Article by: Peter Vogelgesang [Manager, Advanced Recording Technology Magnetic Audio/Video Products Division, 3M Company, St. Paul, Minn. ]

The magnetic material which has been used almost exclusively in sound recording tapes for many years is the gamma form of iron oxide, or gamma Fe2O3. This material is a favorite because it is inexpensive, stable, and easily processed for tape manufacturing. Because early tape recording systems were limited in performance by 55 electronic noise, mechanical instabilities, crude magnetic transducers, and by poor physical properties of magnetic tape, little attention was given to improving tapes by employing magnetic materials which had superior magnetic properties.

Today, solid-state electronic amplifiers produce only a small part of total system noise. Precision magnetic transducers can be manufactured of exotic ferrite materials or metallic alloys and have magnetic gaps controlled precisely to a few millionths of an inch. Magnetic tapes are slit to a width accuracy of one-thousandth of an inch, and tape surfaces have a mirror-like smoothness. Capstans, tape guides, and drive motors have been improved commensurately to utilize the improved physical properties of tape. And, a totally new improvement has been added; a preponderance of all magnetic tape manufactured today is enclosed in plastic cartridges or cassettes which protect it from both handling abuse and environmental contaminants.

As a consequence of these gradual improvements, the magnetic recording industry has seen a continued slowing of tape speed over the years. Full range audio recording once required a tape speed of 60 ips, but is now accomplished at the 1 7/8 ips speed of the audio cassette. Limited bandwidth waveforms such as voice and background music are easily recorded at a speed of less than one inch per second.

With so many refinements occurring in related areas of magnetic recording, it was inevitable that improvement in the properties of the magnetic material used in tape would one day be required. Work directed toward this end was underway seriously in industrial laboratories in the early 60s.

Today, consumers of audio cassettes have a choice of tapes using materials such as chromium dioxide (CrO2), cobalt-modified iron oxide, and tapes made with multiple layers of these and other materials in combination. Manufacturers of cassette recorders have equipped their machines with multi-position switches to accommodate the new tapes by changing recording bias level and equalization.

The unique magnetic properties of chromium dioxide and cobalt-modified iron oxide used in these tapes are described by the generic term, "high energy." It is the purpose of this article to describe high energy materials and to show why and how they are used.

Fig. 1--An electron photomicrograph of a typical iron oxide magnetic material

was made with a magnification of 45,000. The average length of these particles

is about 0.4 microns, and the ratio of length to width is six to one.

Technical Background

Iron oxide magnetic material contained in recording tape consists of tiny, needle shaped or acicular particles which have an average length of 0.4 micron (16 millionths of an inch) See Fig. 1. These particles are mixed as a fine powder with a fluid binder, and the ingredients are milled using a process similar to the manufacturing of paint. The milled material, called a dispersion, is coated onto the surface of polyester film and then oven dried to make recording tape.

Each magnetic particle is an independent miniature permanent magnet. However, it behaves magnetically unlike a large magnetizable bar of iron with which we are all familiar. Because of the small size of the particles, each particle contains only a single magnetic domain. This domain cannot be demagnetized nor can it be made magnetically stronger or weaker. It is forever a permanent magnet of fixed strength, and the only magnetic change it will undergo is a polarity reversal of the magnetic field it produces. Fig. 2 shows how a single particle changes polarity and magnetization when immersed in a magnetic field which is reversing in a sinusoidal manner. A particle will behave in this manner when the direction of the applied field is parallel with the long axis of the particle. A very different characteristic is observed when the field is at right angles to the long axis. In magnetic tape, particles are aligned so that the long axis is parallel with the direction of the recorded tracks. Such orientation is achieved by immersing the coated tape in a strong magnetic field before the coating is dried, and while the particles are still mobile.

The time required for a single domain particle to reverse polarity, or switch, probably has never been measured (1) and may be considered instantaneous in any practical application of magnetic recording. In numerous laboratory investigations and computer simulations of the recording process, particle switching time has never surfaced as a limitation to the highest frequencies that can be recorded. Thus, designers of recording systems have built video recorders which record frequencies in the tens of megahertz without having to take into account a finite-response time of the magnetic tape.

