By JOHN EARGLE

The Philips Compact Cassette is very likely the most universal carrier of recorded music the world has ever known. It is estimated that there are three cassette players per household in the United States; considering the popularity of auto stereo and various forms of personal stereo, this seems reasonable. Overall, the world's population of players is estimated to be greater than one billion.

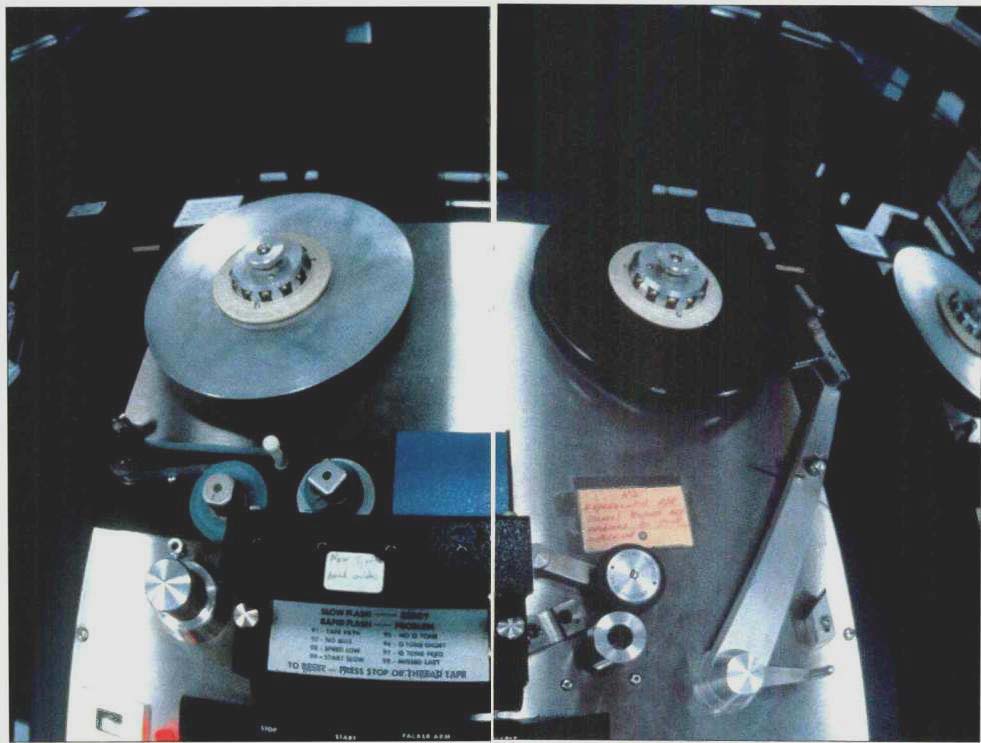

--------Group of Gauss 2400 high-speed recorders.

-------Electro Sound 8000-series high-speed master recorder.

The cassette was introduced into the United States in the mid-1960s, and its basic technical performance went little beyond the requirements of an office dictating machine. At the time, RCA, Ford Motor Company, and Learjet were promoting the Stereo-8 endless loop cartridge for stereo-on-the-go applications. With a tape speed of 1 7/8 ips, the cassette suffered by comparison with the 3 3/4-ips Stereo-8 format.

But in just a few years, the cassette won out, primarily because it allowed the consumer the flexibility of conveniently recording material at home for later replay in the automobile-something that Stereo-8 could not do.

In terms of basic quality objectives for home recording, the cassette was up against reel-to-reel stereo tape. In time, the improvements in tape, shell design, and recorder performance, and above all the addition of Dolby B noise reduction, helped the cassette mount a formidable assault on reel-to-reel; by the mid-1970s the cassette again became the clear winner. Record companies had seen all of this coming and had geared up to produce prerecorded cassettes on a large scale.

In 1983 the unit sales of cassettes in the United States exceeded those of the LP, and the later onslaught of the 1 CD put the LP into further eclipse.

Now, even as the CD gains in momentum, the cassette holds strong and promises to do so for many years to come.

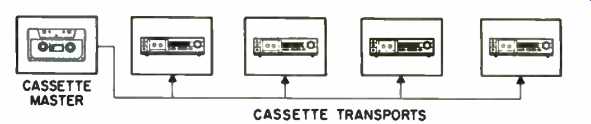

The cassette is mass-duplicated in a manner which is physically identical to the consumer's in-home recording procedure. There are, of course, economies of scale, but essentially the tape p to be copied is run on a master transport, and a number of "slaves" are fed directly from it. On a modest scale there may be no more than four slaves, and the duplicating speed ratio may be no more than 4:1. The slaves themselves may be standard cassette transports which have been modified 1 for the increased speed of operation, and the "master" may simply be a cassette itself. This method is shown in Fig. 1 and would be applicable for very short runs of speech-quality program.

