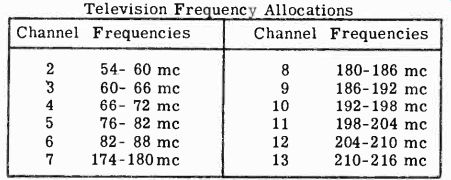

2-1

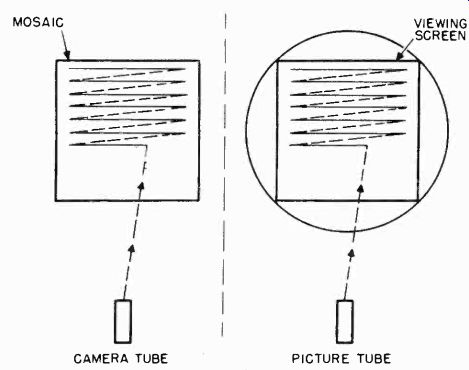

The television system in use today is essentially an electronic system. It was made possible by the development of the cathode ray tube which is the heart of both the television transmitter and receiver.

As was pointed out in Section 1, all television systems must satisfy the 'requirements of the human eye. The cathode ray tube does this remarkably well and television as we know it today has been designed around this tube.

The cathode ray tube performs the two most important functions of the television system. At the transmitter, it "sees" the scene to be televised and transforms it into an electrical signal which can be passed on to the television receiver where the second important function takes place. Here again a cathode ray tube is used to take the electrical signal and from it reconstruct the original scene in the form of a visual picture on the viewing screen.

A brief resume of the history and origin of the cathode ray tube is a good starting point for the discussion of the tube's construction and operation which follow.

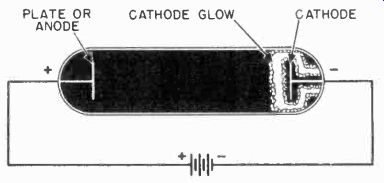

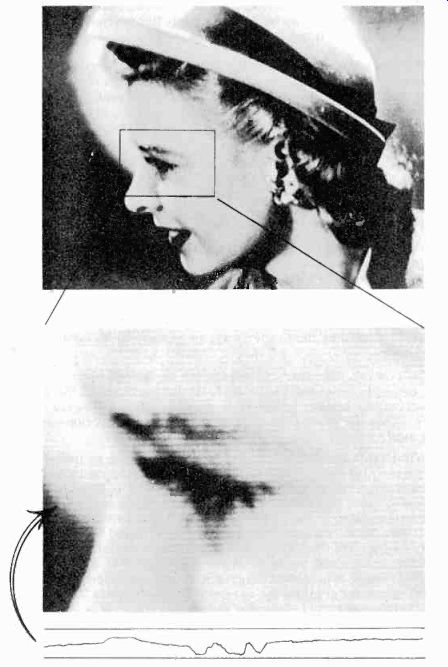

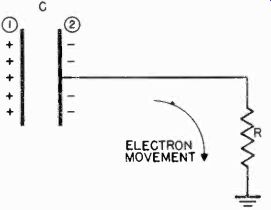

The term "cathode ray" was originated in the last century by a scientist, Jules Plucker, who was investigating the properties of gases. His experiments included putting the gases being studied into cylinder-like glass envelopes. In these glass envelopes, there were two metal plates which were connected to a battery. (Figure 1.) The plate connected to the negative end of the battery was called a cathode, while the plate connected to the positive end was given the name anode. In the experimental procedure, a pressure reducing pump was attached to the tube through an opening. It was discovered that as the pressure was reduced, the region of the cathode acquired a definite, greenish glow. Plucker attributed this glow to invisible rays which, he believed, came from the cathode. He therefore called them "cathode rays".

Figure 1. Plucker's simple gas tube.

Although its basic shape and components were changed, the same type of tube was used in later experiments in the study of gases. Still later, the tube found use as an indicating unit using the cathode rays as a pointer. It was found that as an indicator, it functioned best with almost all of the gas pumped out.

Nevertheless, the name "cathode ray tube" has remained in use, even though at the greatly reduced pressure now utilized, the green colored region in the neighborhood of the cathode is no longer evident, and the alleged "cathode rays" proved to be merely electrons.

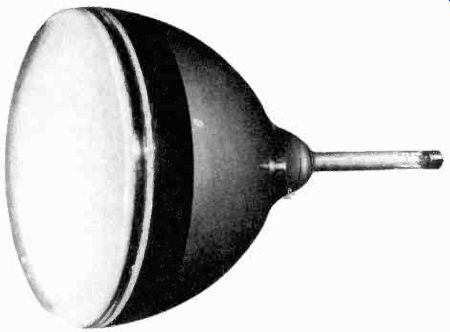

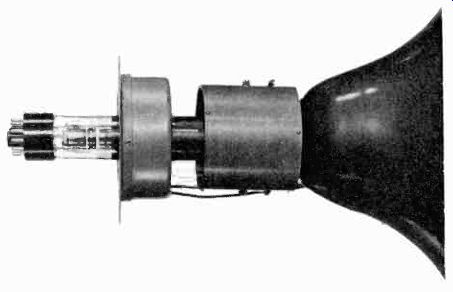

2-2 Modern Cathode Ray Tubes. The modern cathode ray tubes now used in television differ considerably in construction and appearance from Plucker's original gas tube. A Type used in present day receivers is shown in Figure 2. Cathode ray tubes designed for television receivers have been given various names by tube manufacturers. Some of these are "kinescope", "teletron", and "visitron". Since there has been no universal acceptance as yet of a name for the receiver tube, the term "picture tube" will be used in this text whenever reference is made to the receiver cathode ray tube.

Figure 2. A modern cathode-ray tube used in television receivers. (courtesy

GE)

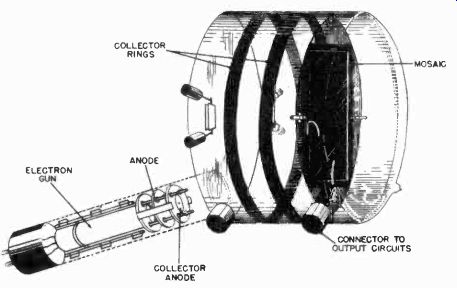

Figure 3. The Iconoscope, a cathode-ray tube used in the television camera.

(courtesy RCA)

There are several types of cathode ray tubes used in the television camera. One of the earliest designs, illustrated in Figure 3, is known as the "iconoscope". This word stems from the Greek word icos, which means "I see". The name is descriptive of the tube, since it actually does see the scene being televised and can change what it sees into electrical signals.

PICTURE TUBE CONSTRUCTION

2-3 Since the heart of the television camera and receiver is a cathode ray tube, it is best to begin the discussion of the modern electronic television system with a description of this tube.

Of the two basic types, the picture tube and the camera tube, the former is more fundamental and a little easier to understand. It is therefore treated first.

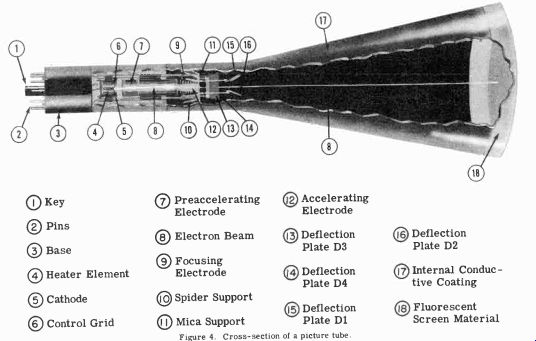

Figure 4 shows a cross-sectional drawing of a picture tube, including its component parts and an imaginary electron beam, number 8, to illustrate the action of the various elements of the tube upon the beam.

The modern picture tube consists of five main sections: (a) a glass envelope, (b) a base which is outside the envelope, (c) the electron gun assembly, (d) the deflection plate assembly, and (e) the screen. The cathode, number 5, provides a source of electrons which are attracted in the general direction of the screen, number 19, by the action of the electron gun. These electrons are molded into a very narrow beam, which can be focused to a small point at the screen.

The inside of the screen is coated with a material which lights up when bombarded by the stream of electrons. The property of the screen which causes it to emit light when struck by the electrons is called fluorescence. When properly focused, the electron beam will strike the screen, causing a very small area of the screen to glow. If the face of the tube is viewed, this area will be a small pinpoint of light.

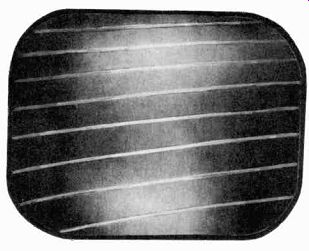

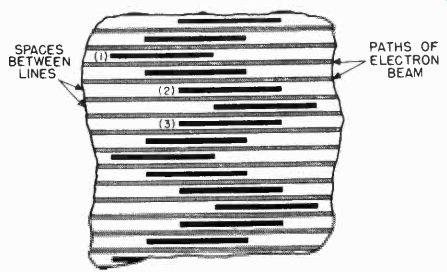

The deflecting plates, numbers 14, 15, 16, 17, can be made to move the beam up, down or sideways (vertically or horizontally). It is possible to apply electrical signals to these plates and cause the beam to move so fast that the eye cannot detect its movement. Since the screen material glows for a short time, even after the electron beam has moved to another position, a pattern can be traced on the screen similar to the one shown in Figure 5. Though the beam is constantly moving while tracing out this rectangular pattern, the pattern actually appears stationary because of the after-glow of the screen and the persistence of the eye.

--------------Fig. 4. Cross section of CRT.

2-4 The Electron Gun. The electron gun is so named because it takes the electrons given off by the cathode and accelerates them somewhat in the manner of a gun. The electron gun can be subdivided into four parts: (1) the cathode-grid assembly; (2) the pre-accelerator assembly; (3) the focusing electrode assembly; and (4) the accelerating electrode assembly. The assemblies are all supported by ceramic or glass rods which run the entire length of the electron gun as shown in Figure 4, number 10.

These rods are usually made of a non-conducting ceramic or glass material to prevent electrical inter-action between the various parts of the gun.

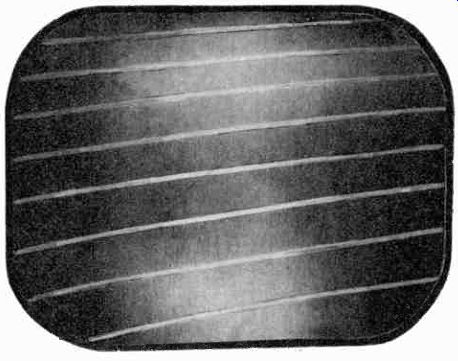

Figure 5. Illuminated pattern obtained on the screen of a picture tube when

the electron beam is rapidly moved vertically and horizontally.