Due to differences in size, shape, and chemical composition, particles within a bulk quantity of material will have a distribution of magnetic responses. In other words, although each particle within a batch switches at one critical intensity of applied field, the critical intensities of all particles are distributed in a manner which produces a familiar bell-shaped curve. Under the influence of a controlled applied field, a portion of the particles can be switched to one polarity, while the remaining particles stay in the original condition. Because the magnetic field produced by a bulk quantity of particles is the sum of all individual particle fields, the bulk quantity can be weakly or strongly magnetized, or it can be completely demagnetized. This effect is explained with the help of the magnetization curve of Fig. 3.

Coercivity of individual particles is largely responsible for coercivity of the bulk material. However, the density with which particles are packed together also influences the coercivity of a specific quantity of material (2). Coercivity of bulk material is reduced as packing density increases. Saturated remanent magnetization of bulk material also is dependent not only upon remanent magnetization of the particles, but on how closely particles are packed. Since the magnetic field produced by a quantity of material is the sum of the fields produced by individual particles, a greater number of particles in a given volume will produce greater remanent magnetization. Thus, remanent magnetization increases as packing density increases.

This fact has led to the necessity of distinguishing between the intrinsic remanent magnetization of particles and the magnetization of bulk quantities of particles. Intrinsic remanent magnetization essentially defines the remanence of isolated magnetic particles, and is determined by the chemical and physical makeup of the material. Remanent magnetization of a bulk quantity of material is dependent on this intrinsic property, but also upon how densely the particles are packed together. Remanence of a magnetic tape, then, is a function of 1) intrinsic remanence of the magnetic material, 2) density with which the material is packed, and 3) how thickly the material is coated on the tape.

Packing density in magnetic tape is limited by the percentage of polymer binder which must be used to hold particles together in a tough film. Attempts to increase magnetic material content beyond this point result in chalky coatings which will not withstand mechanical abrasion in recording machines. The "energy product" of a magnetic material is obtained by multiplying the values of M and H for a given point on the second quadrant of the major hysteresis curve. For the purpose of defining the performance of a particulate magnetic material used in recording tape, the "energy" of the material can be defined as the area enclosed by the second quadrant. Thus, energy can be increased by increasing either coercivity or remanent magnetization, and remanent magnetization, in turn, can be increased either by changing the intrinsic remanent magnetization of the particle or by increasing packing density of particles. For reasons which are the subject of the remainder of this article, increased remanent magnetization by either means should be accompanied by a corresponding increase in coercivity in order to obtain a maximum possible signal output of tapes used in audio cassette recording or any other kind of very short wavelength recording. The so-called "high energy" magnetic tapes avail able today in audio cassettes contain magnetic materials which have higher coercivity than gamma Fe2O3. The term "high energy" is a relative expression which uses iron oxide as the conventional standard.

The Effects of Demagnetization

The magnitude of a long wavelength electrical signal generated in a magnetic transducer during playback of a recorded tape is proportional to the remanent magnetization of the tape. A tape having twice the remanent magnetization of another will produce twice the electrical output. High transducer output is desired in order to obtain a high signal-to-noise ratio in the recording system.

As pointed out previously, remanent magnetization can be increased by 1) increasing the intrinsic remanent magnetization of the particles, 2) increasing the density of the magnetic material by packing more particles into a given volume, and 3) coating the magnetic material more thickly on the tape. At 1 7/8 ips tape speed, none of these approaches to increasing remanent magnetization will produce a corresponding increase of high frequency output. A thicker coating will not increase high frequency output because short wavelengths are recorded only near the surface of a magnetic tape, and the thicker coating will create only an imbalance in the low and high frequency response of the recording system. The other two approaches to increasing remanent magnetization will not greatly improve high frequency output because of an effect known as "self-demagnetization." Self-demagnetization in magnetic tape recording causes a loss of high frequency or short wavelength information at peak sound levels where the tape approaches magnetic saturation.

Although a magnetic recording system may have an ideally flat frequency response at 20 dB below the maximum operating level (MOL) of the tape, the high frequency end of the audible spectrum becomes suppressed as the MOL is approached. Finally a point is reached where no amount of recording level increase will boost high frequency output, even though low frequencies retain a substantial headroom. Figure 4A shows that a cassette tape constructed with magnetic material having a coercivity of 340 oersteds is only 4 dB down at 19 kHz when the recording level is 20 dB below the MOL. At 0-dB recording level the output is 12 dB down at 10 kHz and is virtually non-existent at 19 kHz.