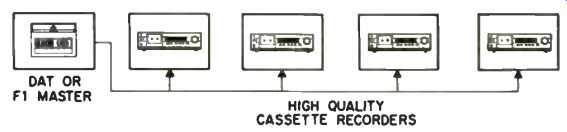

A substantial step forward in quality is shown in Fig. 2. Here, the master is a digital source, a DAT or possibly a Sony PCM-F1. During the mid-1980s, Nakamichi duplicated short runs of very high-quality cassettes using a method similar to this. The source was a digital F1 tape whose transfer quality was carefully monitored by noting the digital block-error rate as the tape was repeatedly played back. The slaves themselves were top-of-the-line Nakamichi recorders which were self-aligning before each run. The duplicating ratio was, of course, 1:1, or so-called real time. Tapes were duplicated with Dolby B or Dolby C noise reduction, and HX Pro headroom extension was routinely used. Each side had to be duplicated separately.

Nakamichi provided this service for owners of their machines who wanted, and were willing to pay for, audiophile quality cassettes from such labels as Delos and Sheffield. Nakamichi could honestly say that these tapes "were first-generation copies of the original digital master" if all steps in the preparation of the running master had been carried out in the digital domain.

These duplicating methods are quite "labor intensive" in that the yield of product per man-hour is limited. However, they remain just about the only way for producing short runs.

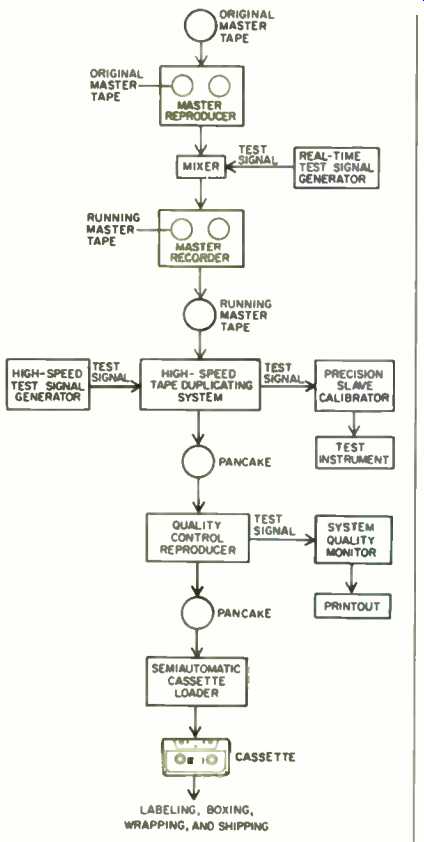

For larger scale duplication, however, some fundamental changes must be made and other considerations enter into the picture. Many slaves may be used, and the duplicating ratio may be as high as 96:1 for music and 128:1 for speech quality. (See Fig. 3.) The production time required for each copy is essentially reduced and can be determined by dividing the playing time in one direction by the duplicating ratio multiplied by the number of slaves. The master itself is run as an endless loop with all four tracks copied at the same time. Figure 3 shows a modern duplicating system with four slaves and an endless-loop tape bin for the master.

The cassettes are duplicated end-to end on large "pancakes" of tape which are subsequently broken down and loaded into the cassette shells.

Many of the larger duplicators injection-mold their own cassette shells and operate large printing shops for paper inserts and labels. Their basic purchased operating materials are commodities, such as plastic, paper and tape-for which prices are relatively negotiable. Such "vertical integration" reduces operating costs considerably in a highly competitive marketplace.

Attention to line scheduling and quality assurance maintains good "loading" of the plant, again in the interests of controlling operating costs and minimizing downtime.

=============

Fig. 1--Modest duplicating setup for limited runs of speech-quality cassettes.

No more than four slaves are used, and speed ratio is 4:1 or less.

Fig. 2--Real-time (1:1) duplication from digital copy master, for high

quality.

Fig. 3--Large-scale duplication, using endless-loop master and slave

recording tape "pancakes." Setup shown here is for music, using

7 1/2-ips master running at 240 ips and tape pancakes running at 60 ips,

a 32:1 duplicating speed ratio. For speech-quality tapes, 3 3/4-ips masters

and still higher speeds would be used, for ratios of 128:1 or more.

Fig. 4--Tape duplicating chain, with electronic quality-control stages.

=============

The duplicating ratios used today are a far cry from the 8:1 methods of the 1960s. The electronic challenges were relatively easy to meet; bias frequency has been raised to the range of 8 to 10 MHz, and equalization requirements have been simply transposed upward as required. The major problems to overcome were in the physical handling of the tape. Tape skew and air filming have been the major problems in ensuring positive tape-to-head contact at high speeds.

The design of the endless-loop tape bin for the master was a considerable challenge, in that the requirements were to move the tape at a speed as high as 480 ips while handling it gently to minimize wear and damage.

At this point, we will follow a master tape through the entire duplicating cycle, noting the many procedures which ensure quality and process control.

