Manufacturer's Specifications:

Drive System: Belt.

Motor Type: 24-pole synchronous.

Speeds: 33 1/3 and 45 rpm.

Dimensions: With optional dust cover, 19 in. W x 15 1/2 in. D x 7 in. H (48.26 cm x 39.37 cm x 17.78 cm).

Weight: Approximately 38 lbs. (17.3 kg).

Price: Without arm. $975; with Well Tempered arm, $1.695: dust cover, $120.

Company Address: c/o Transparent Audio Marketing. Rte. 202, Box 117, Hollis, Maine 04042, USA.

[Also see: Well Tempered Tonearm and Van Den Hul MC-One Cartridge (July 1988)]

After Bill Firebaugh had designed the Well Tempered tonearm, he decided to apply some of his ideas on viscous damping to the design of a turntable. The absorption of energy from external vibrations is something that most turntable designers are concerned about; however, most of them concentrate their efforts on reducing vibration problems in the low-frequency range. They do this by using a suspension system employing strategically located springs.

The compliance of these springs is chosen so as to resonate with the mass of the turntable at some very low frequency, usually below 10 Hz. A suspension of this type tends to reduce the effects of outside vibrations and shocks on the reproduced sound.

One way of reducing vibration effects is to use very compliant springs to suspend a relatively low mass. Other designers use less compliant springs but make the suspended mass very large, which tunes the system to the same range. In this case, however, the Q is usually higher, so some method must be used to damp the springs.

Firebaugh decided to take a different approach. The Well Tempered turntable has what I would call moderate mass, but it has no springs. Instead, it sits on four rubber feet which are fastened to the bottom with screws. Rather than fight the battle of trying to tame the tendency of suspended turntables to rock up and down, side to side, or both, Firebaugh decided to tackle the problems caused by bad-tempered vibrations above the seismic region. He has applied his "well tempered" viscous damping techniques to the motor bearing and the main turntable platter bearing.

The motor is a 24-pole a.c. type that is highly modified. It has a new thrust bearing at the bottom, upon which the motor shaft rests. The bottom of the motor is mounted in a heavy, lead block which Firebaugh refers to as a "brick." Sometime back, there was a flurry in audiophile circles about the taming characteristics of bricks (of this or that material) when placed on amplifiers, CD players, etc. Perhaps that is the connection, but this brick is really beneficial since it gives tremendous stability to the motor.

Stability is very important in this case, because the motor of the Well Tempered turntable is completely separate from the rest of the machine and is connected to it only through the belt; it needs the mass to remain in position. The shaft of the motor turns in a bath of viscous fluid which smooths the rotation and reduces the tendency of the a.c. motor to "cog." The turntable platter shaft also runs in a bath of viscous fluid, and this tempers the rotation of the platter and helps reduce flutter.

First Impressions

The translucent white platter sitting on the three-tiered, satin-black base certainly gives the Well Tempered turntable a striking appearance. The turntable and base are one piece, unlike most other designs, and I must admit that I wondered how it would do during the usual shock tests.

When I saw that the motor was completely separate, I remembered having seen the same technique on some early disc-cutting turntables. This approach was taken because some of the early, high-torque motors required to turn the massive cutting turntables had excessive vibration.

Good ideas of the past have a way of returning, and, although this motor has very little vibration, separate mounting has to help.

Mounting a tonearm--other than the Well Tempered arm--to this turntable will not be a trivial task. There is no separate mounting board, and the base is solid in this area, except for a hole precut to fit the Well Tempered tonearm.

The turntable cannot be ordered precut for other arms (Firebaugh has rot yet tested the table with any), and I am certain that changing to a different tonearm later would not be easy.

I also noticed that the drive belt seemed thinner and narrower than most of the other belts I have seen. Firebaugh recommends putting a single twist in the drive belt, between the motor pulley and the turntable platter, and this looks a little strange at first.

Features

The base of the Well Tempered turntable is part of the turntable and not a separate entity, as it is on most other turntables. It measures 19 inches wide, 15 3/8 inches deep, and 5 1/4 inches from the bottom of the rubber feet to the top of the center spindle, which is the highest point. When the record clamp is in place, the total height is about 5 3/4 inches. With the Well Tempered tonearm, which is higher than most, the height with the clamp is 7 1/2 inches. The table weighs 26 pounds without the motor, which is completely separate. The base is solid and consists of three pieces of medium-density fiberboard, each 1 inch thick, plus two layers of damping material between them. The rounded edges on the base, and the satin-black finish, give it a very nice appearance. A 5 1/4 x 5 1/4-inch cutout on the left side of the base allows for the motor, which sits in this area. Four soft rubber feet are fastened to corners of the lead brick to which the motor is mounted.

