Troubleshooting -- Repair

Interpreting test patterns -- Alignment

9-1 The troubleshooting and repair of television receivers is a task requiring considerable skill. It should not be attempted without careful preparation. With a basic knowledge of television circuit design, and by application of systematic methods of service and use of proper test equipment, no real difficulties should be encountered.

The servicing of television receivers can be broken down into three separate operations:

1. Troubleshooting, 2. Checking and Adjusting, and 3. Alignment.

Troubleshooting is the determination of what is wrong with the receiver. Before repairing, adjusting, or aligning a receiver, the trouble must be isolated to a particular stage, and if possible to a particular component. Because of the complexity of a television receiver, troubleshooting procedures must be carried out in a systematic, organized fashion; otherwise, considerable time will be wasted in probing aimlessly from one circuit to another. Experience in servicing television receivers for the past few years has indicated that the majority of faults can be located quicker without test equipment and without the need for readjusting or aligning the circuit, if logical troubleshooting methods are used.

After a repair has been made, it is usually necessary to make one or more adjustments. For example, if the linearity control in the vertical sweep circuit is replaced, it must be adjusted to give a picture of proper vertical linearity.

The alignment of television receivers generally refers to the tuning of the amplifiers in the RF, video and sound circuits.

These circuits operate at high frequencies and their alignment is critically affected by component or wiring changes. Realignment is often required when a tube is replaced or because one of the fixed components has changed in value.

9-2 Test Equipment. Several pieces of test equipment have been developed for television servicing in order to simplify the task of troubleshooting, adjusting, and aligning. The operation and function of each of these instruments are described in detail in the Test Equipment section. It is well, at this point, to briefly outline the test equipment which applies to the three categories of television servicing.

For troubleshooting the receiver, a cathode-ray oscillograph is the most useful and versatile piece of test equipment. Discontinuities in circuits can be checked and the shapes of the various waveforms can be observed on the oscillograph. By recognizing certain characteristic oscillograms, the technician can readily determine the cause of a fault in a circuit.

A vacuum tube voltmeter is another useful instrument for troubleshooting. All operating voltages in the receiver may be checked with it to determine whether the power supplies are functioning properly and whether a faulty component is responsible for the wrong potential at a certain point in the circuit.

Shorted or open components and faulty wiring are best located with a multimeter. Other useful instruments for troubleshooting are a voltage calibrator for the oscillograph, a kilo-voltmeter for checking the high voltage power supply, a tube checker, and a resistance-capacitance bridge for testing critical components.

Most adjustments to the receiver can be made while observing a test pattern that is transmitted by a television station. When such a pattern is not available, it is possible to make most adjustments with a signal generator, oscillograph, square wave generator, and a vacuum tube voltmeter.

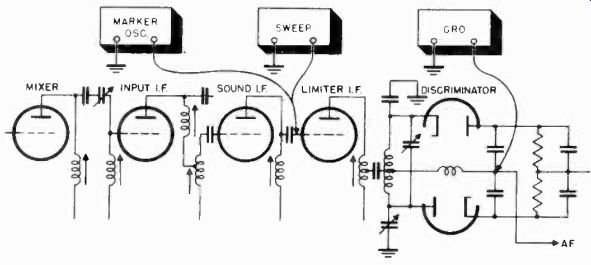

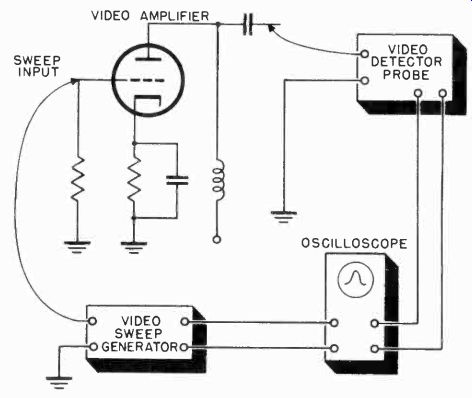

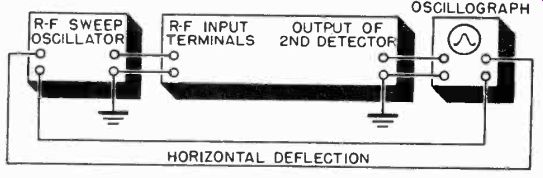

Three pieces of test equipment are basic requirements for alignment. They are a sweep frequency generator, an oscillograph, and a marker generator.

In addition to the instruments listed above, there are several accessory devices which are now available for television servicing. Although not essential, they often greatly simplify the problems of servicing. Into this category fall such instruments as grid dippers, Q-meters, and cross-hatch generators.

TROUBLESHOOTING

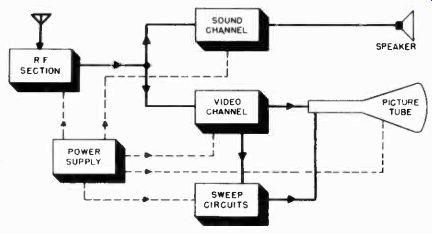

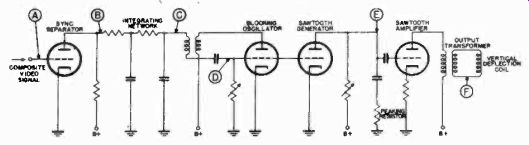

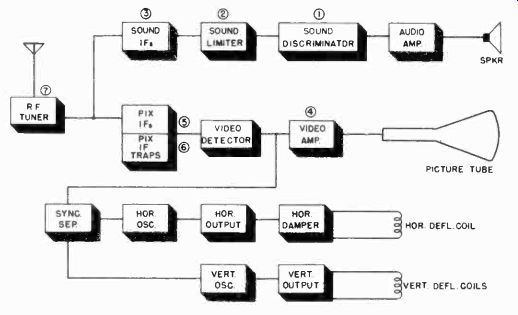

Figure 1. Block diagram of six basic sections of television receiver.

9-3 In order to approach the subject of troubleshooting with logical and well coordinated procedures, the television receiver is broken down into six sections, each of which has characteristic faults. By first localizing the trouble to one of these sections, the technician will save considerable time and effort.

Figure 1 shows a block diagram of the television receiver divided into these six sections:

1. The R-F Section, 2. The Sound Channel, 3. The Video Channel, 4. The Sweep Circuits, 5. The Picture Tube, and 6. The power supplies.

The heavy lines and arrows on the block diagram indicate the paths of the television signals as they travel through the receiver. This diagram emphasizes the fact that a television receiver is actually made up of several sections, each of which can be considered to operate almost independently of the other. If the fault can be isolated to one of these sections, there is generally no need to work on the other sections. The following discussion will help clarify the reasoning upon which this method of fault isolation is based.

1. The signal enters the R-F Section and branches out into the Sound Channel and the Video Channel. If poor sound and picture exist, it is probable that the fault lies in the R-F Section, because after this point the signals are separated.

2. When the signal branches off to the Sound Channel, it passes through several audio stages which make up an independent FM receiver, except for being connected to the common power supply. If trouble exists only in the sound, the Sound Channel is the logical section of the receiver to troubleshoot first.

3. The output of the R-F Section is also fed to the Video Channel. Here again a separate amplifier system is used to amplify the video signals. If the sound and all other sections of the receiver appear to be operating correctly, the trouble probably exists in the Video Channel.

4. The amplified video signal is fed to the Picture Tube and the Sweep Circuits. Certain troubles in the Picture Tube circuits can be recognized readily by watching the picture. For example, a misaligned yoke or focus coil causes characteristic distortions of the picture.

5. Since the video signal is fed to the Sweep circuits to synchronize the sawtooth deflecting signals, the Sweep Circuits will be partially interdependent with the Video Channel. If the picture is synchronizing well and scanning trouble exists, the fault is usually accredited to the Sweep Circuits.

6. The Power Supply affects all the other sections of the receiver. If the receiver is completely dead, the trouble usually can be traced to the Power Supply. Other Power Supply faults will show up in a characteristic manner in other sections of the receiver, as will be described later.

While it is not always possible to treat each section of the receiver as a unit operating independently of the others, the majority of faults can be isolated in this manner. When more than one section appears to be contributing to the trouble, the technician must attack each suspected section in logical order.

Several typical examples of the methods of fault location just described follow:

1. Assume that sound, but no picture can be received from all stations.

2. The intensity control should be turned up to see if there is a raster. If the raster is present, there is nothing wrong with either the vertical or horizontal sweep circuits, or with the power supply. Since the sound channel is working properly, the trouble must be in the picture channel.

3. The next step is to tap the grid of the video amplifier. If white bands appear on the screen of the picture tube, the video amplifier is functioning properly. Therefore, the trouble must be in the picture IF section. (The RF channel must be operating properly because sound is being received.)

4. Having isolated the fault to the picture IF channel, the tubes in this section should be checked. If the trouble is not the tubes, the next approach is to feed a modulated signal into the grid of each IF stage and note the output on an oscillograph.

The faulty stage in the section can be located in this manner.

5. Once the trouble has been tracked down and corrected, the receiver should be tried immediately.

If it is assumed that in the previous example no raster was observed when the intensity was turned up, but that instead a spot appeared on the picture tube, the trouble would then not be in the picture channel. In all probability the trouble is not in the sweep generators because neither vertical nor horizontal sweep is present. It is probably in the power supply which furnishes plate and screen voltages to both of the sweep generators. The rectifier tube and other components in the power supply should be checked. If a component has not failed, a check should be made for an open circuit.

As another example, assume that when the intensity control is turned up only a horizontal line is observed. The place to look for the trouble, in this case, would be in the vertical sweep generator; or conversely, if a vertical line is observed, in the horizontal sweep generator.

These examples will serve to illustrate how a visual analysis of the receiver assists in the isolation of faults. By recognizing the characteristic troubles of the various sections, the technician will develop similar fault isolation techniques of his own.

9-4 Other Troubleshooting Techniques. Much of the technician's work in troubleshooting television receivers can be simplified if he fully understands the significance of the test patterns transmitted by stations. A thorough familiarity with these patterns will enable the technician to recognize the majority of receiver faults in a matter of minutes. A complete analysis of test patterns is presented later in this section.

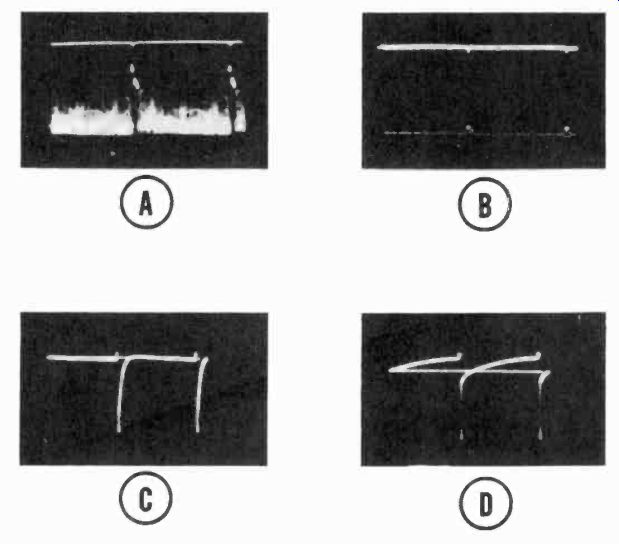

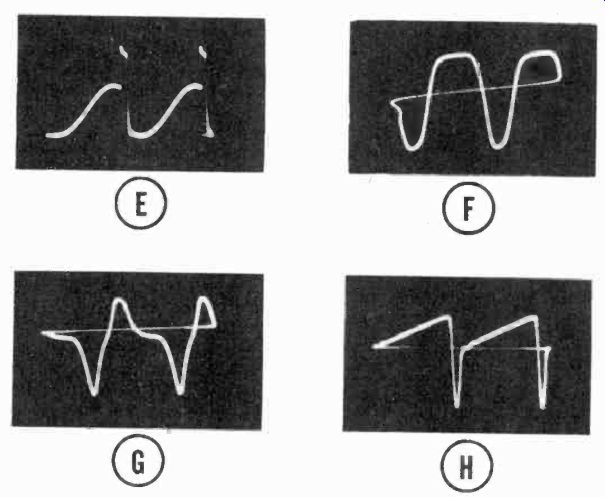

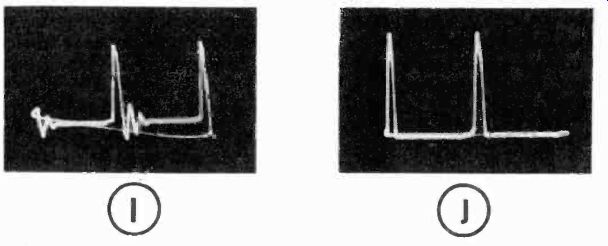

Another approach to troubleshooting is the signal tracing of the receiver circuits with a cathode-ray oscillograph. This method is particularly useful in checking the sweep section when visual analysis indicates this section is at fault.