Duplicating plants prefer to receive a master in the form of a digital clone of the final edited master, with A and B sides clearly indicated. The digital tapes are then carefully checked to determine if there are any potentially troublesome high frequencies present in the program. If not, then the digital masters are transferred to 1/2-inch tape running at 7 1/2 ips. If the cassettes are to be in Dolby B (most of them are), then the 7 1/2-ips tapes will be made as a Dolby B copy. In a single pass, side A is copied in one direction, while side B is copied in the other. The tape made at this point is referred to as the running master.

Should there have been any problems with the source tapes, these would be discussed with the client and adjustments made either at the client's studio or at the duplicating plant.

Before the actual production run, the master will be copied onto a cassette on a master-slave setup, which, in effect, duplicates all production conditions. It is transferred at the intended production level and on the intended tape stock. It is then sent to the client as a reference of what the finished product will sound like. The client usually has a technician check the tape and judge the quality of the transfer. Then, if all has gone well, the client will send an approval to the duplicating plant and production can then get underway.

The production control department takes over at this point and ensures that all paper components (labels, inserts) are on hand. Even though the entire order for cassettes may be quite large, the client may not want more than, say, 5,000 or 10,000 units at any one time. The run is scheduled accordingly, and the master tape is loaded into the endless-loop bin. For high quality music duplication, a ratio of 96:1 would probably not be exceeded.

At this duplication ratio, and assuming a total program length of about 40 minutes, a single slave can produce about 1,800 copies per eight-hour shift. Thus, a master transport with four or five slaves might easily handle the production run in about half a shift.

Obviously, one cannot play every cassette to ensure that everything has gone properly. Cassettes are spot-checked according to established sampling procedures, but more to the point, all of the process and the incoming materials are carefully monitored.

The duplicating chain itself is subject to several levels of maintenance, including those which are performed daily, such as cleaning, and those that are done at much wider intervals, such as replacement of heads and bearings. Between these extremes is routine electrical checkout of the systems.

While the incoming raw tape stock is sampled to make sure it meets magnetic requirements, each duplicated 8,400-foot pancake of tape is recorded with a diagnostic sequence of signals.

This serves as a running check on outgoing quality, since no pancake will be loaded into cassette shells unless the pancake passes the test.

A pancake contains many passes of the master, and between each pass is a low-frequency cue tone which is used during the breakdown process.

At this stage, the pancake is loaded onto the cassette winder, and individual cassettes are loaded at speeds up to 360 ips. The cue tone stops the winding process when each cassette is fully loaded. The operator then removes the loaded cassette and replaces it with a new shell.

The loaded cassettes then find their way to the labeling machine, which affixes the appropriate label to each side of the shell. Then, they move on to final packing and shrink-wrapping.

--------- Injection-molding department, Sonopress, Weaverville,

N.C.

With recent developments in random access memory (RAM) capability and high-speed digital-to-analog (D/A) conversion, it is now possible to operate duplicating slaves directly from a digital source, thus bypassing the analog running master completely. The technology for this was developed by Concept Design, and one of the major installations of this is at the Sonopress manufacturing facility in Asheville, N.C. Master tapes are received from clients, preferably in the Sony 1630 format, which stores the program on 3/4 inch videocassettes. From this source, the plant's mastering department makes a pair of R-DAT clones, one for side A and one for side B. When a program is to be duplicated, the two R-DATs are loaded into RAM simultaneously, but on a real-time basis. Thus, it takes about 20 minutes to "load in" each new program. When duplication gets underway, the RAM and high-speed D/A converter function just like the running master and master transport in the typical duplicating setup.

The duplicating ratio is 80:1, so this helps offset some of the rather long load-in time for new programs. In all other regards, the plant works very much like a traditional duplicator.

Sonopress is owned by BMG, which is the parent company of RCA Records, and the technology can be heard on RCA cassettes as well as A & M, Delos, and Telarc product. Sonopress places great emphasis on quality-control procedures to ensure that the benefits of the new technology will clearly find their way into the consumer's home.

The process gets us one step nearer to the digital master, in that each cassette is a first-generation copy of the digital master, but the next major technical leap forward for the cassette will be the DCC, or Digital Compact Cassette. The DCC is designed to complement the standard cassette and not necessarily make it obsolete. Since all DCC players will also play standard cassettes, there will be no need for wholesale adoption of the new medium. In fact, it may be quite reasonable to make the conjecture that speech only cassettes, a very large market indeed, may remain analog based for the foreseeable future.

Tape duplicators and manufacturers of duplicating equipment are overwhelmingly in favor of DCC because it reinforces their fundamental investment in technology. DCC is designed to be duplicated at a 64:1 ratio on traditional slaves which have been outfitted with new heads. A number of details have yet to be worked out in DCC but it appears poised for introduction in 1992.

(source: Audio magazine, Jul. 1991)

Also see:

= = = =