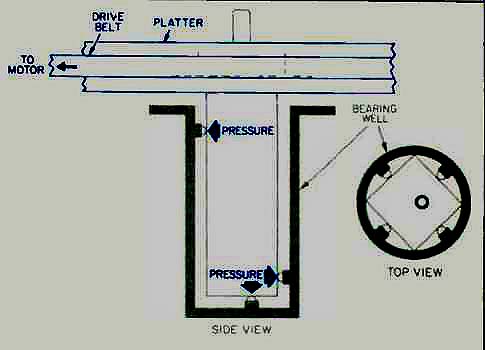

Fig. 1--Cross section and top views of the turntable shaft bearing. Tension

on the drive belt presses the thick shaft against the thrust bearings on

the sides of the shaft well.

The main bearing well is made of black Delrin. The body of the well is 2.89 inches deep and 1.492 inches in diameter. It has a collar, 1.75 inches in diameter and 0.10 inch thick, with a "V" notch that must be pointed toward the motor when it is installed in the mating hole in the turntable base. Instead of the usual sleeve bearing in the spindle well, there are two Teflon thrust-bearing pads at the top, on the side facing the motor, and two near the bottom on the side away from the motor (Fig. 1). The drive belt pulls the spindle shaft against them! It is a weird experience to have the turntable platter move down against the base when pressure from a record cleaning brush, for instance, is applied on the right side. The one-piece record spindle/platter shaft is pressed into a hole in the center of the main platter. It has a half-inch-diameter shaft with a flat bottom which turns on a bearing at the bottom of the main bearing well. The upper part, which fits into the platter, is 0.725 inch long and 0.75 inch in diameter. It has a 0.980 x 0.125-inch lip that carries the weight of the platter and keeps the spindle shaft in place. The top section of the spindle has a diameter of 0.287 inch to fit the record hole.

The 11.5-inch diameter turntable platter is made of solid, translucent acrylic and has a 0.75-inch diameter hole in the center for the metal spindle shaft. There is a recess, 4.085 inches in diameter and 0.050 inch deep, to accommodate the extra thickness of a record at the label area. The platter is 0.915 inch thick at the edge and is machined in such a way that the surface is dished down toward the center to allow an LP to be pulled down by the record hold-down clamp. The clamp is 1 inch high and 1.75 inches in diameter, with two knurled rings for better gripping. The design of the record clamp is very clever, although it can be used only with the Well Tempered turntable. Inside its center hole is a recessed #10-32 hex-head bolt which mates with #10-32 threads inside the spindle. When you turn the clamp on the spindle, it rotates down and pushes the record against the turntable, making it easy to adjust the force to the amount desired.

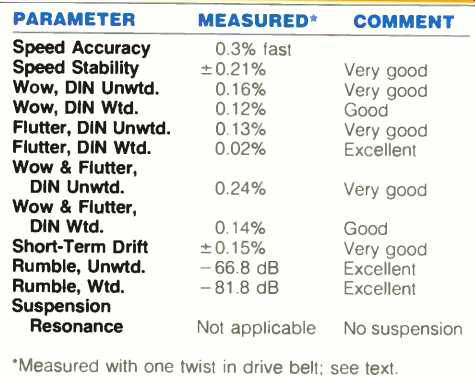

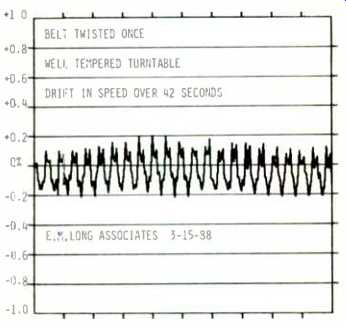

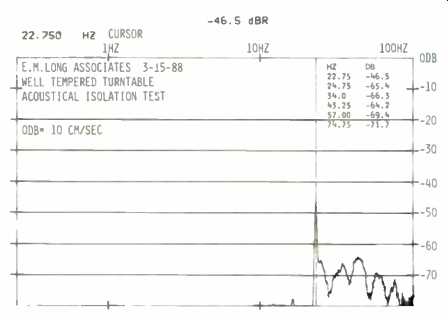

Note the improvement in performance with the belt twisted (see text). The arm/cartridge resonance with the van den Hul MC-One cartridge and Well Tempered tonearm is at 10 Hz. This resonance, which is normally visible in such plots, cannot be seen due to the arm's high damping.