-------

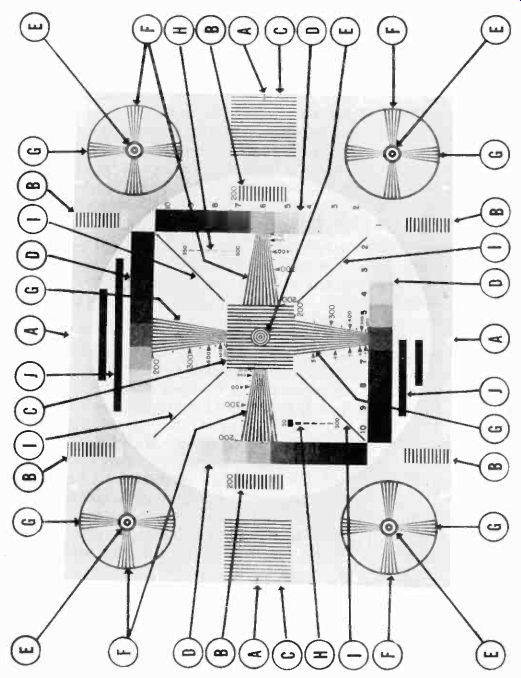

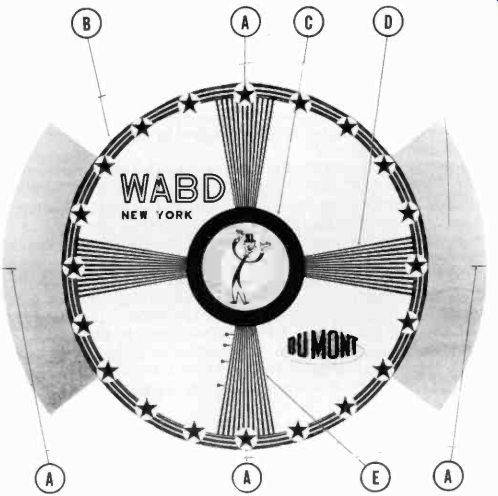

Figure 2. The R.M.A. Standard Test Chart. The call-out letters identify the

geometric designs which are used to check the following: OA Vertical and Horizontal

OF Vertical Resolution.

Size and Aspect Ratio.

Vertical Linearity.

Horizontal Resolution.

Horizontal Linearity.

"Ringing" or Damped Oscillations.

OD Contrast and Brightness. OI Interlacing.

EO Spot Size and Focus.

JO Low Frequency Phase Shift.

The checking of tubes and voltages is the best approach to tracking down trouble after it has been isolated to a stage in the receiver. The manufacturer's literature often contains the approximate voltages which should be present at various points in a receiver when it is operating properly. By comparing measured voltages with those given by the manufacturer, the technician can locate faulty components. Resistance and continuity checks will also usually turn up faulty components in a circuit.

After the trouble has been isolated and corrected, one or more of the adjustment and alignment procedures described later in this section may have to be carried out in order to put the receiver back into perfect working order.

9-5 Troubleshooting with Test Patterns. For several minutes before each broadcasting period, and at intervals as long as several hours during the day, each television station transmits a test pattern which displays the station's call letters. The test pattern contains geometric designs which are very useful in troubleshooting and adjusting receivers and installations. In the succeeding paragraphs, the significance of the features of the various test pattern designs which are in common use are discussed. Following this discussion there is a group of typical test patterns, as they appear on the television screen. They illustrate a major portion of the faults which the technician is likely to encounter in troubleshooting and servicing television receivers and installations. Each test pattern is accompanied by a description of the faults which cause it to appear.

9-6 The R.M.A. Test Pattern. In order to assist in standardizing the performance of television transmitters and receivers, the Radio Manufacturers Association has designed a test pattern which it recommends for use in testing television equipment.

This pattern is shown in Figure 2. It is considerably more complex than the test patterns which are transmitted by television stations, but an understanding of its design will enable the technician to make use of any type of station test pattern. For purposes of explanation, "call-out" letters have been marked on the R. M.A. pattern to identify its important features. A key to these letters is given below the pattern and a more detailed description of the various geometric designs follows.

9-7 Vertical and Horizontal Size, and Aspect Ratio. The test pattern which is transmitted by the station has an aspect ratio of 3 to 4. To make certain that the scanning circuits are correctly adjusted in the receiver so as to reproduce the pattern in the same aspect ratio, four crosses (A) are marked on the R.M.A. test pattern. These crosses, two black and two white, are located at the center of each edge of the chart. The height and width of the received pattern should be adjusted so that the white crosses touch the top and bottom of the mask opening and the black crosses touch the left and right sides. The correct picture size and aspect ratio are then obtained on the receiver screen.

9-8 Vertical Linearity. The vertical linearity is adjusted with reference to the six groups of horizontal lines marked (B). The linearity should be adjusted for equal spacing between the lines.

Note that the vertical linearity lines do not extend continuously from top to bottom, but appear in three groups at the top, center, and bottom. The lines could have extended the full height of the pattern. This was not done in order to minimize confusion. It is necessary only to adjust the vertical linearity for equal distribution of the lines in each group. The scanning lines between each group will then be linearly displaced, unless the vertical sawtooth voltage has an irregular shape an unlikely condition.

9-9 Horizontal Linearity. The vertical lines in the three groups marked (C) are used to check the horizontal linearity. If the horizontal linearity controls in the receiver are correctly adjusted, the lines in each group will be equally spaced.

9-10 Contrast and Brightness. The four groups of squares marked (D) are used to measure the ability of the receiver to reproduce a picture of good contrast and illumination. They also help to correctly set the contrast and brightness controls. The squares are numbered from 1 to 10 and extend from pure white through several shades of gray to the tenth square, which is black. An ideal receiver will enable the viewer to distinguish each of the ten squares in the gray scale. The quality of the receiver is measured in terms of how far up on the gray scale the squares can be distinguished. When making this measurement, the contrast and brightness controls should be adjusted for maximum contrast between adjacent squares, as well as for even illumination of the grey background of the pattern.

9-11 Spot Size and Focus. The small, white dots (E) at the centers of the five bulls-eyes on the R.M.A. pattern are provided to make possible the checking of the spot size and shape of the electron beam in the picture tube, and to help focus the image. The focus control on the receiver should be adjusted to obtain the roundest and sharpest white dots possible. If the receiver is equipped with an astigmatism control, the control should be adjusted with the focus control to obtain a round, sharply focused spot.

9-12 Vertical Resolution. Vertical resolution is expressed as the maximum number of evenly spaced horizontal lines which can be resolved on the test pattern. The horizontal wedges marked (F) are designed for the measurement of vertical resolution. The wedges are calibrated with numbers from 200 to 600. If the horizontal wedges are distinct all the way across the point marked 600, the picture is said to have 600-line resolution.

Lower resolution is indicated by a blurring of the narrow part of the wedge. For example, if the lines are distinct only half way across the horizontal wedges, the picture has 300-line vertical resolution. The significance of this figure, which expresses the degree of vertical resolution, is explained by the manner in which the wedges are calibrated.

Although there are 525 scanning lines in the television picture, only about 93% (490) of these lines are visible in the picture. The other seven percent are blanked out during the vertical blanking period. If the electron beam in the picture tube can be focused to a spot small enough to trace out 490 lines without overlapping, the maximum vertical resolution will be 490 lines. In other words, the present 525-line television system is only capable of 490-line vertical resolution. In actual practice, the vertical resolution is even less. It should be noted that the R.M.A. test chart indicates 800-line resolution which is more than the present television system can reproduce.

The vertical resolution, as measured on the test pattern, is determined mainly by the size of the spot on the picture tube screen. It is not affected by the low or high frequency response of the receiver. The construction of the electron gun in the picture tube and of the focusing system are the principal factors which affect spot size.

9-13 Horizontal Resolution. Horizontal resolution is dependent upon the spot size of the electron beam and the high frequency response or bandwidth of the receiver. The bandwidth determines the number of video signal frequency components which are passed by the amplifiers, and in turn determines the number of distinct, vertical black and white lines which can be reproduced on the screen.

Horizontal resolution can be expressed in two ways, in terms of the number of vertical lines which can be resolved, or in terms of the frequency response of the receiver amplifiers.

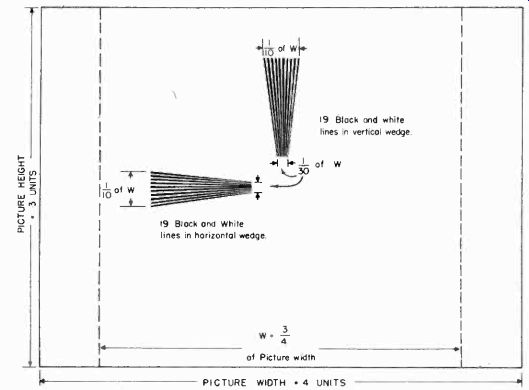

19 Black and white lines in vertical wedge.

19 Block and White lines in horizontal wedge.

of Picture width

PICTURE WIDTH 4 UNITS

Figure 3. Method used to compute calibration numbers on resolution wedges.

The vertical wedges marked (G) on the R.M.A. test pattern are designed to measure horizontal resolution. The upper wedge is calibrated in terms of number of lines, while the lower wedge is calibrated in number of lines and frequency response. The numbers to the left of the bottom wedge represent frequencies from 3 to 7 megacycles; the numbers to the right of the wedge indicate the equivalent number of lines, ranging from 200 to 600. Like the vertical wedges, the horizontal wedges are designed to exceed the resolution capabilities of the present 525-line television system.

To understand the significance of the numbers on the vertical wedges and the method by which they are calibrated, it is necessary to explain the geometric configuration of the wedges in relation to the overall size of the test chart.

1. In order to have a common basis for comparison of the horizontal and vertical resolution, horizontal resolution is based on the number of distinct black and white vertical lines which can be resolved by the electron beam scanning across three quarters of the usable width of the picture. This distance (3/4 of picture width) is equal to the picture height and gives a square area in which an identical number of lines can be fitted vertically or horizontally. This square is shown in Figure 3 in relation to the overall picture size. For convenience, three quarters of the picture width, which is the length of a side of the square, is labeled "W". Also shown are the vertical and horizontal wedges of the R.M.A. test chart.