================

Fig. 2--The switching characteristics of a single domain particle. The "X" axis

represents the polarity and magnitude of a magnetic field, measured in oersteds,

applied to a magnetic particle so that the direction of the field is parallel

with the long axis of the particle. The sinusoidal waveform shows how the field

changes with time. The "Y" axis represents the magnetization (M)

of a single domain particle measured in gauss.

Starting at T0, the applied field increases in a positive direction, passing through point A, which is equal to the coercivity (He) of the single particle, or about 340 oersteds for gamma Fe2O3. At this point, the applied field acts upon the particle to reverse its field virtually instantaneously. The new magnetization of the particle is exactly equal to the previous value, but polarity Is reversed, producing a symmetrical figure.

The sinusoidal applied field returns to zero, but the particle remains magnetized in the positive direction. Not until the applied field reaches point C does the particle again switch to its original state. The pattern formed by these two variables is an ideal rectangle having sharp corners due to the instantaneous switching of the particle. This kind of figure is obtained with a single domain particle and will be considerably modified when particles having a wide distribution of coercivities are combined.

Fig. 3--The magnetization characteristics of a bulk quantity of iron-oxide

particles which have a distribution curve in which a preponderance of particles

switch at a coercivity of 340 oersteds. A small percentage have lower coercivity,

and a similar percentage have higher coercivity, as shown in the figure. The

distribution curve is essentially symmetrical. When initially mixed together,

it can be assumed that the particles will be oriented in a random manner so

that the net magnetic field produced by a bulk quantity is zero. In this state

the bulk quantity can be considered demagnetized.

If an applied field is increased in the positive direction, magnetization of the bulk quantity follows an "initial magnetization curve" which is the integral of the distribution curve. The point of steepest slope of the initial magnetization curve coincides with the peak of the distribution curve, and this is the point where a maximum number of particles are switched. When the applied field is said to have reached saturation, and no further increase in applied field will increase magnetization.

Once saturated, the material then changes magnetic state in a manner described by the major hysteresis curve, and magnetization of the material in the absence of an applied field is termed remanent magnetization.

Fig. 4A-Frequency response of a gamma Fe2O3 tape at widely separated recording

levels. Frequency response of a cassette tape is almost ideally flat when operated

at a recording level 20 dB below the maximum operating level, which is generally

defined as that level which produces 3 percent third harmonic distortion in

the reproduced signal at a frequency specified by a particular standard.

High frequency output is greatly reduced when the tape is operated at the maximum output level, creating intermodulation distortion.

Fig. 4B-Less severe high frequency suppression occurs in a tape made with "high

energy" magnetic material having a coercivity of 550 oersteds because

of reduced self-demagnetization of the recorded signal.

Fig. 5-The internal magnetic field of a long, thin permanent magnet exists

largely in the air. This configuration will produce minimum self-demagnetization.

Fig. 6-Most of the internal magnetic field of a short, broad magnet passes

through the body of the magnet, increasing self-demagnetization.

Fig. 7-The thickness of the magnetic coating and the wavelength of the recorded

information establishes the proportionality factor of the "magnets" in

a long wavelength recording. Even though the magnetic material is continuous,

the magnets behave as though they were physically independent.

The magnets grow shorter as the recorded frequency increases and will also become thinner at wavelengths shorter than one thousandth of an inch (about 2 kHz) because short wavelengths are recorded only near the surface of the tape.

Fig. 8-In this recording depth vs. wavelength curve, the solid curve shows

the recording depth that would occur in a thickly-coated magnetic tape moving

at 1 7/8 ips. Such a tape would produce far greater relative output at low

frequencies than at high frequencies because more magnetic material would be

utilized at the longer wavelengths. A typical cassette tape is coated only

200 microinches thick, so recording depth below 2 kHz is limited by the physical

thickness of the coating.

==================

Although many people will not consider a loss of high frequency response at high levels to be a serious listening defect, intermodulation distortion which results from this problem has a profound effect upon the quality of recorded music. With most types of music this intermodulation distortion may be more destructive to good listening quality than harmonic distortion, and it will occur in a magnetic recording system at levels well below the conventionally accepted maximum output level.