The separate 24-pole a.c. motor weighs about 2 pounds. It has been highly modified with a new thrust plate and the addition of viscous fluid inside the motor bearing. The motor mounts to a 0.25-inch thick, 4.5 x 4.5-inch soft iron plate that provides excellent shielding of the motor's magnetic field. The motor is mounted on the 10-pound lead brick and is sandwiched between the steel top plate and the brick by two long screws. A pushbutton a.c. power switch is mounted on the top plate. The 5-foot a.c. power cord exits from the bottom of the brick. The motor pulley, which is force-fitted to the motor shaft, is made of Delrin and has two steps, for 33 1/3 and 45 rpm. Speed change is accomplished manually by moving the belt to the proper step on the pulley. The motor has good torque and accelerates the turntable from zero to full speed in 1.5 S. When the power is turned off, the turntable platter comes to a full stop in 2.5 S. The drive belt is thinner than usual, only 0.0135 inch thick and is 0.125 inch wide. It wraps around the outside edge of the platter and the motor pulley.

Measurements and Listening Tests

Bill Firebaugh tells me that, during the design and testing of the Well Tempered turntable, one time he accidentally put a single twist in the drive belt while putting it over the motor drive pulley. He didn't notice this right away and continued testing. The wow and flutter measurements were lower than usual, and when he looked at the turntable, he saw the twisted drive belt. Firebaugh reasoned that perhaps the twist in the belt made it come off and go back on the platter more smoothly as the platter rotated. It seemed to him that the reproduced sound from records, particularly piano music, was more realistic. To check this out, I listened to some piano music with and without a twist in the drive belt. I think Firebaugh is right; I found that the piano sounded better with one twist in the belt. (I don't know if this would work as well with other belt-drive turntables because I haven't had the chance to try it.) Figure 2 shows the wow and flutter spectrum with and without the belt twisted. The level below about 10 Hz is lower with the belt twisted, except at 2.25 Hz. There is more output in the range from around 50 to 60 Hz, but it is extremely low in both cases, and the flutter readings listed in the Measured Data table (below), which would be affected by the output in this range, are excellent. During the listening evaluation, I put a twist in the drive belt and left it that way.

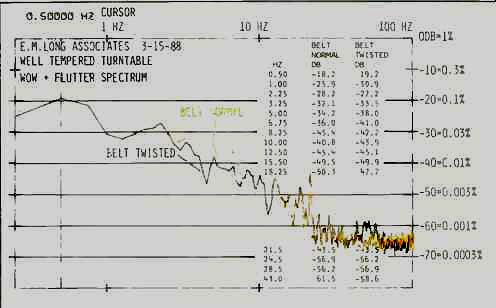

----- MEASURED DATA -----

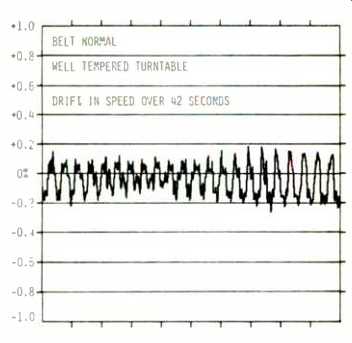

Comments from members of the listening panel indicate that they thought that the sound of the piano was a little better with the Well Tempered turntable than with the reference system: "Sustained chords were very steady" and staccato passages "very precise." With the belt normal, the variation in rotational speed for 33 1/3 rpm (Fig. 3) looks a little strange, since it is not consistent. However, if you compare it with data from reports I have done on other turntables, you will see that the greatest and smallest variations in speed on the Well Tempered turntable are comparable to results from some of the best units tested. Figure 4 shows that the speed also varies with the belt twisted and that there is a smaller variation over the 42-S period measured. That, too, is comparable to some of the best tables.

Fig. 2--Wow and flutter spectrum, from 0 to 100 Hz.

Fig. 3--Speed drift over 42-S period, with no twist in belt. Cyclic variations

at 1.8 S, or 0.56 Hz, are related to the rotational speed.

Fig. 4--Same as Fig. 3 but with belt twisted.

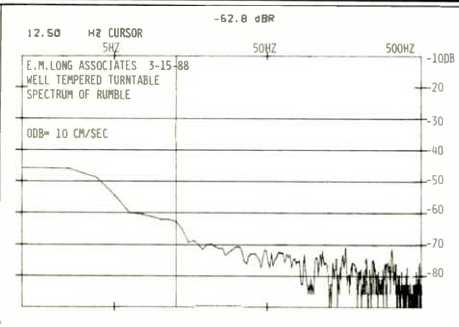

Fig. 5--Rumble spectrum. Due to the well-damped arm resonance, the output

is extremely low.