2. The vertical wedge has 19 alternate black and white lines.

The top of the wedge is slightly more than 1/10 of W. Considering only the top of this wedge, 10 x 19, or 190 lines, so spaced, could be fitted across the length W. The lower part of the wedge is only 1/30 of W. 30 x 19, or 570 lines, so spaced, could be fitted into a space equal to W. Actually, the above calculations are only approximate because the ratio of the width of the wedge to the length W is not exact. The same points on the R.M.A. test chart in Figure 2 which are determined precisely, are marked 200 lines and 600 lines, respectively. The other numbers on the wedges are calculated in a similar manner.

3. To use the vertical wedges to measure horizontal resolution, simply note how far down toward the narrow portion of the wedges the lines can be distinguished. The resolution may then be read directly from the numbers on the wedges.

The horizontal resolution may also be expressed in terms of frequency to indicate the bandwidth of the amplifiers in the receiver. The numbers on the wedges which provide a line calibration may be converted into an equivalent frequency by dividing the number of lines by 80. This conversion factor is arrived at in the following manner:

1. It takes the electron beam 1/15,750 seconds, or 63.5 microseconds to scan one horizontal line. Of this time, 10.2 microseconds are consumed by the horizontal blanking period, during which the spot retraces its path and begins the next line.

The spot actually appears on the screen for 63.5 minus 10.2, or 53.3 microseconds.

2. To compare the horizontal resolution with the vertical resolution, only 3/4 of the length of a horizontal line is considered.

The spot requires 3/4 of 53.3, or 40 microseconds to scan three quarters of the line.

3. Consider now a signal of one megacycle frequency which produces one complete cycle in one microsecond. When this signal is fed to a picture tube, the positive half of each cycle produces a white dot, and the negative half a black dot.

4. In one microsecond, or one cycle, two dots are produced on the screen by a one-megacycle signal. In 40 microseconds, a one-megacycle signal produces 80 dots, alternately black and white; a 2-megacycle signal, 160 dots; 3 megacycles, 240 dots; 4 megacycles, 320 dots.

5. As the electron beam scans successive lines, the dots appear as vertical lines. The word lines may therefore be substituted for the word dots in step 4. Thus a relationship is established between video frequency and the number of vertical lines which are produced in three quarters of the scanning width.

A one-megacycle signal is equivalent to 80 lines. To convert the number of lines to frequency, divide by 80. Conversely, to convert the horizontal resolution of a receiver, as expressed in frequency, to the equivalent number of lines, multiply the frequency (in megacycles) by 80. For example, if the vertical wedge can be read down to 300 lines, the equivalent bandwidth of the receiver amplifier is 300/80, or 3.75 megacycles. Or if the amplifiers have a bandwidth of 3 megacycles, it should be possible to resolve down to the point on the vertical wedge which corresponds to 3 x 80, or 240 lines.

9-14 Precautions in Checking Resolution. When the wedges in a test pattern are used to measure the vertical and horizontal resolution of a television receiver, several precautions should be observed in order to obtain accurate results.

The contrast, brightness, and focus controls should be adjusted to give a uniformly illuminated picture with sharply focused lines. As pointed out previously, the spot size of the electron beam affects the resolution. Do not over-drive the contrast control, for an over-contrasty picture makes the resolution appear better than it actually is.

Do not measure the resolution with a very weak signal or when the picture is marred by "snow" or other noise interference.

Under these conditions, the resolution appears poorer than the true capabilities of the receiver.

Always try to measure the resolution on more than one station test pattern as a check on the quality of signal transmitted by the station. Some stations may be transmitting pictures of low definition, in which case the poor resolution may exist at the transmitter and not at the receiver.

9-15 "Ringing" or Damped Oscillation. The lines marked (H) on the R.M.A. test chart are provided to show "ringing" or damped oscillations which occur in the receiver amplifiers at certain frequencies. These lines are marked 50 to 300 on one range and 350 to 600 on the second range. The significance of these markings and different weights of lines is as follows: It takes 50 alternate black and white lines, equal in thickness to the line marked "50" to fill three quarters of the width of the picture. It takes 600 alternate black and white lines, equal in thickness to the line marked "600", to stretch across three quarters of the full width of the picture.

If an amplifier in the receiver breaks into spurious oscillation when excited by a particular frequency, the single line in the groups marked (H) which is equivalent to the frequency of oscillation, will be distorted. For example, a video amplifier may break into oscillation at 2 megacycles when a video signal containing this frequency is fed into it. When the electron beam scans across the line in group () which corresponds to 2 megacycles, the video amplifier will oscillate momentarily. The oscillation will take place when line 160 (160/80=2 Mhz) is scanned. As a result of this oscillation, several echoes or ghosts will be visible on the pattern, trailing off in diminishing intensity after line 160, and perhaps those lines above and below it.

9-16 Interlacing. The four diagonal lines marked (I) are included at the center of the pattern to check the quality of interlacing. Jagged diagonal lines indicate that the scanning lines are not interlacing and that the lines in successive fields are not displaced from one another by exactly half a horizontal line.

9-17 Low Frequency Phase Shift. The heavy black bars marked (j) at the top and bottom of the R.M.A. pattern are used as a check for low frequency phase shift. Since the black bars are relatively long with respect to the total scanning width, the video signal does not make many changes in amplitude while the electron beam scans across these bars. Therefore, the video signal contains very low frequency components which must be passed by the video amplifiers. The longer and heavier the bars, the lower is the video frequency and the more severe is the test of the ability of the amplifiers to reproduce low frequencies without amplitude or phase distortion. If such distortion is present, the right ends of the black bars trail off, rather than cut off sharply. This trailing off appears as a grey smear. All thick, black, horizontal lines in the test pattern exhibit this smearing on their right edges if low frequency phase distortion is present in the amplifiers. For example, the 10 black squares in the grey scales will be similarly distorted by poor low frequency response.

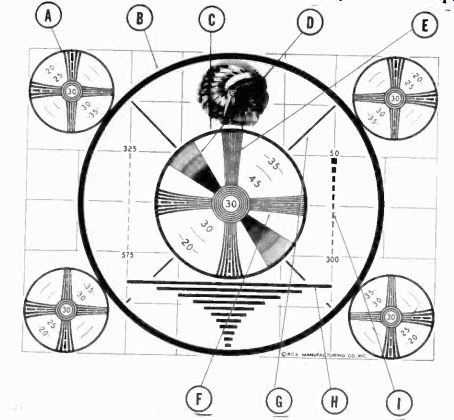

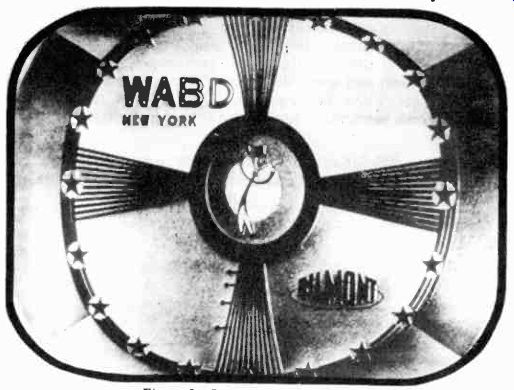

Figure 4. The "Indian head" test pattern.

9-18 The "Indian Head" Test Pattern. Some manufacturers and stations use the "Indian Head" test pattern, which is generated by a monoscope camera, to check the performance of receiving and transmitting equipment. This pattern is shown in Figure 4. It is simpler than the R.M.A. chart, but it is adequately suited for routine test work. The functions of the various geometric designs are as follows:

1. The circles marked (A) should touch the four corners of the mask for a picture of correct size and aspect ratio.

2. The circles marked (A), (B) and (C) are used to check vertical and horizontal linearity. All the circles are round when the sweep signals are linear.

3. All sections of the grey scale marked (D) should be sharp and distinct. These scales check contrast and brightness.

4. Focus is checked using the small circles in the center of the pattern as well as the circles (A) at the four corners of the pattern.

5. The vertical resolution is checked using the horizontal wedges marked (E).

6. The horizontal resolution is checked using the vertical wedges marked (F). Note that on the Indian Head pattern the last zero is omitted on the calibration numbers near the resolution wedges. Thus "20" actually means 200 lines.

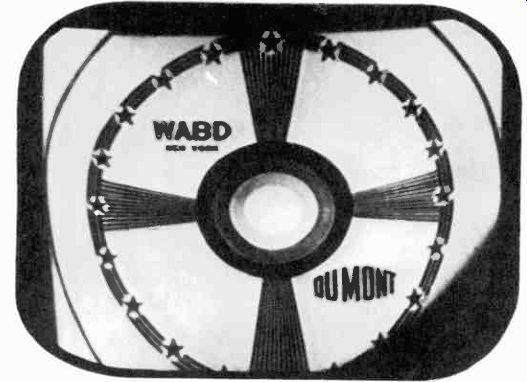

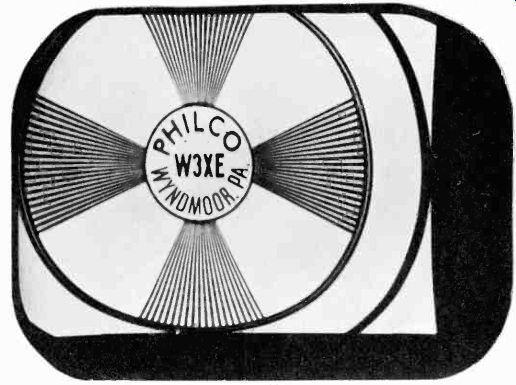

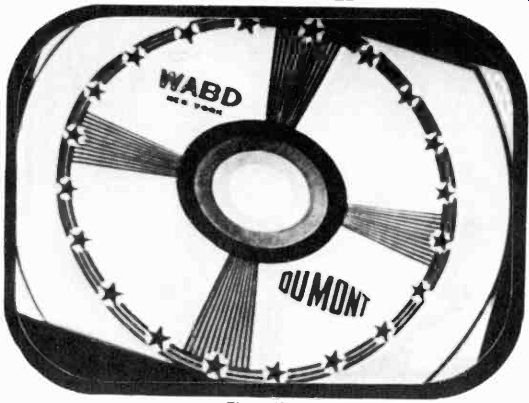

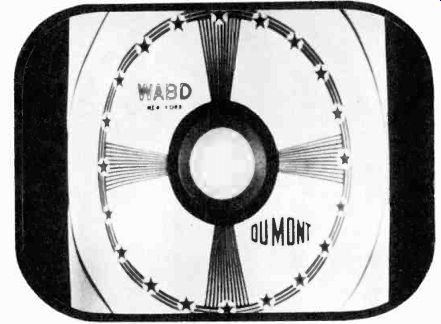

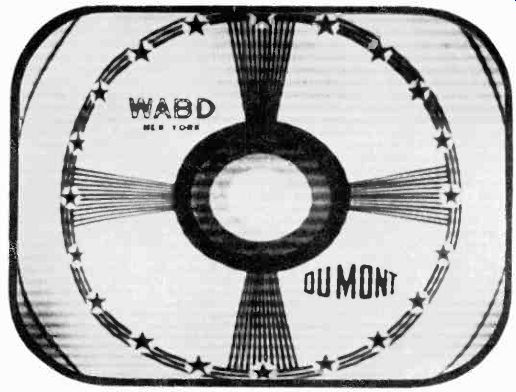

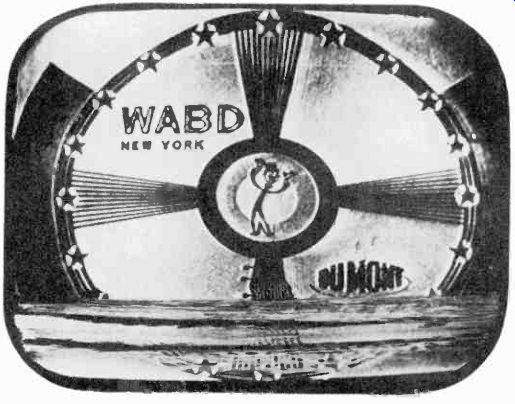

Figure 5. Typical station test pattern.