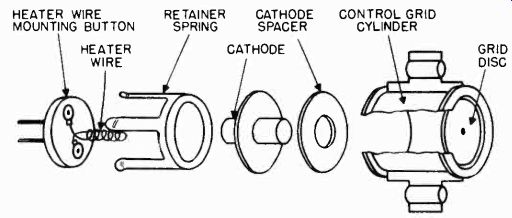

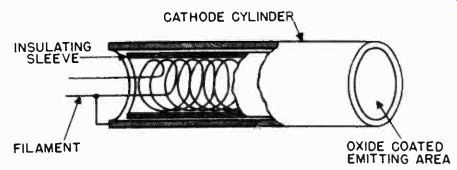

2-5 The Cathode-Grid Assembly. The cathode-grid assembly consists of the heater element, the cathode, the control grid, and other supporting components, as shown in Figure 6. This illustration is an exploded view of the cathode-grid assembly and does not show the actual spacing of the components. The heater element, a coiled wire, is usually made of tungsten or an alloy of tungsten. This material is chosen because it is easily heated to a high temperature when an electrical current passes through it.

The cathode is a thin metal sleeve surrounding the heater coil.

The metal sleeve, usually nickel alloy, is coated on one end with a substance which emits electrons in great quantities when heated sufficiently. This substance is usually an oxide, such as cesium oxide. The cathode is electrically insulated from the heater and is therefore said to be indirectly heated. Indirect heating is used because it isolates the emission qualities of the cathode from the power source supplying the current to the heater, and permits the use of an alternating current source.

If alternating current were applied directly to the cathode to heat it, the flow of electrons would fluctuate according to the frequency of the current. Early cathode ray tubes used a heater-cathode assembly in which the heater itself emitted the electrons. For proper operation, these tubes required a direct current heater supply. Because it is more economical to supply the current for the heater from an a-c source, the indirectly heated cathode is now used almost exclusively.

Figure 6. The cathode-grid assembly.

The control grid in the cathode-grid assembly is a cylinder, completely surrounding both the heater and the cathode. The grid is open at one end, but closed at the other end by a disc.

The disc has a small hole in its center to permit the passage of electrons. Since all electrons which pass to the screen must go through the hole in the disc, the grid electrode can assist in controlling the electron flow.

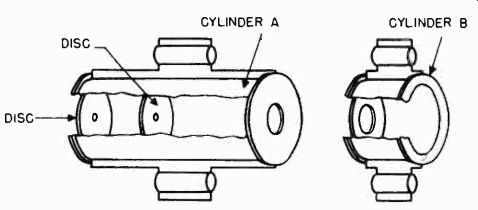

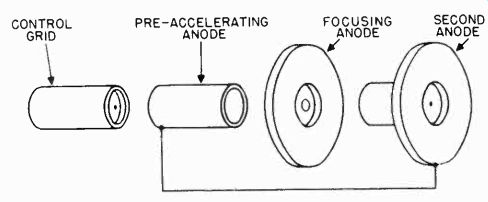

2-6 The Pre-Accelerator Electrode Assembly. The pre-accelerator electrode assembly is shown in Figure 7. It usually consists of two parts, A and B, each of cylindrical shape, with several discs enclosed in them. All of the discs have holes in their centers to permit the passage of the electron stream.

This assembly gets its name from the electrical function it performs in the electron gun. It causes the electrons to move more rapidly in the direction of the screen. Its function is essentially the same as that of the accelerator (to be mentioned later), which also increases the speed of the electrons. Since the electrons pass through this electrode before they pass through the accelerator, it has been named the pre-accelerator.

DISC; CYLINDER A; CYLINDER B

Figure 7. The pre-accelerator electrode assembly.

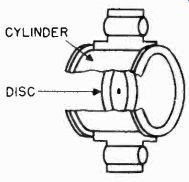

2-7 The Focusing Electrode Assembly. The focusing electrode assembly performs the function which its name implies. It focuses the electron beam to a fine point on the screen. (Figure 8) The focusing electrode assembly. The focusing cylinder is shorter in length than the grid and pre-accelerator electrodes, but is of essentially the same shape.

It does not contain the discs included in the grid and pre-accelerator electrode assemblies.

Figure 9. The accelerating electrode assembly.

Figure 10. The deflection plate assembly.

2-8 The Accelerating Electrode Assembly. The accelerating electrode assembly performs the same function as does the pre-accelerator. It increases the speed of the electrons traveling toward the screen. The construction of the accelerating electrode is shown in Figure 9.

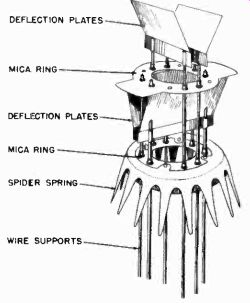

2-9 The Deflection Plate Assembly. The deflection plate assembly, shown in Figure 10, is mounted between the electron gun and the fluorescent screen. This assembly consists of two pairs of rectangular metal electrodes referred to as deflection plates. The four deflection plates are mounted with the aid of two mica rings which support and insulate them from one another and from the electron gun. A spider spring, made of a flexible metal material, centers the deflection plate assembly in the neck of the picture tube. As the electrons travel from the electron gun to the fluorescent screen, they must pass between each of the pairs of plates. The deflection plates are so placed in the tube that if a voltage differential appears across either pair, it will cause the electron beam to be deflected. Since the pairs of plates are mounted at right angles to one another, either horizontal or vertical deflection is possible by applying an electrical signal on the proper pair.

Figure 11. The glass envelope is coated on the inside with a conducting material.

The second anode cap is connected to the aquadag coating. (courtesy DuMont)

2-10

The Envelope. All of the elements of the picture tube are mounted inside of a glass envelope. Almost all air is evacuated from this envelope which must be strong enough to withstand the pressure of the atmosphere.

The inside of the glass envelope between the neck and the screen is coated with a conducting material, as shown in Figure 11A. Graphite is the major component of this material which is known commercially as “Aquadag" or "Dixonac". The coating is connected to the accelerating electrode so that it operates at the accelerating potential. In picture tubes which operate at very high accelerating potentials, a small metal contact is fused to the funnel portion of the tube. The second anode and aquadag coating are connected to this contact instead of to a pin in the base. Figure 11B shows a picture tube with this type of construction. When stray electrons approach the coated insides of the tube, the high potential on the coating repels them backward toward the accelerating anode, so that electrons striking the walls of the tube are returned to the circuit. The potential on the conductive coating also eliminates inter-action between the electron beam and electrons rebounding from the screen.

Some picture tubes are equipped with an additional element referred to as an intensifier band. The intensifier band consists of a ring of graphite, coating the inside of the tube envelope. A non-conductive coated area between the intensifier band and the accelerator coating insulates the two coatings from each other. A small metal pin is inserted through the glass at a point where it will contact the intensifier band so that an electrical connection can be made to the band. Since the intensifier ring completely encircles the electron beam, it does not affect the path of the beam once the beam has been deflected. The purpose of the intensifier band is to further accelerate the electrons without making it more difficult to deflect the beam. If the beam is traveling too fast, deflection is quite difficult, requiring extremely large electrical signals on the deflection plates. With an intensifier band tube, it is possible to deflect the beam when it is moving at low speed when deflection is relatively simple. Then, after the beam has been deflected, the voltage on the intensifier band imparts to the beam additional acceleration to provide a brighter image on the screen.

2-11 The Tube Base. Except for the fact that it is larger and usually has more pins, the picture tube base is similar to an ordinary vacuum tube base. The leads which connect to the various parts of the internal assembly of the tube are brought through the glass seal at the end of the tube and are inserted into pins in the base.

2-12 The Fluorescent Screen. The fluorescent screen consists of a thin chemical coating which is deposited on the inside face of the tube. This coating consists of a silicate, sulphide, sulfate, or tungstate, and a binding material which holds the chemical to the glass. The thickness and uniformity of the coating are very critical and must be held within very narrow margins to assure uniform color and light output when the electron beam impinges upon the screen.

OPERATION

2-13

All of the parts of the picture tube just described perform important functions. The principle parts of the picture tube will now be discussed from an electrical standpoint, for the purpose of assisting the reader to understand their operation.

2-14 The Heater Coil. The sole function of the heater coil, or filament, is to heat the cathode to its proper operating temperature. No useful electron emission takes place from the heater coil. The manner in which the heater converts electricity into heat may be understood from a simple discussion of electricity.

INSULATING SLEEVE FILAMENT CATHODE CYLINDE OXIDE COATED EMITTING AREA

Figure 12. Heater and cathode assembly.

All material consists of small particles called atoms. Included in each atom are small negatively charged particles referred to as electrons. The wire which makes up the heater coil, therefore, consists of atoms and the electrons which are part of them.

When a potential is placed across the ends of the heater wire, it causes electrons to be released from their atoms. These electrons move along the wire and constitute a current flow. The moving electrons strike other atoms and electrons which oppose their motion. This opposition is referred to as "resistance". As a result of the opposition or resistance to the electron flow, some of the energy which causes the current to flow is converted into heat.

2-15 The Cathode. The cathode must supply the electrons which later are formed into the beam which is directed toward the face of the tube. It is placed over the heater coil so that the heat generated by the filament can be radiated to it (Figure 12). The cathode is insulated from the filament so that no electrical inter-action may take place. When heated to a temperature of about 700 degrees centigrade, the oxide coated cathode emits comparatively large amounts of electrons. To perform most efficiently, the cathode must emit the largest possible number of electrons at the lowest possible temperature. It has been found that certain oxides of alkaline earth metals such as cesium meet these requirements and are best suited for the cathode coating.

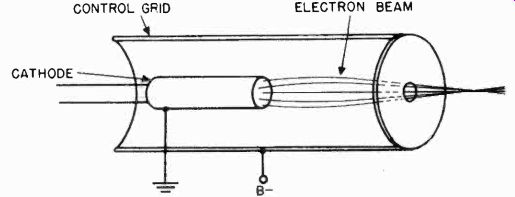

CONTROL GRID ELECTRON BEAM

Figure 13. The grid limits the number of electrons which pass to screen.

2-16

The Grid. The electrons emitted from the cathode must pass through the hole in the grid. The grid controls the number of electrons which flow through the accelerator electrodes.

When a more negative potential than the cathode potential is placed on the grid. it decreases the number of electrons which pass through the hole in the grid. When the negative charge on the grid is varied, the number of electrons passing through the hole in the grid also varies. The grid can therefore be used to control the number of electrons in the beam, and for this reason, is usually referred to as the control grid. If the negative charge on the grid is great enough, the electron beam will be entirely cut off.

The control that the grid can exert over the electron beam is one of the important features of the picture tube which have made electronic television possible. The greater the number of electrons (beam current) in the beam, the greater will be the light output from the screen. When the television signal is fed to the grid, it controls the passage of the electron beam and thus the intensity of the glow of the screen.

2-17 Grid Action. In order to control the stream of electrons passing to the screen, the grid is placed around the cathode (Figure 13). The cathode and grid in a cathode ray tube function in the same manner as the cathode and grid in a conventional vacuum tube. If the grid were at the same electrical potential as the cathode, the electron beam would be limited only to those electrons which were traveling along an axis which passes through the small hole in the disc at the end of the grid.

