Manufacturer's Specifications:

Overall Length of Radial Tracking Tonearm: 9 1/2 inches.

Pivot to Stylus Distance: 7 to 8 1/2 inches.

Maximum Tracking Error: 0°.

Cueing Assembly: Damped and adjustable.

Anti-Skating Adjustment: Not required.

Tracking Force Range: Up to 6 grams.

Cartridge Weight Range: Up to 20 grams.

Vertical Bearing Type: Air.

Lateral Bearing Type: Air.

Damping System: Magnetic.

Vertical Tracking Angle Adjustment: Micrometer calibrated in 0.001-inch increments.

Headshell: Integral part of tonearm.

Tonearm: Interchangeable.

Finish: 24-karat gold plate.

Price: $1,250.00; additional tonearm tubes, $100.00.

Record "masters" are made on an aluminum-acetate blank using a straight-line cutting lathe with a heated chisel like cutting stylus to cut the stereo information into the blank. To accurately reproduce the information on the groove walls, it is necessary to maintain the stereo playback stylus absolutely tangential to the record groove wall so as to trace the exact path of the cutting stylus used in the recording process. If the playback stylus deviates from a straight line, the stereo information presented to the playback stylus will be somewhat different from the original, and the sound that is produced will also be slightly different.

The vast majority of tonearms in use today are of the pivoted type, having either a J or S shape. When properly mounted, the pivoted tonearm stylus path scribes an arc across the record. This curvilinear motion causes a varying error in the angle between the stylus and the record groove, which will be minimal if the cartridge is mounted correctly.

The stylus can be tangential to the record groove at only two points along the entire arc. The tracking error can range from 1.5° to 3.5°. Additionally, a frictional drag of the stylus in the groove, in combination with the offset of the cartridge, generates a centripetal force in the groove over most of the arc. This, in turn, causes an increase in the stylus pressure on the inner groove wall. To reduce this angular force, an anti-skating device is usually employed, but these devices frequently introduce other problems.

On the other hand, a tangential (lateral) tracking tonearm follows the path of the original cutting stylus, nullifying tracking angle error and obviating the need for anti-skating devices, as the arm is always tangential to the record groove. It is quite obvious that a lateral tracking tonearm is inherently a better design than a pivoted arm, but-individual lateral arm designs can enhance or diminish this advantage.

Lateral tracking tonearms have been around for some time. The early lateral tonearms operated in real time since they were driven only by the record groove. As the record groove propelled the stylus along its path, the stylus-cantilever assembly also attempted to move the arm in real time along its guide rails, but simply could not overcome the friction present at this point. Eventually, the cantilever broke or was badly bent in the process of moving the arm.

The first relatively successful linear tracking tonearm was the Rabco, which utilized a servo system both to move the tonearm across the record and keep the stylus tangential to the groove. Unfortunately, the servo motors generate noise in their attempt to consistently keep the lateral tracking error of the stylus at zero. The small deviation made by the stylus advancing towards the center of the record must first be detected by the servo motor before any correction can be made. Only then does the servo motor move the arm to the new tangential position. Consequently, servo-equipped tone arms always exhibit a varying lateral tracking angle (tracking error) because the correction is always after the fact.

