records. Cast in the chassis is an opening for the 45-rpm adapter disc. Cleverly made with two "levels," the adapter is lifted into a position where it may be grasped easily by pressing slightly on the back half. Along the left side of the chassis toward the front is a housing for a neon lamp which illuminates the rows of dots comprising the stroboscope. At the front left corner is a three position lever switch for power and speed selection, and to its right are two small knobs for vernier adjustment of speeds.

The tonearm is just as loaded with unique--or at least intelligently designed-features. It has all the usual functions and characteristics such as offset, angled horizontal pivot, viscous damped lift and lowering mechanism, locking cartridge head, and so on, but all in a precise form. The one feature that is unique, in our opinion, is the adjustment for balancing the arm.

This is a true rack-and-pinion type of adjustment, which is not unusual; many turntables are so equipped. But, once the cartridge and arm are balanced, the balancing knob is then pulled outward and presto! the indicator is automatically at zero, and the desired stylus force is set with the indicator functioning correctly. The arm height is readily adjustable, as is the amount of lift after the correct normal position is set. Similarly, the amount of anti-skating compensation is set by adjusting a knob to the indicated stylus force position.

The dust cover of smoke-colored plastic is molded with slots which engage with the hinges mounted on the rear of the chassis, providing easy removal when desired, yet holding the cover in the upraised position firmly during record changing operations.

Electronic Speed Control

The motor, described as a brushless d.c. unit, actually operates on pulsating d.c. controlled by three power transistors, which are in turn controlled by the interaction of a locally generated signal of approximately 50 kHz with a toothed wheel which rotates with the platter. The signal is picked off by three coils which effectively generate a three-phase 50-kHz signal.

These three signals are rectified and compared to a reference voltage from the regulated supply and in turn control the power transistors which govern the pulsating d.c. which actually drives the rotor and hence the platter. The advantages of this system are that there are no 60- or 120-Hz a.c. hum-producing fields around the motor, and the correction signals fed to the driving power transistors operate so fast that there is practically no deviation from the predetermined speed. Wow and flutter figures are sufficient proof of this.

Measurements

As usual, the normal system of measurements were made with this unit to substantiate the specifications of the manufacturer. Using NAB specifications, wow and flutter measured 0.4 percent. Measured separately, wow was 0.04% and flutter was 0.035%, all within specifications. Noise and rumble together measured -58 dB below a stylus velocity of 3.54 cm/ sec at 1000 Hz. This measurement was made over the whole audio spectrum, but machine-run curves supplied with the machine showed noise and rumble levels ranging between -50 and -60 dB in the vicinity of 25 to 35 Hz, with no peak levels exceeding -65 dB over the spectrum above 45 Hz. Truly remarkable performance. While line frequency variation had no effect on speed, line voltage did. With the line voltage lowered to 85, speed dropped off materially. This is undoubtedly not a function of the motor itself, but of reduced operating voltages for the electronic portions of the mechanism which may cause a shift in frequency of the local oscillator, or insufficient potential to maintain complete regulation. However, in most instances the normal line voltage usually exceeds the nominal 117, often rising to 125 or more during off-peak-load periods. In our tests, speed/voltage consistency was within 0.2% from 90 to 125 volts.

In addition to the fine packaging of the SP-1200, now practically standard with any high-quality Japanese-built product, the unit is furnished with the ubiquitous polishing cloth, the necessary screws for mounting the cartridge, the 45 adapter, a small screwdriver, and a tube of special oil for the motor, which requires ten drops of this oil after 2000 hours of playing--which amounts to 5 1/2 years if the device is used only one hour per day. The tube of oil should last at least as long as the turntable's owner.

-C. G. McProud

(Audio magazine, Jul 1974)

Also see:

Technics by Panasonic SL-1350 Automatic Changer/Turntable (Equip. Profile, June 1977)

Technics SL- series direct-drive turntables (ad, Feb. 1974)

= = = =