7. The interlacing is checked using the diagonal lines marked (G).

8. Low frequency phase shift is checked using the heavy horizontal lines marked (H).

9. "Ringing" or damped oscillations are checked by the groups of lines marked (I).

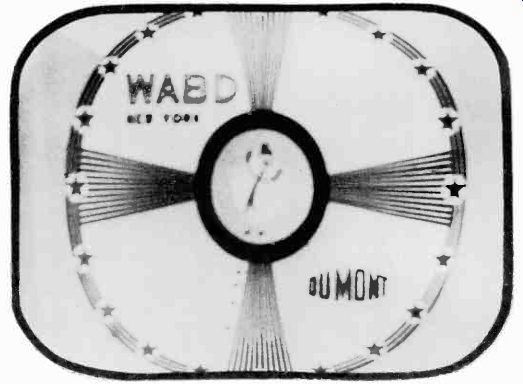

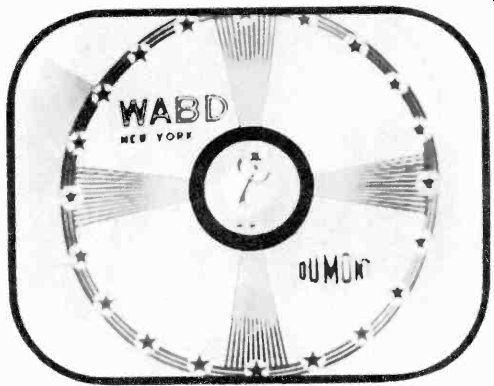

9-19 Typical Station Test Pattern. Test patterns are used by almost all television stations to display their call letters. These patterns are much simpler than the Indian Head pattern just described. A typical station test pattern is shown in Figure 5.

The following performance checks can be made using such a station test pattern:

1. The points marked (A) should touch the edges of the mask for a picture of correct size and aspect ratio.

2. The circles marked (B) and (C) are used to check vertical and horizontal linearity. Non-linear Scanning in either direction is readily apparent by distortion of the circles.

3. The gray scale is made up of the circles in the bulls-eye marked (C). The relative clarity of these circles is a check on the setting of the contrast and brightness controls.

4. Focus can be checked by observing the sharpness of the stars on circle (B) and the sharpness of the wedges.

5. Vertical resolution may be checked by using the horizontal wedges marked (D).

6. Horizontal resolution may be checked by using the vertical wedges marked (E). Note that the wedges are not numbered, but that the lower vertical wedge is marked by dots. Since most stations do not show the calibrating resolution numbers on the test pattern, the technician must calibrate the wedges himself, or he may contact the station for the information. The equivalent number of lines at any point on either the vertical or horizontal wedges may be calculated by multiplying the number of black and white lines in the wedge by the ratio of picture height to the width of the wedge at the desired point on the wedge. To convert to frequency, divide the number of lines by 80. These measurements are subject to the errors introduced by non-linearity of scanning when the width of the wedge is scaled off the received test pattern.

7. Interlacing may be checked by using the sharpness of the alternate black and white lines in the horizontal wedges. If the interlacing is poor, the black lines will appear blurred and jagged.

8. Low frequency phase shift may be checked by observing heavy black objects, such as the stars and the black circle in the bulls-eye.

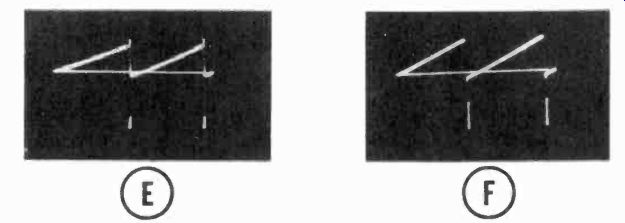

9-20 Test Pattern Analysis. Having studied the significance of the various geometric designs in television test patterns, the technician should be able to use these patterns to check the performance of receivers. On the following pages there are presented a series of test patterns illustrating the effects of various faults which are commonly encountered in television receivers and installations. Below each pattern are troubleshooting clues for locating and correcting the faults.

Until he is completely familiar with them, the technician will find it advantageous to keep this series of patterns handy when servicing a receiver. By comparing the faulty pattern on the receiver screen with one or more of the patterns which follow, he may quickly diagnose the trouble. Most of the effects illustrated are also discernible on the screen when a program is being broadcast; and when the technician has learned to recognize the effects when they appear in a test pattern, he will usually be able to recognize them when they appear during a program.

It would be difficult to overemphasize the important part which an ability to diagnose test patterns can play in rapid television troubleshooting.

CONTRAST AND BRIGHTNESS CONTROLS MLSADJUSTED

Figure 6. Contrast control set too high.

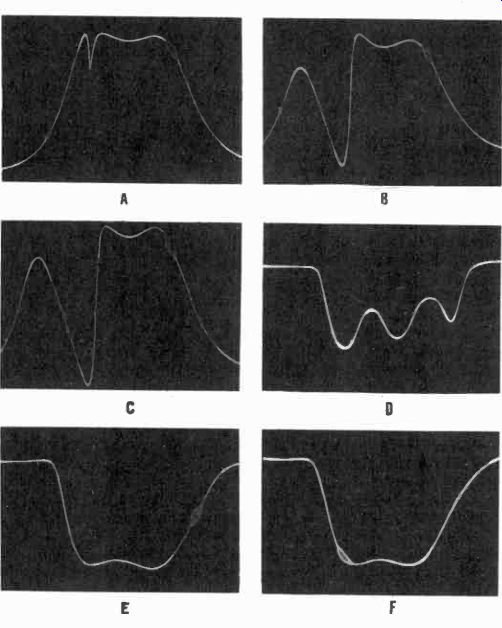

The test patterns which illustrate the misadjustment of the contrast and brightness controls are grouped together, for these two controls are adjusted simultaneously to obtain a properly illuminated picture. Various conditions of adjustment of the contrast and brightness controls are shown in Figures 6, 7, and 8.

Figure 6 illustrates the appearance of a test pattern when the contrast control is set too high. The various shades of grey in the bulls-eye appear as a solid black area. The details of the picture are blurred and there is a lack of half-tone quality.

When the brightness control is set too high, as shown in Figure 7, the picture appears white, fuzzy, and washed out. Figure 8 illustrates a condition where the contrast control is set too low and the brightness control too high so that the vertical retrace lines can be seen.

To properly set the contrast and brightness controls, turn the contrast control fully counter-clockwise (no picture on the screen). Advance the brightness control until illumination barely appears on the screen. Then advance the contrast control until the best picture is obtained.

If a properly illuminated picture is not obtained by setting these controls, check the d-c voltages across them.

Figure 7. Brightness control set too high.

Figure 8. Contrast too low, brightness too high.

IMAGE OUT OF FOCUS

Figure 9.

The appearance of the test pattern when the electron beam is improperly focused is illustrated in Figure 9. The lines in the pattern as well as the scanning lines are not sharply defined.

In most cases this condition may be corrected by simply adjusting the focus control of the receiver. The focus control should be readjusted whenever the brightness control or contrast control is reset.

Often the picture goes out of focus when a receiver has been operating for a long period of time. This happens because the temperature of the focus coil increases, thereby changing the resistance of the coil and the current flowing through it. Or, over a long period of operation, the line voltage may vary and change the focus current. The viewer must readjust the focus control periodically and should be informed of this necessity when an installation is made.

If no setting of the focus control gives uniform focus over the full area of the screen, the focus coil should be rotated slightly and moved back and forth along the neck of the tube, while simultaneously adjusting the focus control. Picture tube and focus coil combinations which uniformly focus the scanning lines over the entire face of the tube are rarely encountered. The best compromise focus should therefore be sought.

FOCUS COIL OR ION TRAP MISALIGNED

Figure 10.

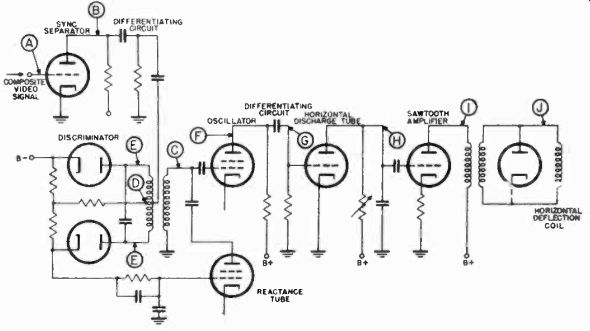

The shadowed corner and improper positioning of the pattern in Figure 10 indicate that the electron beam is off center and is striking the neck of the tube during part of the scanning cycle.

This trouble is due to misalignment of the ion-trap magnet or of the focus coil on the neck of the tube. Since the positions of both coils affect the centering of the beam, it is necessary to adjust both of them in proper sequence in order to determine which coil is causing the trouble.

The ion-trap magnet should be adjusted first. Rotate it slightly, while simultaneously moving it back and forth along the neck of the tube, until the brightest pattern is obtained on the screen with minimum cutoff of the picture. The focus coil should then be tilted back and forth and left and right until the pattern is properly centered and the shadow eliminated.

If it is impossible to locate positions of the ion-trap magnet and focus coil which clear up the trouble, check the yoke to make certain that it is up against the funnel portion of the picture tube.

If it is not, the beam is probably striking the neck, even though the ion-trap magnet and focus coil are correctly aligned. If the yoke is properly located and not causing the trouble, then the d-c positioning voltages on the yoke may have moved the beam off center while the ion-trap magnet and focus coil were being adjusted.

PINCUSHIONING OR BARRELING OF THE PATTERN

Figure 11.

Pincushioning (or barreling) of the test pattern, as the name implies, appears as bowing or curving of the edges of the picture. Figure 11. This type of distortion is confined mainly to magnetically deflected and focused picture tubes, but may sometimes appear in electrostatically deflected tubes when the deflection plates are not operated at the same potential as the second anode.

In magnetic tubes, pincushioning is caused by improper positioning or faulty construction of the yoke, focus coil, or ion trap. The effects of the magnetic fields surrounding these components are interdependent, and pincushioning can result because of the cumulative action of all of them. The most likely cause of pincushioning is the focus coil. It may be either tilted or not properly centered on the neck of the tube. At times, stray magnetic fields from the focus coil interact with the yoke and cause this condition. The focus coil should be moved back and forth along the neck of the tube to find a position which produces the minimum distortion.

Poorly shaped vertical or horizontal deflection coils in the yoke can produce pincushioning. If it is found that the focus coil is not causing the trouble, a new yoke should be tried. It is also possible that the yoke is not designed for the face curvature of the tube with which it is being used.

PICTURE ROTATED

Figure 12.

The test pattern in Figure 12 is "out of square" with respect to the edges of the mask opening. In the case of receivers employing magnetically deflected tubes, rotation of the picture in this manner is caused by the improper positioning of the deflection yoke. This fault can be corrected by loosening the bolts which hold the yoke in place and rotating the yoke until the edges of the picture line up with the mask. The bolts may then be tightened to secure the yoke in its proper position.

The improper orientation of the picture with respect to the mask may also be caused by a damaged yoke in which the vertical and horizontal coils have been moved out of line and are no longer mutually perpendicular. A damaged yoke is indicated when it is found that rotating the yoke around the neck of the tube does not line up the picture with the edges of the mask.

In receivers equipped with electrostatic deflection, the condition shown in this test pattern is caused by an improperly oriented picture tube. The tube itself has rotated with respect to the mask opening. The trouble may be corrected by rotating the tube until the picture is "in square" with the mask. If rotating the tube does not overcome the trouble, the vertical and horizontal deflection plates are probably out of line. Another tube must be substituted to check this possibility.

