By Martin Clifford

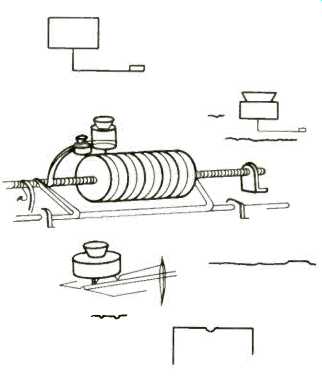

Thomas Alva Edison has been credited with many inventions, but he gathers no plaudits for being one of the progenitors of a portion of today's hifi systems. And yet, almost 100 years ago (1877 to be exact) he had the idea that sound waves could be represented by the displacement of a stylus. This concept isn't at all outrageous if you consider that sound waves comprise rarefactions and compressions of air molecules. The amount of sound (its volume or intensity) is the deciding factor in determining the total movement of the stylus. Edison used tinfoil wrapped around a cylinder as his recording medium (Fig. 1). The number of indentations in the foil, and their depth, produced by a cutting stylus riding progressively on top of it, was determined by two factors-pitch and sound intensity. A reverse process was followed to recover the sound. A stylus riding in the grooves produced by the cutting stylus would wiggle in a somewhat reasonable approximation of the shimmies of the original recording cutter.

Fig. 1. First sketch by Thomas A. Edison of the phonograph.

We can't afford to be patronizing about it, for despite the fact that it preceded radio and television by many decades, it is still the same system we use today--with some changes, of course. A little humble pie is good for the hi fi soul.

Edison's recording cylinder concept digressed into office machine recording equipment, while spirally grooved flat discs or records were used for home entertainment purposes. However, those early phones were purely mechanical, operated by spring-wound motors, with everything in a happy state of resonance.

The stylus, referred to as a needle and made of steel, reproduced the music and so did the device that held the stylus.

There were no amplifiers for the entire mechanical assembly supplied music.

Some of the sound was also conducted to a box or chamber faced by a pair of wooden doors mounted on hinges with the amount of door opening constituting the volume control. Life was simpler in those days provided you understand that simplicity is not a synonym for better. The sole criterion in making a phonograph purchase was loudness.

The basic difference between those yesteryear reproducers and today's is that the mechanical movement of the stylus is converted, not directly into sound, but rather into an electrically equivalent signal. The signal is then amplified by a voltage amplifier or pre-amp followed by a power amp and into a speaker system. Modern units, then, are transducers, changing the mechanical energy of the moving stylus into electrical energy.

The Record

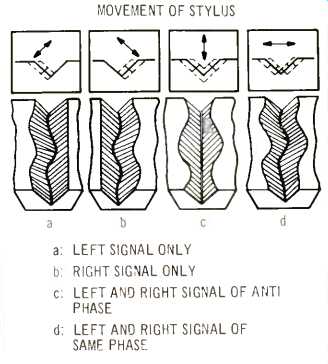

On a stereo disc the sound information is contained in the two walls of the microscopic grooves. One of these, the inner wall or the wall closer to the center hole of the record, carries information for the left stereo channel. The other or outer wall is used for the right channel, with the two walls forming an angle of 90° (Fig. 2).

Fig. 2. Stereo grooves and stylus movement.

The Record Playing System

A record playing system consists of a turntable, a motor to rotate it, a stylus, a cartridge and a tonearm for holding the cartridge. These are the basic elements and that is what you get when you buy a record player. But, as in the case of automobiles, there are all sorts of options: speed changing components, mechanisms for raising and lowering the tone arm, and supplementary devices working as aids in tracking and stylus pressure.

Motor and Drive System

The job of the motor sounds simple and that alone should make us suspicious. Simply rotate the turntable platter at a constant speed, usually 33-1/3 and 45 rpm, preferably not simultaneously.