The action of the disc on the electron beam, however, is not sufficient to limit the beam properly. It also does not provide a means for changing the number of electrons in the beam. Therefore, the grid is given a potential more negative than the cathode and this potential is made variable.

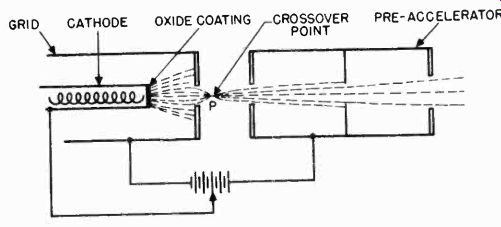

Figure 14. The "crossover" point of the electron beam is between

the grid and the pre-accelerator electrode.

Some of the electrons which are emitted by the cathode do not go through the grid opening. This is because the cathode is much more positive than the grid and exerts a greater attracting force on the electrons than do the positive potentials on the more remote accelerating anodes. At the same time the negatively charged grid repels the negative electrons back to the cathode. This action of the grid in repelling electrons is aided by the presence of what is called a «« space charge" which exists around the cathode. The space charge is created by the electrons themselves. Some of the electrons in breaking away from the cathode do not have sufficient energy to reach the grid.

These electrons hover around the cathode as a sort of electron cloud and sometimes even return to the cathode. The space charge created by these electrons forms a barrier for other electrons which are freed from the cathode. If the new electrons do not possess a sufficient amount of energy to penetrate the space charge, they are forced back to the cathode. With these factors: (1) the negative grid, (2) the space charge, (3) the attraction of the cathode for the electrons, and (4) the small opening in the grid disc, it is very difficult for electrons to pass through the grid to the accelerating assembly beyond. Many electrons, however, break free from the cathode with sufficient energy to overcome these barriers and pass through the opening in the grid.

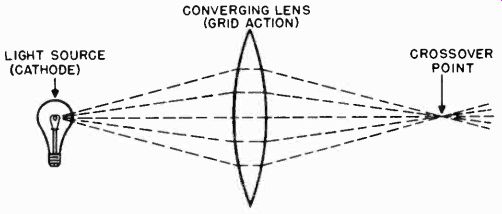

CONVERGING LENS (GRID ACTION) LIGHT SOURCE (CATHODE) CROSSOVER POINT

Figure 15. The focusing of an electron beam is similar to the action of a

lens on a beam of light.

The electrons which pass through the grid, because of the pulling forces exerted by the positive charges on the accelerating electrodes, converge into a narrow beam. This convergence is due to the relatively high negative potential at the grid which makes each forward traveling electron move toward the axis of the electron beam. The cumulative actions of the electrical fields at the grid and at the pre-accelerator electrode causes the paths of the electrons, which pass through the grid, to meet and cross over at point P as shown in Figure 14. This point is called the "crossover point" and is between the grid and the pre-accelerator electrode.

The field between the grid and the pre-accelerator electrode acts on the electron beam in a manner similar to the action of a lens on a beam of light. In fact, the substitution of an "electrostatic" lens for the grid and pre-accelerating electrode, as shown in Figure 15, may help the reader to understand the action of these electrical fields in narrowing down the electron beam to the crossover point.

2-18 The Pre-Accelerator. In early cathode ray tubes the focusing electrode was located right in front of the control grid.

With this type of construction, adjustments of the voltage on the focusing electrode effected the grid action and changed the intensity of the electron beam. In more modern tubes this interaction is prevented by the pre-accelerator electrode which is inserted between the control grid and focusing anode, as shown in Figure 16. The pre-accelerator is connected directly to the second anode and provides the initial acceleration of the electron beam.

Figure 16. The pre-accelerator electrode is inserted between the control

grid and the focusing anode.

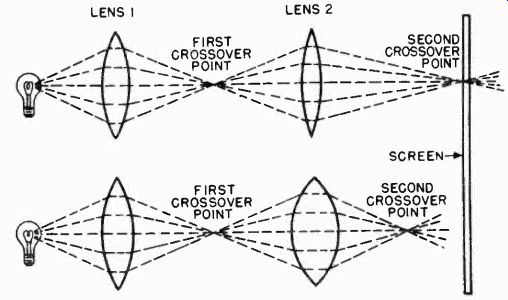

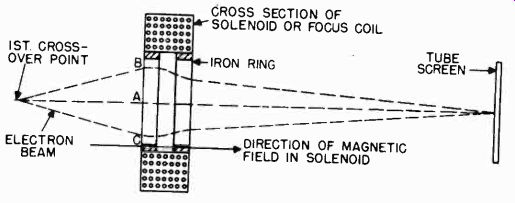

Focusing Electrode. After the electrons converge at the crossover point, they begin to spread out again. A means had to be provided to force the electrons back to the axis of the tube and retain the narrow beam until it reaches the screen. Two methods are used in modern picture tubes to focus the beam in this manner. They are called (1) electrostatic focusing and (2) electromagnetic focusing. The term focusing is used because of the similarity to the focusing of a light beam by an optical system.

Electrostatic focusing is most easily understood by referring to an optical analogy of the action of an electrical field on an electron beam. With a lens, light rays can be made to converge to a point and afterwards they will begin to diverge again. The diverging beam can then be made to converge once more, by introducing another lens as shown in Figure 17.

By substituting lenses of different curvatures for the second lens, the distance to the second crossover point can be varied.

If a screen is located a certain distance away, the light rays can be made to cross over, or focus, at the screen by the proper selection of lens curvature.

Figure 17. The distance to the second crossover point is determined by the

curvature of lens 2.

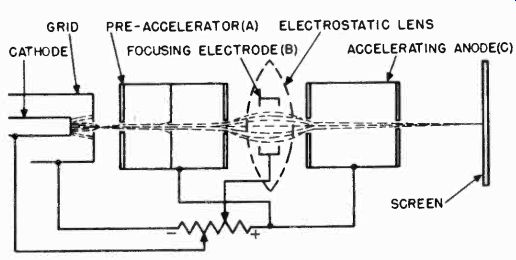

GRID PRE-ACCELERATOR(A) ELECTROSTATIC LENS CATHODE 1 FOCUSING ELECTRODE(B) ACCELERATING ANODE(C)

Figure 18. The electrostatic field inside the focusing electrode focuses

the electron beam to a second crossover point.

If an "electrostatic lens" and an electron beam are substituted for the optical system and light beam, electrostatic focusing can be illustrated as in Figure 18. As the beam of electrons leaves the pre-accelerator assembly, it is diverging. This divergence is caused by the fact that the focusing electrode, (b), is more negative than the pre-accelerator, (a). The repelling force set up by the more negative focusing electrode slows up the electrons and makes them scatter. As the diverging electrons pass from the focusing electrode, (b), into the field between the focusing electrode and the accelerator, (c), their speed is once more increased, since the accelerating anode is more positive than the focusing electrode. The electrostatic field again acts in the manner of a lens and focuses the electron beam to a second crossover point. This crossover is adjusted so that it occurs at the screen.

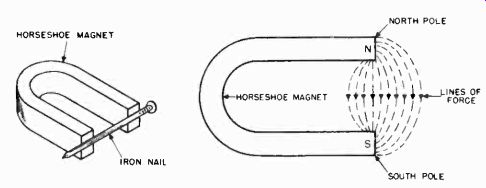

HORSESHOE MAGNET

Figure 19. Left, the magnetic field between the poles of the horseshoe magnet

pulls the nail to the magnet. Right, the lines of force around a horseshoe

magnet.

The electrostatic focusing action must take place for many different beam currents. These differences in beam current are caused by the potential on the grid. To compensate for this, the potential on the focusing electrode is made variable so that the electrostatic fields on each side of it may be made weaker or stronger to permit the focusing of smaller or larger amounts of beam current.

2-20 Electro-Magnetic Focusing. Electro-magnetic focusing is another method that is used to focus the stream of electrons to a point on the screen. Whereas in electrostatic focusing the focusing action is accomplished by applying d-c voltages to the electron gun in the manner previously discussed, electromagnetic focusing is accomplished by placing a coil of wire over the neck of the picture tube, and passing a d-c current through the coil. Electromagnetic focusing action may be more easily understood by reviewing the basic theories of magnetism.

Between the ends or poles of a horseshoe magnet, such as shown in Figure 19A, there exists a field of magnetic force.

The existence of this field can be demonstrated by holding an ordinary iron nail near the poles of the magnet. As the nail is brought close to the poles, the magnetic field will pull the nail to the magnet. When the nail is some distance from the magnet (outside of its magnetic field), there is little pulling action. The extent of the magnetic field surrounding the magnet is determined by the degree to which the metal in the magnet is magnetized.

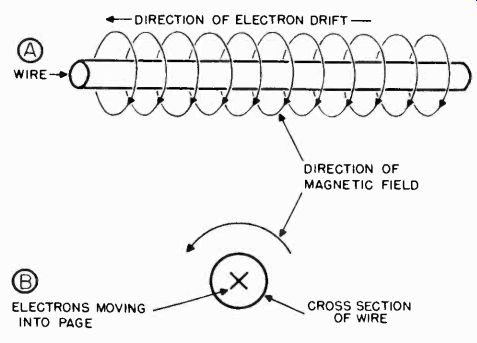

Figure 20. Direction of electron current flow in, and direction of magnetic

field surrounding, a wire.

In an attempt to picture a magnetic field, it is assumed that it consists of lines of force or flux. The lines of force around the horseshoe magnet are shown in Figure 19B. Notice that the flux extends in one direction from one pole to another. The pole at which the lines originate is called the north pole, and the pole at which they terminate is called the south pole.

A similar magnetic field surrounds electrons. An ordinary metal wire is made up of atoms which contain electrons. As explained above, each magnetic field has a definite direction; that is, the lines of force travel from one point to another. When no current flows through a wire, the electrons in it lie at random, and the directions of the magnetic fields around the electrons are so different from each other that they effectively cancel out. The net effect is that no magnetic field is set up outside of the wire. However, when a current flows through a wire as shown in Figure 20A, the electrons flow in one direction only.

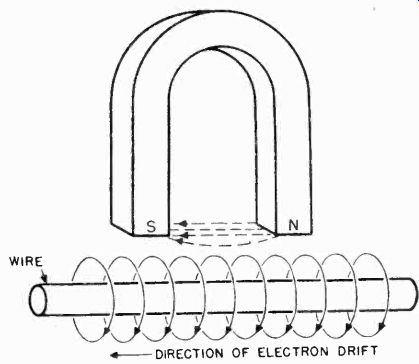

Figure 21. A wire which is parallel to the magnetic lines of force set up

by a horseshoe magnet is not influenced by the magnet.

Since the electrons all move in the same direction, their magnetic fields all act in the same direction. This direction is around the axis of the wire. The accumulative effect of the magnetic fields of the electrons acting in the same direction, is the creation of a magnetic field around the wire. Looking at the wire along its axis, as shown in Figure 20B, if the current were going into the page as indicated by the x, the magnetic flux would flow in a circle around the wire in a counter-clockwise direction.

