By Conrad Persson [Persson is editor of ES&T.]

The TV, VCR or personal computer is lying open on your work bench. You've applied all your di agnostic skills, probed with meter, scope and a handful of other test equipment, and you've finally isolated the cause of the problem--one or more of several parts on a printed circuit board.

It's been quite a struggle, but victory is in sight. You take the soldering iron in hand and carefully liberate the troublemakers from the board. If life were fair, the war would be won. All you would have to do is locate the correct replacement in your inventory, solder it in and perform the smoke test.

Life is not fair, however. Often, the end of the struggle to locate the defective part merely signals the beginning of the struggle to locate a suitable replacement. There are the older units that have be come obsolete and for which replacements are no longer made.

There are the manufacturers who require a hefty minimum order be fore they'll ship any parts. There are the units for which you can't find any servicing information.

And many times you either use a universal substitute you have on hand or order a universal substitute and find that the pin arrangement is not quite the same.

This article, based on information, tips and hints found in parts catalogs from Philips ECG, General Electric, MCM, Motorola, NTE, RCA-SK, Workman Electronics, Zenith and others, is intended to provide you with information that will help you find and select the right replacement part. It will also suggest ways to ensure that the replacement does the job for which it was intended.

RF considerations

Any time you substitute a universal replacement for an original-equipment component in an un-tuned amplifier stage operating at a low signal level (for example, the untuned RF-amplifier [antenna] stage of the radio receiver, or a low-level AF-amplifier stage), it usually is not necessary to make any circuit adjustments to assure proper performance of the equipment. However, when a replacement is made in a tuned RF-amplifier stage, RF-oscillator, converter or IF-amplifier stage, it is always advisable to check the alignment of the associated tuned circuits to assure proper tracking and to achieve the required gain without loss of stability.

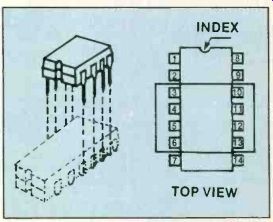

Figure 1. Some linear IC devices that were originally supplied in 14-lead

DIL case are now available in 8-pin mini-DIP cases. The pins 1, 2, 7, 8, 13

and 14 were not connected in the original version, so the 8-lead package can

be installed as shown.

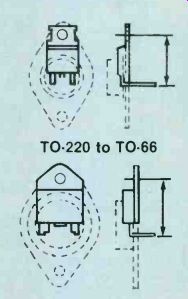

Figure 2. Some plastic-case devices are direct retrofits for metal-case types.

Just cut the center lead of the plastic device and bend the two outside leads.

Considerations in high-power stages

When making a replacement in a stage that operates at relatively high power levels (such as Class A and Class B AF output stages of automobile radios, phonographs and AF-amplifier systems), the transistor bias should be checked and adjusted, if necessary, to protect the replacement transistors against excessive dissipation and to minimize distortion. Means for making such adjustments are generally provided in the equipment, and the necessary instructions are usually given in the equipment manufacturer's service data.

Using replacements properly

When you install a universal re-placement in an FM tuner, TV tuner or other circuit operating in the VHF or UHF regions, it is extremely important not to change any of the mechanical details of the original circuit. Before removing the original transistor, carefully note its position with respect to other circuit components. Also note the lengths and placement of the transistor leads, and duplicate these details as precisely as possible with the universal replacement transistor. If you don't do this, the result could be improper tuning or circuit instability, particularly in UHF TV tuners.

The same holds true for using re placement integrated circuits in place of an original-equipment type in FM radios and TV receivers. Be careful to note the IC's position and lead placement.

Replacing 14-pin ICs

You may run across situations where a replacement IC for a 14-lead linear DIP (dual-in-line package) IC comes with only eight leads. In this case, pins 1, 2, 7, 8, 13 and 14 are not connected to anything internally in the package, so the 8-pin package is a direct plug-in replacement. The 8-pin re placement should be installed as shown in Figure 1.

Be careful with stud-mounted devices

When you're trying to replace a stud-mounted device, it sometimes isn't possible to find a replacement with exactly the same thread and stud size as the original. In this situation, the device may be replaced with a device that has the same size or larger stud.

If you must use a component with a larger diameter stud, be careful that you don't enlarge the mounting hole any more than 1/64th of an inch larger than the replacement component's stud. Al so, the edge of the hole should have a chamfer not exceeding 0.01-inch radius. It is also important that the mounting hole be drilled perpendicular to the surface within 1/10 of a degree. You should use heat sink compound be tween the heat sink and the re placement unit.