But the motor/platter combination isn't electronic; it's electromechanical, and so, like any other moving mechanical system, there is always the possibility of wobble, inaccurate speed, drifting speed, and slow starting. A motor, operated by AC, is comparable to turning a large wheel by hitting it along the side at regular intervals, and so running a motor on AC is equivalent to using a pulsating torque process. This sort of torque can cause the turntable speed to change rapidly. The unhappy result is a form of frequency modulation of the reproduced sound known as flutter.

Manufacturers specify flutter in terms of percentage. Good units will have a flutter of less than 0.1% with many down to below 0.05%.

The motor isn't the only flutter villain in this drama. It can be caused by such less obvious things as a record with a slightly eccentric hole, or some minor defect in the drive system, or a turntable that isn't perfectly flat. To check whether it's the system or the record, try a number of different records. They can't all be bad.

Flutter is actually a signal generated by a record reproducing system and imposed on the sound recorded in the disc. And as such it can have a number of different pitches-that is, frequencies.

Flutter having a very low frequency is called wow because this was the exclamation of the individual back in recorded history who first heard this form of distortion, and because that is the word that closest describes the sound.

To minimize flutter, manufacturers use heavy platters with some form of drive isolation between the motor and the platter. Manufacturers also specify the weight of the platter, but this in itself isn't enough. A more meaningful figure is the ratio of the mass of the turntable to the motor. And so a heavy platter isn't necessarily a guarantee of minimum flutter. There are brighter ideas than that of using a VW engine to drive a 10-ton truck.

Nevertheless, there is a good argument for making the turntable platter as large and heavy as the motor torque will permit. Once in motion such a platter serves as a flywheel and keeps the speed constant by its own inertia. Turntable platters are made of pressed steel plate or die-cast aluminum alloys. The aluminum alloy platter is preferable since it will not become magnetized by the motor's magnetic field. And manufacturers like it because it is easier to machine than steel. However, if the heavy platter is to take advantage of fly-wheel effect, it must be accurately balanced, comparable to the idea of balancing an automobile wheel.

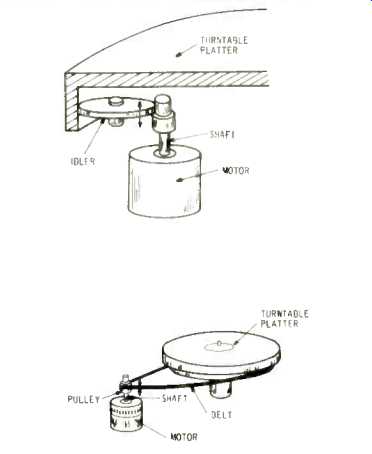

Fig. 3. Idler drive system (above) and belt drive system (below).

The Motor's Code of Behavior

The motor must meet six conditions.

It must rotate at a specific constant speed; this speed must remain constant for varying line voltage conditions and for varying load conditions (that is, whether the tonearm is resting on the record or not); it must not vibrate; it must have sufficiently powerful torque (rotational force) so that it maintains its speed at the precise moment the stylus makes contact with the record grooves; it must not produce any magnetic flux leakage as this can induce hum in the pickup system; and it must be able to work for hour after hour, if required. There are also some incidental conditions. The motor must not overheat. It must be absolutely quiet. It must be able to get the platter from a condition of zero rotation to required speed in the minimum amount of time.

It must be troublefree for as long a time as possible. The motor represents the guts of a record player and like its human counterpart, must never intrude. At least not in polite society.

The absolute speed of a turntable platter is the unchanging speed at which it rotates over a period of time. If this speed is a constant 33 rpm when it should be 33-1/3 rpm, it is unlikely you would notice the difference. What is more serious is the short term speed stability. If a platter has an operating speed of 33-1/3 rpm with this speed representing an average, with a variation above and below this figure, then the platter is speed wobbling with 33-1/3 rpm as its rotational average, not a good situation at all, either for the motor, or for the listener.

