by Dr. Hedi Benz [Benz Mikrodiamanten Co., Andelfingen, Switzerland.]

WITH TODAY'S high quality phono cartridges, reduction of mass is a prime consideration for the design engineer. Although mass of the stylus has been whittled down to a low of 0.9 mgm, further reduction still appears to be desirable. Additional decreases in the mass of the cantilever and needle assembly would result in decreased record wear, greater trackability, extended frequency response, and higher peak velocity for the handling of heavily modulated musical passages.

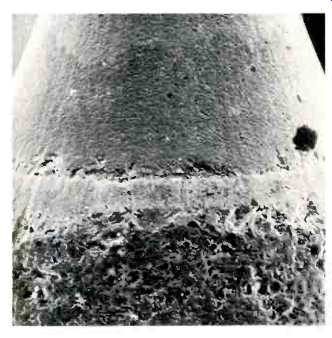

Fig. 1--The gold-nickel-base bond is clearly visible between the diamond

tip at the top and the sapphire shank below. (416X magnification, scanning

electron micrograph.)

On one hand we have the bonded stylus with a diamond grain bonded to a steel or molybdenum shank. The main advantage of this type is the relative ease of manufacture, which results in a low price. Their disadvantage is a relatively high mass due principally to the high specific gravity of the shank material. The only way to further reduce the mass of a stylus of this type is to reduce its physical dimensions. Usual dimensions for a stylus of this type is 0.012 in. for the diameter of the small end and a length of 0.030 in. Even with these dimensions, handling and assembling are quite a problem, one which obviously becomes greater if the dimensions are reduced.

On the other hand is a stylus made of solid diamond, one which is carefully polished like a gem diamond. A limited demand exists for this type because of the "quality regardless of cost" approach. Since the specific gravity of diamond is 3.9, the mass of this type of stylus is only half that of a conventional stylus. Unfortunately mass production of such styli is extremely difficult since uniform diameter and length cannot be maintained.

Selection of styli into groups with the same diameter and length is necessary in order to match them with their corresponding assemblies. This consequently increases their ultimate price.

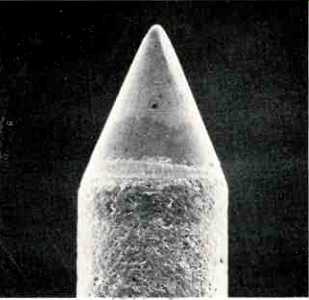

Fig. 2--The differing textures of the sapphire shank and diamond tip are

clearly apparent. (144X magnification, scanning electron micrograph.)

The Benz Mikrodiamanten Co., of Switzerland has developed an entirely new stylus, combining the advantages of both types of styli, and has applied for patent. A new bonding method allows a diamond to be bonded to an aluminum oxide (Al2O3) sapphire shank. The bond itself is superior in strength to the aluminum oxide shank material.

Fig. 3--The diamond tips are bonded to the sapphire shanks in this controlled

atmosphere furnace.

The new stylus offers a number of advantages. Only the tip, the actual working section, is made of diamond, resulting in a large savings in costs. The shank is made of aluminum oxide, with its inherent advantages of relative ease of manufacture and low mass. Holding accurate diameter and length is no problem. In consequence, this facilitates the mounting of the tip into the stylus assembly. Styli made with this method, having a 0.010 in. diameter and 0.030 in. length, have the extremely low mass of 0.11 mgm. One further advantage of these styli is their corrosion resistance since only gemstones and noble metals are used in manufacture.

(Audio magazine, Aug. 1972)

Also see:

Understanding Phono Cartridges (Mar. 1979)

A Practical High-Frequency Trackability Test for Phono Pick-Ups (Aug. 1972)