Figure 4B contrasts the high frequency performance of a tape which employs a magnetic material having a coercivity of 550 oersteds. The improvement in short wavelength response is attributable to a reduction of self-demagnetization.

Loss of high frequencies due to demagnetization occurs because of the very short wavelengths produced by a tape speed of only 1 1/ ips. The cassette is most vulnerable to this problem.

Demagnetization losses at tape speeds of 15 and 7 1/2 ips are negligible. Let us examine the causes of demagnetization using the familiar example of bar magnets.

Any permanent magnet has both an internal and an external magnetic field. The shape and intensity of both fields are dependent upon the physical shape of the magnet. The ratio of length to cross-section dimensions of a magnet is called the proportionality factor. That part of the internal field which passes through the body of the magnet has a demagnetizing effect which limits the magnitude of remanent magnetization, that is, it limits the strength of the magnet after the magnet has been withdrawn from a magnetizing field. As shown in Fig. 5, the pole ends of a long permanent magnet are far apart, and much of the internal field extends into air around the magnet. A magnet with this configuration will experience little demagnetization, and therefore it can be magnetized to a fully saturated state. The magnet in Fig. 6 is broad relative to the distance between pole ends. In this case a larger part of the internal magnetic field will exist in the body of the magnet, causing demagnetization. Even though these two magnets may be subjected to the same magnetizing field, the short magnet may have less remanent magnetization when withdrawn.

Demagnetization is resisted by maintaining a certain ratio between remanent magnetization and coercivity. A magnet having relatively low remanent magnetization will not have an intense internal field, and thus will remain saturated even though it may have a corresponding low coercivity. But a high remanence magnet must also have a high value of coercivity, otherwise the internal field will spontaneously demagnetize the magnet, reducing remanence to a level which the coercivity will sustain.

Permanent magnets are used generally in magnetic "circuits" where magnetic fields are directed through soft iron poles. Examples of such uses are loudspeakers and permanent magnet motors. In these instances the soft iron circuits reduce the internal fields of the magnets, reducing susceptibility to demagnetization.

It is the self-demagnetizing effect that promotes the practice of placing a "keeper" across the pole ends of horseshoe shaped magnets to prevent demagnetization when not in use.

The keeper is made of soft iron, and it short circuits the magnetic field to prevent the internal field from causing self-demagnetization.

Because the strength of the total field in and around a magnet is also dependent upon the level of magnetization, a magnetic material which is weakly magnetized will not demagnetize itself even though it may have a very poor proportionality factor. Self demagnetization occurs primarily when an attempt is made to saturate the magnet or in other words to subject it to an intense magnetizing field which will leave it magnetized to the maximum level it will sustain. Summarizing, self-demagnetization in a saturated magnet is a function of 1) the dimensions of the magnet or proportionality factor, 2) the coercivity of the magnetic material, and 3) the remanent magnetization of the material.

Self-demagnetization induced by a poor proportionality factor is an important cause of loss of high frequency information in magnetic tape when high frequencies are recorded at short wavelengths (slow tape speed). If a square wave is recorded on magnetic tape, the recording signal will magnetize the magnetic layer in a series of end-to-end alternately polarized magnets, as illustrated in Fig. 7. The magnetic intensity of the magnets will be dependent upon the recording level and on the remanent magnetization of the tape. The length of the magnets is established by the frequency being recorded and the speed of the tape across the recording transducer. At low frequencies (long wavelengths), the proportionality factor of the recorded magnets, which is established by the thickness of the magnetic coating on the tape and the recorded wavelength, is favorable towards preventing self-demagnetization. Consequently, the tape will sustain a high level of magnetization at low frequencies. At very short wavelengths the proportionality factor is poor because the magnets are shorter. The recorded magnets will relax back to less than saturation at the instant they leave the magnetizing field of the recording transducer.

Recalling that self-demagnetization is greatest when an attempt is made to saturate a magnet, it can be seen that a low-level recording (low magnetization) will produce little demagnetization at either long or short wavelengths, and output of the tape is relatively uniform at all frequencies. But at high levels of magnetization, short wavelengths will spontaneously demagnetize as the recorded areas of tape move away from the recording transducer. Under this condition high frequencies will be suppressed relative to low frequencies.