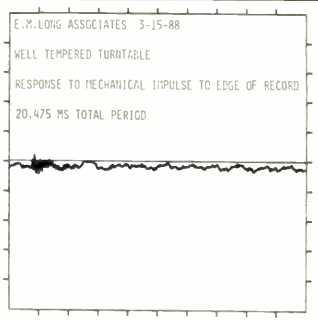

Fig. 6--Output vs. time for mechanical shock applied to edge of a stationary

record, with stylus resting in groove.

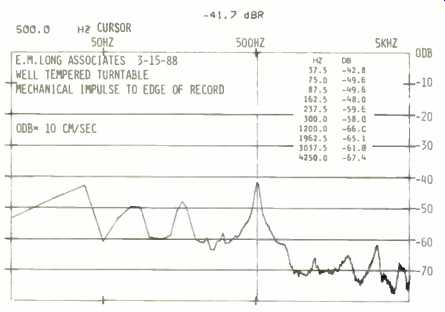

Fig. 7--Spectrum to 5 kHz of output from a series of 16 mechanical impulses

(averaged) applied to edge of a stationary record, with stylus resting in

groove.

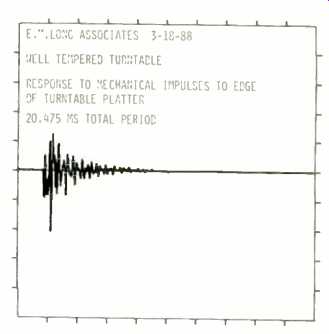

Fig. 8--Output vs. time for mechanical impulse applied to edge of the turntable

platter, measured with accelerometer on the platter's edge.

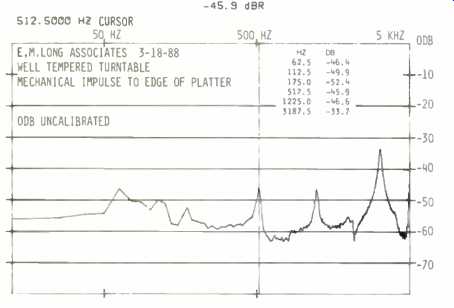

Fig. 9--Spectrum to 5 kHz of the vibrations caused by mechanical impulse

applied to edge of the turntable platter (16 impulses, averaged).

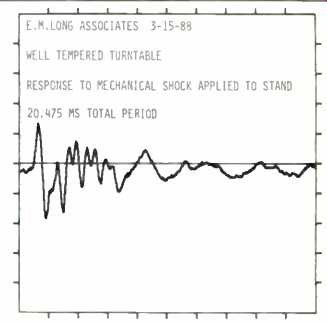

Fig. 10--Output vs. time for mechanical shock applied to heavy stand on

which the turntable rested.

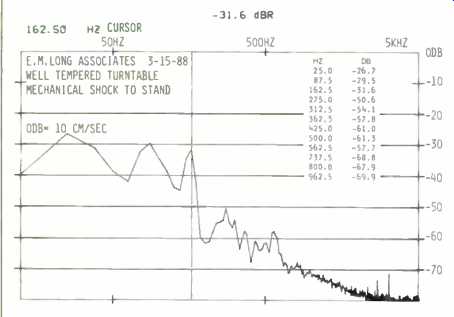

Fig. 11--Spectrum to 5 kHz of the vibrations caused by mechanical shock

applied to turntable stand (16 impulses, averaged).

Fig. 12--Spectrum to 100 Hz of the vibrations from an acoustic field of

100 dB SPL at the surface of a record. Stylus is resting in a groove near

the middle of the record. Acoustic isolation is excellent.

The rumble spectrum (Fig. 5) shows something I have tried to emphasize in past reports: That the tonearm/cartridge resonance is one of the major contributors to rumble as well as to wow and flutter. The mass of the Well Tempered tonearm, and the compliance of the van den Hul MC One cartridge used during my evaluation of the Well Tempered turntable, resonate at 10 Hz, but the Q of this resonance is very low, due to the arm's excellent damping. In other words, when this resonance is excited by rumble or wow, there is very little output. Figure 5 shows very little rise in output around 10 Hz because of this. Look at Fig. 2 again and you will see that, at 10 Hz, there is also very little indication of the tonearm/cartridge resonance. This means that if I took only readings from a meter while testing for rumble or wow, I would get lower readings when the tonearm/cartridge resonance is well damped (as it is in this case) than I would if I used a poorly damped tonearm/ cartridge combination. The turntable would be rated better or worse depending upon the arm/cartridge combination used to test it. That is why I show the spectrum of the rumble and the wow and flutter. Although the tonearm/cartridge resonance must be considered as affecting the overall quality of the sound, when trying to rate the turntable by itself--with respect to rumble or wow-the amount of output around the tonearm/cartridge resonance should be ignored.