UNSTABLE HORIZONTAL SYNCHRONIZATION

Figure 13.

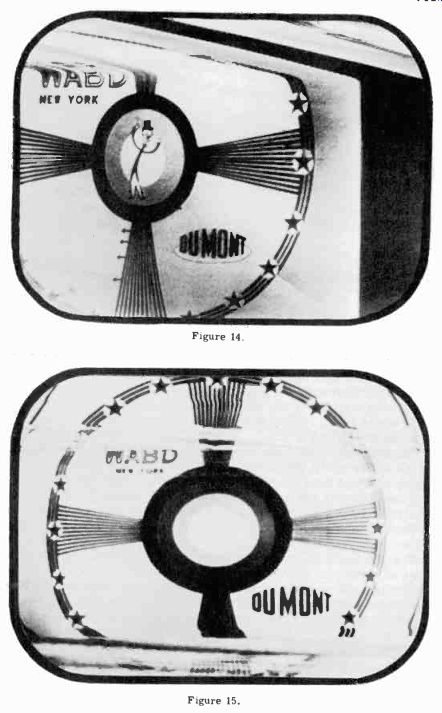

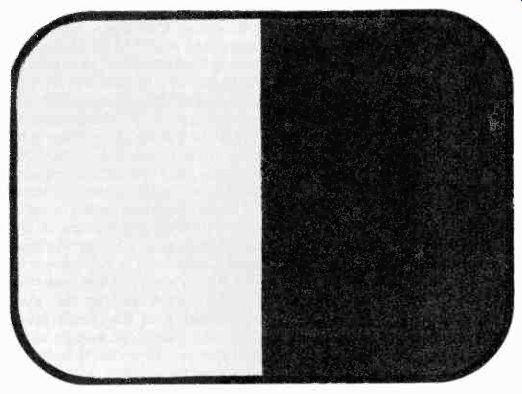

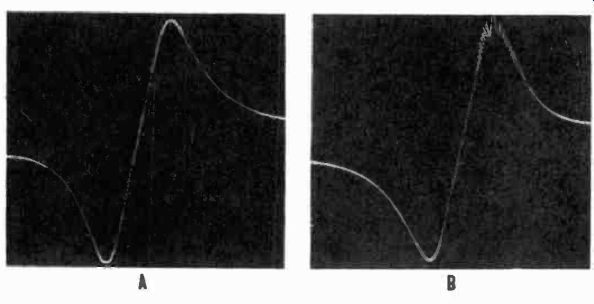

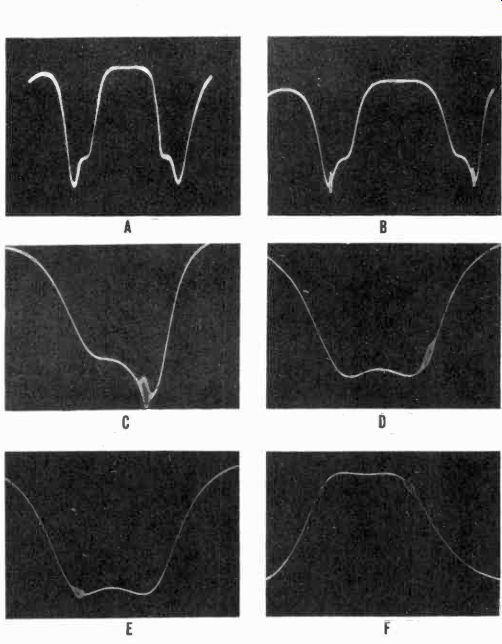

Figures 13,14 and 15 illustrate three degrees of unstable horizontal synchronization of a receiver with conventional triggered sync. The main characteristic of these patterns, which distinguishes them from those appearing on a receiver equipped with automatic frequency control of the sync circuit is the tearing of the picture into strips. If a receiver is equipped with a.f.c., the picture as a whole rolls out of synchronism.

In Figure 13 the horizontal hold control is far off frequency.

As it is adjusted to approach synchronism, the pattern of Figure 14 is obtained. In Figure 15 the picture is correctly synchronized, but there is a slight tearing at the top and bottom which may be due to a microphonic or noisy tube in the sync circuits or a loose connection in the RF, IF, or horizontal sync circuits.

Figure 14.

Figure 15.

Unstable horizontal synchronization can exist regardless of the setting of the horizontal hold control. It may be due to too weak a signal, too strong a signal, a defective sync separator or amplifier tube, or a circuit defect such as loss of supply voltages, an open circuit, etc. Under these conditions it is best to signal trace the sync circuits to isolate the fault. Pull out the horizontal sweep oscillator tube and signal trace the sync signals with an oscillograph, starting at the grid of the sweep oscillator and working back toward the input of the sync separator.

HORIZONTAL SYNC OFF FREQUENCY

Figure 16.

Figure 16 shows the test pattern as it appears when the horizontal oscillator is off frequency in a receiver with automatic frequency control of the horizontal sweep circuit. The picture as a whole rolls rather than tears out, as is characteristic of a triggered sync circuit.

The unstable sync condition illustrated above may be caused by an incorrectly set horizontal hold control. If no setting of the horizontal hold control pulls the picture into synchronism, the oscillator in the a.f.c. sync circuit is probably out of tune.

The oscillator frequency should be so adjusted that the picture locks in when the hold control is set at either end of its range.

This condition may be checked by tuning the receiver to a station while the hold control is in its center position. If the picture is synchronized, turn the control to either end and switch to another channel. Upon switching back to the original channel, the picture should immediately lock-in when the hold control is at either end of its range. If the picture does not readily synchronize over the entire range of the hold control, the oscillator frequency should be readjusted until this condition is achieved. Since adjustment of the oscillator also affects the phasing control in an a.f.c. sync circuit and visa versa, it is best to consult the manufacturer's service manual for the sequence in which these adjustments should be made.

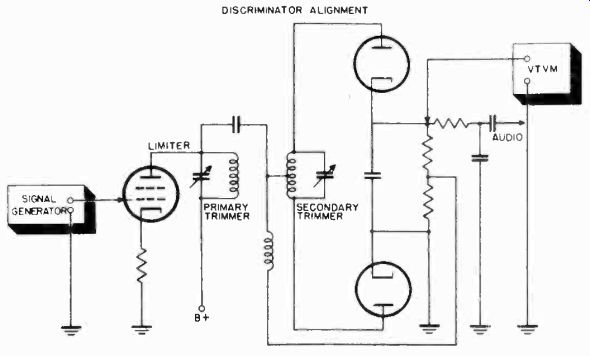

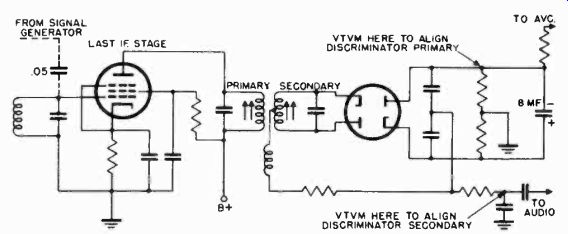

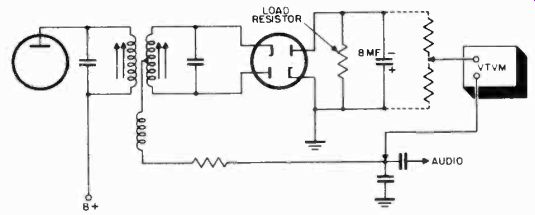

HORIZONTAL SYNC DISCRIMINATOR PHASE MISADJIJSTED

Figure 17.

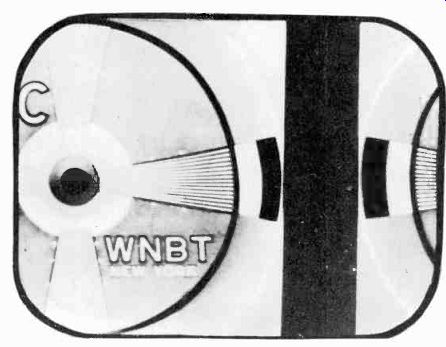

Figure 17 shows the effect, on the received test pattern, of an incorrectly adjusted phasing control in the discriminator circuit of an automatic frequency control sync system. The picture is synchronized to a constant frequency, but the horizontal saw tooth sweep voltages occur at the wrong time in the scanning cycle. As a result, the horizontal retrace, which occurs during the blanking period (the vertical black bar near the right side of the image), appears on the screen.

In most cases proper phasing of the picture can be obtained by simply readjusting the phasing control on the discriminator transformer. This balances the voltages at the plates of the discriminator diodes so that their output is zero at the time when the start of the sweep should occur. Adjustment of the phasing control may also affect the horizontal oscillator frequency. The latter must then be readjusted according to the procedure described on the preceding pages. Most manufacturers' manuals outline the proper sequence for adjusting these controls with a minimum of difficulty.

The unbalanced sync and oscillator voltages in the discriminator circuit which lead to the trouble shown in this pattern may also be caused by a defective diode or other component.

VERTICAL HOLD CONTROL MTSADIUSTED

Figure 18.

The appearance of the test pattern when the vertical scanning is out of synchronism is shown in Figure 18. The picture rolls or jumps from top to bottom. In most cases, this trouble is caused by the incorrect adjustment of the vertical hold control which sets the frequency of the vertical scanning oscillator. The vertical hold control should be turned until the picture locks in vertically. This control is on the front panel of some receivers and must periodically be set by the viewer. In other receivers it is located on the rear of the chassis and is adjusted by the technician, after which it needs no further attention.

If the vertical synchronization is unstable, check the signal level coming into the receiver to make certain that it is above the Minimum strength recommended by the manufacturer.

If the signal at the input of the receiver is adequate, and if resetting the vertical hold control does not synchronize the picture, then the trouble is probably in the vertical sync circuits.

It is best to signal trace the vertical scanning system to locate the fault. Starting at the grid of the sweep oscillator, check for a clean, positive vertical sync pulse (the oscillator tube should be pulled out when making this check). Then proceed to each section of the integrating network and check for vertical sync signal continuity. Continue to the plate of the sync separator where clean sync signals should exist.

POOR INTERLACING

Figure 19.

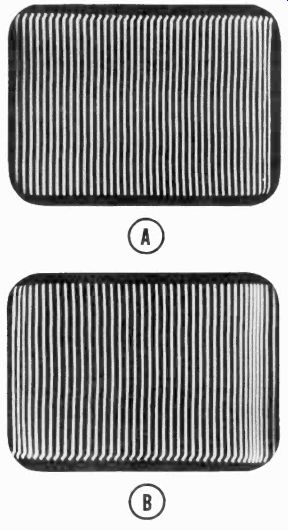

Figure 19 shows the appearance of the test pattern under conditions of poor interlacing. The scanning lines are easily visible because the odd and even lines overlap, rather than fall between each other. In some cases, the scanning lines may drift in and out of interlace as is evidenced by the ripples in the horizontal wedges.

Poor interlacing at the receiver may be caused by improper adjustment of the vertical hold control, by erratic vertical sync pulses which do not repeat at constant frequency and phase, or by spurious signals which modulate the vertical sync pulses.

A defective component in the vertical integrating network is likely to distort the vertical sync pulses and therefore affect the stability of synchronization. The operation of the integrating network may be checked by removing the sweep oscillator tube and connecting a cathode-ray oscillograph between the grid pin on the empty socket and ground. The vertical sync pulses at the output of the integrating circuit can be observed at this point.