If the current in the wire were flowing in the opposite direction, the magnetic flux would flow clockwise.

From the previous discussion, it has been shown that magnetic fields can be produced by two methods:

1. By magnetizing certain metals such as iron (a horseshoe magnet).

2. By sending a current in one direction through a wire.

When a number of fields of magnetic force are merged, they either add to create a more powerful field or cancel each other, resulting in a diminished field. The factor which determines whether they will add or cancel is their direction or polarity.

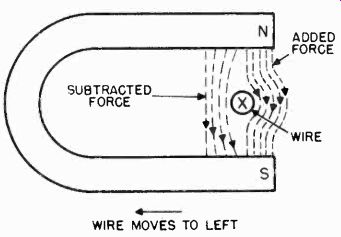

WIRE MOVES TO LEFT

Figure 22. Wire placed at right angles to the lines of force from the horseshoe

magnet.

Suppose a wire with a d-c current flowing through it were placed near the poles of a horseshoe magnet, as shown in Figure 21. The wire is parallel to the magnet lines of force set up by the horseshoe magnet. Under these conditions, the magnetic field surrounding the wire is at right angles to the horseshoe's magnetic field. The two fields neither aid nor oppose each other, and therefore, they will not influence one another.

If the wire is now placed at right angles to the lines of flux from the horseshoe magnet, the fields will be in the same direction on one side of the wire, and in opposite directions on the other side. Looking at the end of the conductor, the fields appear as in Figure 22. To the right of the wire, the magnetic fields from the horseshoe magnet and from the current flowing in the wire are in the same direction. To the left of the wire, the directions of the two fields oppose each other. The result of this opposition to the left of the wire and reinforcement to the right of the wire is that of forcing the wire to the left.

If an electron beam is substituted for the wire with current flowing in it, a similar action will take place, and the beam will be forced into a different path, because a magnetic field surrounds the electron beam in exactly the same manner as it does a wire carrying a direct current (Figure 23). An electron beam flowing in the direction indicated and at right angles to a magnetic field will be forced to the left just as was the wire in Figure 22.

Figure 23. Direction of magnetic field set up by an electron beam.

SOLENOID DIRECTION OF MAGNETIC FIELD

Figure 24. Direction of magnetic field in a solenoid.

The ability of a magnetic field to move an electron-beam from its path when the beam is traveling at right angles to the field is the principle upon which magnetic focusing is based.

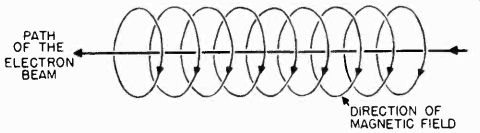

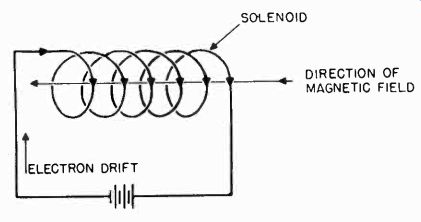

In magnetic focusing, an electro-magnet is used instead of a permanent one. An electro-magnet consists of many turns of wire wound in the shape of a coil. Such a coil of wire is called a solenoid. If current flows through a solenoid, the addition of the magnetic fields created around each turn of wire results in lines of force which travel along the axis of the solenoid, as shown in Figure 24. If this solenoid is fitted around the neck of a cathode ray tube in which electrons are flowing, there will be two sets of magnetic fields in action: (1) the field due to the electron beam, and (2) the field due to the current flowing in the solenoid. As shown in Figure 25, electrons (A) traveling along the axis of the solenoid are not affected since the field due to the electrons is parallel to the magnetic field of the solenoid.

Electrons which are diverging from the axis of the tube are affected (B and C). The magnetic field due to the diverging electrons is reinforced on one side but opposed on the other side, and thus the electrons are forced back to the axis of the tube.

Since the electrons are moving forward, in addition to the side motion resulting from the field surrounding the solenoid, they follow a spiral path through the magnetic field created by the focusing coil. After leaving the magnetic field surrounding the solenoid, they continue to approach the axis of the tube. Electrons (A), (B), and (C), therefore, converge again.

By properly locating the solenoid (referred to as the focusing coil) and correctly adjusting the current through the coil, the paths of electrons passing through the coil can be changed so that all of the electrons meet at the screen to form a small, "focused" spot. If the current in the coil or the location of the coil is changed, the beam will no longer be focused on the screen.

FIELD IN SOLENOID

Figure 25. Focusing of an electron beam by a magnetic field inside of a solenoid.

2-21 Focus Coil Construction. Commercial focus coils (Figure 26) are made by winding many turns of wire around a soft iron core. An air gap is left in the center of the iron core (Figure 25) to concentrate the lines of flux at the center of the focus coil. By concentrating the flux in this manner, stray magnetic fields around the coil are reduced and are less likely to magnetize the elements of the electron gun. Concentration of the field increases the efficiency of the coil and reduces the direct current required to set up a sufficiently strong focusing field.

Figure 26. A commercial focus coil. (courtesy RCA)

In practice, the focus coil is moved along the length of the tube neck to obtain the best focusing of the beam on the screen.

Fine adjustments of the focusing action are made by changing the current flowing through the coil.

2-22 Electromagnetic Focusing vs. Electrostatic Focusing.

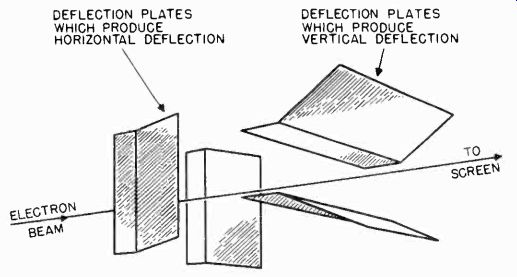

Since the use of electromagnetic focusing eliminates the need for a focusing electrode, the electron gun structures used in magnetic tubes are simpler and more economical than those used in electrostatic tubes. The focusing action secured with the electromagnetic focusing system is generally better than that obtained with electrostatic focusing. Electromagnetic focusing usually gives a smaller minimum spot size. This is a distinct advantage as the reader will realize later.

2-23 Deflecting the Electron Beam. Part of the job of creating a television picture on the screen of a picture tube consists of moving or "deflecting" the electron beam from side to side and from top to bottom of the screen. Two methods have been devised to provide the control over the electron beam necessary to accomplish this horizontal and vertical deflection. The two methods used are called (1) electrostatic deflection and (2) electromagnetic deflection. The functioning of both of these deflection systems is similar to that of the related methods of electron beam focusing.

DEFLECTION PLATES WHICH PRODUCE HORIZONTAL DEFLECTION

BEAM DEFLECTION PLATES WHICH PRODUCE VERTICAL DEFLECTION

Figure 27. Two pairs of deflection plates mounted at right angles to each

other.

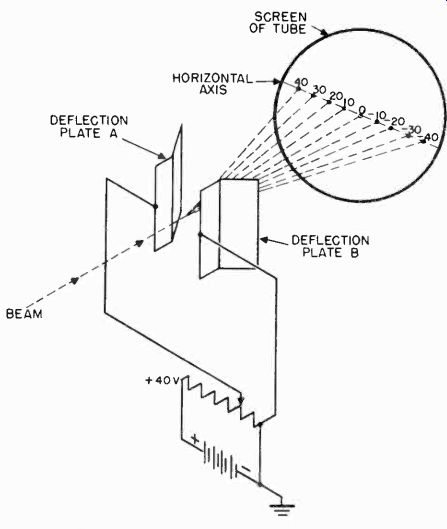

2-24 Electrostatic Deflection. In the description of focusing systems, it was explained that electrons carry a negative charge and are therefore attracted by positively charged bodies and repelled by negatively charged bodies. It follows then that if a positively charged body is brought close to an electron beam, the beam will be drawn toward it and conversely that the beam will be forced away from a negatively charged body. This is the principle upon which electrostatic deflection is based.

2-25 Electrostatic deflection of the electron beam in a picture tube is accomplished by mounting two pairs of metal plates between the electron gun and the fluorescent screen. The pair of plates which deflect the beam vertically are mounted one above the other and are referred to as the vertical deflection plates.

The pair of plates which deflect the beam horizontally are mounted side by side and are known as the horizontal deflection plates.

The designations "vertical" and "horizontal" indicate the direction in which the plates, referred to, move the beam and not to the physical orientation of the plates themselves.

Figure 27 shows two pairs of deflecting plates. The two pairs of plates are mounted at right angles to one another. The ends of the plates nearest the screen are bent outward toward the wall of the tube. This bending is necessary so that the beam will not strike the sides of the plates when it reaches the extreme angles of deflection.

Figure 28. The electron beam is moved horizontally when a d-c potential is

applied to the horizontal deflection plates.

With the plates mounted in the tube, it is only necessary to place a potential across the proper pair of plates to secure vertical or horizontal deflection of the beam.

Figure 29. The horizontal and vertical deflection plates, with separate sources of voltage connected to them.

Figure 28 illustrates a pair of horizontal deflection plates across which a variable potential has been placed. When the potential across the plates is zero, the beam is not deflected and strikes the screen at 0.

If the variable resistor is adjusted toward the positive end so that a 10 volt potential difference exists between the plates, the beam will be deflected and will strike the screen at the point marked 10. The deflection takes place in the direction of plate A because it is the positive plate. If the potential difference is increased to 20 volts, the angle of deflection will be increased, and the beam will strike the screen at the point marked 20. If the voltage is increased to 30 and again to 40, the point at which the electron beam strikes the screen will move to the point marked 30 and then to the point marked 40. If the leads from the battery are reversed so that deflection plate B becomes the positive plate, the beam will be deflected in the opposite direction. By following the procedure previously outlined, the beam can be made to strike the screen successively at the points marked -10, -20, -30, and -40.

Figure 30. The electron beam traces out a vertical line when a high frequency

sine wave is applied to the vertical deflection plates.

The operation of the vertical deflection plates is identical to that of the horizontal plates except that the plates are mounted one above the other and therefore cause the beam to be deflected up or down. If the upper plate is made positive, the beam will be deflected upward; and if the lower plate is made positive, the beam will be deflected downward.

Figure 29 shows both horizontal and vertical deflection plates.

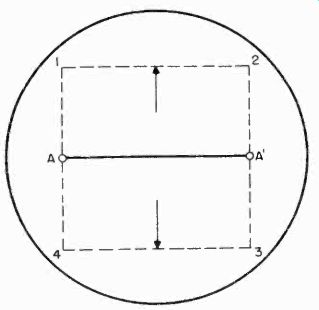

Separate sources of voltage are shown connected across each set of plates. The horizontal plate A and the vertical plate C are positive and as a result, the beam is deflected upward and to the left simultaneously. If the voltage across the horizontal plates is the same as that across the vertical plates, the beam will move between 1 and 2 in the figure as the voltages are increased equally. The beam can be positioned to any part of the screen by applying deflecting voltages of the correct polarity and amplitude.