The mounting hardware usually consists of a nut and either a pal or a lockwasher. Either type will work as long as the proper torque is applied. A good torque wrench is a necessity.

--------------

Choosing an alternative vendor

The following are edited comments from Gershon Cooper, president of ORA Electronics, suggesting how to choose an alternative parts vendor.

Many popular parts, particularly semiconductors for products of Japanese manufacturers, are now available from alternative parts sources, frequently at prices below the manufacturers' prices. Many of these alternative sup pliers stock a variety of replacement parts, plus other technician aids, installer aids and accessories. The semiconductors stocked are the same as those supplied by the original manufacturer.

Some unscrupulous companies offer surplus parts re-marked with the part number, so care should be taken when dealing with replacement parts vendors.

How to choose a vendor

Most alternative parts vendors are catalog operations. The company publishes a catalog that is mailed to service dealers. The catalog lists and describes all available parts and a phone number is provided to place the order.

By looking at the catalog, reviewing the sales terms and conditions, and talking to the people on the phone, you can learn a lot about the operations of the company and then decide which company will get your business.

Words of advice

Deal only with reputable companies. If you receive frequent catalogs or sales flyers, check to see whether the catalogs/flyers are neat, printed on a decent paper, and show clear pictures of the products. This will tell you a lot about the reputation of the company.

Deal with companies that offer toll-free numbers. A toll-free number is a good indicator that you're dealing with a large, established company. Deal with companies that offer you such services as fast delivery and on-line information on in- and out-of-stock items.

Deal with companies that offer easy return privileges for unacceptable and defective parts.

After receiving an order from a company, check:

1) How long it took for the order to arrive. If the parts are cheap, but it takes a long time (more than one week) to receive the order, then you are the loser.

2) How are the products packaged? Paper bags, newspaper and other cheap materials can al low the goods to be damaged.

3) How much of what you ordered actually arrived? It should not be less than 70%.

4) Is the invoice clear? Are all charges reasonable? Avoid buying from companies that charge for handling or charge surcharges. Reputable companies charge freight only in the amount charged to them by the carrier, and never charge surcharges for credit card transactions or handling charges.

Also avoid dealing with companies that charge freight and other charges on a percentage basis; i.e., $5 on orders up to $70; $10 on orders $70 and up; or 10% for orders up to $100, and 5% for orders $100 and up.

5) Is your order accurate? Mis takes do happen, but an excessive number of mistakes is a clear sign of a problem company.

----------------

Replacing a metal-case device

The JEDEC TO-220 outline is a direct retrofit for devices in the JEDEC metal TO-66 case. Like wise, the CP-3 plastic device can be used to replace types in the JEDEC TO-3 metal case. In either of these cases, you make the re placement by cutting the center lead of the plastic device and bending the two outside leads to install the device. (See Figure 2.) Some other precautions There are many other precautions to be observed in handling re placement components. We will just mention some of them here, as many of them were covered in the article, "Replacement Parts," published in the June 1986 issue.

Other problems to watch for, such as ESD (electrostatic discharge), which was covered in detail in our October issue, have been discussed in recent issues. To eliminate handling damage, use the following precautions:

In order to avoid electrostatic discharge damage to a static-sensitive replacement part, don't open the static-shielding package until you're ready to install the part.

Make sure you're wearing a static grounding wrist strap when you handle static-sensitive parts, and, make sure your workbench is clear of any material that might be carrying a static charge. With today's advanced technology sets, a lot of the components are static sensitive, so some manufacturers recommend working at all times as though the components you're handling will be damaged if you don't observe static handling pre cautions.

Use the right sized soldering iron and proper soldering techniques, and limit the amount of time you hold a soldering iron in contact with the component's leads. Most components are heat sensitive, and if you're not careful while soldering in a replacement component, you might destroy it before it ever sees service. If you think a component might be dam aged by heat even if you're careful, clamp a heat sink or pair of long-nosed pliers around the lead be tween the component body and the soldering point. This precaution will dissipate most of the heat before it reaches the component.

When working on a product that uses surface-mount devices, don't desolder a surface- mount IC un less you're absolutely sure that it's defective. These units are extremely delicate and heat sensitive, and they will likely be dam aged or destroyed by the removal operation. And never place a surface-mount component that you have de-soldered back onto a circuit board. If you desolder a surface mount component, discard it.

