Regardless of whether transistors or vacuum tubes are used in a color receiver, the functions of the several circuit systems remain unchanged.

That is, a solid-state set still has a tuner, IF strip, horizontal and vertical deflection systems, chroma system, etc. Thus, the radical changes brought about by the adaptation of transistors to color-receiver circuitry occur in the circuits themselves, not in the overall design concept. There is one exception to this statement; the use of solid-state devices makes modular construction much more feasible than it was in vacuum-tube designs. A vacuum-tube color receiver of modular construction has been marketed (Setchell-Carlson), and at least one manufacturer is contemplating a solid-state color receiver which does not have modular construction. The relative merits of the two types of construction are not an appropriate subject of discussion here.

Review of Transistors

In presenting the following information, we assume that the technician has some prior knowledge of transistor circuitry. For this reason, we will not dwell on the theory of their operation. The physical laws which govern the operation of solid-state devices have been published many times and the interested reader may pursue the subject by studying any of a host of books. For our present purposes, we will consider most of the transistors used in a color receiver as "black boxes" which amplify.

It is worth noting that some of the characteristics of transistors dictate significant changes from conventional tube circuitry. In their most usual configuration, transistors exhibit very low input impedance.

For this reason, resistors in the circuit arc usually relatively small and capacitors have relatively large values.

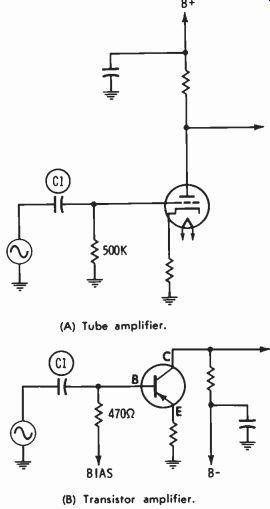

Fig. 1 will help to illustrate this important point. Assuming that each circuit must operate at 1 kHz. we will calculate the value of C1 which will allow reasonably good energy transfer from the first stage (represented by a generator) to the second stage. As a general rule of thumb, the impedance of the coupling capacitor should not exceed 1/10 of the impedance of the input circuit of the following circuit. In the vacuum-tube circuit (Fig. 1 A) the maximum impedance of C1 may be n5 greater than 50K ohms and the capacitance may be calculated by:

To maintain the same impedance ratio between coupling capacitor and input, the value of C1I in the transistor circuit (Fig. IB) may not exceed 47 ohms.

Because large coupling capacitors are necessary, it is sometimes more practical to eliminate them entirely and couple successive stages directly. This is also done in vacuum tube circuitry where response to very low frequencies is desirable, but each direct-coupled stage requires, roughly, at least 100 additional volts from the power supply, a serious limitation. Transistors operate from more moderate voltages than tubes, and several stages may be direct coupled even though the power supply produces only 100 volts or less. By using alternate NPN and PNP transistors in a direct-coupled cascade, an almost unlimited number of stages may be direct coupled without increasing the power-supply voltage.

While the use of direct-coupled transistor stages is desirable from the point of view of economy and design simplicity, it may introduce a troubleshooting problem. A direct coupled amplifier will pass DC as well as any other frequency, and so any change in emitter-to-base DC potential of the first stage is amplified in each following stage. Thus, if a shift in bias of 0.1 volt should occur at the front end of a string having a gain of 100, a change in output of 10 volts would result.

In practical applications, a DC swing of 10 volts is nearly impossible because some transistor in the string probably would either saturate or cut off at a smaller shift in bias. The result is the same-the problem area is in front of the circuit where the symptoms are most likely to be detected.

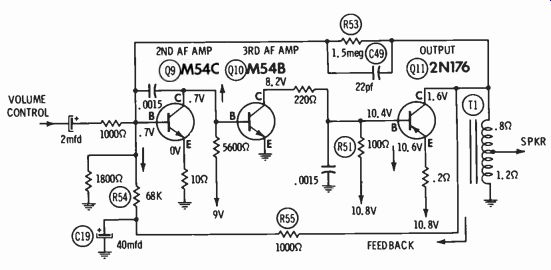

DC feedback loops and current limiters are often used in transistor circuits to prevent the runaway condition just described. The circuit shown in Fig. 2 has such a feedback path. (The circuit is not in the Motorola receiver.) Assume that the positive base voltage of Q9 de B+ creases for some reason. The conduction of Q9 will decrease, causing the base voltage of Q10 to rise. The increased conduction of the collector of Q10 causes an additional drop across R51, and the base of Q 11 becomes less positive. This causes increased collector current in Q11 and the collector swings positive because of the increased drop across T1.

Without a feedback loop, a small decrease in bias at the base of Q9 might well cause such a large increase in collector current through Q11 that the transistor would be damaged. The feedback loop consists of R55, C19, and R54, connected between the collector of Q11 and the base of Q9. By virtue of this loop, as the collector voltage of Q11 tends to rise, a portion of this positive-going voltage is coupled back to the base of Q9 to increase its conduction. Thus, the action of the feedback loop is always to oppose any change in the DC operating potentials of the transistors. Note that C19 acts as a low-pass filter in the feedback loop.

Because of it, only DC, or low frequency AC, is fed back to Q9.

In our discussion about the DC feedback loop, we assumed that the potential at the base of Q9 changed for some unspecified reason. While idle conjecture about the cause of this shift is pointless, it is true that changes within Q9 itself, or variations among transistors in a production run, are a major source of the variations. Thus, we may conclude that DC stabilization is required for two reasons: the DC instability of direct-coupled amplifiers, and the inherent DC instability of transistors themselves.

In general, it is also true that the gain stability of transistors is poorer than it is for vacuum tubes. For this reason, an AC feedback loop also may be incorporated in an amplifier string. Referring again to Fig. 2, the AC feedback network consists of R53 and C49. A portion of the amplifier output is fed back to the input in phase opposition.

Thus, if the gain of the overall circuit increases, so does the amplitude of the inverted signal fed to the input, and the gain is maintained constant. Note that this feedback circuit incorporates a high-pass filter so that it is insensitive to DC. Another characteristic of transistors which is sometimes confusing to the technician is the manner in which they fail. Although a triode with a grid-to-plate short is quite rare, a base-to-collector short in a transistor is a distinct possibility.

Furthermore, while a grid-plate short probably would be destructive to associated components, a base collector short may cause no external damage. A transistor with a base-collector short may pass the signal (without amplifying it, of course) but there will be no inversion of the waveform.

Typically, vacuum tubes fail because of gradually decreasing cathode emission and lowered trans conductance. This is unlike transistors which usually maintain a nearly constant gain throughout their lives; failures are due to shorts or excessive leakage.

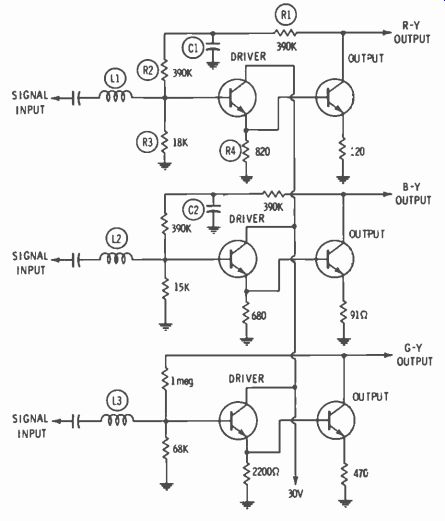

Motorola 23TS-915 and 919 Chassis Chroma Circuitry

Fig. 1. Comparison of transistor and vacuum-tube amplifiers.

Fig. 2. Feedback loops in a transistor amplifier.

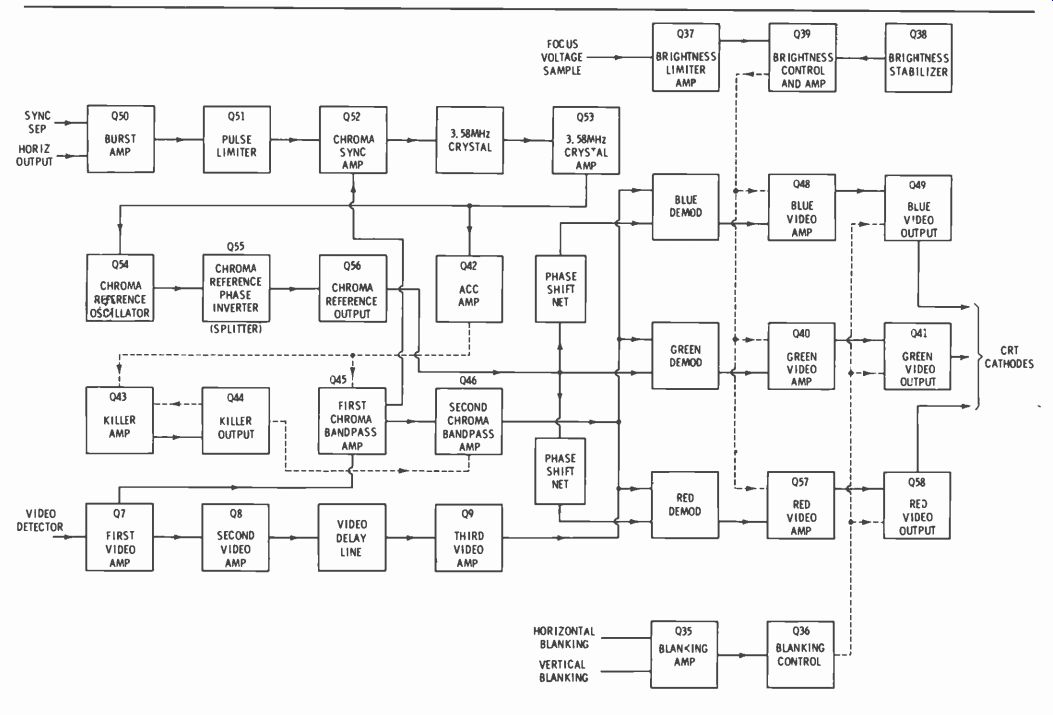

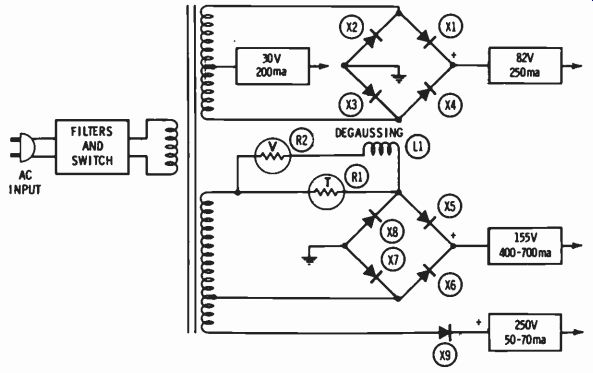

Fig. 3. Detailed block diagram of the Motorola solid-state chromes circuits.

Fig. 3 is a block diagram of the chroma circuits used in the Motorola 23TS-915 and 919 chassis. Although most of us are accustomed to only about half this number of blocks, the functions performed by this chroma circuit and one using vacuum tubes are essentially the same. With the exception of the demodulators and color amplifiers, which are rather novel, the entire chroma circuit is quite similar to a vacuum-tube design.

Reference Circuits

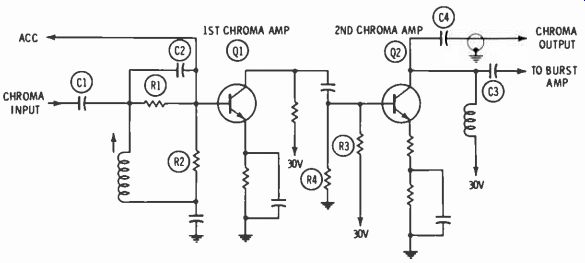

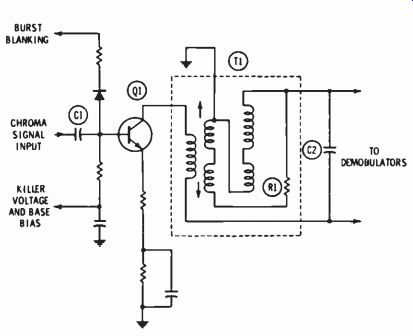

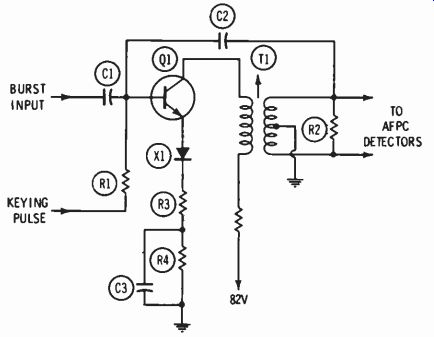

Following the same sequence that was used in Section 4 of this guide, we shall examine the reference-signal circuits first. Video from the first video amplifier is fed to the first chroma-bandpass amplifier, which has two outputs. One of these outputs, consisting of the chroma side bands and the color burst, is fed to the chroma-sync amplifier. The chroma-sync amplifier is the equivalent of the burst amplifier of conventional designs and is a coincidence gate. Also fed to the chroma-sync amplifier is an enabling pulse from the burst amplifier and pulse limiter. This pulse gates the sync amplifier on at the time when the color burst is present at its input, allowing it to pass. During the remainder of the scanning interval, the sync amplifier is gated off, removing the chroma sidebands from its output.

The color burst from the sync amplifier is developed across the 3.58-MHz crystal, causing it to ring from one burst to the next.

The crystal is amplified by Q53 and the output of this stage is a CW signal which is re-phased at the start of each horizontal scan.