The foregoing analysis of self-demagnetization versus recorded wavelength can be easily visualized in a physical sense. Although a typical magnetic tape may have a coating thickness of about 200 microinches, studies of the recording process (3) have shown that a thickness of only 50 microinches is utilized in recording a wavelength of 0.0001 inch (which is the wavelength generated by 19 kHz at 1 7/8-ips tape speed) (see Fig. 8). Thus the cross-section dimension or thickness of the recorded magnets can be considered to be 50 microinches. The length of a recorded magnet is one-half the recorded wavelength, also about 50 microinches at 19 kHz frequency. The end-to-end magnets at this wavelength are only as long as they are thick, and this proportionality factor of one-to-one gives rise to substantial self-demagnetization.

The second quadrant of the M-H curve of a magnetic material, as shown in Fig. 9, can be analyzed to approximate the effect of self-demagnetization of tape for various wavelengths and values of coercivity and remanence. Remanent magnetization of a tape recorded at very long wavelengths is indicated by the point at which the second quadrant magnetization curve intersects the M axis. This point also corresponds to the saturated output level of the tape at low frequencies, and is determined by the intrinsic remanent magnetization and packing density of the material used in the magnetic coating.

The saturated output level of the tape at high frequency can be determined by using a "demagnetization loss" line drawn through the M-H curve. The angle of this line is dependent upon wavelength, and the angle will rotate counterclockwise as the wavelength becomes shorter (3). At the point where the loss line intersects the M-H curve, a second line is drawn perpendicular to the M axis. The point where this second line intersects the M axis represents the magnetization of the tape for a specified wavelength. Note that remanent magnetization (and output) at 20 kHz is substantially less than that of long wavelengths for a tape having a coercivity of 320 oersteds.

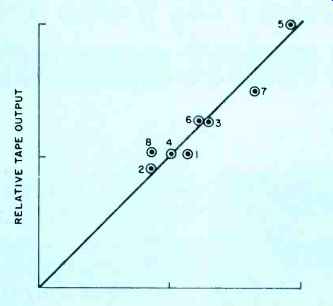

As mentioned earlier, the angle of a demagnetization loss line is a function primarily of wavelength, and will be the same for any tape tested. This angle was determined empirically by testing numerous tapes having widely separated magnetic properties and variable thicknesses. In every case, measured output of the tapes correlated closely to a demagnetization loss line of the same angle for a given wavelength (4). Figure 10 shows second quadrant magnetization curves for eight tapes which have widely ranging ratios of remanent magnetization to coercivity. The angle of the demagnetization loss line drawn through the tape curves corresponds to 0.1 mil wavelength. If the intersections of this line with the magnetization curves ideally define magnetization of the tapes (and consequently output), then measured outputs of the tapes should all fall on the line of Fig. 11. Note that an excellent correlation is obtained.

This method of predicting demagnetization applies only to the near saturated case, and therefore applies to tape output where the recording level is near the maximum operating level of the tape.

It should be pointed out that, in addition to demagnetization of a recorded signal caused by poor proportionality factor of the recorded "magnets," another type of demagnetization occurs as the result of magnetic interactions of the tape and the recording transducer. This second kind of demagnetization is termed "recording loss," and is included in the total demagnetization predicted by the demagnetization loss line. A definition of recording loss is beyond the scope of this paper.

Numerous conclusions can be drawn from the loss line method of predicting demagnetization losses. First, it can be observed from the curve of tape 2 in Fig. 10 that an increase in remanent magnetization without a corresponding increase in coercivity will not produce a proportional increase in 20-kHz output. The intersection of the 20-kHz demagnetization loss line occurs at a nearly vertical slope in the second quadrant curve, so increasing the height of the curve will produce only a small change in the height of the intersection point. In attempting to develop superior magnetic pigments for short wavelength audio recording, a mere increase in remanent magnetization is of limited value.

Second, remanent magnetization or output of a tape at 20 kHz can be substantially improved without any increase in the intrinsic remanent magnetization of the magnetic material.

By increasing coercivity from 320 to 550 oersteds, as shown in Fig. 9, demagnetization at 20 kHz is reduced to half. This result clearly points to the direction of increasing coercivity to obtain improved short wavelength saturated output.

Third, the greatest improvement of short wavelength saturated output is obtained by simultaneously increasing both remanent magnetization and coercivity. High remanent magnetization is needed to produce magnetic fields of high intensity, and coercivity is needed to prevent spontaneous demagnetization that would otherwise occur.