Only two types of AC motors can fulfill all the motor requirement conditions for record players-the induction motor and the synchronous motor. Of these, the induction motor is used mainly for low-priced turntables since its speed can fluctuate with load variations, but this can be overcome with some kind of regulatory mechanism. The synchronous motor has its speed locked in to the AC line frequency and therefore is constant, even if the line voltage fluctuates. Power line frequency can shift, but deviations are small and the average is excellent. Looking at an electric clock is equivalent to an expression of faith in the frequency stability of your local power company's generators.

A special-and substitute expensive for special-variation of the synchronous motor is the hysteresis synchronous. Its features include freedom from vibration and noise-free operation. A more recent motor design is the brushless DC servo Hall motor, using Hall elements, a kind of semiconductor. DC motors for turntables require switching devices, such as a mechanical commutator, but the DC servo Hall motor uses Hall elements instead. The Hall motor has large torque, causes no electrical or mechanical noise. The advantage of a DC motor is that it is free of the torque pulsations associated with induction and synchronous motors.

The operating speed of the motor is another important consideration. Many motors turn at 1800 RPM, but there are some available that work at 600 RPM, 300 RPM, and at still slower speeds. The lower the speed, the less opportunity for such hazards as wow and rumble. Rumble is a low-frequency noise heard in the reproduced sound, caused by the motor, or parts associated with it. In operation, the motor can vibrate at a low-frequency rate, a vibration that can be transmitted to the platter, and thence to the stylus, producing a form of sound modulation.

Not all manufacturers indicate amount of rumble in their spec sheets, but when they do it is in the form of dB. The larger the dB figure, the better. A quality record player will be -35 dB, or more.

The frequency of rumble is a sub-multiple of the motor's operating speed, and can go down to 30 Hz. Since the second harmonic is 60 Hz it is quite easy to confuse rumble with hum. A simple way to check is to lift the tone arm. If the disturbing sound remains it is hum-caused, but if it appears only when the stylus is tracking, then the problem is rumble.

The Drive System

Since motors run at higher speeds than 33-1/3 and 45 RPM, they must be coupled to the turntable by some type of reducing linkage, usually accomplished in any of several ways. In one system, known as rim or idler drive, one or more idler wheels (Fig. 3) transfer rotational power from the motor pulley to the turntable platter through friction drive of their rims. Advantages are relatively low cost, easy speed changes, and the opportunity (for the manufacturer) of using motors having lower torque. The difficulty with this method is that as the rubber drives wear a certain amount of slippage is bound to occur. Further, if the wear isn't uniform, drive may become uneven.

The other common drive system uses a rubber or plastic belt (Fig. 3), such as polyurethane. Polyurethane is preferable since it can be made impervious to aging, heat or oil, and has low elasticity. Rubber is a vegetable product, tending to become brittle as it gets older. It is also subject to stretch deformation.

Speed changes are made by guiding the belt around either of two motor pulley sections with different diameters.

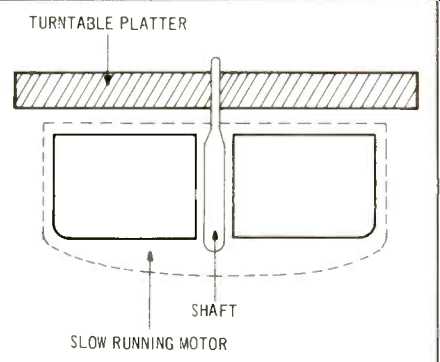

Fig. 4. Direct drive system.

The belt prevents motor vibrations from reaching the turntable, reducing noise and rumble. Some turntables with slow speed motors (Fig. 4) are coupled directly to the turntable platter-the motor's shaft is also the turntable axle.

Speeds are controlled by electronic servo mechanisms.