The pulses should be sharp and free of jitter. If not, trace back through each section of the network with the oscillograph to locate the faulty component. Cross-coupling with the horizontal deflection circuits due to improper lead positioning, defective B+ by-pass condensers, or a leaky sync separator tube may cause poor vertical interlacing.

INCORRECT HORIZONTAL SIZE

Figure 20.

The width of the picture is determined by the amplitude of the sawtooth voltage applied to the horizontal deflection coils or deflection plates. The test pattern in Figure 20 illustrates the effect which results when the sawtooth amplitude is not properly adjusted. The amplitude of the sawtooth voltage is controlled, in most receivers, by varying a potentiometer in the charging circuit of the sawtooth generator. The range of adjustment is usually sufficient to permit setting the picture to the correct width. In some receivers other controls, such as the horizontal linearity, horizontal drive, and horizontal damping controls, also affect the width of the picture. These controls should be adjusted simultaneously with the horizontal width control to obtain correct picture size and optimum linearity.

A faulty horizontal sweep amplifier tube or a defective component in the sawtooth charging circuit will also affect the picture width. Signal tracing with an oscillograph is the recommended troubleshooting procedure when no setting of the horizontal size control results in proper adjustment. Check the amplitude and waveshape of the sweep voltages against those given in the manufacturer's instruction book at the following points in the circuit: across the horizontal deflection coil, the grid of the sweep amplifier tube, and the output of the sawtooth generator.

INCORRECT VERTICAL SIZE

Figure 21.

The most common cause of the condition shown in Figure 21 is improper adjustment of the vertical size control. The pattern shown illustrates a condition caused by excessive vertical sweep amplitude. If the amplitude of the vertical sweep is low, the pattern will be compressed, leaving a dark space above and below it. The vertical size control is generally located on the rear of the receiver chassis and should not be disturbed by the viewer. It must be set by the technician when the receiver is installed. The vertical size control is a potentiometer located in the vertical sawtooth generator or vertical sweep amplifier circuit. By varying this control, the sawtooth voltage fed to the deflection yoke or deflection plates is changed, thereby changing the height of the picture. The vertical size control should be set so that the picture just fills the mask opening.

If no setting of the size control produces a picture of sufficient height, the amplitude of the vertical sawtooth voltage is low.

With an oscillograph, check the peak-to-peak sawtooth voltage at the output of the sawtooth generator across the yoke and compare with the manufacturer's recommendations. A weak sweep amplifier tube, defective yoke or defective sweep output transformer are common causes of insufficient sawtooth voltage.

Check the a-c line voltage and the plate supply voltage.

HORIZONTAL CENTERING MLSADJUSTED

Figure 22.

If the horizontal centering control is not correctly adjusted, the test pattern will appear as shown in Figure 22. Two methods of centering the picture are employed in television receivers.

The simplest method, used in low-cost receivers, is to center the picture horizontally by adjusting the mechanical position of the focus coil. When centering the electron beam by positioning the focus coil, adjustments of the ion-trap magnet must be made simultaneously to prevent cutting off of the picture at its corners.

It may also be necessary to compromise on the quality of focus in order to achieve a centered picture. Receiver s in which horizontal centering is achieved by positioning the focus coil usually have adjustable mounting bolts to vary the orientation of the coil.

Electrical centering of the picture is used in some receivers.

A potentiometer, the horizontal centering control, varies the dc voltage applied to the deflecting yoke or deflection plates.

By varying this control in a properly operating receiver, the picture may be centered horizontally. The centering control is generally located on the rear of the receiver chassis and is set by the technician, after which it should require no adjustment by the user. If the picture cannot be centered with the horizontal centering control, check the dc voltage across the control to see if it corresponds to the manufacturer's rating.

VERTICAL CENTERING MISADJUSTED

Figure 23.

When the vertical centering control is not correctly adjusted, the pattern is not properly centered, as shown in Figure 23.

Vertical centering is accomplished in two ways, by the mechanical positioning of the focus coil, or by injecting a dc voltage into the deflection yoke or deflection plates.

In receivers employing mechanical positioning of the focus coil to center the electron beam, adjustable mounting bolts are provided to move the coil into the correct position. The focus coil and ion-trap magnet should be adjusted simultaneously in order to avoid cutting off the corners of the picture, to properly center the picture, and to secure the best possible focus.

When vertical centering is obtained by electrical means, a variable dc voltage is applied to the deflection plates or deflection yoke. The amplitude of this voltage is controlled by a potentiometer referred to as the vertical centering control. If proper centering cannot be obtained by varying the vertical centering control, check the line voltage and dc voltage across the positioning potentiometer. If these voltages do not meet the manufacturer's specifications, check the power supply and all components in the centering circuits.

HORIZONTAL LINEARITY MISADJUSTED

Figure 24.

The method used to adjust the linearity of the horizontal deflection signal differs widely in the various television receiver designs. Many receivers use more than one control. It is therefore best to consult the manufacturer's service manual to determine the effect each control has upon the linear distribution of the picture elements. Distortion of the horizontal linearity is easily recognizable by an egg-shaped test pattern, as shown in Figure 24, or by cramping of one side of the picture.

In the simplest type of deflection circuit, as used with electrostatic deflection, a potentiometer in the cathode circuit of the sweep amplifier serves as the linearity control. Adjustment of this control changes the operating bias of the tube and corrects for distortion of the sawtooth voltage. In magnetic deflection systems, linearity controls are located in the cathode of the sweep amplifier tube as well as in the damping circuit. Usually, the linearity control must be adjusted in combination with the horizontal width control in order to obtain an image of proper width and linearity. If no combination of settings of these controls produces linear scanning, check the values of the components in the horizontal sweep circuits. A defective component in the horizontal deflection circuits, such as the charging capacitor, charging resistor, etc., can cause a non-linear sweep.

HORIZONTAL LINEARITY MISADJUSTED (cramped on right)

Figure 25.

It is sometimes found that no matter how the horizontal linearity control is adjusted, the right side of the picture is cramped as shown in Figure 25. This condition is sometimes caused, in magnetic deflection circuits, by an improperly adjusted horizontal drive control. The control is located in the output of the sawtooth generator circuit and controls the voltage applied to the deflection amplifier tube and the point on the scanning trace at which it conducts. By virtue of its position in the circuit, the drive control affects the width and horizontal linearity of the picture. It is normally set for the widest possible picture without cramping the right side. The width control and linearity control are then adjusted to obtain the correct scanning width and good line distribution across the middle and left side of the image. However, if the drive control is set too far, the right side is crowded, and no amount of adjustment of the linearity or width controls can compensate for the distortion.

In some horizontal deflection circuits, a feedback system is used to feed a negative pulse from the output transformer to the grid of the sweep amplifier, in order to determine its point of conduction. In such circuits, the drive control is a potentiometer, connected across part of the secondary of the output transformer, to control the amplitude of the feedback pulse.

DEFECTIVE DAMPING OF THE HORIZONTAL SWEEP

Figure 26.

Receivers employing magnetically deflected picture tubes use a damping tube or damping network to suppress shock oscillations which occur during the retrace period of the saw-tooth voltage. The damping components are subjected to high peak voltages during the retrace period and may break down if their ratings are exceeded. When failure occurs in the damping circuit, the left side of the pattern is distorted as shown in Figure 26. The picture folds over at the left, or white, vertical bars appear near the left edge. Note that only the horizontal scanning can be affected by such a failure.

No amount of adjustment of the horizontal linearity controls can eliminate the foldover caused by a damping circuit failure.

If a diode or triode is used as a damping tube, it should be replaced by a new tube as the first step in tracking down the trouble. Some manufacturers provide waveform diagrams in their service manuals which illustrate the voltage waveshapes which should be obtained at various points in the damping circuit of a normally operating receiver. These points should be checked with an oscillograph. Signal tracing in this manner often turns up a defective component, other than the damping tube.

In some receivers, a variable potentiometer in the cathode of the damping circuit may be in need of adjustment.

VERTICAL LINEARITY MISADJUSTED

Figure 27.

Misadjustment of the vertical linearity control distorts the vertical scanning as shown in Figure 27. The vertical linearity control is generally a potentiometer located in the cathode circuit of the sweep amplifier tube. By varying this potentiometer, the tube is made to operate on either the straight or curved portion of its characteristic curve and corrects for distortions in the sawtooth voltage. When adjusting the linearity control, it may be necessary to re-set the vertical size control because the linearity control also affects the amplification of the tube.

Other conditions which cannot be corrected by setting the linearity control may cause distortion of the vertical linearity. A defective sweep amplifier tube or defective component in the output stage are common faults. A partially shorted winding in the vertical output transformer or deflection coil also affects the linearity. A defective component in the sawtooth generator circuit or low plate supply voltage to the sweep circuits is another possible cause of vertical sweep distortion.

An examination of the waveshape of the voltages at the grid of the sweep amplifier tube and across the deflection coil will help to isolate the trouble to either the sawtooth generator circuit or the sweep amplifier stage.

FOLD OVER AT TOP OF PICTURE

Figure 28.

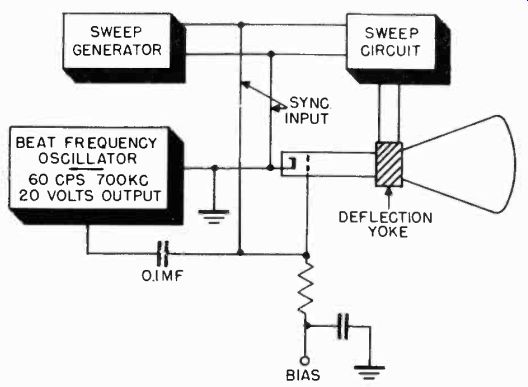

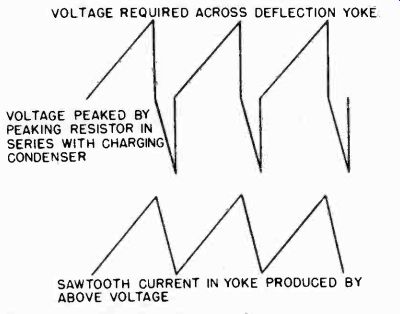

A type of vertical distortion which may occur in magnetic deflection systems is shown in the test pattern of Figure 28. The top lines of the picture are crowded and, in extreme cases, overlapping or foldover of the lines occurs. This distortion is caused by the vertical discharge circuit and no adjustment of the vertical linearity or size control can eliminate it. It will be recalled that in order to produce a linear sawtooth current in the vertical deflection coil, it is necessary to add a pulse to the sawtooth voltage which is applied to the coil. This pulse is produced in the discharge circuit by inserting a resistor, referred to as a peaking resistor, in series with the charging condenser.

The value of the resistor is chosen to suit the design of the deflection coil, the coupling transformer, and the sweep amplifier tube. If the peaking resistor or charging condenser is defective, the amplitude and shape of the pulse added to the sawtooth voltage are affected, causing crowding of the lines or foldover at the top of the picture.

To correct the peaking voltage, replace the peaking resistor with a potentiometer whose total resistance is greater than that specified for the peaking resistor. Vary the potentiometer resistance until the crowding or overlapping of lines disappears.

Then measure the portion of the potentiometer resistance which is used and solder a fixed resistor or equal value in its place.

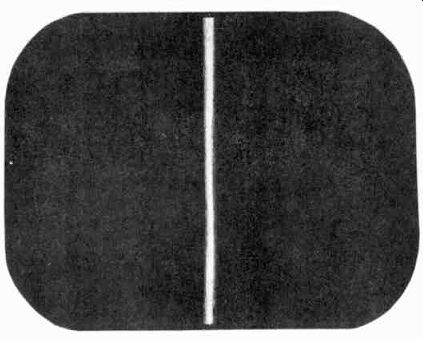

NO HORIZONTAL SWEEP

Figure 29.