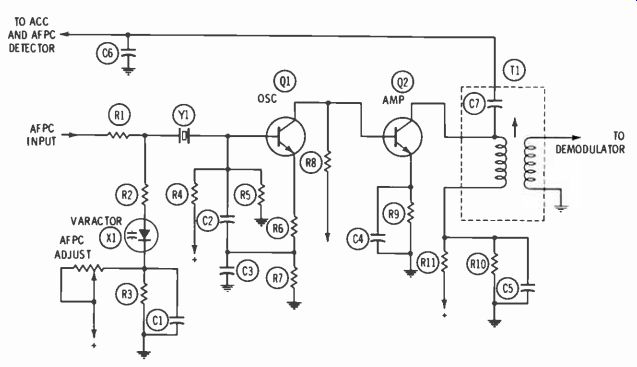

The chroma-reference oscillator, Q54, is a Colpitts oscillator which free runs during black-and-white reception. However, if a color burst is present, the output from the crystal amplifier phase locks the oscillator, causing its output to be in phase with the color burst.

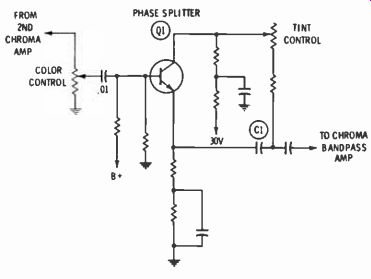

The chroma-reference phase inverter is actually a splitter which develops two out-of-phase signals from the single input. A potentiometer across these outputs, the hue control, selects the specific phase of reference signal required for correct hue of the picture.

Finally, the reference signal is amplified by Q56 and fed to the three demodulators. The phase of the signal from Q56 is correct for the green demodulator, and phase shifting networks develop the correct phase for the blue and red axes.

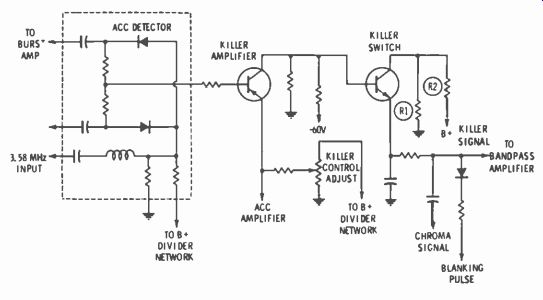

ACC and Color Killer

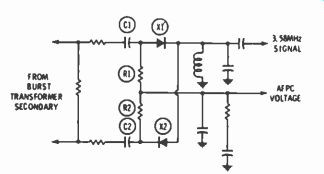

A portion of the output from the 3.58-MHz crystal amplifier is rectified and fed to the ACC amplifier.

If the amplitude of the burst increases, the output of the crystal amplifier increases, and this, in turn, causes the bias developed in the ACC amplifier to increase. This decreases the gain of the first chroma bandpass amplifier to maintain a constant-amplitude output with a varying input. (See "Closed Loop ACC" in Section 5 of this guide.) The output of the ACC amplifier also is supplied to the killer amplifier, Q43. In conjunction with Q44, the killer output stage, Q43, operates as an electronic switch. That is, the circuit is either cut off or saturated-there is no "in between." In the absence of a color burst, the killer cuts off the second chroma-bandpass amplifier; when a burst is present, the second chroma-bandpass amplifier is turned on. The color intensity control is located in the network between the killer and the second bandpass amplifier.

Bandpass Amplifiers

The two chroma bandpass amplifiers, Q45 and Q46, are straightforward in design. As stated above, the gain of the first stage is controlled by the ACC amplifier and the second stage is cut off during monochrome reception by the color killer circuit. The color intensity control also is incorporated in the input of the second bandpass amplifier. The two stages are tuned to pass sidebands having frequencies up to 500 kHz above or below the burst frequency.

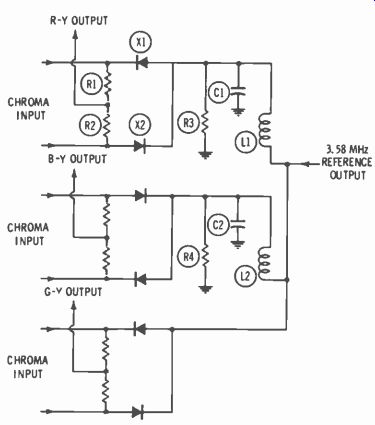

Chroma Demodulators

The diode chroma demodulators used in this receiver are similar in many respects to the ones used in some General Electric receivers.

The essential difference is that a third input, the luminance (or Y) signal is also fed into the three Motorola demodulators.

Today, the majority of color receivers recombine the luminance signal and the ,three color-difference signals within the CRT. (See Section 4 of this guide.) This practice was adopted because of its relative simplicity and economy, but it makes the ability of the receiver to track the gray scale dependent on the degree of nicety with which the three guns of the CRT can maintain identical trans-conductances. The concept of recombining the luminance and chrominance information outside the CRT allows more accurate adjustment of gray-scale tracking and the possibility of correcting for long-time variations in CRT parameters and also for changes in the external circuits.

Time will tell whether or not this second-generation external matrix will fulfill expectations.

The three demodulators of Fig. 3 are identified simply by the color (not color-difference) signals which they produce. This is entirely proper, since color-difference signals never appear in this chassis; chrominance and luminance information are recombined (matrixed) in the demodulators. One of the demodulators will be examined in detail later in this article.

Color Amplifiers

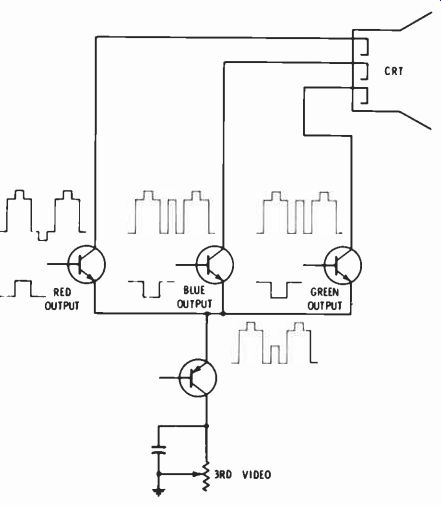

Each of the color demodulators is followed by a pair of amplifiers which raise the signal level to an amplitude sufficient to drive the CRT cathodes. These amplifiers are direct coupled, allowing the brightness control to be connected to the emitters of the first stages of each amplifier string. Making the emitters of Q40, 048, and Q57 more positive causes the collectors to swing in the same direction. This swing is inverted in the output stages, driving the CRT cathodes negative and increasing the brightness.

The emitters of 041, Q49, and 058 (NPN types) return to ground through the blanking-control transistors Q36. When Q36 is cut off during horizontal and vertical retrace, the video-output transistors also are cut off, driving the CRT cathodes positive into cutoff.

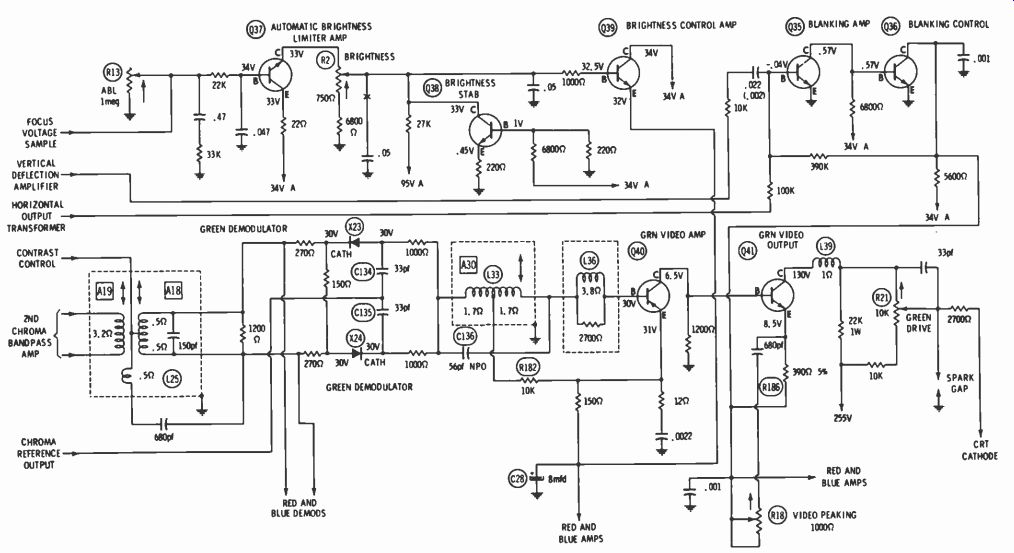

Fig. 4. Motorola demodulator and color amplifiers.

Brightness Circuit

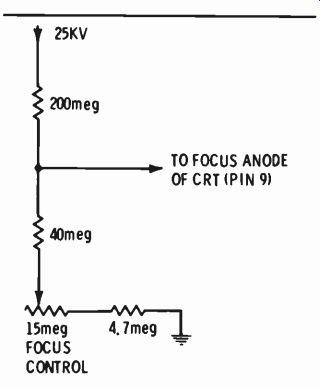

The brightness circuit, Q37, Q38, and Q39, includes the manual brightness control and also an automatic brightness limiter (ABL). The purpose of the ABL circuit is to maintain constant CRT beam currents (for a given brightness control setting) even though shifts in video-amplifier gain, line voltage, horizontal-output voltage, etc. might tend to change the brightness. Also, the ABL control allows the technician to preset the maximum brightness for optimum operation.

A sample of the focus voltage is used as a control voltage for the ABL. Any shift in brightness will shift the level of the control voltage.

For example, if the CRT brightness decreases for some reason, the focus voltage will increase. A positive going control voltage increases conduction of the video amplifiers, video outputs, and the CRT guns to increase brightness.

Blanking Circuit

Positive pulses derived from the vertical sweep amplifier and from the horizontal-output transformer are coupled to the blanking-control stage, Q36. by the blanking amplifier. These pulses cut off the video output transistors during retrace.

To reduce the load on the horizontal-output circuitry. the horizontal retrace time of this chassis is longer than usual and the CRT is over-scanned slightly. The width of the horizontal-blanking pulse is increased accordingly, and it is normal for a portion of the first color bar from a keyed-rainbow generator (yellow-orange) to be partially blanked and off the left side of the raster.

Chroma-Circuit Analysis

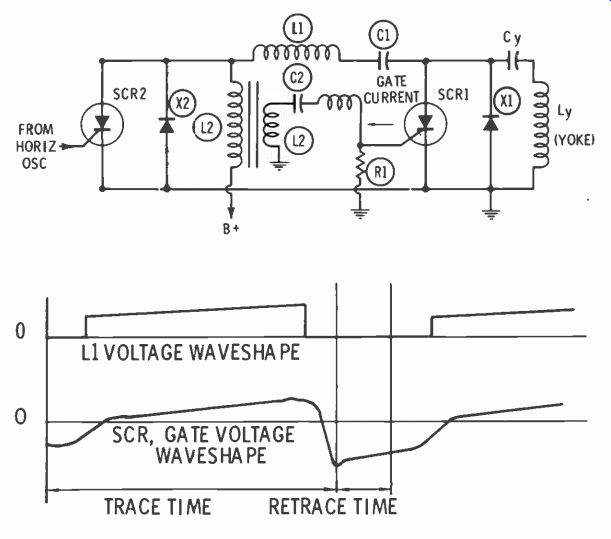

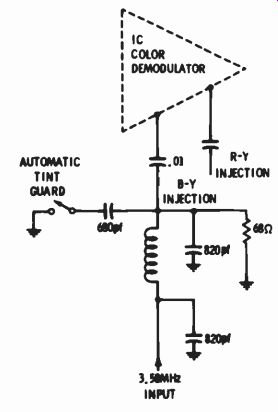

The three demodulators are practically identical, with the exception of the phase of the reference input and the value of the input attenuation. Since it serves no useful purpose to treat them separately, only the green demodulator is shown in Fig. 4.

During reception of a black-and white signal, there are two inputs to the demodulator. A free-running, 3.58-MHz signal is fed to the junction of C134 and C135. Positive video from the contrast control, situated in the output circuit of the third video amplifier, is fed to the center of the secondary of L25.

There is no input from the chroma bandpass amplifier, since it is cut off by the color killer.

The reference signal produces no output at the base of 040 because of the traps, L33 and C 136, between the demodulator and the video amplifier. These same traps remove the 3.58-MHz ripple during color reception.

Positive video (a positive signal makes a black raster) passes through X24 and is developed across R 182. The video passes through the trap and is duly amplified by the two video amplifiers and fed to the CRT cathode. Of course, the same things take place in each of the other demodulators and their amplifiers. Thus, the luminance signal is amplified and fed to the three CRT cathodes to produce a monochrome picture.

The operation of diode chroma demodulators is discussed in detail in Part 5 of this guide.

To summarize, if the reference and chroma signals are in phase, a maximum output of one polarity is realized; if they are out of phase, a maximum output of the opposite polarity results; if they are 90° out of phase, the output is zero. In the demodulator of Fig. 4, in-phase signals produce a negative voltage at the base of Q40 and increase the CRT conduction, voltage at the base of Q40 and increase the CRT conduction.

So far, we have considered the chrominance and luminance signals separately, but, since both of these signals are developed across the same resistor, R 182, they are effectively added at this point. This sum (or difference) of the two signal voltages passes through the traps, which remove the 3.58-MHz ripple, to the base of Q40 and, ultimately, to the CRT.