When bending leads to prepare the replacement component to be inserted into the circuit board, al ways use a pair of pliers or another method to hold the lead near the body of the component to avoid damaging the part.

Sources of replacement parts

Although finding the right re placement part can sometimes seem like an impossible task, the more suppliers you're familiar with, the more likely you'll be able to find the part you need. Some of the suppliers listed in the accompanying sidebar sell through traditional distributors; others sell via mail order. Check them all out.

You might be surprised to find that suppliers like Philips ECG, RCA-SK, NTE Electronics, Zenith and others who you thought sold only TV parts can also provide you with replacement digital ICs for computers, remote control units, test meters and more.

Sources of replacement parts:

Abatron Electronics 971 Ball Ave.

Union, NJ 07083

All Electronics 905 S. Vermont Ave.

Los Angeles, CA 90006

Allied Electronics 401 E. Eighth St.

Fort Worth, TX 76102

Antique Electronic Supply 1725 W. University Tempe, AZ 85281 Asti Magnetics 32 Piermont Road Cresskill, NJ 07626 Circuit Specialists Box 3047 Scottsdale, AZ 85257 Consolidated Electronics 705 Watervliet Ave.

Dayton, OH 45420-2599

Dalbani Corporation of America 785 E. 14th St.

Los Angeles, CA 90021

Dick Smith Electronics P.O. Box 2249

Redwood City, CA 99063

Digi-Key P.O. Box 677 Thief River Falls, MN 56701

Digitron Electronics 110 Hillside Ave.

Springfield, NJ 07081 E.S.I.

3171 Hempstead Turnpike Levittown, NY 11756

Electronic Salvage Parts 2706 Middle Country Road Centereach, NY

11720 Electronic Parts Supply 741 E. 14th St.

Oakland, CA 94606

Electronics Warehouse 1910 Coney Island Ave.

Brooklyn, NY 11230

Etco Electronics North Country Shopping Center Plattsburg, NY 12901 EVG 1 Lee Place Freeport, NY 11520 Fox International 23600 Aurora Road Bedford Heights, OH 44146 Fuji-SVEA P.O. Box 3375 Torrance, CA 90510 GC Electronics 400 South Wyman St.

Rockford, IL 61101 Hitachi 401 West Artesia Blvd.

Compton, CA 90220 Jameco Electronics 1355 Shoreway Road Belmont, CA 94002 Joseph Electronics 8830 N. Milwaukee Ave.

Niles, IL 60648 Matsushita Engineering & Service 50 Meadowlands Parkway Secaucus, NJ 07094 MCM Electronics 858 E. Congress Park Drive Centerville, OH 45459-4072 Mid America Company 2309 S. Archer Chicago, IL 60616 Milo Associates 4169 Millersville Road Indianapolis, IN 46205 Mouser Electronics P.O. Box 9003 Lakeside, CA 92040 NTE Electronics 44 Farrand St.

Bloomfield, NJ 07003 Nippon America 9600 NW 12th St.

Miami, FL 33172 OHM/Electronics 746 Vermont Ave.

Palatine, IL 60067 Omnitron Electronics 770 Amsterdam Ave.

New York, NY 10025 Optima Electronics 2022 Tigertail Blvd.

Dania, FL 33004 PanSon Electronics 268 Norman Ave.

Greenpoint, NY 11222 Pfanstiehl Chemical Corporation 3300 Washington St.

Waukegan, IL 60085 Philips ECG 100 First Ave.

Waltham, MA 02254 Projector Recorder Belt 200 Clay St.

Whitewater, WI 53190-0176 RCA Special Products 2000 Clements Bridge Road Deptford, NJ 08096 Richardson Electronics, Ltd.

3030 N. River Road Franklin Park, IL 60131

TEC 83 E. Central Ave.

Pearl River, NY 10965 Thordarson-Meissner 628 Belmont St.

Mt. Carmel, IL 62863 Unity Electronics P.O. Box 213 Elizabeth, NJ 07206 Workman Electronics Products 75 Packinghouse Road Sarasota, FL 33578 Zenith Svc., Parts & Accessories 11000 Seymour Ave. Franklin Park, IL 60131.

Also see: What do you know about electronics? A trip to the deathnium traps.

Troubleshooting the chopper circuit

Dealing with power line problems