============

Fig. 9--This figure shows the second quadrants of the M-H curves of two tapes.

Saturation magnetization at a given frequency, after self-demagnetization,

is predicted by the points of intersection of the curves with the "demagnetization

loss" line.

Fig. 10-Second quadrant analysis of eight experimental tapes shows the demagnetization

loss line for a recording wavelength of 0.1 mil represented by the dotted line.

Note 1500 that the predicted output of tape 1 is very much lower than might

be anticipated by remanent magnetization alone. This tape provides an extreme

example of self-demagnetization.

Fig. 11-Measured output of eight experimental tapes. The second quadrant analysis

of self-demagnetization would predict that the output of the eight tapes of

Fig. 10 would fall on the line.

Fig. 12-The relative energies of four magnetic recording pigments. The area

enclosed by the second quadrant of the hysteresis curve represents the "energy" of

a magnetic material. Coercivity of cobalt-modified iron oxide can be adjusted

in the manufacturing process to cover a very broad range, from that of Fe2O3

to well beyond the recording capabilities of a magnetic transducer. Metallic

magnetic materials are probably the materials of the future since they combine

an exceptionally high remanent magnetization with high coercivity.

============

Fourth, and finally, the shape of the magnetization curve can also have a significant effect upon demagnetization. If one imagines a second quadrant curve which has a sharp corner as opposed to a slanted curve, the point of intersection on the demagnetization loss line would be much higher on the M axis (5). Since the shape of the curve is a function of the distribution of coercivities of the magnetic particles, narrow distribution is a quality to be sought. Distribution is made narrow principally by maintaining uniformity in size and shape of the magnetic particles, and by obtaining chemical purity of the material.

The effect of reducing demagnetization by narrowing distribution can also be visualized as an elimination of those low coercivity particles of pigment which are most susceptible to demagnetization. As remanent magnetization of a pigment is increased, the low coercivity particles will be the first to demagnetize. If these particles represent a large portion of the total material, then demagnetization will be appreciable, even though the value of coercivity represented by the center of the bell shaped curve is high.

In certain types of short wavelength recording, such as FM video and high density digital recording, a very narrow distribution is highly desired. In fact, a magnetization curve similar to that of a single particle would be ideal. But audio recording is an analog recording process where the instantaneous magnetization of the magnetic material in the tape must be exactly proportional to the instantaneous value of the audio signal. If distribution is too narrow and if the magnetization curve is too steep, sensitivity of the tape becomes too critical to allow proper setting of recording levels. Fortunately this problem is not encountered in particulate magnetic materials because small variations in physical shape and dimensions, as well as variations in chemical composition of particles inherent in the manufacturing process, combine to produce a slope in the magnetization curve which is suitable for analog recording.

The foregoing analysis provides a quantitative means of translating several bulk magnetic properties of materials to performance of a tape, but more importantly, it clearly shows the direction that must be taken in the future development of magnetic materials. All areas of magnetic recording, including television, digital data, and instrumentation recording, are trending toward shorter wavelengths. Advanced materials having higher coercivity and remanence must be developed to meet future needs in all areas.

Material with increased coercivity is the most recent development to find a way into the marketplace. Chromium dioxide and cobalt-modified iron oxide became available in audio cassette tapes several years ago. The coercivity of chromium dioxide is nominally 550 oersteds, as compared to 340 oersteds of gamma Fe2O3. This value of coercivity is determined by the chemical nature of the material and by the size and acicularity of the magnetic particles. Approximately one-third of the coercivity is attributable to chemical composition and two-thirds to size and shape. A coercivity of 550 oersteds is a fortuitous characteristic of CrO2 particles, since this value is ideally suited to compensate for demagnetization losses which occur at 1 7/8 ips tape speed.

Saturated remanent magnetization of CrO2 is slightly greater than that of gamma Fe2O3.

Unlike CrO2, cobalt-modified iron oxide obtains a high coercivity by combining a small amount of cobalt with the iron oxide crystal. Coercivity can be controlled over a very wide range, up to 2,000 oersteds, by adjusting the amount of cobalt introduced into the iron oxide. This flexibility allows cobalt-modified materials to be adjusted precisely to the application.