Blanking Control

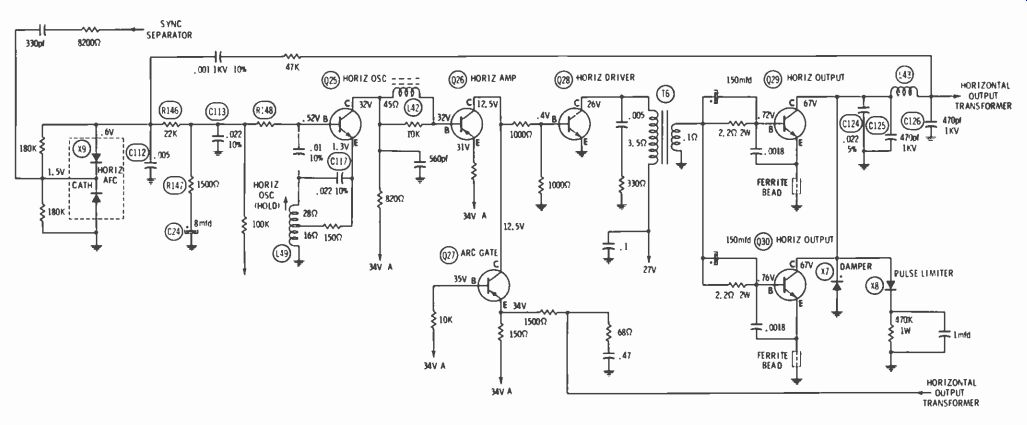

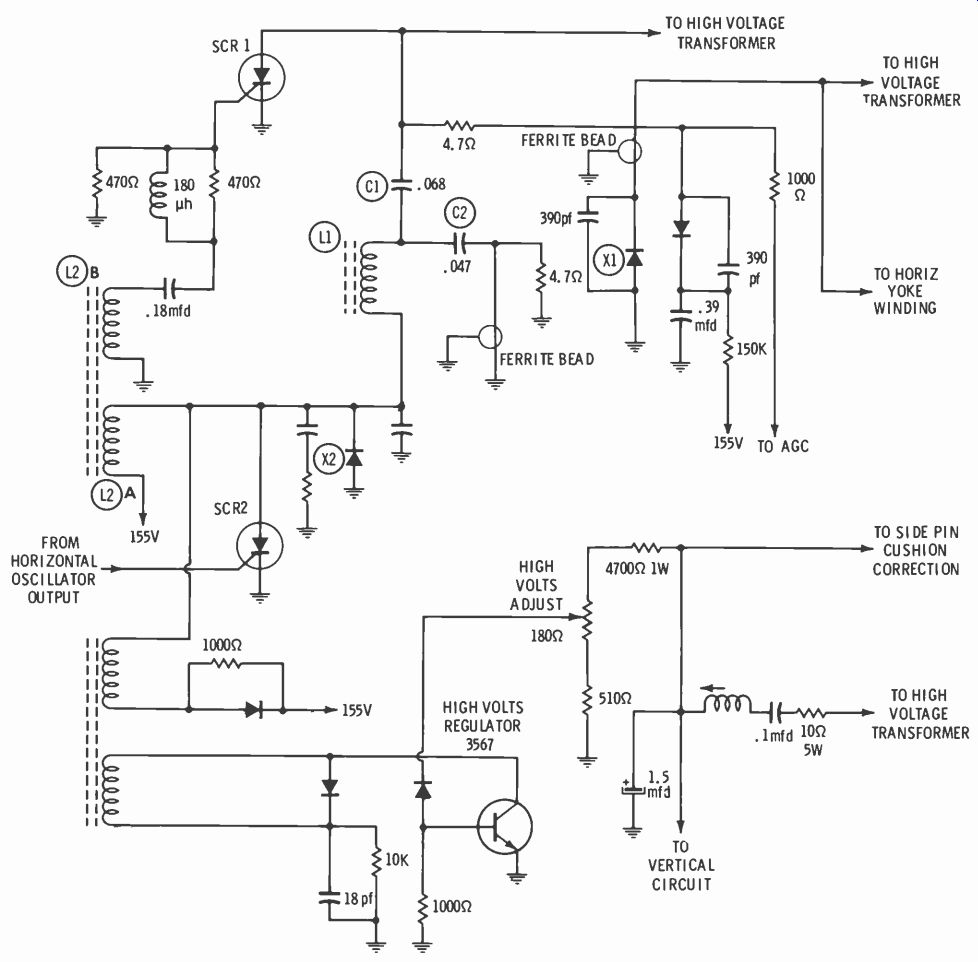

Fig. 5 Solid-state horizontal-oscillator and output circuit.

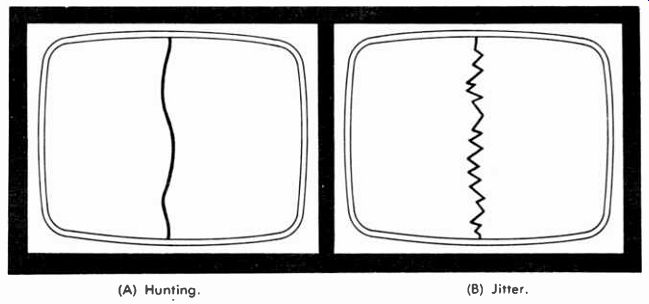

Fig. 6. Appearance of horizontal hunting and jitter . (A) Hunting. (B) Jitter.

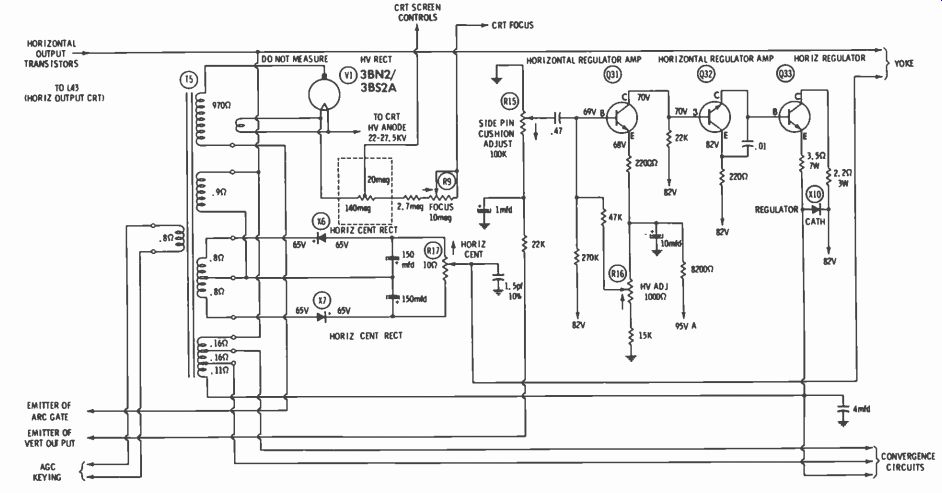

Fig. 7. Horizontal regulator circuit.

The blanking and brightness control circuits also are shown in Fig. 4, not because the functions they perform are novel, but because the use of transistors results in unusual circuit configurations The emitter currents of the three color-video output transistors must al flow through the blanking-control transistor, Q36. During scanning time, Q36 is forward biased and the complete circuit path of the collector current of Q41 is from ground, through Q36, R186 and Q41 to the CRT cathode and the 255-volt supply.

During retrace, Q35 is driven to saturation by the positive pulse on its base. This removes the forward bias from the base of Q36, cutting it off. This effectively opens the low-resistance path from ground to the emitters of the video-output transistors, cutting them off.

Automatic Brightness Limiter

The level of the sample of focus voltage taken from the low end of the CRT screen-control potentiometer indicates the total load on the high-voltage and focus-voltage supplies, and hence, the amount of CRT conduction, or brightness. The adjustment of R13, the ABL control, determines the size of the sample (control voltage) taken and acts somewhat as a coarse control of the brightness.

Q37 is connected as an emitter follower, roughly equivalent to a cathode-follower tube configuration, and the emitter voltage is dependent on the amplitude of the control voltage. Because of Q37, the voltage at the top of the brightness control cannot become more positive than the 34-volt supply at the collector of Q37. This limits maximum brightness of the CRT. The voltage on the base of 039 is determined by the setting of the control voltage. Q39 also is connected as an emitter follower, and the voltage on its base controls the bias on the video amplifiers, Q40, Q48, and Q57. Notice that the base voltage of Q39 is stabilized by Q38, which acts as a regulator for the circuit.

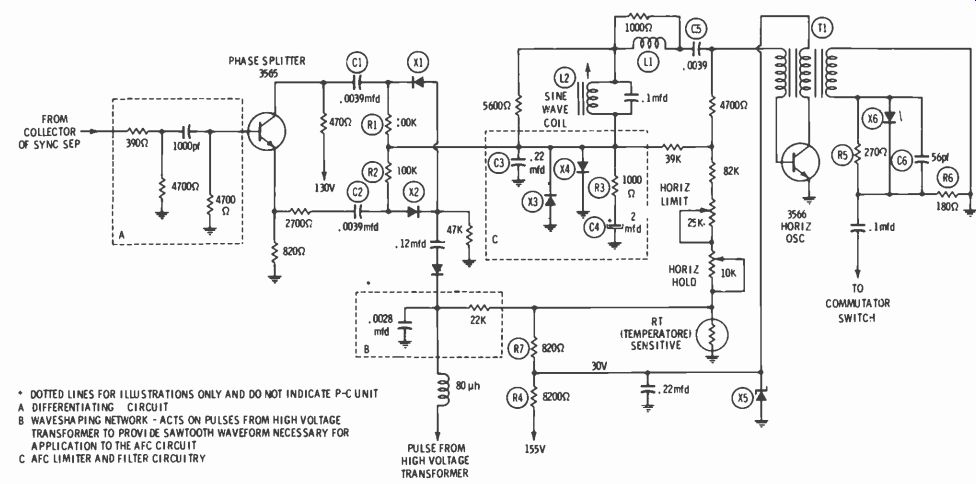

Analysis of Horizontal-Deflection Circuits

Space is not available for an analysis of all circuits in the Motorola solid-state chassis, so this discussion is necessarily limited to those of greatest significance. In addition to the chroma circuits already covered, the design of the horizontal deflection system is sufficiently different from designs using tubes to justify an analysis.

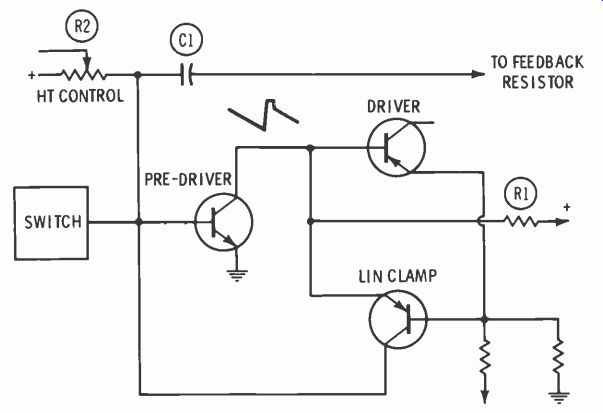

Horizontal Oscillator and AFC

The horizontal oscillator and the AFC circuit (Fig. 5) which controls its frequency are very similar to designs using tubes. The AFC circuit compares the phases of the horizontal sync pulse and the output of the horizontal-output transistors, Q29 and 030, to develop a control voltage. This control voltage is integrated by R146, R147, C24, C112, and C113, and it is used at the base of Q25 to control the oscillator frequency.

The function of the integrating circuit between the AFC detector and the oscillator is not particularly mystifying, but it appears, from the number of letters we receive, that malfunctions in this circuit cause a great number of problems to our readers. The following comments apply to nearly all sets, vacuum tube or solid-state.

Failures in the integrator fall into four general categories:

(1) Loss of control voltage caused by R 148 going open, for example. In this case, there is no horizontal sync.

(2) Radical change in the DC level of the control voltage which causes a radical change in horizontal frequency, or may cut off the oscillator.

(3) Too much integration of the control voltage.

(4) Not enough integration of the control voltage.

The first two categories named above are generally not too difficult to diagnose, but the last two seem to cause many difficulties. If the control voltage is integrated too much, the response time of the system becomes too great. Therefore, the raster appears to slowly move back and forth across the CRT. The complete raster will not necessarily float the same amount, and so a vertical line on the CRT may curve back and forth from top to bottom (see Fig. 6A) . This is called horizontal hunting.

Too little integration causes the oscillator frequency to be overcorrected. With insufficient integration, the control voltage at the oscillator (or AFC tube) shifts slightly during each scan. This causes the scanning time of each horizontal line to be slightly different and a vertical line on the CRT appears ragged or broken as shown in Fig. 6B. This is called horizontal jitter.

Jitter is usually caused by a decrease in value of C24 (or its counterpart in another set), hunting is usually caused by an increase in resistance of R146 or R147, or their counterparts.

Referring again to Fig. 5, the horizontal oscillator is a Hartley oscillator; L49 and C 1 17 determine the frequency. When the top of the tank is negative, Q25 is cut off. As the top of the tank swings positive, the transistor begins conduction at some point on the sine wave. This point is determined by a combination of fixed bias and the control voltage from the AFC. The collector current of Q25 is a series of pulses and the waveform at the base of Q26 is approximately a square wave.

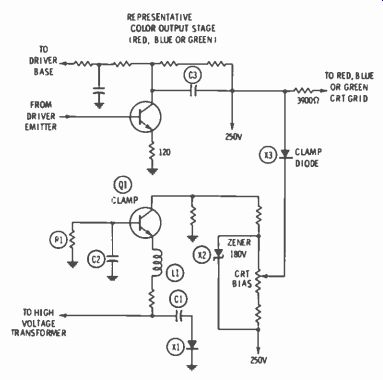

Amplifier, Driver and Output

The train of pulses is fed to the driver through the horizontal amplifier, and the output of the driver is coupled through T6. The phasing of T6 is such that the output transistors are turned on when the driver is cut off. Deflection of the trace from center to the right edge of the CRT occurs while Q29 and Q30 are conducting. At the instant that Q29 and Q30 are cut off, the sweep retraces, the damper begins conduction, and the left side of the raster is scanned.