Figure 31. Raster pattern traced out by two sine waves, of equal amplitude,

but of different frequency, which are applied to the vertical and horizontal

deflection plates.

The cathode ray tube is sometimes used as an indicating device to measure voltages. A voltage to be measured is applied to one set of deflection plates. The position to which the spot is deflected on the screen is directly related to the magnitude of the voltage on the deflection plates, and by measuring the distance the spot has moved, the voltage on the plates may be determined.

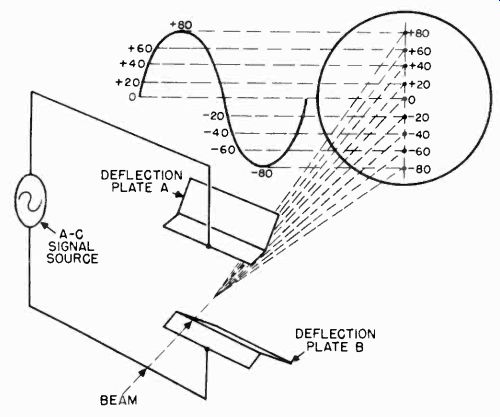

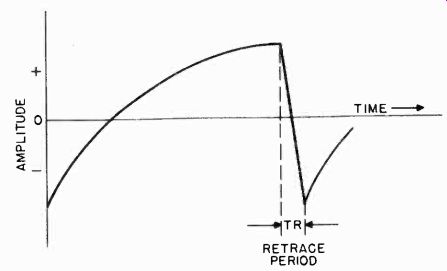

For television purposes, very rapidly varying voltages are applied to the vertical and horizontal deflection plates. To illustrate the effect of a varying voltage on one pair of plates, Figure 30 shows a sine wave voltage connected to the vertical plates. In a single cycle, the voltage starts at zero, increases to a positive maximum of 80 volts, reduces to zero again, falls to minus 80 volts, and returns to zero once more. With this signal applied to the plates, the electron beam will move under its influence and trace out a vertical line. If the sine wave is of low enough frequency (less than 10 cycles/sec.), the beam will move up and down slowly, and the human eye will detect its movement. If a sine wave of higher frequency is applied (about 60 cycles/sec.), the eye will no longer detect the movement of the beam, and the path traveled by the spot will appear as a straight line on the screen.

If a similar voltage is connected to the horizontal plates of a cathode ray tube, a horizontal line will be traced out by the beam.

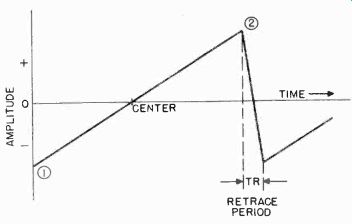

Figure 32. A sawtooth voltage.

If alternating voltages of the same amplitude, but of greatly different frequency, are applied simultaneously to both the vertical and the horizontal deflection plates, the pattern on the screen will no longer be a line, but a square. This may be explained with reference to Figure 31. The line A-A' represents the pattern which is obtained if a varying voltage is applied to the horizontal deflection plates only. Imagine now that another varying voltage is applied to the vertical plates at the same time. The result will be the moving of line A-A' up and down at the frequency of the vertical deflecting voltage. If this frequency is greater than 10 hz, the eye will not detect the movement of the line and the screen will appear to be illuminated over an area bounded by points 1, 2, 3, and 4. The action of the electron beam in tracing out the square pattern is known as "scanning". The illuminated pattern which appears on the fluorescent screen by virtue of this scanning action is known as a "raster".

Figure 33. Illuminated pattern produced by applying sawtooth voltages, of

different amplitudes, to the deflection plates.

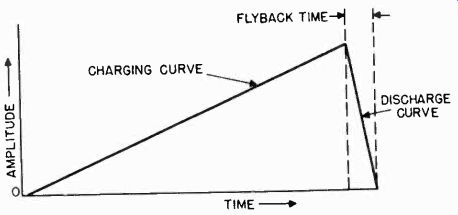

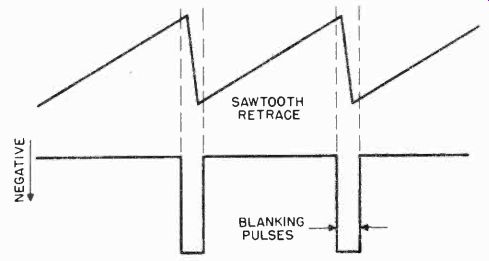

2-26 Sawtooth Wave. In television, sine wave voltages are not used to secure the scanning action. For reasons which will be apparent later, it is desirable to use a deflecting signal which will move the beam from left to right and then, almost immediately, return it to its original position. The same is true for vertical deflection where it is desirable to move the beam from the top of the raster pattern to the bottom and then return the beam very quickly to the top again. The deflecting voltage which meets these requirements is shown in Figure 32. Such a signal is called a "sawtooth" because of its shape. If such a voltage is applied to the horizontal deflection plates of a picture tube, the beam will move across the horizontal axis at a uniform rate of speed during the rising portion of the curve. The beam will return rapidly to its original starting point when the sawtooth voltage drops back to zero. The time consumed during the return is known as the "flyback time" or "retrace time".

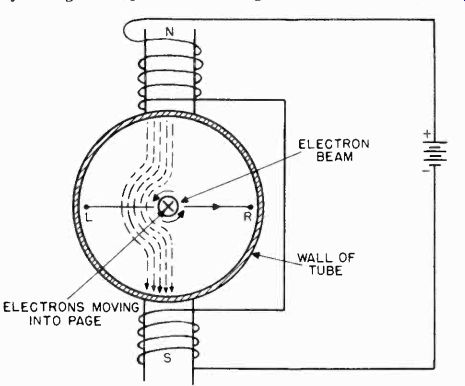

ELECTRONS MOVING INTO PAGE

Figure 34. Method of magnetically deflecting the electron beam.

A sawtooth voltage is also applied to the vertical deflection plates. When vertical and horizontal sawtooth voltages act on the beam simultaneously, an illuminated pattern, such as shown in Figure 33, is obtained. This pattern is not square, as that shown in Figure 31, because the vertical sawtooth voltage is not as large as the horizontal sawtooth voltage. Later the part which the sawtooth voltages and the scanning raster play, in creating the television picture on the screen, will be explained.

2-27 Electromagnetic Deflection. Electromagnetic deflection requires the use of coils to influence the beam as does electromagnetic focusing. Figure 34 shows a cross-sectional view of the neck of a picture tube with a pair of solenoids positioned to effect horizontal deflection of the beam. Current flows from the battery through the top coil then through the bottom coil and back to the battery. The coil is split into two parts, each of which is connected in series and placed on a different side of the picture tube. The current through the coil sets up a magnetic field as indicated by the lines of force. In the figure, the electron beam traveling through the center of the tube is going into the page as indicated by the x. The magnetic field, due to the travel of the electron beam, is reinforced by the lines of force from the external field on the left side, while on the right hand side, the fields oppose. This causes the beam to be forced to the right. Similarly, another set of deflecting coils placed perpendicular to the coils, shown in the figure, will deflect the beam up or down, depending upon the direction of the magnetic field surrounding the coils. Since the current through the coils determines the direction of the magnetic field, it also determines the direction in which the beam is deflected.

When magnetic deflection is used, the magnetic field must vary in strength and direction in a manner similar to the varying voltages on the plates of an electrostatically deflected tube. It has been shown that electrostatic deflecting voltages have a saw tooth shape for television scanning. The strength of the magnetic field must also increase and decrease in a sawtooth fashion. Since the magnetic field surrounding a coil is proportional to the current in the coil, the deflecting current will likewise have a sawtooth shape.

Figure 35. A commercial yoke.

Coils used for electromagnetic deflection consist of many turns of wire and are called solenoids, as in the case of electromagnetic focusing. In order to make a neat and compact arrangement, the vertical and horizontal deflecting solenoids are placed in a cylindrical container called a "yoke". The shape and configuration of the deflection coils in a commercially manufactured yoke are shown in Figure 35.

2-28 Magnetic Focusing vs. Magnetic Deflection. So that the reader will not confuse the action of magnetic fields in focusing the electron beam with the deflecting action, the following is a review of both. In magnetic focusing, the lines of flux around the solenoid placed over the neck of the tube, are parallel to the axis of the tube. A d-c current is fed to the focusing coil to force electrons back to the axis of the electron beam. In magnetic deflection, the lines of flux surrounding the deflecting coils are perpendicular to the axis of the tube. A varying current in the vertical and horizontal deflection coils moves the entire electron beam up and down, or left and right.

The yoke is positioned between the focus coil and the point where the neck joins the funnel portion of the tube, as shown in Figure 36. The electron beam is therefore focused before it reaches the deflection coils. Once the beam has been focused, the deflection coils impart vertical or horizontal motion to it.

Figure 36. Positions of yoke and focus coils on the neck of a picture tube. (courtesy

DuMont)

2-29 Electromagnetic vs. Electrostatic Deflection. Electromagnetic deflection is preferred over electrostatic deflection when a large diameter picture tube is used. This choice is based mainly on the cost of the circuits necessary to generate the saw tooth voltages or currents which deflect the electron beam. With the larger cathode ray tubes, greater accelerating voltages are necessary in order to obtain a sufficiently intense spot on the fluorescent screen. Since the beam is traveling faster, it is more difficult to deflect. If electrostatic deflection is employed with a large tube, sawtooth voltages of very great amplitude are necessary. It is difficult to build circuits which can generate large sawtooth voltages, while large sawtooth currents can be generated with relative economy. With tubes ten inches and larger in diameter, magnetic deflection is preferred; however, in small tubes, seven inches or less in diameter, electrostatic deflection is used because small sawtooth signals are required to deflect the beam, and the electrostatic system is quite inexpensive. Electrostatically deflected tubes are invariably electrostatically focused. A few magnetically deflected tubes, such as the 5TP4, are electrostatically focused.

2-30 Fluorescent Screens. As mentioned previously, the screen of the picture tube is used to produce a visual pattern of the movement of the electron beam. If a screen were not used in a picture tube, a slight glow would be visible where the electron beam struck the glass face of the tube, even though the beam itself is invisible. The glow would not be satisfactory for viewing purposes and, therefore, a screen material is necessary to produce a bright image on the face of the tube. The screen material used is of such a nature that it glows when bombarded by electrons. Some of the chemicals which react in this manner are zinc orthosilicate, calcium tungstate, and zinc sulfide. The intensity and color of the light emitted by a fluorescent screen depends upon: 1 the chemical used in the coating; 2 the thickness of the coating; 3 the velocity of the electrons striking the coating; 4 the number of electrons which strike the coating (beam current); and 5 the length of time that the beam remains in one position on the coating.

The term "fluorescence" was introduced previously in the discussion of picture tube screens. (Section 2-12). Fluorescence is the property of the screen which causes it to glow when it is bombarded by the electron beam. In describing picture tube screens, the term "phosphorescence" is also used.