The Pickup System

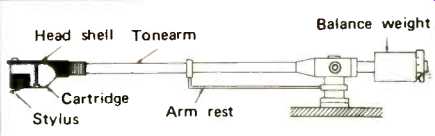

The basic elements of the pickup system (Fig. 5) consist of the stylus, cartridge, head shell, tonearm, balance rest, and a balance weight. It sounds straightforward, but the technology of the pickup system is rather complex.

Books could be written just on this subject alone if for no other reason than the presence of so many conflicting requirements. In many cases, a quality pickup system represents a compromise, an attempt to reach an armistice between the hostile demands of each of the parts of the pickup system.

Fig. 5. The pickup system.

The Stylus

The usual stylus is a diamond, preferable because of its longer service life contrasted with other materials, with some 400 to 800 hours of operating life. Its durability depends largely on the tracking force--that is, the weight with which the stylus is pushed against the walls of the record grooves. The tip of the stylus is machined to extreme precision. It can be spherical, with a tip radius of about 0.5 mil to 0.7 mil, or elliptical. Elliptical styli usually deliver better response to high audio frequencies, that is, they track the high notes better. (Not all authorities are convinced of the superiority of elliptical styli. One thing is certain: if an elliptical stylus is not made accurately and mounted correctly in a properly aligned arm it can cause more distortion and record wear than a conical type-Ed.) Mono records can be played with a 1 mil stylus, but the smaller spherical stylus designed for stereo recordings can also be used on mono discs. The elliptical stylus has a radius of about 0.2 mil, or less, for contacting the undulations in the record walls. The larger radius of the elliptical stylus is about 0.7 to 0.9 mil and keeps the stylus from running along the bottom of the groove.

There is no signal impressed here and so the only result would be unnecessary wear of the stylus, and, what is worse, the production of distortion. The disadvantage of the conical stylus is that its shape will not prevent it from riding along the groove bottom, something that can happen if the stylus diameter happens to be very small.

Most styli today are the elliptical type. The changeover from a conical to elliptical stylus isn't just a matter of doing some switching. The elliptical has a smaller region of contact between the stylus and the grooves and so the tracking pressure should be less. The elliptical stylus can be used to play both stereo and mono records. The motion of the stylus is generally transmitted by means of a cantilever strut to a transducer inside the cartridge--with the transducer converting the mechanical motion of the stylus to an electrical signal.

The Phono Cartridge

The stylus fits into the cartridge, which, in turn, is mounted in a shell at the tip of the tonearm. As the stylus tracks in the rotating grooves, it is deflected laterally and vertically, depending on the modulations inscribed in the groove walls. In theory this sounds easy enough, but if the stylus is to track well, it must follow the complicated meanderings of the groove instantly and it must do so without bottoming (that is, without hitting the bottom of the grooves), without losing contact with the walls, yet not pressing unduly hard against them, and without jumping out of the grooves. Further, its contact or pressure must be the same against both walls--inner and outer--despite the fact that the very motion of the stylus makes such an equilibrium very difficult. To be able to do all this, the mass of the stylus and moving parts must be kept as little as possible, since the greater the moving mass, the greater its inertia--that is, the greater its resistance to quick changes in motion. And so the conditions for good tracking are quite difficult. But these aren't the only requirements. There must be a sufficient downward force, known as tracking force, on the stylus, to keep it in the grooves. Too much will cause stylus and records to wear out more quickly than necessary.

The stylus assembly must have freedom of movement--technically called trackability of compliance. The greater the compliance, the smaller the tracking force required. And since the stylus is going to wiggle around thousands of times a second as the record rotates beneath it, it becomes obvious that with high compliance we are permitting the stylus to do its job, to follow even the most delicate tracings in the groove walls.

(Audio magazine, Mar. 1973)

Also see:

The Language of High Fidelity--Part VIII (Feb. 1973)

The Language of High Fidelity--Part VII: The Basic High-Fidelity System (Dec. 1972)

Language of High Fidelity--Part XI (May 1974)

= = = =