The network consisting of C124, C125, C126, and L43 is a low-pass filter which prevents any high frequency transients which may be generated in the amplifier, driver, or output stages from being coupled to the horizontal-output transformer. The pulse-limiter diode, X8, limits the amplitude of the collector pulses of Q29 and Q30 to protect them.

In case of a high-voltage short, a positive pulse is developed at the emitter of Q27, causing it to conduct. This clamps the base of 028 to the base of Q27, causing it to conduct and cutting off the horizontal-output transistors until the arc clears.

Horizontal Regulator and Pincushion Circuit

The circuit which includes Q31, Q32, and Q33 (Fig. 7) performs the two functions of injecting a portion of the vertical deflection signal into the horizontal sweep system for pincushion correction, and it also regulates the high voltage. Both of these functions are accomplished by controlling the supply voltage for the horizontal-output transistors.

A parabolic voltage derived from the emitter of the vertical-output transistor is amplified by 031 and Q32 and added to the supply for the horizontal output transistors.

The supply voltage is increased when the vertical sweep is at the center of the tube, causing the horizontal scan to expand at this time to correct for pincushion effect.

R15 picks off the amount of vertical sweep voltage which is required for optimum correction.

At the same time, the relative values of the 82-volt supply and the 95-volt supply are compared in the emitter-base circuit of Q31. As CRT beam current increases, the load on the horizontal-deflection circuit increases and the output of the 82-volt power supply drops.

This decreases the forward bias of Q31, causing the collector voltage to increase. This increase in collector voltage increases the conduction of Q32 and 033, which tends to raise the supply voltage to the horizontal-output transistors, thereby regulating the high voltage.

Admiral's K10 Hybrid Color Chassis

To reduce the possibility of damage occurring in one section while working on another, Admiral has designed two etched-circuit boards: One contains the solid-state circuitry; the other, the vacuum tubes.

These etched boards are separated into zones by heavy white lines.

Each zone is identified by a large white letter designating the section.

A-Video IF B-Sound. AGC, and video amplifiers C-Chroma amplifiers D-Chroma oscillator and color killer, color burst amplifier, and color demodulators E-Vertical F-Horizontal G-Convergence H-Miscellaneous chassis components U-UHF tuner V-VHF tuner This coding system also makes it easier to find the components on the schematic. Resistor RC64 on the wiring diagram will be found in zone "C", with the number "64" written beside it on the board.

Circuit Description

Admiral chassis K10 is comprised of twenty-six transistors, twenty-four diodes, seven vacuum tubes and a CRT. The transistors are used for all signal-processing functions, while the vacuum tubes are used in circuits that have heavier power requirements.

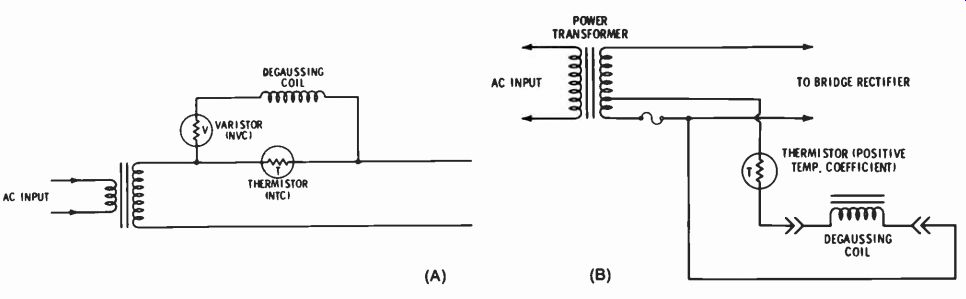

Power Supply The power transformer is used only for the transistor circuits, although it does have a 6.3-volt AC tap to supply filament voltage to the CRT. A line choke is used to prevent any unwanted RF signals from entering the various circuits through the source voltage.

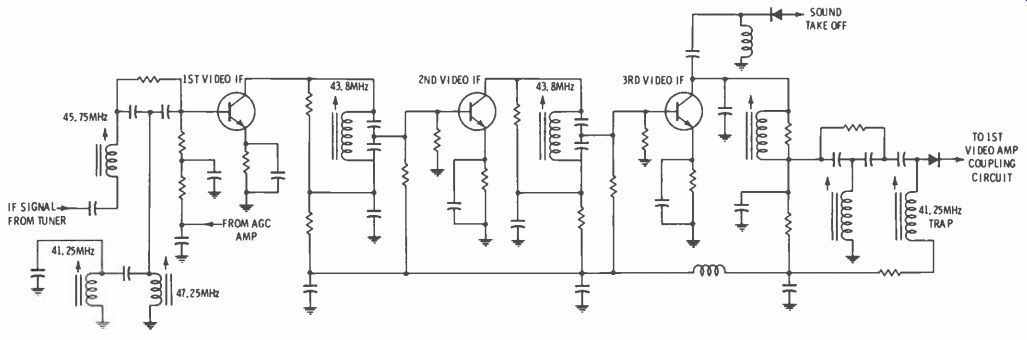

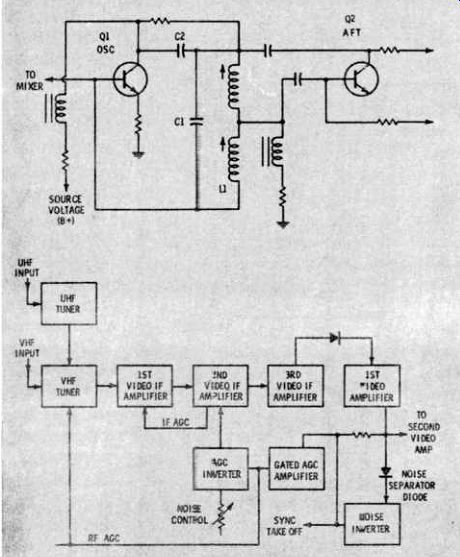

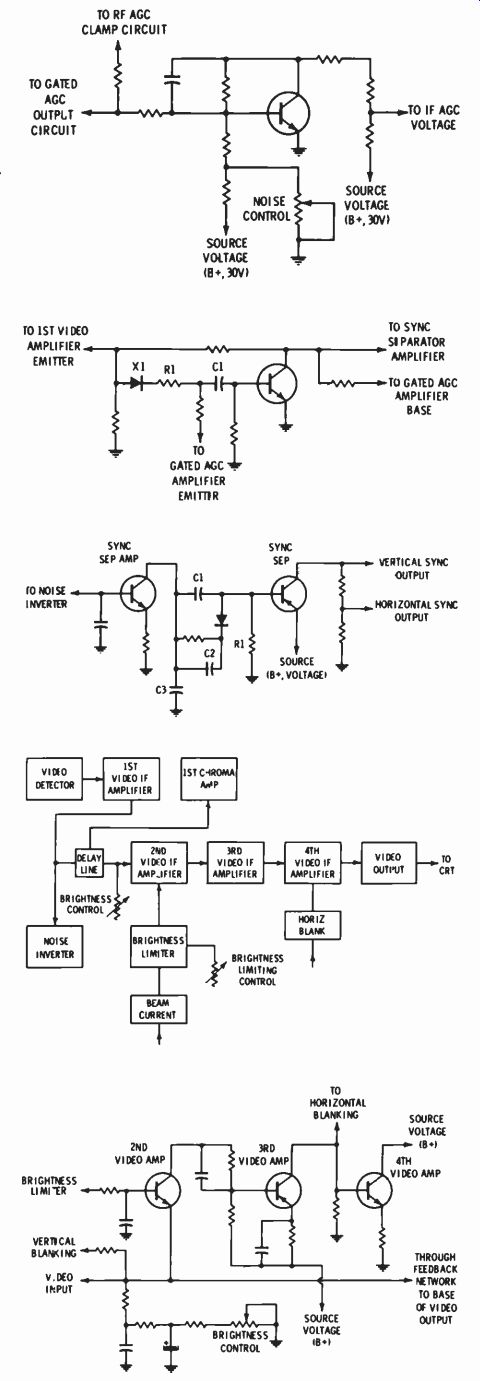

Video IF Strip (Fig. 8)

The outputs of the first and second video IF transistors are applied across tuned coils. These coils are shunted by a pair of capacitors to form a capacitance voltage divider.

The input signal for the next stage is obtained from the junction of these capacitors. This configuration results in the proper impedance match for efficient signal transfer.

The sound "take-off" is from the collector of the third video IF. Sound Circuits.

The sound section consists of the sound takeoff, sound IF, oscillator limiter, ratio detector, audio driver and audio output stages.

Oscillator Limiter

The oscillator limiter stage is self oscillating, with the frequency determined by the incoming signal from the sound IF stage. This incoming sound signal serves as a "sync" signal for the oscillator limiter. Because of the dependency of the output of the oscillator on the incoming signal, the output of the oscillator does not change in amplitude and is, therefore, a very effective limiter stage. The output of the oscillator limiter is then applied to the ratio detector.

AF Sound Circuitry

The AF sound circuitry has two direct-coupled transistors driving an output transformer. A voltage dependent resistor (VDR) is connected across the primary of the audio output transformer to prevent damage to the receiver if it is operated with the speaker disconnected.

The output transistor is mounted on the end of the chassis, utilizing the chassis as a heat sink. A mica wafer isolates the collector (transistor case) from the chassis, resulting in a potential of 105 volts DC on the transistor case.

Fig. 8 Three-stage transistorized video IF employed in Admiral's K10 hybrid

chassis.

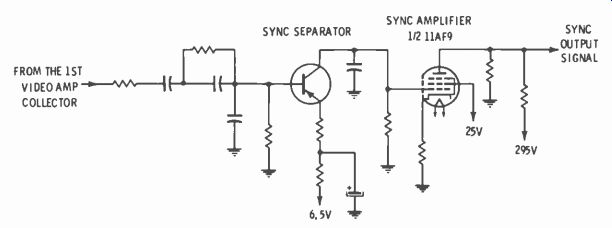

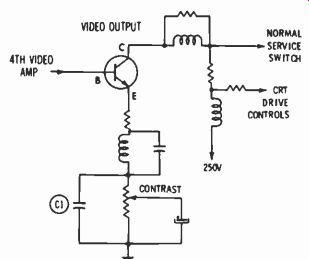

Fig. 9 Transistor and vacuum tube are mated in sync separator/amplifier section

of K10.

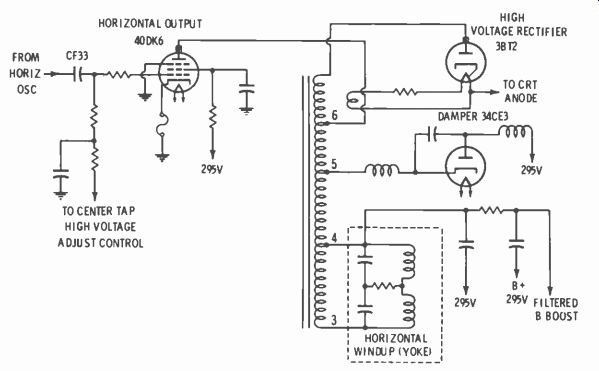

Fig. 10 Fuse in cathode circuit of horizontal output stage provides overload

protection for horizontal output and flyback.

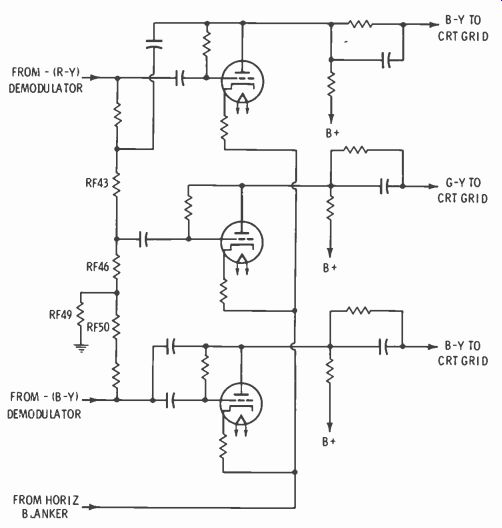

Fig. 11 Triple-triode 8AC10 performs color-difference amplification function

in Admiral's hybrid chassis.

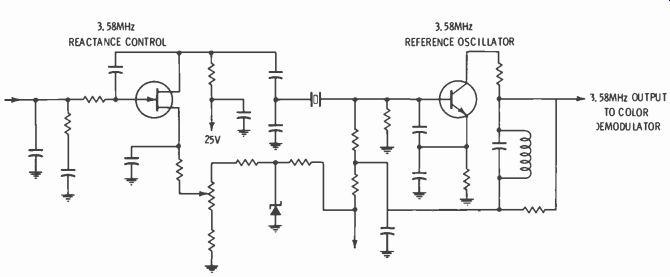

Fig. 12 Field-effect and conventional NPN transistors serve in the reactance

control and chroma reference oscillator section of the K10's chroma circuitry.

Sync and Sweep

A transistor is used as a sync separator with its output driving a vacuum-tube (11 AF9) sync amplifier (Fig. 9). The sync output voltages are taken from the plate and applied to the vertical and horizontal circuits.

The horizontal phase detector and horizontal oscillator are similar to those used in previous Admiral models.

The horizontal output stage (Fig. 10) operates as a controlled switch.

It conducts during half of the scan line, and is cut off the other half.

When drive pulses are applied to the grid coupling capacitor (CF33), grid rectification produces an extremely high negative grid voltage.