Phosphorescence is a property of the screen material which causes it to glow after the electron beam has been removed.

The term "persistence" is used when referring to the phosphorescent property of the screen. A screen which glows for a comparatively long time after being struck by electrons is said to have along persistency, and a screen which glows for a short time is said to have a short persistency. The persistence of the picture tube screen is important in television, since a certain amount of persistence is desirable to make the television pattern appear stationary to the human eye. As the electron beam moves across the screen, it lights up successive points. Because of the phosphorescent quality of the screen material, the points on the screen glow until the beam scans across them again. This enables the eye to retain an image of the spot between successive scans.

Cathode ray tubes are made with screens which have persistencies of from a few microseconds to as long as several minutes. The persistence and color of the glow of screen materials are designated by letters and numbers. For example, a Pl screen has a green fluorescence with a medium persistence.

The P4 screen, used mainly in television, has a white fluorescence and medium persistence. This screen is preferred for television because it produces a black and white picture. Other types of screen are the P7, which has a blue fluorescence and a long yellow phosphorescence, and the P5 and P11 screens, which are blue fluorescent and have a short persistence. The P1, P7, P5, P11, and several other screens are found in tubes used in cathode ray oscillographs.

Figure 37. Forming an image on the screen.

2-31 Tube Nomenclature. The nomenclature used for cathode ray tubes has been standardized so that the numbers and letters refer to certain characteristics. The first number -- 5, 7,10, 12, 15, etc. -- indicates the diameter of the screen in inches. This number is followed by a letter A, B, C, etc. which is assigned to indicate the order in which the tube was developed with respect to tubes of the same diameter. Following this letter is the letter P, which stands for phosphor and another number 1, 2, 4, etc. which identifies the type of screen. Examples of picture tubes in use today are the 10BP4, 12JP4, and 15AP4. Illustrating the nomenclature, the 15AP4 tube type has a screen 15 inches in diameter; the "A" indicates that it was the first commercial 15 inch diameter tube to be developed; and the P4 designates the screen as being of the white fluorescent type preferred for use in television receivers.

2-32 Forming an Image on the Screen. If the proper potentials are applied to the elements of the electron gun of a picture tube, an electron beam will be formed. This beam will pass through the tube and strike the screen where, if the beam is properly focused, a small pinpoint of light will appear.

If, in addition to the above, sawtooth signals of sufficient amplitude are applied to the horizontal and vertical deflection plates, a raster will appear on the screen. As described in Section 2-25, a raster is a rectangular pattern of light which appears on the screen when the beam is scanned back and forth and up and down the face of the tube.

In order to form an image on the screen, an additional element of control over the beam is necessary. The number of electrons in the beam must be increased and decreased as the beam moves across the screen. Changes in the number of electrons in the beam will cause some parts of the screen to glow more brightly than others. If the number of electrons in the beam is varied in the proper way, an image will be formed on the screen.

The control, necessary to change the number of electrons in the beam, is provided by the grid. If the potential on the grid is varied, the number of electrons passing through the grid will vary. This function of the grid was described in Sections 2-16 and 2-17.

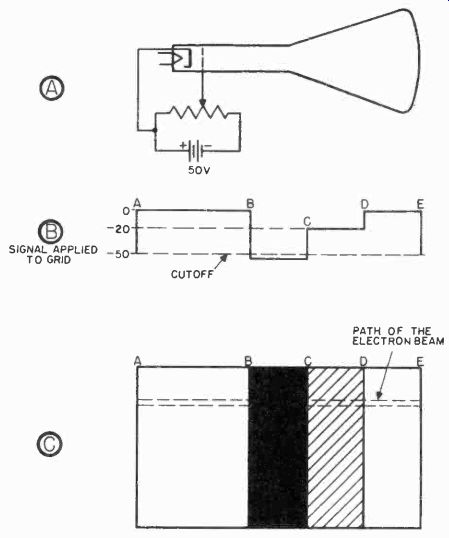

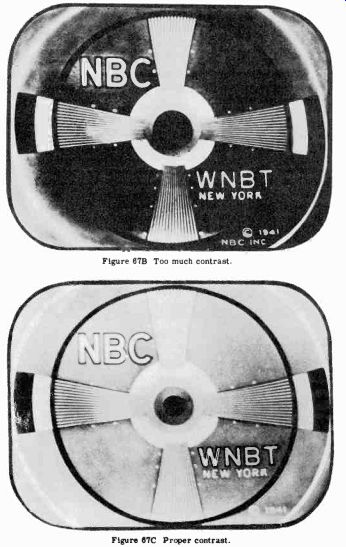

Figure 38. Grid voltage variations necessary to form one line of a picture.

To illustrate the operation of the tube in forming an image on the screen, assume that a battery and a variable resistor are connected to the grid of a picture tube, as shown in Figure 37A. Assume, also, that sawtooth voltages are being applied to the deflection plates and a raster is being formed on the screen of the tube. When the variable resistor is adjusted to place-50 volts on the grid, the electron beam will be completely cut off, and the screen will be dark. When the resistor is adjusted so that no voltage is placed on the grid, a great many electrons will pass through the grid and the screen will glow brightly. At voltages between zero and-50 volts, the screen will glow with varying degrees of brightness, which can be represented as shades of grey.

If, as the beam is deflected across the screen from left to right, the potential on the grid is varied as shown in Figure 37 B, a portion of the pattern shown in Figure 37C will be formed. The portion formed will consist of a thin horizontal line.

As the beam scans across the screen from point A to point B, the potential on the grid is zero and the screen will glow brightly. At the moment the beam reaches point B, the voltage on the grid is reduced to-50 volts. This causes the beam to be completely cut off, and the screen does not glow until point C is reached. At this point, the voltage on the grid is raised to-20 volts. Sufficient electrons reach the screen under this condition to cause it to glow dimly, as represented by the grey portion of Figure 37C. The voltage on the grid remains at-20 volts until the beam is scarped to point D. When point D is reached, the potential on the grid is again zero and the screen glows brightly between points D and E. By this process, one line of the pattern of Figure 37C is formed. When the line has been completed, the action of the saw tooth signal present on the vertical deflection plates moves the beam down slightly. At the same time, the sawtooth signal on the horizontal plates returns the beam, almost immediately, to the left side of the screen. The beam then moves from left to right and another line is formed. This process is repeated until the complete pattern has been formed. All of this takes place in a very short period of time.

It will be remembered that due to the persistence of the screen, it continues to glow after the electron beam has passed over it.

This property of the tube in combination with the persistence characteristic of the eye enables the observer to retain the upper portion of the image while the lower portion is being formed.

After the complete image has been formed, it fades out very rapidly.

The pattern in Figure 37C is a very simple one, but its formation is essentially the same as that of the complex pictures normally encountered in television. Figure 38 shows a complex picture and the grid voltage variations necessary to create one line of it. Note that each line of this picture is different and requires a different group of grid voltage variations to bring about its formation. This is the only difference between the pattern of Figure 37C and the picture of Figure 38.

The picture tube is used in television receivers, where it reproduces scenes transmitted by the television station. Before a scene can be transmitted over the air it must be transformed into an electrical signal. The major part of the task of transforming a scene into a television signal is performed by the camera tube.

THE CAMERA TUBE

Several types of cathode ray tubes have been devised for the purpose of picking up the television picture. The iconoscope is treated first because an understanding of its operation will prove helpful when discussing other types of camera tubes, such as the orthicon, the image dissector, and the mono-scope, which are described in Section 4.

The function of the iconoscope in the television system can be compared to that of the microphone in conventional radio system. The microphone picks up sound and transforms it into an electrical signal. In the television system, the iconoscope picks up light images and transforms them into electrical signals.

The iconoscope is similar in many respects to the cathode ray tube used in the television receiver, and the foregoing discussion of the picture tube applies in many cases to the operation of the iconoscope.

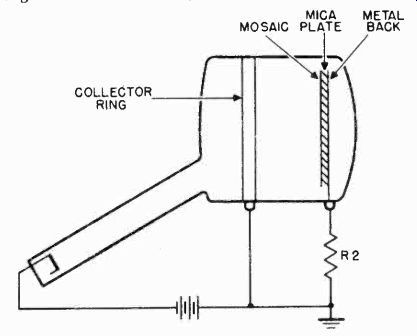

ELECTRON GUN COLLECTOR RINGS ANODE

CONNECTOR TO OUTPUT CIRCUITS COLLECTOR ANODE

Figure 39. Construction of the Iconoscope.

MOSAIC

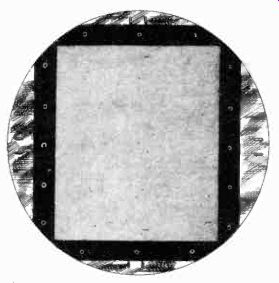

Figure 40. The mosaic of an iconoscope tube.

2-33 Iconoscope Construction. The modern iconoscope, Figure 39, consists of six major parts: a the glass envelope; b the tube base; c the electron gun assembly; d the deflection plate assembly; e the mosaic; and f the collector rings. The tube base, the electron gun assembly, and the deflection plates are the same as those in the picture tube. The shape of the glass envelope is quite different as shown in Figure 39. The important parts of the iconoscope which are not used in the picture tube are the mosaic and the collector rings. The mosaic is a sensitized plate which transforms light into an electrical signal. This signal is passed on to the collector ring, which is a conductive coating on the inside surface of the glass envelope.

2-34 The Mosaic. The mosaic is a mica plate coated with a metal film, as shown in Figure 40. The material used to coat the mosaic is a mixture of chemicals consisting mainly of silver oxide. The mosaic is actually covered with millions of small particles, each of which is insulated from its neighbor.

This structure is obtained by coating the silver oxide on the thin (0.001 inch) mica sheet, and baking the combination in an oven, until the heat transforms the silver oxide into pure silver. During the transformation, the silver forms into tiny particles or globules which are separated from each other by approximately 0.001 inch. the globules are made responsive to light by the addition of cesium vapor. The cesium vapor combines with the silver and forms a thin film around each globule.

The globules when treated in this manner are made responsive to light ("photosensitive"). When a treated globule is exposed to light, it gives off electrons in an amount proportional to the intensity of the light which falls on it. The back of the mica plate, known as the "signal plate," is coated with a conducting material such as aluminum. The aluminum is applied with a brush, spray, or similar method. The mosaic is suspended in the iconoscope by glass members which are molded into the glass envelope. A connection is provided to couple the signal plate to the outside circuit.

ELECTRON MOVEMENT

Figure 41. Each globule on the mosaic acts like a condenser.

The shape of the iconoscope tube is such that the electron stream from the electron gun strikes the same side of the mosaic as does the light from the scene being picked up.

2-35 Electrical Operation of the Mosaic. Two theories have arisen to describe how the electron beam, the light rays, and the mosaic function to form a television signal. An understanding of either theory would permit the reader to grasp the fundamental problems in forming an electrical signal from an optical signal. Both explanations will, however, be given here.

