Manufacturer's Specifications

Speeds: 33 1/3 and 45 rpm.

Wow & Flutter: Less than 0.065 percent.

Rumble:-65 dB per DIN 45-539.

Features: Auto lift, belt drive, 45-degree gimbal arm suspension.

Dimensions: 18 in. (45 cm) W x 15 in. (37.5 cm) D x 6 in. (15 cm) H.

Voltage Required: 200/250 or 100/125 a.c.

Power Consumption: Less than 5 watts.

Price: $220.00.

Connoisseur is one of the oldest manufacturers of turn tables anywhere in the world, and it is interesting to recall that the firm's founder, Arnold Sugden, was making stereo records long before they were generally available commercially. The company is situated in Yorkshire, England, not far from some other British hi-fi equipment manufacturers including Rank/Wharfedale, Fane Acoustics, Richard Allen, and Castle Acoustics.

The Connoisseur turntable selected for this review is the Model BD2A, and I must say it right at the outset-the design will not appeal to those who are addicted to lights, bells, whistles, and other sorts of fluff which do not, at least in my opinion, affect the bas c performance. There is no digital read-out, variable speed control, logic circuitry, or rows of shining push buttons. The BD2A doesn't even boast a calibrated tracking-force dial or a strobe light speed indicator.

Rather, the design will appeal to those who are interested in a simple, no-frills concept-a good basic design, providing first-rate basic performance, but no more. Through the use of a small a.c. motor with a belt drive to the platter, and by application of a healthy dose of common sense and lots of precision engineering, better than average results are obtained. And all of this comes in at what must be considered these days to be a rather moderate cost.

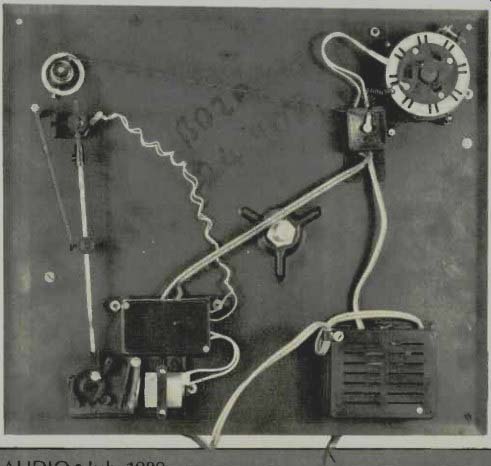

The motor is a synchronous constant-speed type with self-aligning bearings made of bronze, and it rotates at 450 rpm when running on 60-Hz current. The drive is taken from a twin-stepped pulley wheel to the platter by a rubber belt, which is round in cross-section and treated with a silicon compound. Speed changes are effected through a lever which moves the belt by means of a fork. The motor itself is suspended on a sort of rubber bushing, and there is a bias tension to offset any pressure from the driving belt. Such a tension will help keep the bearing in proper round and pre vent any asymmetrical wear.

The platter is made from a lathe-turned aluminum casting, weighs 2 3/8 lbs., and rotates on a manganese-bronze bearing fitted with a hard steel thrust ball. Following what is the most common European practice, the arm uses a straight-line tube design, while the angled headshell simply plugs in. The counterweight is mounted at the rear of the arm and, as stated earlier, is not calibrated. The correct tracking force is obtained by use of the high-precision balance supplied with the BD2A. An unusual feature of the arm is the use of 45-degree pivots which allows the connecting leads to be brought through the center and thus avoid torsional twisting. Anti-skating bias is provided by means of a tiny rod and weight which are carried on a concentric gimbal.

The cue lift platform is located just in front of the arm base, and it is operated by a knob on the right-hand side of the unit, up near the front. The height setting is controlled by a small thumb wheel at the base of the lift platform, which a so contains a reed switch for operating the automatic arm lift at record ending. When the stylus enters the run-out groove, a tiny magnet mounted under the arm triggers the switch, which then discharges a capacitor through a solenoid. The on/off switch is at the front, to the left, and it controls a mechanical brake, as well as switching the power off.

Styling is clean and uncluttered, with a matte-black vinyl covering on the base and top plate contrasting nicely with the aluminum rectangle going around the top plate and the aluminum plate carrying the On/Off and Cue levers. The friction lid hinges are more substantial than those commonly used, while two black plastic buttons allow the dust cover to be lifted without leaving fingerprints. The unit stands on four acoustically sprung and damped isolation feet, and it comes complete with mounting hardware for the cartridge, a small bottle of oil, a tube of silicon compound for the belt, extra weights for tracking and anti-skating adjustments, the afore mentioned balance scale, and a cardboard protractor.

Measurements and Use Tests

For test purposes a Stanton 881S phono cartridge was mounted in the low-mass headshell and aligned as suggested in the instructions. This gave a maximum error of five degrees, which is fairly typical of arms with a length of 81/4 inches with an overhang of 9/16 inch. Tracking force was set to 1 1/2 grams (after checking the balance for accuracy, which was extremely good, by the way), and the anti-skating weight adjusted accordingly.

Wow and flutter measured 0.06 percent (DIN 45-507), and rumble was a low-63 using the ARRL weighting. The ARRL weighting, as most will know, is not strictly comparable to the DIN method used by Connoisseur for their specification. However, the two methods are sufficiently alike that it is to be expected that the BD2A should be pretty well on spec.

Arm resonance with the Stanton cartridge came out at 10.5 Hz, with a rise of 4 dB. Both lateral and vertical bearing friction were insignificant. Speeds were less than 0.1 percent fast, and torque was apparently unaffected by use of a Dust Bug or similar device, which does not always happen with belt-driven turntables. The cue lift was nicely done, quite positive to the touch, and I found the backlash negligible when the control was adjusted for minimum height. Although the initial tests were made with a tracking force of 1.5 grams, I found later on that the cartridge performed quite happily at 1 gram in this arm. However, to be on the safe side, I would recommend that both tracking and anti-skating forces beset at 1 1/4 grams. Acoustic feedback proved to be less of a problem with the BD2A than with many other turntables, apparently because of the good design of the isolating feet. Mechanically, the unit is remarkably quiet, while the unit as a whole is well engineered and made. The low-friction, low-mass tonearm can be used with confidence in combination with most any high-compliance phono cartridge.

To sum up:

This turntable represents good value for dollar in that it provides good basic performance at a price which must be considered as moderate to low in these days of heavyweight inflation. It is not for everyone; those who are after a turntable with everything will be turned off by the economy of this straightforward design. But, to others, design simplicity and engineering elegance are virtues, which lead to the truly good standards of performance, and the BD2A will appeal to folks such as these.

-George W. Tillett

(Audio magazine, Jul. 1980 )

Also see:

BSR McDonald Model 810 Automatic Turntable (Equip. Profile, June 1972)

BSR 710/X Total Turntable (Feb. 1974)

= = = =