When the output tube conducts, heavy current flows through the flyback windings. At the end of the line scan, the output tube ceases conduction, and the flyback field collapses, providing the flyback pulse. This pulse is stepped up by the high turns ratio of the high-voltage transformer windings. It is then rectified by the high-voltage regulator which provides the high CRT anode potential. As the collapsing flyback field shifts into its negative half cycle, the damper tube becomes forward biased, causing a strong damper current to flow. The yoke current will then increase and conduct in the same direction as the output tube. The damper causes the beam to sweep the remaining half line.

Simultaneously, the boost capacitor is charging up to boost level.

The dampered flyback field will produce an output that is added to the B+ potential. This boost voltage is filtered and used to supply the CRT screen voltage, vertical oscillator plate and vertical output bias requirements.

The horizontal output circuit is protected by a fuse in the cathode of the horizontal output tube. This circuit protection, which hasn't been used in a few years, saves the fly hack. The HV regulation is provided by a "pulse feedback" circuit.

Chroma Oscillator

The reactance control stage provides (when necessary) a correction voltage to the 3.58-MHz subcarrier oscillator (Fig. 12). An N-channel junction field-effect transistor (FET) performs this function. Because FET's are susceptible to damage from static discharges and arcs from the CRT, care must be exercised when working in this area. One method of testing is to check for the presence of voltage on the gate of the FET when the 3.58-MHz oscillator is slightly off-frequency.

Check operating potentials on the gate, drain and source, and compare the readings to the voltage values shown on the schematic.

As with most control circuits, the reactance control does not operate when the subcarrier oscillator remains on frequency. Varying the feedback correction voltage from the color phase detector or changing the setting of the reactance control potentiometer will initiate conduction in the FET. This changes the tuning, or phase, of the 3.58-MHz subcarrier oscillator.

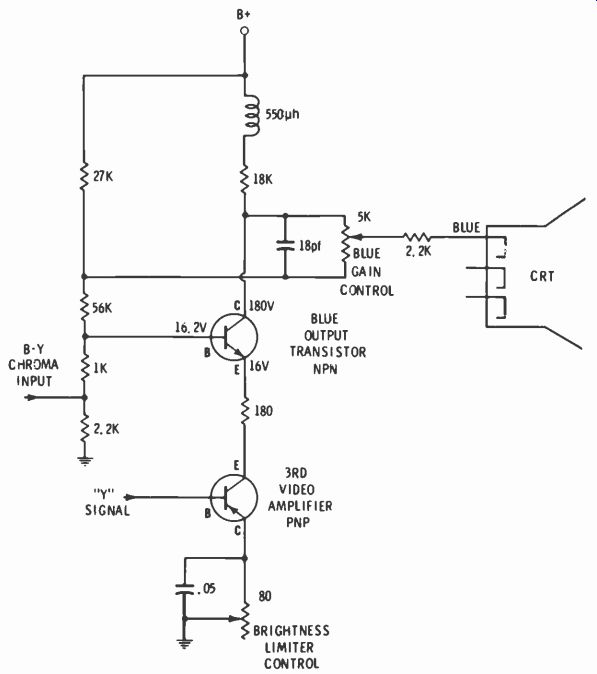

Color Demodulation

Color detection is accomplished using-(R-Y) and-(B-Y) signals.

The output of the demodulators is then inverted and amplified by the color difference amplifiers, and becomes R-Y and B-Y. The demodulators are essentially electronic switches with the 3.58 MHz subcarrier signal directing their operation. The amount of conduction is determined by the amplitude of the chroma signal delivered to them by the bandpass amplifier.

The color demodulators used in the K 10 chassis are PNP transistors.

The chroma signal from the bandpass amplifier is applied to the emitters of the demodulators through a resistive voltage divider network.

The switching signal (3.58 MHz) is fed to the base of each demodulator.

Under these conditions, the negative-going peaks of the 3.58-MHz signal will cause conduction, and an amplified color difference signal will be present on the collectors of the demodulators.

To control the time of demodulator conduction, the 3.58-MHz signal is coupled directly to the-(R Y) demodulator and through a phase shift network (90°) to the -(B-Y) demodulator. The 3.58 MHz signal present on the collectors of the demodulators is trapped out by a capacitance/inductance network.

Fig. 13 Cutoff of transistorized horizontal blanker during horizontal retrace

drives cathodes of color difference amplifiers more negative; difference amplifiers

become saturated and their plate voltage decreases, biasing off CRT grids.

Fig. 14 Transistor buffer amplifier supplies 3.58-MHz reference signal to

color-killer and phase detector diodes.

Fig. 15 Color-killer and associated detector circuitry.

Color Difference Amplifier (Fig. 11)

The color difference amplifiers arc housed in a three-section triode tube, type 8ACIO. The outputs of the color demodulators are fed through the difference amplifiers, and the signals are amplified, inverted and applied to the CRT red, blue and green grids. The-(R-Y) and-(B-Y) signals come directly from the demodulators, and the-(G-Y) signal is formed by a matrix circuit comprised of resistors RF43, RF46, RF49 and RF50. Horizontal Blanker (Fig. 13)

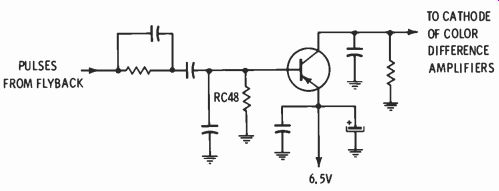

To accomplish horizontal blanking, each color difference amplifier is biased off during horizontal retrace time. A negative blanking pulse is applied to each color-difference amplifier cathode, causing heavy conduction through the triodes, producing a high-amplitude pulse on the CRT grids. The color difference amplifier is driven into saturation, the plate voltage is decreased sharply, and the CRT is driven into cutoff. This action results in some signal detection, which provides a measure of DC restoration to the CRT. The horizontal blanker stage cuts off the CRT during horizontal retrace time by driving the color difference amplifier into saturation.

The PNP transistor acts as a switch at the horizontal rate.

During the horizontal scan time, the horizontal blanker conducts strongly, due to the biasing action of the base resistor, RC48. During the retrace interval, a positive pulse from the flyback transformer drives the base-emitter junction into a reverse-bias condition, and the transistor becomes an open switch. The collector voltage decreases to zero.

When the cathode bias voltage of the color difference amplifier is removed (horizontal blanker collector at zero volts), the color difference amplifiers are driven into saturation.

The plate voltage decreases sharply, cutting off the CRT grids.

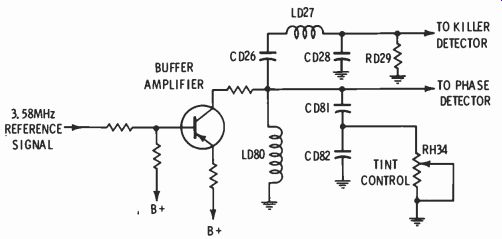

3.58-MHz Reference Feedback System (Fig. 14)

A buffer amplifier (3.58-MHz reference feedback amplifier) supplies a 3.58-MHz reference signal for the color-killer detector diodes and the phase detector diodes. The color demodulator diodes control the phase of the redeveloped chroma subcarrier.

The 3.58-MHz signal is coupled to the base of the buffer amplifier.

The tint control, RH34, and capacitors CD81 and CD82, connected across inductance LD80, are connected in the collector circuitry and alter the phase of the output signal, controlling the color demodulation when the tint control is varied. Inductor LD27, capacitors CD26, CD28 and resistor RD29 restore the phase of the reference signal applied to the killer detector.

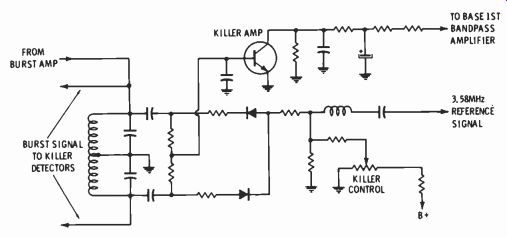

Color Killer System (Fig. 15)

The color-killer amplifier cuts off the first bandpass amplifier when no color information is present in the received signal. When no color information is present, the color-killer amplifier conducts heavily, driving the first bandpass amplifier to cutoff. This prevents color noise from contaminating the b-w picture.

When color information is present in the signal, the detected burst signal is applied to the base of the killer amplifier. When the killer amplifier is cut off, no killer bias is applied to the first bandpass amplifier and it is free to amplify the chroma signal.

When color information is not present, a positive voltage, derived from the color-killer control (connected to the 25-volt line), supplies forward bias to the killer amplifier through the color-killer detector diodes.

When color information is present, the color signal is detected and a negative voltage is developed to cancel the forward-bias voltage RCA's CTC40 Color Chassis RF Amplifier (Fig. 16 & 17)

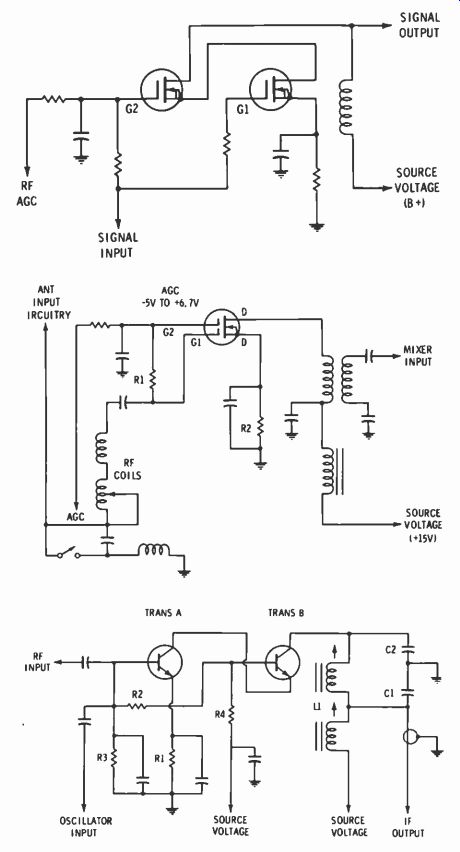

A dual-gate MOS field-effect transistor is used in this stage. Operation of this device (shown in Fig. 1) is as follows: A dual-gate FET functions in much the same manner as two vacuum tubes connected in a cascade configuration. Internal feedback capacitance, which tends to cause amplifier instability (oscillations), is defeated by the relatively low input impedance of the driven portion of the FET. Because of this characteristic of the FET, neutralization is not necessary at VHF frequencies. RF gain control is accomplished by reverse biasing of gate G2. This reverse gain-control voltage reduces the amplifier gain by reducing the drain current of both sections of the FET. Since this control voltage (reverse bias) is derived in combination with the chassis circuitry, it actually forms the RF AGC. Circuit Operation (Fig. 17)

Signal from a 300-ohm antenna input is applied to an impedance matching circuit on the cabinet back to match the 75-ohm input impedance of the receiver. This signal is fed to gate GI of the FET through the high-pass filter network and the RF tuned circuitry. The RF AGC voltage is applied to gate G2 of the FET. This voltage may range from-5.0 volts on a very strong signal to a 6.7 volts on an extremely weak signal. The bias for gate GI is comprised of a portion of the AGC voltage applied through resistor 121 and the voltage developed across the source resistor, R2.

In this circuit the source and gate GI voltages will coincide or vary with applied AGC, minimizing input capacitance variations. Printed inductances are utilized to couple the RF amplifier output signal to the mixer input circuit.

Mixer (Fig. 18)

The mixer stage is also connected in a cascade configuration, using two transistors. Transistor A operates in a common-emitter circuit and its output drives a common-base amplifier. As with the FET RF amplifier, the principal advantage to this type of circuit is its inherent stability.

The base bias network for transistor A is comprised of resistors R1, R2, R3 and R4. This bias voltage is maintained at a value designed to allow the most efficient mixing action. Transistor B base bias is derived from a biasing network composed of resistors R2, R3 and R4.

Fig. 16 Circuit diagram illustrating the basic operation of the dual gate

MOS FET employed in RF amplifier.

Fig. 17 Simplified schematic of RF amplifier employed in CTC40 chassis.

Fig. 18 Mixer stage employing two transistors in cascade arrangement.

The output, or resultant IF signal, is coupled from the mixer by a circuit configuration called "low-side C." The IF output signal is developed across capacitor C1. This capacitor is connected from coil L1 of the tuned output circuit (L1 and C2) to ground. From this circuit configuration comes the term low side C. This coupling arrangement tends to minimize the amount of oscillator energy that might be coupled into the IF circuit. At oscillator frequencies coil L1 acts as an RF choke and greatly reduces the amount of oscillator energy developed across C1.

Oscillator (Fig. 19)

The local oscillator is basically a Colpitts-type arrangement. Energy at the selected frequency of the oscillators is developed across the tank circuit. The inductance of the tank is composed of L1 (channel 13 adjustment) and the oscillator coil, which changes for each channel selected. The capacitance of the tank is supplied primarily by capacitor C1 and the AFT transistor. Oscillation is sustained by a capacitive voltage divider made up of the transistor internal capacitance existing between the emitter and collector (CCE) and the emitter and base (CEB). Capacitor C2 couples the oscillator transistor output to the tank circuit.

Automatic fine tuning is provided by transistor Q2. The internal capacitance of this transistor varies in proportion to the AFT control voltage applied to its collector and base terminals. This transistor then controls a portion of the oscillator tuning capacitance and, thus, the frequency output of the oscillator.

The KRK-132 UHF Tuner The UHF tuner used in the CTC 40 chassis is a KRK-132 and has been used previously with several other RCA chassis. It contains no physical or electrical changes from those originally used.