In both theories of the electrical operation of the iconoscope, the mosaic and the metal back of the mica plate are believed to act as millions of small capacitors, one plate of each capacitor being common to all of the others. The common plate is the metal backing. Tor the purpose of discussion, it is convenient to visualize one of these small capacitor elements, as shown in Figure 41. When light is focused on the mosaic, each globule emits electrons. The number of electrons emitted depends upon the amount of light to which each globule is exposed; that is, a globule emits more electrons when exposed to a lighter part of the scene than does another globule which is exposed to a darker portion of the scene. In emitting electrons, each globule becomes positively charged. In Figure 41, plate 1, which represents the mosaic, loses electrons and becomes positively charged. This action causes plate 2 to become negatively charged with respect to plate 1. Plate 1 attempts to acquire electrons from the nearest source available in an attempt to become neutral again. The negative plate 2 cannot neutralize the positive plate because of the insulated gap between them.

An electron beam which consists of negatively charged electrons can supply the charges necessary to neutralize the positive side of the capacitor. If an electron beam is allowed to impinge upon plate 1 of the capacitor, the negative charges on plate 2 of the capacitor will be repelled because the electron beam will neutralize or discharge the positive plate 1. The repelled charges, which are electrons, will flow through the resistor R, connected to plate 2. As a result of the current flow, a voltage will develop across the resistor which will be proportional to the original charge on the capacitor. Since the charge was a result of the light to which the capacitor was exposed, the voltage across R is proportional to the amount of light which fell on the capacitor. In this way, light is converted into an electrical potential.

Returning to the mosaic, each globule on the mosaic is a plate of a capacitor. When an image is focused on the mosaic, light rays fall on the globules. The intensity of the light rays falling on any particular globule depends upon the brightness of the part of the scene which is focused on the globule. Thus globules upon which light rays from bright portions of the scene fall, become more positively charged than globules upon which darker portions of the scene are focused.

It will be recalled that an electron gun is mounted in the iconoscope. The electron beam which is created by this gun is made to scan the mosaic in the same manner that the beam in the picture tube scans the picture tube screen. As the beam scans across the mosaic, the electrons in the beam strike each successive globule and equalize the positive charge created by light rays from the scene. As the charge on each globule is equalized, electrons leave the signal plate because it is effectively the opposite plate of a capacitor which has been discharged. The electrons flow through a resistor connected to the signal plate and set up a voltage across it. The voltage changes as the current through the resistor changes, which in turn changes as the electron beam scans across globules which have different positive charges.

The voltage across the resistor consists of a series of electrical impulses which represent the scene focused on the mosaic.

These electrical impulses are the television or "video" signal.

The electron beam which discharges the globules is actually much larger in diameter than a single globule. The diameter of the electron beam is approximately 0.01 inch, whereas the average diameter of a globule is approximately 0.001 inch. When scanning across the mosaic, the electron beam actually discharges many globules simultaneously. The signal which appears across the load resistor is then the average of the charges stored on a number of globules. A group of globules discharged at any one time by the electron beam is referred to as an "element". An element is the smallest area of the mosaic that can be resolved by the electron beam.

Figure 42. Path of electrons in iconoscope circuit.

In the above explanation, there must be a complete circuit around which electrons flow in order for it to be an accurate account of what happens on the mosaic. To satisfy the necessity for a complete circuit, electrons are said to travel from the electron beam to the mosaic, from the metal plate on the back of the mosaic, through the resistor, through the iconoscope power supply, to the cathode, as shown in Figure 42.

The second theory regarding the electrical operation of the mosaic succeeded the first one after it was learned that the current flowing through the load resistor was many times greater than the number of electrons which fell on each globule. The first theory does not explain where the extra electrons in the output circuit originated. The second theory accounts for this discrepancy and is generally accepted as the more accurate version.

The newer theory continues to assume that the mosaic is made up of tiny capacitor elements which are charged by exposure to light. From this point on, the theories differ.

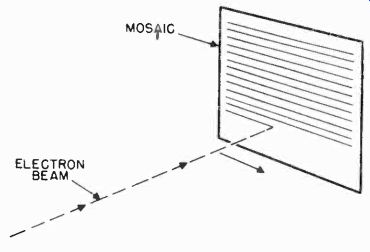

Figure 43. Scanning motion of electron beam across the mosaic.

As the scene being viewed is focused on the mosaic, the photosensitive globules emit electrons. The distribution of the emitted electrons, which accumulate in front of the mosaic, is an electrical reproduction of the scene, greater numbers of electrons being present in bright areas and fewer electrons in the darker areas.

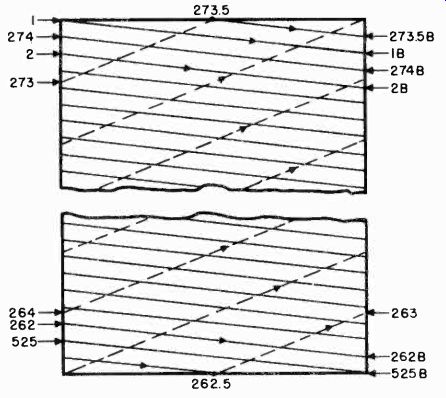

The beam of electrons from the electron gun sweeps over the entire mosaic in a number of successive movements from one side of the mosaic to the other, as shown in Figure 43. each movement or sweep across the mosaic is slightly lower than the previous one until the beam reaches the bottom of the mosaic. At this point, the beam is brought up to the top of the mosaic very quickly and repeats the sweep or "scanning" motion.

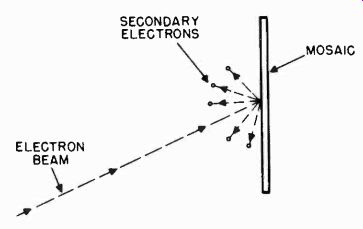

As the electron beam scans one globule, the beam strikes the globule with sufficient force to cause additional electrons, called "secondary electrons", to be knocked off the atomic structure of the globule, as shown in Figure 44.

The electrons, which are emitted by the mosaic due to the action of the light which is focused on the mosaic, collect in front of the mosaic in a sort of cloud, or space charge. The number of electrons in front of areas of the mosaic which are exposed to bright portions of the scene is greater than in front of areas exposed to the dark portions of the scene. When the electron beam scans across the mosaic and releases secondary electrons, the electrons in the space charge tend to repel the secondary electrons back to the mosaic. Since the space charge is stronger in front of strongly illuminated areas of the mosaic, fewer secondary electrons will be released from these areas.

Figure 44. Secondary electrons emitted by a globule on the mosaic.

Thus when the electron beam scans across areas of the mosaic which are highly illuminated, very few secondary electrons are emitted, and when the beam scans across dimly illuminated areas, many secondary electrons are emitted.

The secondary electrons flow to the collector ring through the load resistor where they set up a voltage which varies as the beam scans across light and dark portions of the image. This varying voltage is the video signal.

When a scene is focused on the mosaic, a few of the electrons which are released by photo-emission drift to the collector ring and thence to the load resistor. Since only a few reach the collector ring, the difference in potential between the mosaic and the collector ring is but a few volts. Most of the emitted electrons collect around the mosaic and form the space charge.

When the electron beam strikes a globule, the number of secondary electrons emitted is greatly in excess of those emitted due to light rays from the scene. This largely increased supply of electrons increases the difference in potential between the mosaic and the collector ring. Therefore, when the electron beam is striking globules, a much larger current flows through the load resistor than results from light rays. The variations in current are in exact synchronism with the motion of the electron beam as it passes over each element. The varying current through the load resistor of the iconoscope forms the picture signal which is transmitted to the receiver, and fed to the grid of the picture tube.

2-36 Iconoscope Efficiency. Only a small portion of the total number of electrons emitted by the mosaic find their way to the collector ring and pass through the load resistor. The electrons which leave the mosaic as a result of photo-emission and secondary emission go to one of three places: 1. they travel to the collector ring; 2. they are repelled by the other electrons which have been emitted before them and return to the globule from which they started; and 3. they are repelled by the electrons emitted before them and return to neighboring globules.

It is estimated that only 25% of the electrons which are emitted find their way into the field between the mosaic and the collector ring. Since the potential difference between the collector ring and the mosaic is small, between 15% and 20% of these electrons never reach the collector ring. Therefore, of all the electrons emitted, only 5% or 10% are used in forming the signal.

2-37 Bias Lighting. A method known as "bias lighting" has been developed to increase the efficiency of the iconoscope. As pointed out previously, a great many of the secondary electrons which succeed in escaping from the mosaic do not reach the collector ring because the difference in potential between the mosaic and the collector ring is very small. It has been discovered that many of these electrons collect on the glass wall of the envelope and remain there. The cesium oxide used during the manufacture of the tube not only collects on the mosaic but also on the walls of the envelope. The secondary electrons fall on this cesium oxide surface.

Figure 45. Uneven illumination of the test pattern caused by spurious secondary

electrons in the iconoscope.

The bias lighting method consists of placing small flashlight bulbs in the camera behind the iconoscope. The photosensitive mosaic is not affected by this light source since the bulbs are behind the signal plate. The light from the bulbs falls on the cesium oxide which has coated the inner surface of the glass envelope, and the electrons which have collected on the cesium oxide are released. In this manner, the electrons which were deposited on the walls of the envelope return to the vicinity of the collector ring. Since the electrons carry a negative charge, they increase the potential difference between the surface of the mosaic and the collector ring and increase the efficiency of the iconoscope. While the increase in efficiency is comparatively small, it is important because it increases the sensitivity of the iconoscope. The improvement in sensitivity makes it possible to reduce the intensity of the light on the scene to be televised.

Since the light which must be used is so intense that it is extremely uncomfortable for people to work under, and is also very costly, bias lighting brings about a worthwhile improvement.

2-38 Spurious Secondary Electrons. In addition to its inefficiency, another shortcoming of the iconoscope is the irregularity of illumination it produces on the picture tube in the television receiver. When light is not falling on the iconoscope mosaic, it would be expected that no image signal would appear at the load resistor. Actually, however, a signal does appear and produces the uneven shading shown in Figure 45. When a scene is televised, the uneven shading is superimposed on the picture.

The signals which cause this shading are thought to be secondary electrons which are given off by the mosaic when it is scanned by the electron beam. These secondary electrons accumulate around the mosaic and form an "electron blanket". Many of the electrons emitted during subsequent scannings are repelled by the electron blanket and return to the mosaic. These electrons do not return to their original globules, but "shower" back to others. The result is an uneven distribution of electrons because some portions of the mosaic accumulate more electrons than others. This process takes place whether or not an image is focused on the mosaic. The uneven electron distribution causes different potentials to be set up between the collector ring and various portions of the mosaic. When light from a scene to be televised is focused on the mosaic, the signal voltage developed across the load resistor is a result of the light from the scene, and of the unevenly distributed electrons in the electron blanket.