Failure of the horizontal sweep circuit cuts off the horizontal deflection of the scanning beam, leaving only a vertical line on the screen as shown in Figure 29. In order to avoid burning a line in the screen while troubleshooting for the fault, turn down the brightness control so that the line is barely visible.

Since the vertical sweep is still working, it is probable that the plate voltage which is fed to the sweep circuits is all right.

The fault is most likely caused by a defective component or open lead in the horizontal sweep circuit. A systematic waveform check with an oscillograph should readily isolate the trouble.

Signal trace the horizontal sweep circuit, starting at the horizontal deflection coil and work back in the circuit toward the sawtooth generator. The check points across which the oscillograph may be connected safely are as follows: the horizontal deflection coil, the cathode and grid of the sweep amplifier tube, the plate of the sawtooth generator tube, and the grid of the sweep oscillator tube. At each check point, compare the waveform obtained with that illustrated in the manufacturer's service manual. The waveform should check both in amplitude and shape. Signal tracing in this manner will indicate whether or not the sweep oscillator is functioning and the sawtooth voltages are being generated.

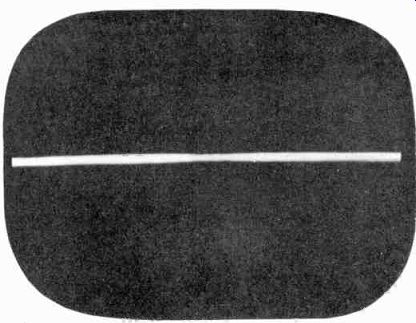

NO VERTICAL SWEEP

Figure 30. A horizontal line on the screen as shown in Figure 30 indicates

that vertical scanning is not present. Before attempting to troubleshoot the

vertical sweep circuit, turn down the brightness control so that the screen

will not be damaged.

Since the horizontal sweep is working (as are probably the sound and video circuits), the power supplies are functioning properly. The fault is generally due to a defective component or open lead in the vertical sweep circuit. The most common failures in this circuit are open vertical deflection coils or sweep transformer windings, and defective sweep amplifier and vertical discharge tubes. The trouble may readily be isolated by signal tracing the discharge circuit and the sweep amplifier stage with an oscillograph. With the oscillograph connected across the following points in succession, check for signal continuity as well as proper amplitude and waveshape: the vertical deflection coil, the grid and cathode of the sweep amplifier tube, and the plate of the vertical discharge tube. Finally, check the waveform at the grid of the vertical sweep oscillator tube to make certain that this stage is oscillating and feeding discharge pulses to the sawtooth generator. There is no need to check further into the sync circuits for they do not affect the generation of the vertical sawtooth sweep voltage.

NO VIDEO SIGNAL, RASTER ONLY

Figure 31.

When a raster appears on the screen as shown in Figure 31, the following line of reasoning may be used to isolate the trouble.

Since a raster is obtained, there is no trouble in the sweep circuits, sweep power supplies, and probably not in the sync circuits. If the audio is coming through, the RF circuits must be operating properly. On the other hand, if both the audio and video are dead, then the trouble most likely lies in the RF section or the power supplies.

Assuming that the audio and video sections are not working, check the supply voltages with a voltmeter. If the voltages are correct, proceed to the RF section. Tap the grid of the mixer tube. A click should be heard in the speaker and dark bands should appear on the screen if the audio and video IF circuits are working. The same results should be obtained when the input to the antenna coupling stage is tapped if the RF section is functioning. Also check the oscillator stage by simply looping the oscillograph input lead around the oscillator tube or coil.

A high frequency oscillation should be observed on the scope if the oscillator is operating. If it is assumed that the audio is coming through, the trouble probably lies in the video section.

It can be isolated by tapping the grid or plate of each tube. Dark bands should be observed on the screen when the tubes are tapped if there is signal continuity.

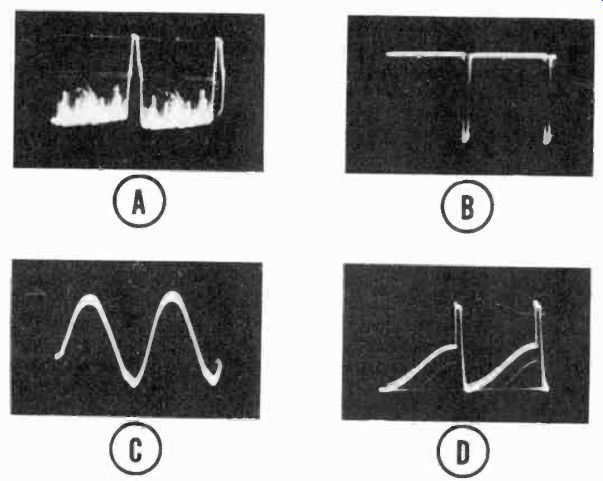

POWER SUPPLY HUM OR RIPPLE IN PICTURE

Figure 32.

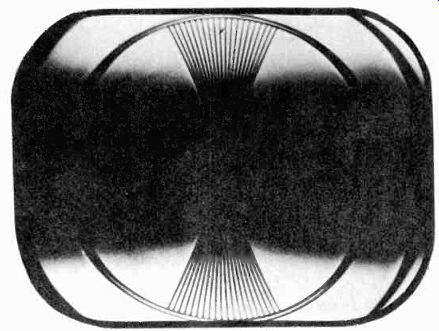

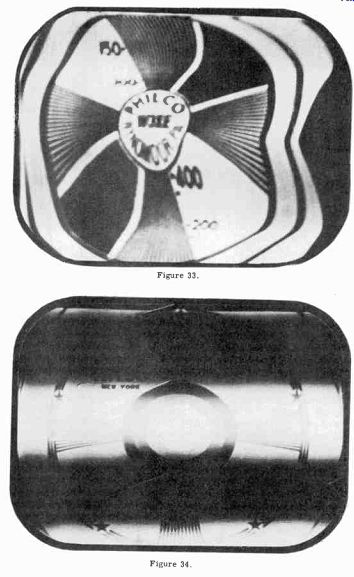

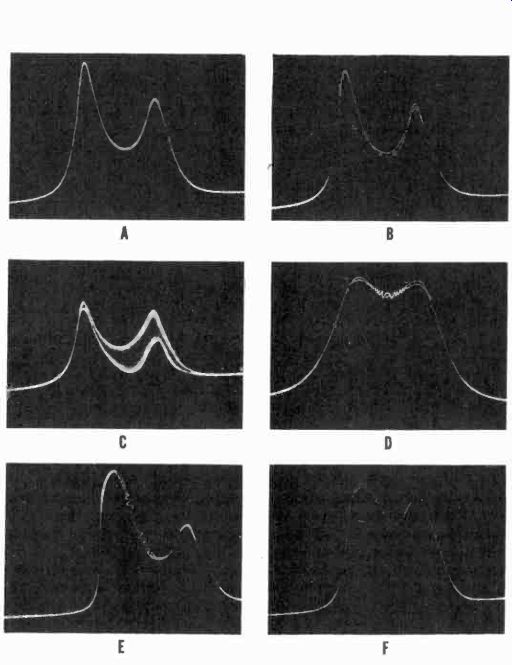

Hum or ripples show up in the test pattern as dark, horizontal bands of constant intensity or wavy edges of the picture. The cause is usually a defective component or an open lead in the power supply filter section, or in the by-pass circuits of any stage in the receiver. The hum bars are due to excessive 60 cycle or 120-cycle ripple. Troubleshooting should start at the output of the plate and bias supplies. Check these points with an oscillograph for any noticeable ripple. If hum does not exist at this point, the trouble is probably a defective by-pass condenser in the video or sweep circuits. The fault may readily be confined to a particular section of the receiver by recognizing on the screen the hum pattern which shows up in a characteristic manner when a stage is troubled by excessive ripple. The patterns are illustrated in Figures 32, 33 and 34.

Figure 32 shows a test pattern in which 60-cycle hum, coming through the video amplifier or video IF stages, produces uneven illumination.

Excessive 60-cycle ripple in the horizontal sweep circuits is Shown in Figure 33.

The effect of 120-cycle ripple appears as twice the number of dark and light bands that are produced by 60-cycle ripple as shown in Figure 34.

Figure 33. Figure 34.

LOSS OF HIGH VIDEO FREQUENCIES

Figure 35.

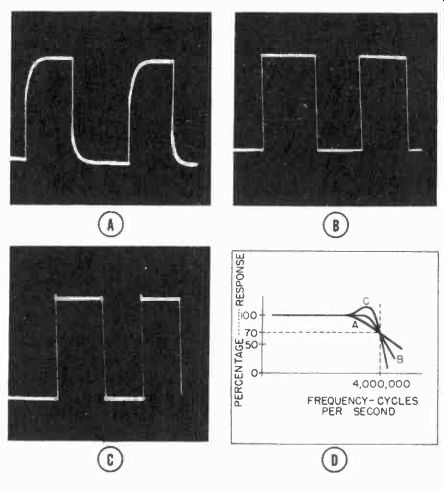

The loss of the high video frequencies shows up in the test pattern as a lack of sharpness of the fine details, particularly apparent in the vertical wedges. Figure 35 shows a test pattern as reproduced by a receiver which suffers from a considerable loss of high video frequencies. Note that the fine lines in the vertical wedges wash out before they reach the bulls-eye.

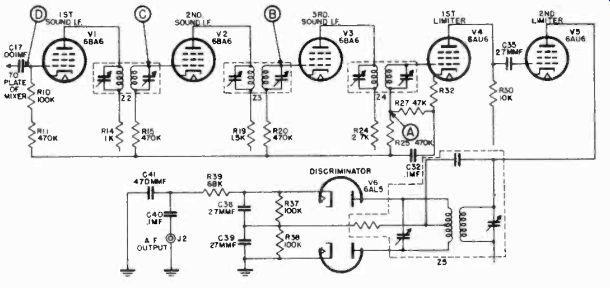

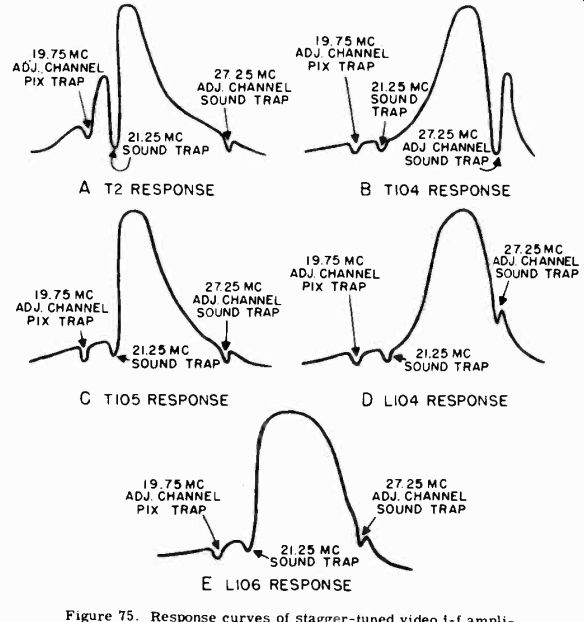

In order to reproduce fine details in the test pattern, the amplifiers in the RF and video sections of the receiver must have uniform response up to 3.5 to 4 megacycles. An improperly aligned amplifier stage will narrow the overall bandwidth and attenuate the high frequencies. If this condition exists as indicated by the lack of detail in the vertical wedges, it is best to first check the alignment of the video IF amplifiers with an oscillograph, sweep generator, and signal generator. An overall check of all the video IF stages will suffice, unless this check indicates that the trouble exists in one of the stages. A stage by-stage check should then be made to locate the misaligned coupling transformer.