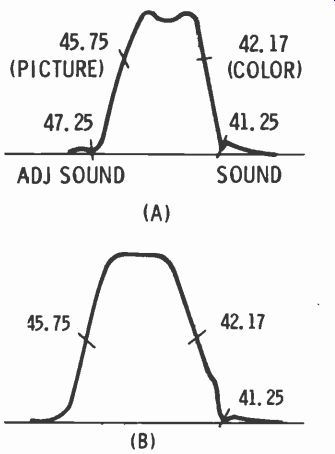

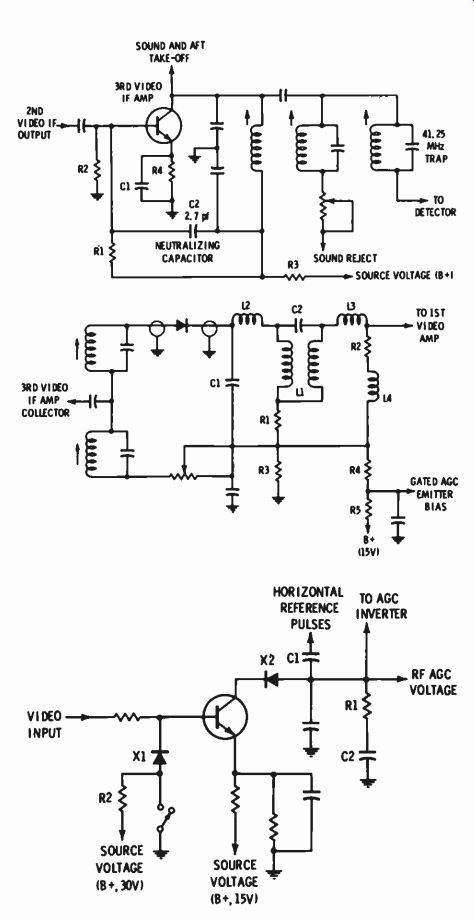

Video IF Circuits The CTC40 IF section contains three common-emitter amplifier stages (see Fig. 20) capable of supplying a maximum of 80 dB gain to frequencies within the limits of the IF bandpass. This IF bandpass is established through the proper tuning of eight tuned circuits located within the IF system. Alignment of these circuits is very similar to the alignment process of similar RCA circuits employed in tube-type receiver chassis.

Gain in the first and second IF stages is under AGC control and it is possible to reduce the overall gain of the IF section up to 70 dB under very strong signal conditions.

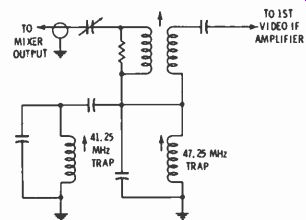

Link Coupling (Fig. 21)

The IF signal contained in the output of the mixer stage is link coupled to the first IF amplifier.

The link coupling circuit used in the CTC40 chassis is very similar to other recent RCA color chassis. The circuit is basically a double-tuned, or overcoupled, network consisting of the mixer collector coil, coupling capacitor, the first IF base transformer and two trap circuits with their associated capacitors. The link coupling components are essential in obtaining a good IF response curve.

It is necessary that they be aligned and adjusted exactly. The correct curve is shown in Fig. 22. The manufacturer's specifications or other accurate service data should be consulted for the correct procedures to obtain this response.

First and Second Video IF Amplifiers

The first and second video IF amplifiers are identical. Both are common-emitter types employing identical input and output circuits.

The input coupling circuit to the base of each amplifier consists of a series resistance/capacitance combination. This coupling circuit provides DC blocking and highly efficient impedance transfer. Their output signals are developed identically across single-tuned circuits.

Bias for the first and second IF amplifiers is obtained as follows: The second IF amplifier receives base bias voltage from the output of the AGC inverter stage. This identical voltage (less the small drop across the second IF amplifier base emitter junction) is applied to the first IF amplifier. In this manner both the first and second IF stages receive almost identical AGC control voltages. The emitters of both the first and second IF amplifiers are returned to ground through a 450-ohm, 7-watt wirewound resistor. The positive temperature coefficient properties of this resistor function to vary the bias on both transistors and compensate for long-term temperature-related gain changes. The emitters of both stages are bypassed by a capacitor.

Third Video IF Amplifier (Fig. 23)

The third video IF amplifier is a common-emitter configuration whose output is applied to the video detector, AFT, and sound circuits.

The base bias is derived from a voltage network comprised of resistors RI and R2. The source voltage for this network is taken from the collector resistor (R3) of the third IF amplifier transistor. DC negative feedback is obtained from this arrangement, which improves bias stability. Emitter bias is obtained, or determined, by resistor R4. This resistance is AC bypassed by capacitor Cl. Due to the high gain (40 dB) of the third IF stage, neutralization is a necessity, and it is provided by feedback capacitor C2.

The overall frequency response, which is determined by the efficiency of the link circuit, the interstage tuned circuits and the third IF amplifier output, is illustrated in Fig. 23.

Again, please refer to the manufacturer's data sheet or PHOTO FACT for information relating to alignment procedures.

Video Detector The video detector circuit (Fig. 24) does not differ greatly from the circuits previously used in tube-type chassis. Harmonics of both the detected carriers and difference frequency signals are bypassed by Cl.

The 4.5-MHz difference frequency developed by mixing the picture and sound carriers is removed by a 4.5 MHz bridged-T trap composed of coil L1, capacitor C2 and resistor R1. L2 and L3 decrease harmonics developed by detector functions.

The DC component of the detected video signal is retained by using the average DC level produced by the detector as the major portion of the first video amplifier base bias. The detected video signal is applied across the detector load impedance comprised of resistor R2 and peaking coil L4. This voltage is series added to the comparatively small 'second detector pre-bias voltage derived from the 15-volt supply by a resistive divider network made up of resistors R3, R4 and R5. This voltage sets the initial bias level for the first video amplifier, and also provides a constant emitter bias for the gated AGC amplifier.

Fig. 19 Local oscillator and AFT circuitry employed in KRK-142 VHF tuner.

Fig. 20 Block diagram of tuner and video IF circuits employed in CTC40 chassis.

Fig. 21 Double-tuned link coupling is used between mixer output and video

IF input.

Fig. 22 Correct response curves of (A) link coupling circuit and (B) overall

video IF circuit.

Fig. 23 Third video IF amplifier employed in CTC40 chassis.

Fig. 24 Video detector circuit of CTC40 Is similar to the design employed

in previous tube-type chassis.

Fig. 25 Gated AGC system Is keyed on by positive going sync pulses applied

to base and collector.

AGC

The purpose of any type of AGC is to maintain a constant video detector output level over a wide range of input RF signal levels. The changes or variations in video signal amplitudes are translated into DC voltages which are used to control the gain of the RF amplifier and the first and second IF amplifiers.

in the CTC-40 chassis.

Video information from the first video amplifier is fed to the gated AGC amplifier to produce an output DC voltage that is proportional to the sync tip amplitude. This AGC output is filtered and applied simultaneously to the RF AGC clamp circuitry and the IF AGC inverter.

The RF AGC clamp circuit sets the requirements of the AGC voltage variations that can be applied to the RF amplifier. The RF amplifier operates under reverse AGC control. A more negative voltage (reverse bias) results in gain reduction, and a more positive voltage (less reverse bias) results in increased gain.

An AGC inverter stage is required for the first and second video IF stages to satisfy their requirements for forward AGC control voltage.

The AGC inverter base bias is made variable by the noise control, to establish the proper proportions of AGC voltage applied to the RF and IF stages.

Gated AGC Circuit Operation (Fig. 25)

A video signal which contains positive-going sync pulses is fed to the gated AGC amplifier base. (This signal level is proportional to the picture carrier strength.) The gated AGC amplifier is designed to conduct only during sync pulse time by the positive-going keying pulses coupled to the collector through capacitor Cl. These pulses occur at the horizontal frequency rate and key the transistor simultaneously with the horizontal sync pulses contained in the video signal applied to the base. The bias on the transistor is such that the base-emitter junction can become forward biased only during the positive peaks of the sync pulses. This circuit keeps spurious noise to a minimum.

During conduction time, electron current flow is from the emitter to the collector, leaving a negative charge on capacitor Cl. This negative charge becomes the AGC voltage and its value is directly proportional to the amount of amplifier conduction; and the amount of amplifier conduction is directly proportional to the peak positive amplitude of incoming sync pulses. The RC network, composed of R1 and C2, improves the overall stability of the circuit.

Service Switch It is necessary to provide a blank raster to aid in picture tube setup.

A positive voltage is applied to the AGC amplifier by operation of the service switch. When the service switch is actuated, a 30-volt potential (normally dropped across resistor R2) forward biases diode X1 and appears on the base of the AGC amplifier. This potential is sufficient to saturate the AGC amplifier and, consequently, produces a high negative AGC voltage. This voltage, in turn cuts off the RF amplifier, and the first and second video IF amplifiers. All video information is removed from the CRT, and a blank raster results. Diode X2, in the collector circuit of the AGC amplifier, prevents the developed negative AGC voltage from discharging back through the collector-base junction between keying pulses.

AGC Inverter (Fig. 26)

The first and second video IF stages require forward AGC control voltages; therefore, it is necessary to invert the AGC output before application to the IF circuits. This is the function of the AGC inverter stage illustrated schematically in Fig. 11. It is a common-emitter DC amplifier designed for a gain of approximately 0.15. Fractional gain is necessary to reduce the large voltage range of the AGC amplifier to within the bias base control limits of the IF amplifiers.

The AGC inverter base bias voltage can be varied by the noise control.

The noise control is used to set the proper proportions of AGC voltages applied to the RF and IF amplifiers throughout the AGC control range.

The control is used basically to establish the point at which the AGC voltage starts reduction of RF amplifier gain, or, if you prefer, sets the RF AGC delay point. Changing the bias on the AGC inverter stage by changing the noise control setting varies the bias and the gain of the first and second video IF amplifiers. The gain of these two amplifiers sets the video signal level applied to the gated AGC amplifier, whose output determines the RF AGC voltage. The noise control should be adjusted while observing a noise-free signal and rotating the noise control in the opposite direction until the snow is gone.

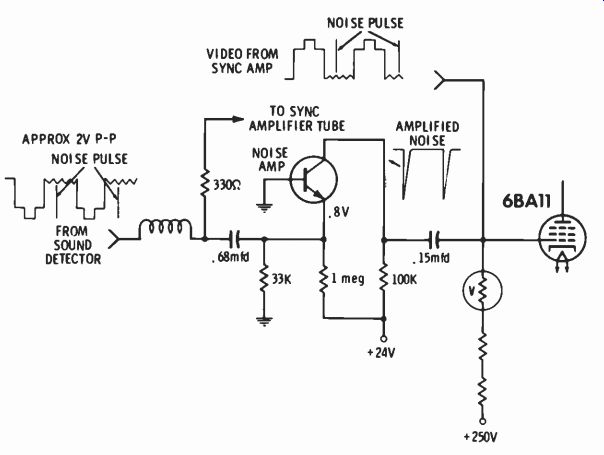

Noise Inverter (Fig. 27)

The purpose of a noise inverter circuit is to prevent any spurious noise pulses that might be present in the video signal from interfering with the smooth operation of the AGC amplifier or upsetting the sync separator. The noise inverter minimizes the effects of any noise pulses by inverting and, thereby, cancelling the pulses before they are applied to the AGC and sync circuits.

The circuit operation of the noise inverter is as follows: A reverse bias is fed to the cathode of X1 from the constant source potential available at the emitter of the gated AGC amplifier. This potential sets the conduction threshold for the diode.

Diode XI conducts only during the interval of positive-going pulses.

These pulses forward bias the diode and are applied to the base of the noise inverter through diode X1 and capacitor C1. The noise inverter transistor does NOT have a DC forward bias; therefore, conduction will occur only when an incoming positive pulse exceeds the base emitter barrier junction potential of 0.6 volt. The positive-going sync pulses fed through diode X1 and capacitor C1 are only at approximately 0.2 to 0.3 volt amplitude and are insufficient to cause conduction.

Only noise pulses in excess of 0.6 volt will trigger the noise inverter into conduction. When the noise inverter does conduct, the noise pulses that triggered the stage into conduction appear amplified and inverted in the collector circuit and cancel the noise pulses coupled to the collector from the first video IF amplifier. Resistor R1 is connected in series with diode X1 to limit the peak conduction rate. This is required to reduce charging of capacitor C1. If this capacitor is allowed to charge excessively, noise inverter action would be blocked until the capacitor discharged to its initial level.

Fig. 26 AGC inverter provides forward AGC control of the 1st and 2nd video

IF stages.

Fig. 27 Noise inverter prevents spurious noise signals from upsetting AGC and sync operation.

Fig. 28 Two-stage sync separator supplies positive going sync pulses to horizontal and vertical sync circuits.

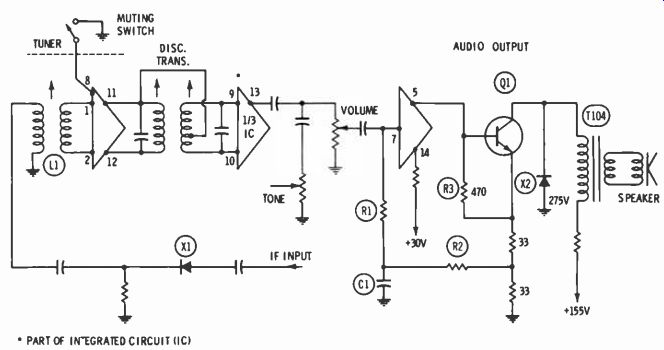

Fig. 29 Block diagram of video amplifier section employed in CTC40 chassis.