A way to partially overcome the effects of spurious secondary electrons has been devised. It consists of coupling a signal into the load resistor of the iconoscope to counter balance that portion of the video signal which is a result of spurious secondary electrons. The signal coupled to the load resistor is furnished by a "shading generator". A shading generator produces signals of several different waveforms. The waveform which gives the greatest improvement is selected by the studio technician who monitors the picture.

Figure 46. Keystoning occurs in the iconoscope because the electron beam

travels unequal paths from the gun to the mosaic.

KEY STONED PATTERN; UNDISTORTED PATTERN

Figure 47. A shows a keystone pattern. B shows correct scanning pattern,

obtained on mosaic when keystone distortion is eliminated.

TOP OF PICTURE BOTTOM OF PICTURE RETRACE TOP OF PICTURE TIME SOLID LINES-HORIZONTAL SWEEP SIGNALS DOTTED LINES-COMPENSATING SAWTOOTH

Figure 48. Compensating signal for overcoming keystoning.

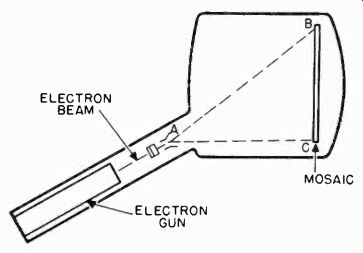

2-39 Keystoning. In the iconoscope, the electron beam and the scene being viewed are both focused on the front of the mosaic.

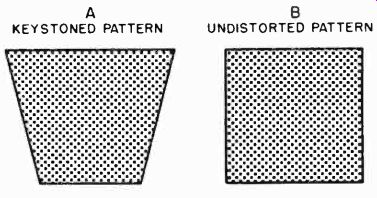

To accomplish this, the electron beam is projected toward the mosaic at an angle. In this way, the electron gun structure is mounted below the mosaic, leaving the area in front of the mosaic clear so that light rays from the scene to be televised can be focused directly on the mosaic. Because the electron gun is mounted in this manner, the electrons in the beam must travel further to reach the top of the mosaic than they do to reach the bottom of the mosaic. This is illustrated in Figure 46 where distance AB is greater than distance AC. Since the beam travels a longer path to reach the top of the mosaic, it has the opportunity to be deflected through a larger horizontal arc than it does at the bottom of the mosaic. As a result, the beam does not trace out a rectangular pattern, but a distorted shape as shown in Figure 47A. This pattern resembles a keystone, and thus the term "keystoning" has been given to the distortion of the image which occurs in the iconoscope.

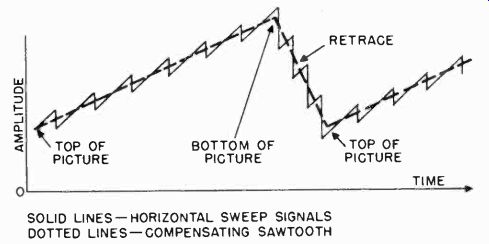

Keystoning of the image cannot be tolerated since it results in the transmission of a distorted picture. To eliminate the distortion, a compensating signal is combined with the sawtooth voltage which controls the horizontal movement of the beam in the iconoscope. The compensating signal is a sawtooth voltage, as shown in Figure 48. Note that the amplitude of the compensating signal increases as the beam travels downward toward the bottom of the mosaic. Therefore, instead of being constant, the signal which produces the horizontal deflection increases in amplitude as the beam moves downward. When the proper amount of compensation is introduced, the pattern scanned on the mosaic will appear as shown in Figure 47B.

VERTICAL DEFLECTION GENERATOR ELECTRON GUT ViEW. G SCREEN

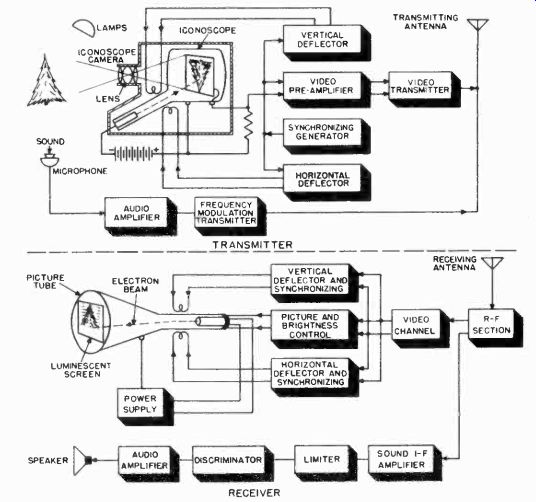

Figure 49. A simplified television system.

A SIMPLIFIED TELEVISION SYSTEM

2-40

In the transmitter and receiver, many tubes and circuits are used to perform the necessary functions of the electronic

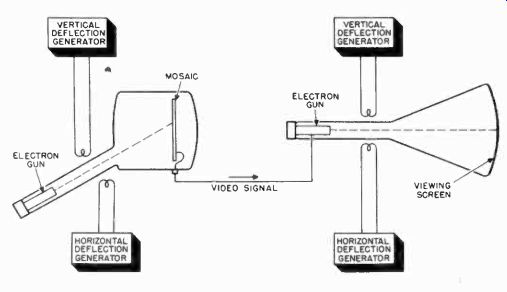

television system. While all of these tubes and circuits are important, a clearer understanding of the operation of the television system may be achieved if some of the elements of the system are disregarded and it is assumed that the television system consists of the units shown in Figure 49. Once the operation of the system is understood, the reader will realize the necessity for the additional components and circuits which link and surround the cathode ray tubes in the television camera and receiver.

The simplified system of Figure 49 consists of an iconoscope camera tube, a picture tube, and horizontal and vertical saw tooth deflection generators for both tubes. The mosaic of the camera tube is shown connected to the grid of the picture tube.

By simplifying the television system in this way it becomes much easier to visualize the actions which take place in an actual television system, even though the simplified version is not practical.

Assuming that the system of Figure 49 is in operation but that no image is focused on the mosaic in the camera tube, the following actions are taking place.

1. The electron beam in the camera tube is moving back and forth across the mosaic. At the completion of each excursion across the mosaic the electron beam is moved down slightly to begin scanning another line.

2. The electron beam in the picture tube is moving back and forth across the viewing screen. At the completion of each excursion across the screen the beam in the picture tube is moved down slightly to begin scanning another line. The motion of the electron beam in the picture tube is exactly the same as that of the electron beam in the camera tube.

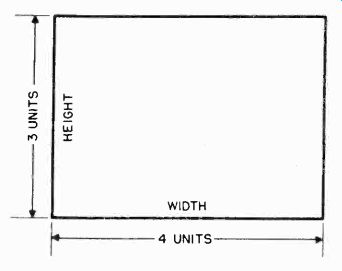

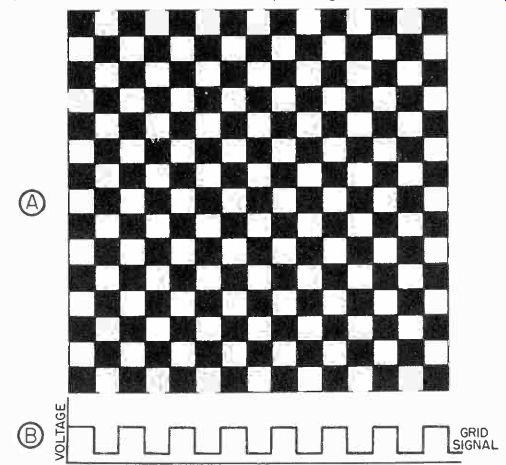

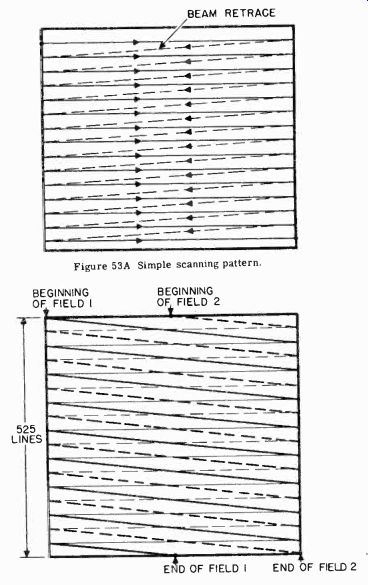

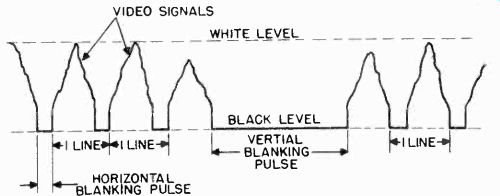

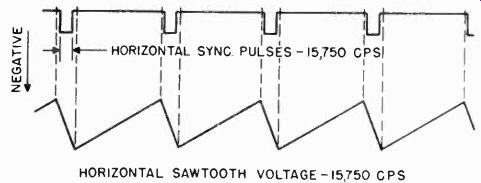

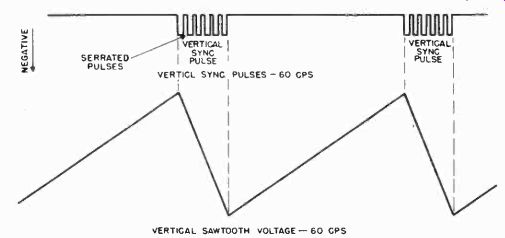

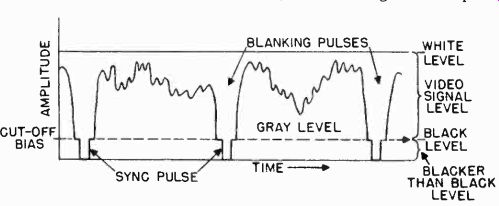

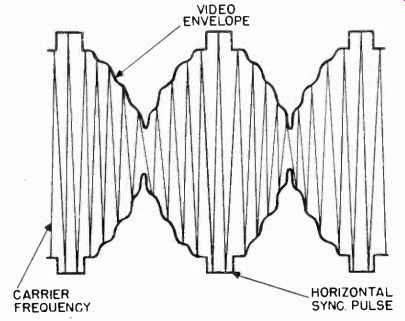

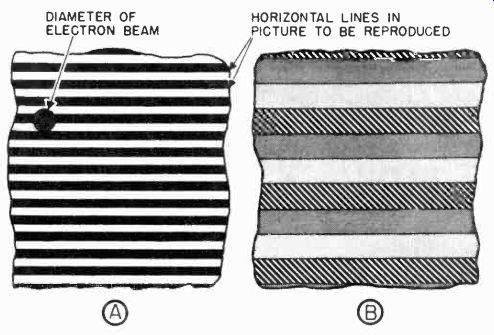

3. The sawtooth signals applied to the horizontal deflection coils of the camera tube and picture tube are of the same frequency (15,750 cps). The sawtooth signals applied to the vertical deflection coils in both tubes are also of the same frequency (60 cps). Because both horizontal signals and both vertical signals are equal, the electron beam in the camera tube moves in exact synchronization with the beam in the picture tube.