Absorbents are used for two main purposes in loudspeaker enclosures, firstly to damp panel vibrations and secondly to damp internal air resonances. The panels of enclosures that are totally sealed or have a small vent to function in the reflex mode, are subject to large pressure differences between their internal and external surfaces. These can cause them to warp in sympathy and thereby themselves radiate sound. Such sound is colored by the resonances of the panels and so adds distortion to that radiated by the loudspeaker cone.

Panel Damping

A heavy and dense absorbent layer fixed to the internal panel surfaces considerably dampens any tendency to sympathetic vibration. A comparatively light panel heavily lagged has proved less prone to vibration than a more substantial panel only lightly damped. Generally, the thicker the layer, the lower the frequency it will effectively absorb. As it is at the lower and mid frequencies that the panels resonate, only a thick or very dense layer is of any use. Various materials have been used for this purpose, but among the best so far discovered are bitumous pads.

All panels of infinite baffle speakers should be internally lagged with these, but not those of reflex cabinets as the resonance effects on which the enclosure depends could be dampened. Transmission line and folded horn partitions do not need lagging, and the operation of the horn in particular would be impaired by it.

The rear panel in the infinite baffle and reflex enclosures, is especially prone to trouble, as high pressure waves can be reflected back to the loudspeaker, and right through the cone which is virtually acoustically transparent. At frequencies when the depth of the cabinet is equal to a quarter and three quarter wavelengths, cancellation occurs, and at those corresponding to a half and whole wavelengths there is reinforcement. A series of dips and peaks result, some accompanied by severe distortion.

Particular attention should therefore be paid to lagging the rear wall to avoid this effect, and even reflex enclosures which are normally un-lagged should have rear wall damping.

Air Resonances

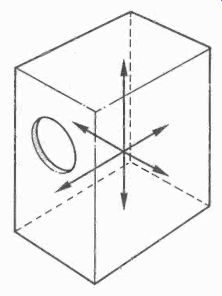

The three enclosure dimensions of a sealed enclosure have their fundamental air resonance frequencies along with harmonics (Fig. 29). To dampen these, absorbent material needs to be located at the positions of maximum air motion or the antinodes.

Fig. 29. The three resonance modes of a rectangular enclosure.

These antinodes are spread across numerous points in all dimensions, so the most practical course with a small enclosure is to completely fill it with absorbent. With larger enclosures the problem is to avoid compression of the lower layers by the weight of the upper ones. One method of overcoming this is to fill the lower area with several vertical rolls of material, then lay a horizontal roll across the top of these.

Reflex enclosures should not have absorbent filling as the air resonance is essential for their operation. As noted above, the only absorbent in a reflex enclosure should be on the rear wall.

The folded horn also should be without absorbent as its purpose is to impart effective air motion to the outside from the movement of the loudspeaker cone. The last thing we want to do here then is to dampen that motion.

Transmission line enclosures need absorbent in the air passage though not fixed to the partitions. The purpose here is twofold, the first being to 'lose' the rear wave so that it emerges from the end greatly attenuated and so has little cancellation effect on the front wave. As the transmission line behaves as a closed pipe, it has a strong fundamental resonance along with odd harmonics. The second function of the absorbent is therefore to dampen these resonance modes.

Extra density at the anti-nodal positions serve to do this.

Materials

A variety of materials can and have been used for enclosure filling. Polyurethane foam is a convenient one as it can be obtained in various sizes, blocks and sheet. Glass fiber has been used, but is not recommended. Its acoustic absorbent properties are inferior to other materials, and it can be a health hazard to work with. However, if nothing else is available, it can be used.

Long-fiber wool is considered the best material of all, but being loose, it is not easy to use and some method of retaining it in place must be devised. It suffers more than most from the problem of compacting under its own weight where large volumes are used. Another factor which must be considered is the need for moth-proofing if the enclosure is open such as with a transmission line.

The material most generally used because of its convenience and acoustic properties is bonded cellulose acetate fiber, commonly known as BAF wadding. It comes in sheets of 1 inch or 2 inch thickness, usually 3 ft, wide, and can be rolled up to form large wads or laid out in several thicknesses. It is quite easy to cut. It is springy and so can be compressed with extra thicknesses at antinodal points, but its density is normally about right for general filling. Over compression can result in too great a density with a reduction of the actual air volume.

BAF should be used wherever possible. It is supplied by the specialist loudspeaker firms such as Wimslow Audio and is available by mail order. It may be difficult to obtain locally, as it is only specialist shops that stock it.

Adiabatic Propagation

When a sound wave travels through air it is assisted by self-generated heat. It is a well-known fact that pressure produces heat. So the regions of pressure within the wave generate corresponding regions of higher temperature. These expand, thereby increasing the pressure and producing more heat. The sound wave quickly passes and the regions at different temperatures soon merge, so there is no lasting effect at any static point in the path of the sound wave.

However, the pressure wave carries a wave of higher temperature with it, the region of high pressure always being at a higher temperature than the mean air temperature. Now the velocity of a sound wave varies with temperature, being greater at higher values. So the velocity of the pressure wave is actually increased by its self-generated heat. The propagation is said to be adiabatic, which means impervious to heat change.

As this is the normal way whereby sound is propagated it is allowed for in our acoustic calculations and is not usually necessary to consider it. It is when conditions differ from this, that we need to take it into account.

Isothermal Propagation

When a sound pressure wave travels through a medium which conducts heat more readily than air which is a very poor conductor, the higher temperature regions lose heat more quickly to the surrounding lower temperature areas. Thus the temperature is not maintained and in fact never reaches the value that it would have done in air. The result is that the sound velocity is slower than in air. The condition is termed isothermal which literally means 'of the same heat' as adjacent regions do not have the temperature differences of the adiabatic condition.

Absorbent material such as BAF, although not seeming to be a good conductor of heat, conducts it better than air. So sound generated in a loudspeaker enclosure filled with an absorbent is propagated in partly isothermal conditions. It is thereby slowed down.

This has a useful bonus effect. The time taken to travel across a filled enclosure is longer, so the enclosure therefore appears to be larger to the sound wave. We thus get the same effect from an absorbent filled enclosure that we would from a larger one that was unfilled.

Unfortunately the difference is not large; for a fully isothermal state, the reduction in sound velocity is V2 or 1.414, giving the effect of an enclosure that much larger in volume.

This would reduce the resonant frequency to about 0.833 of its former value, a very useful reduction. However, the effect of the absorbent is to create an only partly isothermal condition, much depending on the material and the packing density. It is interesting to speculate what effect fine copper wires spun into the material may have in increasing the effect to nearly full isothermal propagation.