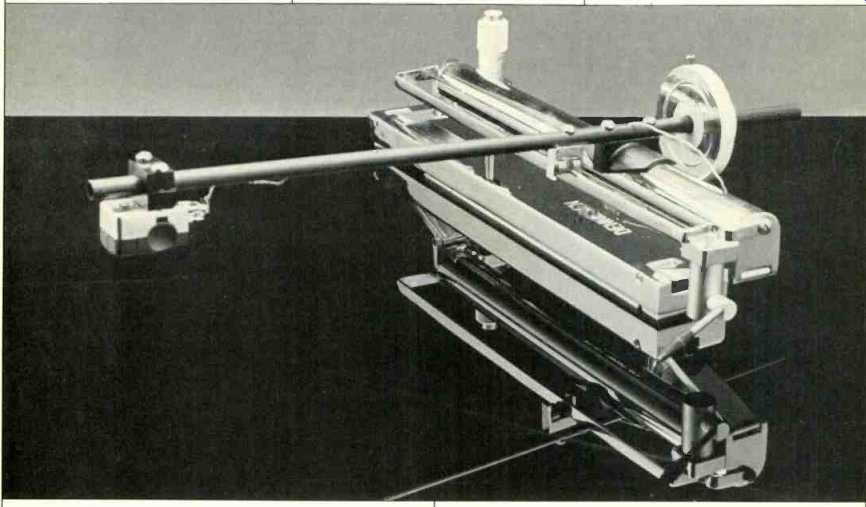

The Dennesen Air-Bearing Linear Tracking Tonearm (ABLT-1) probably represents the first major advance in tonearm design since Rabco developed their unique linear tracking tonearm. The Dennesen ABLT-1 tonearm, designed by Alan Sliski, utilizes basic principles of physics rather than motion induced by an electromechanical system to keep the stylus consistently tangential to the record groove. It combines the desirable features of the linear tracking tonearm without using a servo system. A single air bearing surface provides the two desirable degrees of freedom while restricting all others. Once the bearing has been made frictionless, the need for a complex electromechanical servo system no longer exists. The ABLT-1 arm uses the force of air emitted against an aerodynamically designed foil, causing the arm tube to "hover" in a frictionless state slightly above the air-bearing assembly, while the record groove propels the stylus and arm in real time across the record surface. The vertical tracking angle may be varied by a built-in micrometer which permits accurate adjustments to be made while the record is being played. The design also permits the decoupling of the arm-tube from the base assembly, which allows for easily interchangeable tonearm tubes, thereby simplifying cartridge changes. A specific counterweight is used to properly offset the mass of the cartridge.

Description

The ABLT-1's air-bearing assembly is designed as a parallelogram (a quadrilateral with opposite sides being both equal and parallel). This assembly is made up of four parts held together by rotating pins (a form of hinge) at the corners. The four parts consist of the base which attaches to the turntable and also houses the signal and ground connections, the air-bearing tube, and the two legs that hold the base and air-bearing tube together to form the parallelogram. The parallelogram arrangement allows the air-bearing tube height (which also determines the vertical tracking angle) to be adjusted in 0.001-inch increments with the attached micrometer while maintaining the air-bearing tube constantly parallel with its mounting surface at any height. The entire air-bearing assembly, less tonearm, weighs 1 3/4 pounds (793.8 grams). The air-bearing tube itself is made from a round brass tube, ground to a tolerance of 0.0001 inch. The entire length of the tube's top surface has a single row of 0.010-inch holes, out of which pressurized air is emitted to support the airfoil of the tonearm tube approximately 1 to 1 1/2 mils above the air-bearing tube in an essentially friction-free manner.

Due to the shapes of the airfoil and the tube, motion in the system is restricted to rotation around the tube (vertical) and sideways along the tube (horizontal). No other motion is possible and, therefore, improper or non-tangential tracking is impossible.

The micrometer, located at the rear of the air-bearing tube, adjusts the height of the tonearm above the record via the air-bearing tube, thus permitting the vertical tracking angle to be adjusted while the system is playing. The overall limit of the micrometer may be extended with the addition of one or two quarter-inch spacers, in effect raising the parallelogram to a greater height.

The damped cueing assembly is located at the forward end of the air-bearing tube. A copper bar runs from the cueing assembly to the back of the air-bearing tube to allow cueing the arm up at any point on the record.

Brass was chosen as the base metal due to its machinability and acoustically dead quality. To prevent oxidation (tarnish) and thus alteration of machined tolerances, each machined metal part is carefully polished and plated with 24-karat gold.

The tonearm consists of a black anodized, drawn aluminum tube that is internally resonance-damped. Wiring is pure copper, Litz-type-cable with gold cartridge connecting clips and a four-prong, gold-plated signal plug that is connected to its gold-plated mate on the base. The airfoil is made from aircraft-grade aluminum, precision machined to 0.0005 inch, polished, and black anodized. It is attached to the tonearm tube about three inches from the rear. The entire tonearm, less the cartridge and counterweights, weighs less than one ounce (25.2 grams). Cartridge counter balancing and resonance tuning is provided by varying combinations of four counterweights (two weights, each 15 grams, and two large rings, each 22 grams, which fit over the smaller weights and are secured by a set screw). The counterweights are attached at the rear of the tonearm via a friction fit provided by an elastomeric decoupling compound that is a part of the weights. This allows a range of weights from 15 to 74 grams, and the tonearm can therefore be utilized with cartridges ranging from low to high mass and from low to high compliance. The cartridge is mounted via an adjustable clamp, bearing on a stiffened portion of the tonearm tube. The tonearm tube allows mounting the cartridge up to 8 1/2 inches from the air-bearing. This reduces wow and varying VTA over warps to a minimum.