Future Limits

If magnetic materials could be tailored to any magnetic properties desired, what are the limits to which remanent magnetization and coercivity could be taken? Certainly many different limits are imposed. Not the least significant is the magnitude of the magnetic field which can be generated by recording transducers. Materials which form the pole piece of transducers become magnetically saturated when attempts are made to record on tape having a coercivity of, say, 1500 oersteds. Even though a tape with this coercivity is highly resistant to self-demagnetization and will provide excellent short wavelength output, no practical method exists for placing a distortionless recording on the tape. Until significant improvements in head materials are made, a coercivity of 1200 oersteds is a practical limit for tape in most applications.

With this limit for coercivity established, it is a simple matter to show by analysis of the second quadrant curve what level of remanent magnetization can be employed before self-demagnetization at short wavelengths occurs. These values of coercivity and remanent magnetization become the goals of future pigments, established by the characteristics of magnetic recording transducers and firmly fixed until advances in transducer materials are forthcoming.

The limits of coercivity and remanence established by recording transducers are reached in a new generation of magnetic materials which utilize particles existing in a metallic state. Materials of this type are being developed in several laboratories around the world. One such material, identified by the brand name "Metafine IV," is supplied by the 3M Company. Such particles have an intrinsic remanent magnetization close to the theoretical limit for single domain particles. A comparison of the second quadrant area of the fine iron material and gamma Fe2O3 is shown in Fig. 12. As the figure suggests, the output of a tape made with this material is far greater than that of gamma iron oxide tape.

Magnetic materials having very high remanence are difficult to handle in the tape manufacturing process because of a tendency of the particles to cling together in clumps. Magnetic attraction and repulsion between particles in the fluid dispersion causes them to find stable physical relationships wherein opposite poles are locked together, end to end and side by side. This produces chains of particles which appear under a microscope much like the chains of iron filings used to demonstrate magnetic fields. Chained magnetic particles in tape will not behave as individual particles since the switching of one particle will have an influence on neighboring particles. The result of this infectious switching could be poor signal output from the tape.

Clumping or chaining is controlled by dispersing magnetic materials in fluid polymers and binders in which the chemical forces holding particles apart are greater than the magnetic forces pulling them together. The chemistry needed to achieve this equilibrium becomes more difficult as the remanent magnetization of particles is increased. Thus, chemical dispersion technology must be developed in concert with developments in magnetic materials, and advanced magnetic tapes are not made simply by substituting magnetic materials.

The development of advanced magnetic tapes involves much more than simply increasing the energy of magnetic materials.

The magnetic component is only one ingredient in a complex chemical system, and the entire system must be redesigned whenever this component is substituted or modified.

Summary

This paper has explained the effects of demagnetization on short wavelength saturated recording, and has presented an empirically derived method of equating magnetic properties of particles to short wavelength performance of tapes. Although the examples used relate to cassette audio recording systems, the same principles apply to other short wavelength recording systems, and particularly to the whole new generation of video recorders now available to consumers. The trend toward shorter wavelengths, which has been seen in the past, will go on into the future, and refinements of all aspects of recording systems will continue. Development of magnetic materials having increased remanent magnetization, higher coercivity, and narrower distribution will be a large part of this effort.

The author wishes to acknowledge the work of Dr. T. J. Szczech, of the Data Recording Products Division Laboratory of the 3M Company, whose studies of the magnetic recording process are principally responsible for the information contained herein.

References

1) Jan Smit, "Magnetic Properties of Materials," McGraw-Hill, 1971.

2) A. H. Morrish and L.A.K. Watt, "Effect of the Interaction Between Magnetic Particles on the Critical Single-Domain Size," Physical Review, Vol. 105, No. 5, March, 1957.

3) T. J. Szczech, "Further Studies of Digital Recording," 3M Company Internal Report, November 27, 1968.

4) T. J. Szczech and E. F. Wollack, "A Technique for Determining Short Wavelength Output," IEEE Transactions on Magnetics, Vol. MAG-10, No. 3, September, 1974, pp. 670-673.

5) D. B. Richards and T. J. Szczech, "The Relationship of Switching Distribution to Tape Digital Output, " Journal of Applied Physics,1978.

(Source: Audio magazine, Sept. 1978; by Peter Vogelgesang )

Also see:

All That Data: Tape Deck Frequency Response and Headroom (Jan. 1981)

= = = =