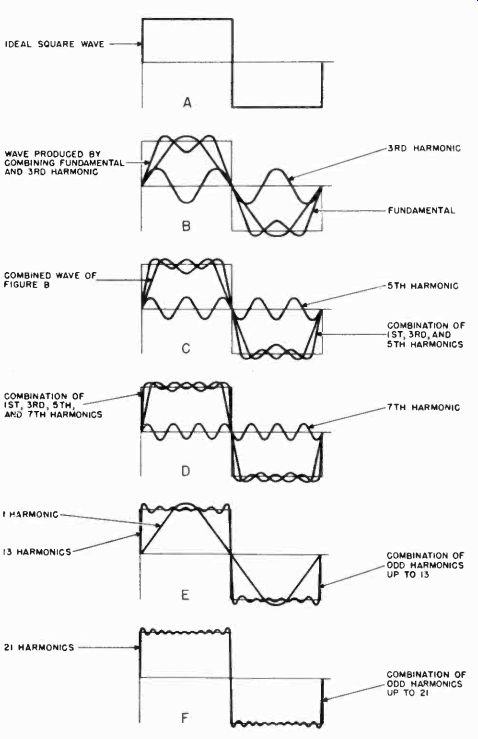

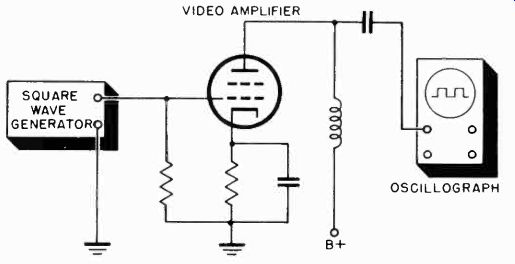

If the video IF stages are correctly aligned, the RF tuner should be checked on each channel. Finally, the frequency response of the video amplifier should be measured with a signal generator and sweep generator (or square wave generator)

in conjunction with an oscillograph.

LOSS OF LOW VIDEO FREQUENCIES

Figure 36.

Poor low frequency response in the amplifiers of the RF and video sections is generally accompanied by phase distortion at these frequencies. This condition is indicated by a smearing of large objects and letters, and a blurring of the horizontal wedges in the test pattern, as shown in Figure 36.

If the sound is loud and undistorted, it is reasonable to assume that the RF section is correctly aligned and that the low frequency distortion is occurring in the video IF amplifiers or the video amplifier. Improper alignment of the video IF amplifiers generally permits sound signals to enter the video circuits.

These signals appear as horizontal bars, drifting up and down on the screen. If these bars are not present and only the smearing effect is observed, it may be assumed that the IF amplifiers are correctly aligned and that the trouble is in the video amplifier.

To definitely establish whether or not the low frequency distortion is taking place in the video amplifier, feed a 60-cycle square wave into the grid of the amplifier and observe its output on an oscillograph which has good low frequency response.

If the top of the square waves slopes downward, low frequency distortion is present in the video amplifier. The poor response is mostly likely caused by a shorted load resistor or an open by-pass condenser in the plate or screen supply circuits.

SOUND IN THE PICTURE

Figure 37.

Figure 37 shows a test pattern which is marred by sound signals riding through the video channel to the grid of the picture tube. The sound signals are those accompanying the video information. When they get into the picture, they appear as horizontal black bands which closely resemble a power-supply ripple in the video amplifier stage. Sound ripple shows up as many bands, changing in intensity and moving up and down the screen in synchronism with the amplitude and frequency of the audio.

The black bands produced by excessive a-c ripple do not vary in intensity, and are one or two in number, depending on whether the ripple is 60 cycles or 120 cycles.

The most common cause of sound modulation of the video signals is improper adjustment of the RF tuner. To tune a receiver correctly, the fine-tuning control should be set for maximum sound. If the sound bars cannot be eliminated by resetting the fine-tuning control, or can only be removed by a tuning adjustment that causes the sound to be distorted, the receiver is probably out of alignment. Misalignment can exist in the RF tuner or the sound traps of the video IF amplifier. First check the alignment of the video IF amplifier and sound traps with a sweep generator, signal generator, and oscillograph. Check the alignment of the RF tuner in the same way.

TOO WEAK A SIGNAL

Figure 38.

The signal strength at the receiver may be so low that only a faint picture can be obtained, accompanied by considerable noise and poor synchronization. See Figure 38. This condition may be deceiving and prompt the technician to attempt to realign the video circuits for greater gain, a procedure which would be to no avail. A field strength meter or calibrated receiver connected to the antenna system will readily indicate the signal level. If this level is below the minimum signal for which the receiver is designed (as indicated in the manufacturer's manual), a few things can be done to increase the signal. Increasing the height of the antenna may help, provided the increased length of transmission line does not introduce additional losses which offset the gain in signal strength. A reflector may be added to the antenna if one does not already exist, or one of the high gain antennas described in Section 5 may be tried. Or, finally, an RF amplifier stage may prove effective. R-F amplifiers or "boosters" are available commercially and are easily inserted in the transmission line.

In some areas the signal strength may be sufficient on all stations except one or two. Erecting separate antennas which are cut and directed for the weak stations may prove a convenient solution.

TOO STRONG A SIGNAL

Figure 39.

Often the signal level at the receiver input is so high that it overloads the input circuits. This condition is indicated by a loss of synchronization, an over-contrasty image, and sometimes by sound modulation in the picture. The overload condition may be remedied by reducing the signal input, using an H-pad attenuator inserted between the receiver input terminals and the antenna transmission line so that the signal is below the overload value for the particular receiver. The signal input should be measured with a field strength meter and resistor values selected to make up the required H-pad. Half-watt carbon resistors should be used. If a field strength meter is not available, various H-pads may be made up and tried. The pad with the minimum attenuation that removes the overload conditions should then be wired into the transmission line.

Another effective means of reducing the signal is to hook a piece of solder, several inches long, directly across the antenna terminals of the receiver. Although this solder may appear to be a short circuit, it actually is long enough at the television frequencies to have sufficient impedance so as not to by-pass the signal completely. In some areas the signal strength is so strong from all stations that it is possible to prevent overloading by eliminating the outdoor antenna.

GHOSTS OR MULTIPLE-PATH SIGNAL

Figure 40.

A ghost or multi-path signal appears on the screen as an offset duplicate of the pattern as shown in Figure 40. The amount of offset is proportional to the difference in the path distance of the direct signal and that of the reflected signal.

If the reflected signal is almost equal in amplitude to the direct signal, it will affect the sync stability of the receiver, since the sweep circuits can synchronize on either the direct or reflected signal.

The reflection can usually be eliminated if a directive antenna, oriented so as to accept the main signal and discriminate against the reflected signals, is used. Under some conditions, where there is no direct path between receiver and transmitter, it is possible to orient the antenna so as to receive a reflected signal. The antenna must then be positioned to accept the best reflected signal and discriminate against all others.

If the reflected signal is received from the same direction as the direct signal, a directive antenna cannot reduce the reflection. The only solution to this problem is to attenuate the composite signal until the reflection disappears. The direct signal will probably still be strong enough to be usable.

If it is impossible to eliminate ghosts on more than one station with a single antenna, separate antennas may be used.

TRANSIENTS IN THE PICTURE

Figure 41.

Transients are caused by improper matching in the antenna system or by improper tuning of the video circuits. As shown in Figure 41, transients closely resemble ghosts in the picture.

In order to establish whether or not the effect is a transient or a ghost, the antenna should be rotated. If the interference disappears or changes, then it is caused by a reflected or ghost signal. If it remains the same, then the effect is due to poor transient response in the antenna system or the video circuits.

Poor transient response is the inability of a tuned circuit to pass sudden amplitude changes without distortion. Instead, there is a tendency toward oscillation when these components occur, resulting in a double image.

To check the antenna system for mismatch, determine the input impedance of the receiver and compare it with that of the transmission line and antenna. If the transmission line or antenna does not match the receiver impedance, suitable matching stubs should be inserted. If it is established that there is no mismatch in the antenna system, then the alignment of the RF amplifier, picture IF amplifier and video amplifier stages should be checked. A sweep generator and oscillograph may be used for the alignment of the RF and video IF amplifiers. No overshoot of the response curve appears when the amplifier has good transient response.

IGNITION INTERFERENCE

Figure 42.

The ignition systems of automobiles produce static which enters the receiver via the antenna system and causes light and dark spots and horizontal streaks in the picture, as shown in Figure 42. When severe ignition noise is present, picture tearing occurs.

When ignition noise is encountered, an attempt should be made to increase the signal pickup while attenuating the noise. Often this can be accomplished by using a high-gain directive antenna.

Anything else done to increase signal strength will improve the signal-to-noise ratio and improve the picture. Shortening the antenna transmission line, using a low-loss transmission line, and elevating the antenna are effective. Coaxial or shielded parallel cable is usually more effective than twin-lead in reducing noise pickup. If twin-lead is used, it should be twisted, since this reduces noise pickup. The outer shield of coaxial or shielded pair lines should be connected to a good ground.

Moving the antenna out of the direct noise field, even at the expense of signal strength, is .often beneficial. If the signal strength is extremely low, a long wire "V", rhombic, or similar type high-gain antenna will help if one can be erected.

DIATHERMY INTERFERENCE

Figure 43.

Although most modern diathermy machines are equipped with RF filters so that radiation and feedback into the power supply system are reduced, there are still many old and defective machines in existence which cause considerable interference with television reception. The high frequency diathermy signals beat with the television carrier and cause the rippled pattern shown in Figure 43. Some diathermy machines operate on fixed frequencies which are close to the IF frequency of television receivers. Often the frequency of the diathermy apparatus drifts and moves into the IF frequency band of the receiver, causing an interference pattern which slowly drifts up and down on the viewing screen. Little can be done to the antenna installation to remove this interference, although a directive antenna may sometimes help. A more practical solution is to locate the machine and ask the owner to maintain the apparatus at its correct operating frequency or shield it. If the technician is absolutely sure that the diathermy machine is operating outside of the assigned frequency band for diathermy machines and the owner is unwilling to cooperate, a report should be made to the Federal Communications Commission.

BEAT FREQUENCY INTERFERENCE

Figure 44.

Often strong AM and FM signals beat with the sound or picture carriers of a television station. If the resulting heterodyne frequency falls within the channel to which the receiver is tuned, an interference pattern is produced which appears in the picture as a series of fine vertical or slanting lines, as shown in Figure 44. The interference pattern drifts slowly through the picture as the television carrier or the interfering carrier changes frequency slightly.

The unwanted carrier maybe filtered out by inserting a wave trap in series or shunt with the antenna lead-in. Suitable values for such traps can be found in Section 8. Another method which is often effective in trapping out the interfering frequency is to connect a piece of coaxial cable or parallel lead-in across the antenna input terminals of the receiver. Starting with a piece about two feet long, the cable is clipped off, a little at a time, until the beat frequency is eliminated. Of course, the use of a wavetrap or piece of transmission line to eliminate the interfering carrier is predicated on the condition that the unwanted signal is fixed in frequency. If it is not and varies over a wide range, little can be done to eliminate it.

9-21 Troubleshooting for other Faults. Many common troubles which occur in the receiver cannot be detected by observing the picture on the screen. In order to locate the cause of such troubles, the technician should first isolate the fault to a particular section of the receiver, as described earlier. To locate the faulty stage and component, two procedures are possible. One is to be thoroughly familiar with the functions of each stage in the section and thus be able to spot characteristic troubles. The other is to signal trace the circuit, looking for the waveforms which are characteristic of a properly and improperly operating receiver. Both of these methods are described, wherever applicable, in discussing other troubles which are common to the six basic sections of a television receiver.