Magnetic (eddy current) damping is provided by two samarium-cobalt magnets mounted on a small horseshoe on the tonearm. In use, this horseshoe with its magnets sits on either side of the copper cueing bar, thereby applying magnetic damping.

Air at a pressure of 1 1/2 pounds per square inch is supplied to the air-bearing assembly by a bellows-type air pump designed for reliable long life operation. The pump is contained within a walnut enclosure along with two air filters. One filter removes dirt, insuring air purity, and the other filter removes pulsations, assuring a smooth, steady airflow. The pump is attached to the air fitting at the rear of the air-bearing tube via 25 feet of 5/16-inch clear plastic tubing to allow placing the air pump in a remote location.

To set up the ABLT-1 for proper alignment, a specially designed Lateral Soundtracktor is used to assure that the offset angle is 0° with no overhang. A bubble level is used to properly level the turntable and the air-bearing tube. The tonearm may be attached to the turntable base by using either heavy-duty double-stick tape or machine screws.

Measurements

The Dennesen ABLT-1 was mounted on a Luxman PD 555 vacuum turntable with heavy-duty double-stick tape, and it has been held in place for about six months without any noticeable deterioration of the tape or movement of the tonearm base.

All measurements were made using the Empire EDR.9 phono cartridge, which weighs 5.2 grams. It is not necessary to statically balance the tonearm prior to setting the tracking force. The tracking force was set at 1.25 grams with the aid of Technics' SH-50P1 Stylus Pressure Gauge.

The capacitance of the tonearm's pure copper Litz wires from the mounting clips to the phono jacks in the base is 30 pF for each pair. Capacitance between the two "hot" leads is 19 pF. Resistance of one pure copper Litz lead from phono jack to cartridge mounting clips is 0.8 ohm.

Using a Dynamic Mass Analyzer (DMA-1) and Low Frequency Vibration Platform (LFP-20) from Dynamic Sound Devices ( P.O. Box 369, Commack, N.Y. 11725), I measured the arm-cartridge dynamic mass as 18.5 grams (minus cartridge mass of 5.2 grams = 13.3 grams). The vertical resonant frequency measured 8.5 Hz, and the dynamic compliance measured 20 x 10-6 cm/dyne at the 8.5-Hz vertical resonance frequency. The lateral resonant frequency, using a test record, measured 12.5 Hz with an amplitude of 4.6 dB. In general, the ABLT-1 is a very well damped tonearm.

Use and Listening Tests

I have used the Dennesen Air-Bearing Lateral Tracking Tonearm for almost a year, playing all types of music, without encountering a problem. The arm functions very well with any warped record without producing audible distortion. The airfoil constantly maintains its proper position without regard to the variation in musical dynamics or even minor jarring of the turntable. I never fail to be amazed by the fact that the single physical contact between the tone arm and any other point is strictly via the stylus, which is in direct contact with the record groove, and that the "hovering" arm is propelled across the record surface only by the stylus as it negotiates the modulated grooves of the record.

I have tried the arm with several phono cartridges, including those with a very high compliance. It was quite comforting to note that I could not detect any spurious resonances or other colorations. The cleanness of the sound was quite extraordinary in all cases. Any fear of damage to highly compliant cantilevers can be dismissed.

As with all precision instruments, the performance of the ABLT-1 tonearm is wholly dependent on the accuracy of the initial setup. When the setup is properly executed, the ABLT-1 simply works as its designer had intended.

Needless to say, a precision tonearm, such as the Dennesen ABLT-1, does not come cheaply. However, if you want the monarch of today's tonearms, it is well worth the price.

-B. V. Pisha

(Adapted from: Audio magazine, Jul. 1982)

Also see:

Which Tracks Best--A pivoted or a radial Tonearm? (June 1982)

Dennesen Geometric Soundtracktor and Vertical Tracking Angle Gauge (Mar. 1980)

Wheaton Tri-Planar II Tonearm (Equipment Profile, Jun. 1988)

Luxman PD-375 Turntable (July 1982)

= = = =