I purposely played a recording that always seemed to have more than a normal amount of rumble and asked the panel to comment on the background rumble. Their response was that the Well Tempered turntable, with the Well Tempered tonearm/van den Hul cartridge combination, produced a little less rumble than the reference system, whose tonearm/ cartridge resonance is less well damped.

Figure 6 shows the output produced when a mechanical impulse was applied to the edge of a stationary record, with the stylus of the van den Hul cartridge resting in a groove near the middle of the record. The output is very low, and since it dies out quickly, it is also very well damped. Figure 7 shows the spectrum of the output caused by 16 mechanical impulses. The main output is at 500 Hz; this could affect the sound, especially that of voices. During the listening evaluation, some panel members said the sound was "bright” and "forward" for the Well Tempered turntable and "clearer" for the reference system when reproducing voices. Energy peaks at 1200, 1962.5, 3037.5, and 4250 Hz might also be related to the rather consistent comments about the Well Tempered turntable being "bright' on most program material. I wanted to determine whether the energy around 500 Hz was due to the resonance of the acrylic turntable platter, so I made a large number of tests using an accelerometer. The result of one of these tests is shown in Figs. 8 and 9. The output versus time for a mechanical impulse applied to the edge of the platter is shown in Fig. 8; the result is similar to that seen in Fig. 6, albeit at a higher level. The level of the tests with the accelerometer is uncalibrated, so only the shape of the envelope and the spacing of the up-and-down undulations is of interest. Comparing the spectrum shown in Fig. 9 to that in Fig. 7 will yield some useful insights about the resonant modes of the platter. Peaks of energy around 500, 1200, 2000, and 3000 Hz can be seen in both figures.

When a record is clamped to the Well Tempered turntable, the output at all but the 500-Hz peak is reduced considerably, but some energy is clearly finding its way into the reproduced sound.

Figure 10 shows the output over 2.05 S for the Well Tempered turntable when a mechanical shock was applied to the heavy test stand upon which it was resting. The results are good, considering that there is no suspension and that the turntable has only four rather ordinary rubber feet. I think that excellent damping of the Well Tempered tonearm/van del Hul cartridge resonance is responsible for this. If a different tonearm/cartridge combination were to be used, the results might well be worse. The spectrum of the output due to 16 mechanical shocks applied to the test stand is shown in Fig. 11. The greatest output is in the range below about 170 Hz. with major peaks at 25, 87.5, and 162.5 Hz.

Figure 12 shows the spectrum of the output due to a 100 dB SPL acoustic field at the surface of a record. The stylus was resting in a stationary groove while the acoustic signal was slowly swept from 20 to 100 Hz. The output is very low, which indicates that acoustically induced feedback should not be a problem.

Conclusions

I must admit that, although I hope you will read my entire report on the Well Tempered turntable, this is the part I usually jump to when I read other reviews. The Well Tempered turntable produced excellent results in both the technical measurements and the listening sessions. Some panel members, but not all, preferred the sound of the Well Tempered system (which included the Well Tempered tonearm and the van den Hul MC-One cartridge) to that of the reference system. For those characteristics of a turntable which can affect the sound quality, without direct reference to the tonearm/cartridge combination, the Well Tempered turntable did very well. The pitch is very steady, the torque is high enough so that the speed remains constant during soft and loud passages, and the immunity to mechanical shock and acoustical feedback is very high. The Well Tempered turntable's unusual design, with the motor separate from the main body of the turntable, provides excellent isolation of mechanically transmitted vibrations. However, it is also something to consider when thinking about mounting or transporting the turntable. Such innovative design ideas may raise questions in your mind, as they did in mine, but they seem to work very well. If you are after a high level of sound quality, you should check out the Well Tempered turntable. I think you will like it.

--Edward M. Long

(Source: Audio magazine, Jul. 1988)

Also see:

Well Tempered Tonearm and Van Den Hul MC-One Cartridge (July 1988)

Well Tempered Record Player and Van Den Hul MM-1 Cartridge (Jan. 1992)

= = = =