Fig. 30 Simplified schematic of the 2nd, 3rd and 4th video amplifier stages.

Sync Separator (Fig. 28)

The sync pulses present at the collector of the noise inverter are applied to the sync separator amplifier base. The output of the sync separator amplifier is of the correct polarity and amplitude to drive the sync separator.

The sync separator is a PNP common-emitter switch which is triggered into conduction by the negative-going sync pulses applied to the base through capacitor C1. Discharge path for coupling capacitor CI is through resistor R1. The output of the sync separator is made up of positive-going sync pulses which are developed across a voltage divider network and applied to both horizontal and vertical deflection systems. The noise immunity features of the sync separator are enhanced during horizontal sync time through the use of 0.01-pf capacitor C1, which provides coupling between the stages. Capacitors C2 and C3 provide filtering for high video and chroma components of the incoming signal.

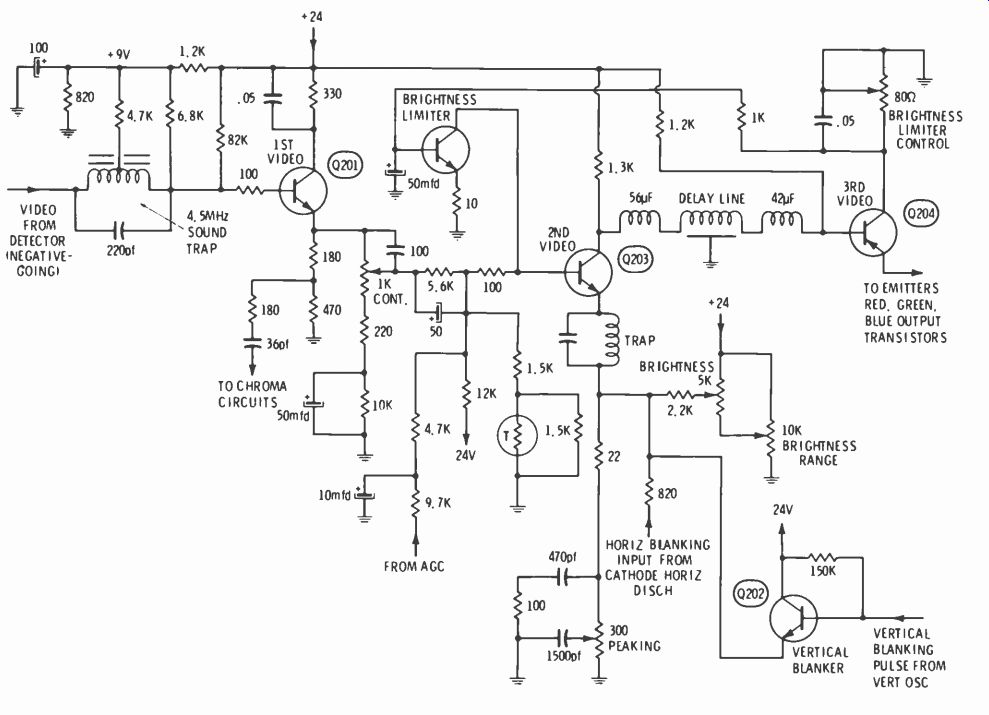

Video Amplifier Section (Fig. 29)

First Video Amplifier

The output of the video detector is effectively in series with the base bias of the first video amplifier.

Base bias is developed by a voltage divider network. The first video amplifier is connected in an emitter follower configuration. This circuit features a high input impedance to match the inherently high output impedance of the detector circuit. Output of the emitter-follower is developed across a 1000-ohm resistor in the emitter circuit. Additional circuit loading results from coupling to the following stages: The output circuit of the first video amplifier is connected to the first chroma circuit, the second video amplifier, the sync separator amplifier, the noise inverter and the AGC gate.

Delay Line

The signal output of the first video amplifier is coupled to the delay line. The delay line must be properly terminated to prevent ringing, faulty color registration, etc.

The CTC40 delay line has a characteristic terminal impedance (input and output) of 680 ohms at video frequencies. A 560-ohm resistor, in combination with the first video amplifier output impedance, provides the delay line with the proper 680-ohm input terminal impedance.

The output terminal of the delay line is applied to the second video amplifier through a 680-ohm resistor. The second video amplifier stage is designed to exhibit an AC input impedance of zero ohms.

Therefore, the output of the delay line is effectively coupled to AC ground through a resistor to properly satisfy termination impedance requirements.

Second, Third and Fourth Video Amplifiers

The simplified circuit configuration illustrated in Fig. 30 points up the relationship of the second, third and fourth video amplifiers. From a functional standpoint their operation is so similar that a brief discussion of the operation of each will suffice.

Second Video Amplifier

The second video amplifier utilizes a common-base configuration and is designed for an input impedance of zero ohms. This is accomplished through the use of a 10mfd bypass capacitor. The stage functions as a power amplifier. Any fluctuations in the DC output of the first video amplifier are amplified throughout the range of video frequencies. This stage provides proper impedance matching between the delay line output and the third video amplifier input. Positive-going pulses at the vertical frequency rate are fed to the emitter to provide vertical retrace blanking.

The operating point of the second video amplifier varies with the setting of the brightness control. Any change in the brightness control results in a change of the operating point by changing the forward bias current. The lower the resistance of the brightness control, the greater the forward bias current. The result is a larger average current flow through the second video amplifier load resistance. This current flow is translated by the remaining video amplifiers as a reduction in CRT cathode bias and, consequently, an increase in brightness.

Third Video Amplifier

The third video amplifier employs a PNP transistor in a common-base configuration. The video signal is fed to the base through a 1000-ohm resistor. This resistance provides proper loading for the second video amplifier and impedance matching between the second and third video amplifiers. It also functions to prevent saturation of the third video amplifier in the event the second video amplifier develops a collector emitter or emitter-ground short circuit. The output signal is developed across an 1800-ohm load resistor and direct coupled to the base of the fourth video amplifier.

Fourth Video Amplifier

The fourth video amplifier is connected as an emitter-follower. The output of the stage is developed across an 1800-ohm resistor and is direct coupled to the base of the video output transistor. Positive bias voltage applied to the collector is decoupled from the chassis 30 volts supply source by a filter network comprised of a 10-ohm resistor and an .01-pf capacitor. This decoupling 'network prevents feedback loops that could cause low frequency smear, etc. Horizontal pulses, which occur simultaneously with the horizontal retrace interval, are fed to the base to accomplish horizontal retrace blanking. This circuit operation is as follows: Horizontal pulses originating at the high voltage transformer are applied through a clamp transistor to an isolation diode. The isolation diode is reverse biased during scan time by a positive DC voltage developed at the collector of the clamp transistor. During this interval the blanking circuit is isolated from the fourth video amplifier to prevent loss of high-frequency components.

The negative-going horizontal pulses, fed to the isolation diode during retrace intervals, overcome the diode reverse bias and permit it to conduct. These negative-going pulses are present at the base of the fourth video amplifier and are of sufficient amplitude to affect cutoff.

These pulses are applied to the CRT through the video output stage. This action causes picture tube cutoff, or a dark screen, during horizontal retrace time.

Brightness Limiter

A brightness limiter circuit is employed in the CTC40 chassis to hold the CRT beam current within proper limits. The drive potential of the horizontal deflection system is such that, with a high, non-limited brightness control adjustment, it is very possible to exceed the current capabilities of the CRT. Brightness limiting action of the CTC40 functions to reduce the forward base bias voltage on the second video amplifier when the preset limit of CRT beam current is attained. The preset limit is 1600 micro-amperes (1.6 ma). Circuit action is as follows: The high-voltage transformer secondary winding is returned to B+ through the brightness limiter control. Therefore, all beam current drawn by the CRT must pass through the brightness limiter control. Connected between the low side of the brightness limiter control and ground is the brightness limiter transistor. The fixed base bias for this stage makes the voltage across it comparatively independent of the current through it, as long as it is conducting. This action is much like that of a zener diode; the zener voltage being determined by the resistive divider network in the limiter base circuit.

The current through the brightness limiter control has two parallel paths: one through the brightness limiter transistor, and the other through the CRT. If the brightness control is adjusted in such a manner that the CRT is cut off, the only path for current flow is through the brightness limiter control and the brightness limiter transistor. When the CRT is cut off, this current will be 1.6 ma, the desired CRT beam current limit. Should the brightness control be adjusted so that the CRT starts drawing current, part of the current will flow through the CRT and the remainder through the limiter circuitry, the total current flow remaining at 1.6 ma.

The constant voltage applied to the emitter of brightness limiter supplies a regulated bias voltage of approximately four volts to the base of the second video amplifier throughout the range of the brightness limiting system.

When the brightness control is set to the point where the CRT draws the total preset current of 1.6 ma, all of the current flowing through the brightness limiter control is beam current. Therefore, there is no current available to sustain conduction of the brightness limiter transistor. This results in a loss of the constant voltage applied to the base of the second video amplifier. If more current is demanded by the CRT, the voltage on the emitter of the brightness limiter transistor decreases, reducing the forward bias voltage on the second video amplifier. This action results in a decrease of average conduction in the second video amplifier, and a decrease in brightness and CRT beam current, holding beam current within the preset 1.6 ma limit.

Video Output (Fig. 31)

The video output circuitry is reminiscent of previously employed tube-type configurations. It consists of a common emitter amplifier whose input is DC coupled to the emitter of the fourth video IF amplifier, and whose output is DC coupled to the CRT. The contrast control is used to vary the value of the series emitter resistance. The contrast control is AC bypassed by a 30-pf capacitor.

This circuit action (varying the AC bypass of the contrast control) effectively controls AC degeneration with the end result of effective gain, or contrast, control.

Further control of the stage is provided by capacitor C1, which functions to reduce high-frequency degeneration and prevent changes in high-frequency response (peaking) at different contrast control settings.

Inductance and capacitance components form a 3.58-MHz trap which functions to reduce the effects of interference resulting from the mixing of chroma signals and high frequency video signals.

Output loading of the video output stage presents a familiar circuit configuration. Identical circuits have been employed in several previous RCA chassis.

Sound Section

An integrated circuit (IC) contains the bulk of the sound section.

This IC performs the functions of sound IF amplifier, detector and audio driver. For circuit analysis purposes, the IC can be considered as made up of three parts, each section representing a specific circuit function. The first section functions to amplify the incoming 4.5-MHz IF signal to a useful level. The output of the first section (sound IF amplifier) is applied to the second, or FM detector, section. The FM detector removes the audio portion of the signal, which is then applied to the audio driver, the third section of the IC. The purpose of the audio driver is to raise the amplitude of the audio signal to the level required to drive the audio output stage.

Detailed Circuit Analysis (See Fig. 32)

The 4.5-MHz FM sound signal is generated in the conventional "mixing" method by diode Xl. This signal is coupled by IF transformer L1 to the sound IF amplifier section of the IC. The output signal from the sound IF amplifier is applied to the phase shift transformer, T2, and, in turn, to the ratio detector diodes. The output of the ratio detector is the audio signal, which is capacitance-coupled to the volume and tone controls. The audio signal is then capacitance coupled from the volume control to the audio driver section of the IC. The audio driver section functions to provide the required current gain to raise the signal to a level sufficient to drive the audio output stage, Q1.

Fig. 31 DC coupling is employed in the input and output of the video output

stage.

The audio output stage is a common-emitter, class A amplifier. The transistor is protected against high amplitude voltage spikes by a 275 volt zener diode connected from collector to ground. DC stability is enhanced by a feedback network (R1, R2) connected from the emitter of the audio output stage to the input of the audio driver section.

Capacitor C1 provides low-frequency compensation for this feedback network. Resistor R3, located between the base and emitter of the audio output stage, functions to provide an additional load for the driver section. This minimizes the effects of output transistor leakage current.

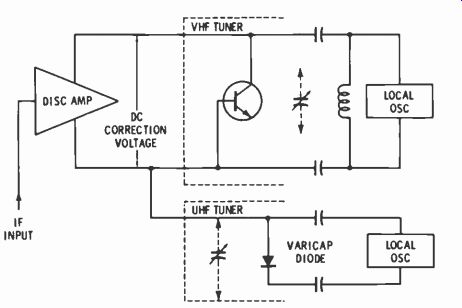

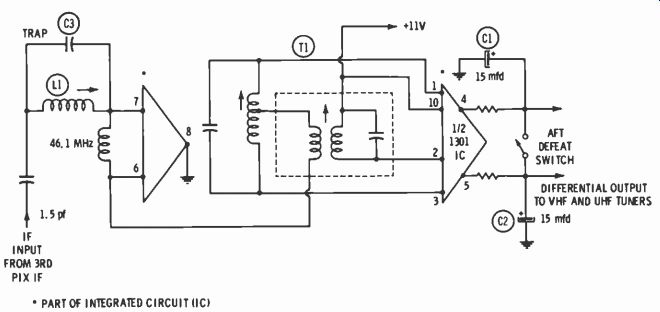

Automatic Fine Tuning (AFT)

The fundamental AFT system is illustrated in Fig. 33. This system is basically the same as that previously used in the RCA CTC30 chassis.

In this system, an integrated circuit (IC) discriminator/amplifier produces a differential DC voltage that is proportional to the applied IF frequency. This signal is then applied to a special "variable capacitance" transistor in the VHF tuner and a varicap diode in the UHF tuner that produce a correction voltage for application to the local oscillator.

Shown in Fig. 34 is a simplified schematic of the CTC40 AFT circuitry. The IC utilizes an internal, regulated power supply and does not require an external reference voltage for defeating the UHF AFT function. Automatic degeneration of the output amplifiers is such that it eliminates all AFT correction signals when the output terminals are shorted for AFT defeat action.

The AFT system is disabled during VHF channel change by the same method used to accomplish AFT defeat during fine tuning--shorting together of the AFT control-voltage outputs. This combination defeat action is initiated by a single switching mechanism built into the plastic housing located on the front of the VHF tuner shaft.

The two 15-mfd electrolytic capacitors, C1 and C2, act to prevent undesired correction voltages generated during channel change time from affecting the local oscillator frequency. These capacitors also function to remove residual video information from the AFT output terminals, allowing only the undistorted DC correction voltage to reach the tuner.

Fig. 32 An IC functions as the sound IF amplifier, detector and audio driver

in the CTC40 chassis.

Fig. 33 Simplified illustrations of the CTC40 AFT system.

Fig. 34 Simplified schematic of the AFT circuitry.

AFT Operation

The IC AFT circuit is a type TA5360 that functions as follows: A sample of the video IF output is applied to the AFT system through a coupling capacitor located in the collector circuit of the video IF amplifier. This signal is applied to a tuned input circuit comprised of L1 and C1. Coil L1 and capacitor C1 perform a dual role: They act as both an adjacent channel sound trap and as an IF frequency peaking circuit. Correct trap frequency is obtained automatically by peaking the input tuned circuit (L1, C1) at 46.1 MHz.

The output of the input tuned circuit is applied to the buffer amplifier section of the IC, the output of which appears across the primary windings of the discriminator transformer, T1. The discriminator primary is tuned to 46.1 MHz; the secondary winding is peaked at 45.75 MHz.

The discriminator transformer secondary windings feed the IC discriminator diodes. The output voltages of the diodes are applied to an amplifier that delivers a differential voltage output. This differential output contains two voltages, one appearing at each of the IC output terminals. The difference existing between these two voltages (differential) is indicative of the amount and direction the incoming 1F signal deviates from the desired 45.75-MHz frequency. If the incoming IF signal is exactly 45.75 MHz, each output signal voltage will be exactly 6.5 volts, and no differential voltage will exist. When the incoming IF signal deviates from 45.75 MHz, one output voltage will increase, and the other will decrease an equal amount. The voltage at each output terminal will increase or decrease, depending on which direction the incoming signal deviates from 45.75 MHz. The maximum differential voltage produced by this circuit is +9 volts, well within the "pull-in" range of the AFT system.

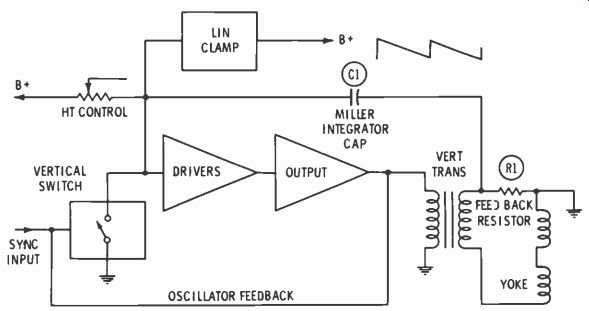

Vertical Sweep

Basic System

The fundamental vertical sweep system employed in the CTC40 chassis is illustrated in Fig. 35. The integrator sweep circuit consists of a high-gain amplification system operating in conjunction with an integrating capacitor. Operation is as follows:

At the start of vertical trace, the integrating capacitor, C1, is charged from a voltage source. This capacitor charge causes the amplifier to supply yoke current, resulting in a voltage being developed across the feedback resistor, R1, which is coupled directly to the integrating capacitor. This feedback action maintains the amplifier input voltage at a constant level, producing a constant rate of voltage "build-up" across the integrating capacitor. The voltage developed across the feedback resistor is directly proportional to the yoke current; therefore, increase of the yoke current is constant, and a linear scan is produced.

The vertical sweep rate is determined by an electronic switch which discharges the integrating capacitor at a 60-Hz rate. Vertical sync pulses are applied to the switching transistor and determine the exact instant the switch is pulsed "on". This action synchronizes the vertical switching action with the transmitted vertical scanning interval. The "linearity clamping" transistor provides the initial charging current to the integrating capacitor.

Fig. 35 Illustration of the fundamental sweep system employed in the CTC40.

Fig. 36 Partial schematic of the vertical switch and associated circuitry.

Fig. 37 Schematic showing basic circuitry of linearity clamper stage.

Vertical Switch (Fig. 36)

The function of the vertical switch is to provide a discharge path for the integrating capacitor at the end of each vertical scan interval. This action causes beam retrace and prepares the circuit for the next vertical scan function. Operation of the vertical switch is made self-sustaining by the action of two feedback paths: One path, consisting of resistors R1 and R2 and capacitor C1, is applied to the base and provides the appropriate pulse to initiate "turn on". Vertical sync pulses, from the sync separator, are integrated by resistors R3 and R4 and capacitor C2 and add to the triggering waveshape. An additional feedback voltage is applied to the switch from the vertical output transformer via the vertical hold control. This additional voltage causes the switch base to pass rapidly through the "turn on" voltage potential. As a result, switch "turn on" is extremely stable and comparatively immune from random noise pulses. The vertical hold control has some control of the "turn on" point and, therefore, the frequency at which the circuit operates.

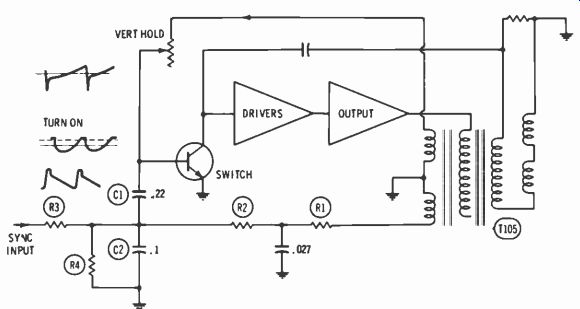

Linearity Clamp (Fig. 37)

Since it is necessary to provide a sufficient amount of initial charging current for the integrating capacitor, a special clamping circuit called the "linearity clamp," is utilized. Operation of this circuit is as follows: The action of the vertical switch discharging capacitor, C1, also cuts off the predriver transistor. This produces a positive voltage on the collector of the predriver. This voltage is of sufficient amplitude to forward bias the linearity clamp transistor. The linearity damper conducts; current flows through the transistor via R1 and the vertical switch. The vertical switch turns off after approximately 700 microseconds, and the linearity clamp then rapidly charges capacitor C1.

As the charge rapidly builds up on capacitor C1, the predriver and driver stages start to conduct, causing the linearity clamp base-emitter junction to become reverse biased due to the voltage drop across the driver base-emitter junction. This circuit action cuts off the linearity clamp and originates vertical scan.

Capacitor C1 continues to charge through the height control, R2, for the duration of scan time.

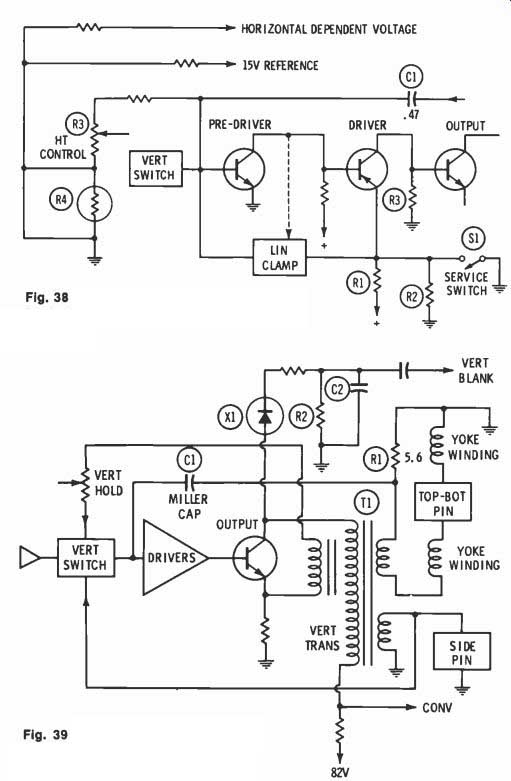

Vertical predriver and driver (Fig. 38)

The vertical driver section is comparatively more familiar. It consists of two stages: a predriver (NPN transistor operating as a common emitter amplifier) directly coupled to a driver (PNP transistor operating as a common-emitter amplifier). Emitter supply voltage for the driver stage is obtained from a voltage divider network composed of R1 and R2. The driver collector load is comprised of R3 and the base emitter junction resistance of the vertical output stage.

Provisions for picture tube setup are provided by switch S1, which functions to "short" the driver emitter to ground when actuated. The waveshape of the input signal to the predriver is determined by the charging action of the integrator capacitor, C1, which is charged through the height control, R3. The height control supply voltage is made relatively immune to temperature induced variables by the action of thermistor R4. A degree of dynamic regulation for the circuit is provided by a signal from the horizontal deflection system. The insertion of this voltage tends to maintain a constant vertical sweep or height, regardless of horizontal scan and high voltage fluctuations.

Fig. 38 A two-stage vertical driver section feeds the vertical output stage.

Fig. 39 Common-emitter amplifier is employed in vertical output circuit.

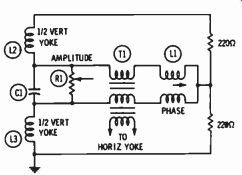

Vertical Output (Fig. 39)

The function of any vertical output circuit is to provide the power necessary to fulfill the vertical deflection requirement of the CRT beam. In the RCA CTC40 chassis the vertical output stage is a common-emitter amplifier with an input from the driver stages. Loading for the vertical output stage is provided by the vertical output transformer, T1, and the vertical convergence circuit.

The vertical output transformer is loaded by the vertical windings of the yoke, two feedback networks, and the pincushion correction circuit. Integrating capacitor C1 is connected to the output circuit by resistor R1, a 5.6-ohm feedback resistor in series with the secondary windings of the vertical output transformer and the vertical yoke windings. There are two feedback networks connected to the vertical switch transistor from the vertical output circuit; both of these networks perform waveshaping functions to provide stable, self-sustaining vertical switching. Diode X 1, in conjunction with capacitor C2 and resistor R2, provides a protective clamping action for the vertical output transistor. Positive-going retrace voltage pulses cause diode X1 to conduct, effectively clamping the vertical output collector to the voltage existing across capacitor C2. A relatively slow discharge path is required for capacitor C2. This is provided by resistor R2. This discharge action sufficiently reduces the voltage across C2 during retrace time to insure the necessary voltage difference across diode X1 when retrace pulses occur. The pulses that appear across capacitor C2 during conduction of X1 are applied to the 2nd video IF stage to provide vertical retrace blanking.

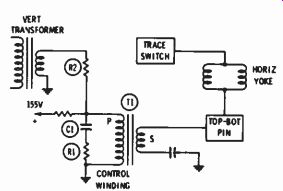

Pincushion Correction (Top and Bottom)

Fig. 40 Top and bottom pincushion correction in the CTC40 chassis is accomplished in a manner similar to methods used in previous RCA color chassis.

A signal voltage derived from the horizontal yoke circuit is coupled to transformer T1. This action energizes a circuit composed of capacitor CI and coil L1, which is tuned to 15,750 Hz and is in series with the vertical yoke windings, L2 and L3.

The resultant sine wave is added to the vertical yoke current waveshape in the proper phase and amplitude to effectively correct top and bottom pincushion distortion. A limited amount of control over the correcting sine wave phase and amplitude is provided by variable inductor, L1, and the damping resistance of R1.

Side Pincushion Correction (Fig. 41)

Side pincushion correction is accomplished by amplitude modulation (at a vertical rate) of the horizontal deflection current. This produces an increase in horizontal scanning width at the center of the raster with respect to the width at the top and bottom. This operation is made possible through the utilization of the saturable reactor circuit illustrated in Fig. 41.

A parabolic waveshape occurring at the vertical frequency is initiated by the action of the control winding of transformer T1, capacitor C1 and resistors R1 and R2. This waveform, coupled to the horizontal yoke circuit by transformer T1, modulates the amplitude of the horizontal yoke scanning current, producing the proper change in raster width.

Fig. 40 Top and bottom pincushion correction circuitry.

Fig. 41 Side pincushion correction is accomplished by amplitude modulation

of the horizontal deflection current.

Fig. 42 Schematic of the switching circuitry that permits the CTC40 to take

advantage of the "instant-on" characteristics of semiconductors.

Fig. 43 Three separate rectifier circuits provide the CTC40 with four separate

DC sources.

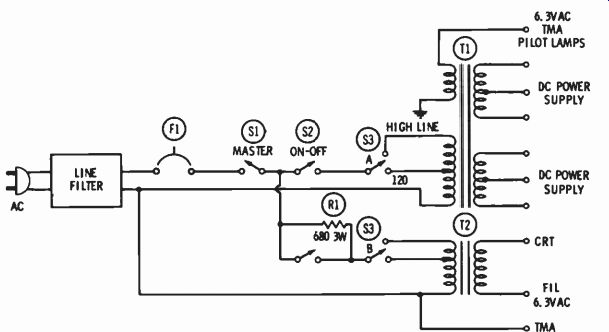

Power Supply

The CTC40 power supply provides four DC sources for general circuitry requirements and two AC power sources. The AC power sources are for the CRT filaments and pilot lamps.

Power supply switching circuits allow the CTC40 to take advantage of the "instant on" characteristics of solid-state devices. This switching circuitry is illustrated in Fig. 42.

Switching Circuit

AC power is applied through the line filter and circuit breaker to the master power switch, Si. The master power switch applies power through the "instant pic" switch, S2, to both the DC supply transformer, T1, and the CRT filament transformer, T2.