| Home | Audio mag. | Stereo Review mag. | High Fidelity mag. | AE/AA mag. |

Details are given in subsequent sections of the dimensions, layout and wiring of each item of equipment. This information is extensive, but no claim is made that it is exhaustive. The constructional sections of each section should be regarded principally as giving some guidance for assembling the equipment, but should not be considered to be absolutely inviolate sets of rules and instructions. An intelligent use of these sections, coupled with references to circuit diagrams, should produce excellent results.

The suggested arrangements of components in the various chassis are those adopted in the prototype equipment. The convenience of the constructor has been borne in mind in evolving these layouts, and economy of space has been effected whenever possible. However, the underlying principle has always been to obtain the best possible standard of performance for a given expenditure. A good margin of stability, a low level of hum, and so on, have never been sacrificed in an attempt to achieve attractive, but less fundamental, properties such as miniaturization.

There is no theoretical method of deducing the best layout for audio equipment. It has to be found experimentally, and it follows that the effect of any deviations from an established arrangement cannot be predicted. Consequently, any alterations to layouts recommended in this guide should not be undertaken lightly. They should be dictated by strong reasons, and the subsequent variations in performance should be analyzed closely.

Similarly, recommendations in this guide for good-quality valve (tube) -holders and for high-stability resistors, for example, are based on experimental proof of their necessity. Any change from the recommendations can alter the performance considerably. The voltage ratings quoted for capacitors, however, should be regarded as minimum values and capacitors with higher ratings may be used if so desired. In these respects, the home constructor is advised to choose his components very carefully, and complete sets of components or constructional kits purporting to be used with specific Mullard circuits should be examined closely. Mullard Limited only design and publish the circuits: they have no control of material and components sold for use with their circuits.

SMALL COMPONENTS

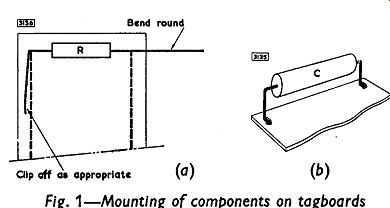

The smaller components are normally mounted on tagboards, and it is generally more convenient to solder them to the tags before the boards are mounted in the chassis. The small carbon resistors should be laid across two tags and the lead wires bent around the tags in the manner shown in Fig. 1(a). If the tagboard wiring diagrams show that neighboring tags should be connected together, the lead wires of the appropriate components should be cut to lengths sufficient to allow this. Waxed capacitors, silvered-mica capacitors and high-stability resistors will require longer leads so that they will not be overheated when soldered into position. The leads should be bent as shown in Fig. 1(b), care being taken in doing so to avoid making sharp bends very close to the ends of the components.

Components such as the germanium diodes (used in the tape-recorder equipment of Sections 11 and 12) which are particularly sensitive to temperature, will also require long lead wires. These wires should also be held with a pair of pliers to act as a heat shunt when soldering. The polarity of Mullard germanium diodes is decided by the outer markings: usually the negative pole is the end on which a band is marked.

EARTH CONNECTIONS

In audio equipment, it is advisable to have only one direct connection to the chassis, and this should be made close to the input socket. With a number of connections, eddy currents can be set up in the chassis and hum voltages can be induced in the sensitive sections of the equipment by the magnetic fields associated with these currents.

Normally, a common earth lead or busbar is recommended, and the center spigots of the valve (tube) holder often serve as convenient points for securing this lead.

To maintain a low level of hum when two or more units are used together (see Section 1), the chassis of the units should be connected by one lead only. If the negative return line is conveyed from one unit to the other by way of the power cable, the connection between chassis should not be duplicated in the a.f. coaxial lead, and one end only of the outer conductor of this lead should be earthed.

Whenever possible, an external connection should be made from the equipment to earth. This lessens hum pick-up and may also help in eliminating any undesirable r.f. signals that can occur in equipment situated near radio or television transmitting stations.

Fig. 1

OUTPUT TRANSFORMER

The quality of the output transformer will govern to a great extent the quality of the output from the loudspeaker. A poor component can give rise to a high level of distortion and can cause instability. The most important factors determining the performance of an output transformer are:

1. Primary-winding inductance

2. Leakage inductance

3. Core material and core size

4. Intrinsic capacitance of the coils (especially of the primary)

5. Capacitances between the various coils

6. Power efficiency.

In an actual design, a compromise has to be found between the inductance and capacitance of the primary winding. The inductance must be high enough to minimize the fall in response which occurs at low frequencies. On the other hand, a high inductance necessarily produces a high self-capacitance because of the large number of turns required, and this can result in a large loss in voltage at high frequencies.

The inductance and self-capacitance of the primary winding form a parallel tuned circuit in the output stage, and the resonant frequency of this must be as high as possible. It is usually between 50 and 100KHz in a good transformer. Furthermore, the capacitance must be low to prevent an increase in the phase shift when feedback is used.

A high capacitance can give rise to low-frequency instability in the amplifier. The capacitance can be minimized by careful winding of the primary coil.

If the coupling between the primary and secondary windings of the transformer is not close enough (corresponding to increased leakage inductance) excessive phase shift will be introduced at high frequencies which may lead to parasitic oscillations. Close coupling is often obtained by dividing the primary winding into sections and winding the secondary turns between these sections.

It is advisable to obtain output transformers from manufacturers who build the components for specific circuits. The commercial type numbers listed with the circuits in subsequent sections have been supplied by the manufacturers, and the transformers should all prove to be satisfactory in the appropriate equipment.

NEGATIVE FEEDBACK

Negative feedback is usually taken from the output transformer to the input stage of a power amplifier to reduce the harmonic distortion in the output signal. The correct polarity of this feedback is essential.

Connection to the wrong side of the secondary winding of the output transformer will give positive feedback and will result in oscillation.

The correct connection can best be found by trial and error, and it is advisable to use a low-grade speaker while doing this. With unsuitable phasing (positive feedback) the resultant violent oscillation might damage a delicate speaker-coil suspension. If a low-grade speaker is not available, a momentary completion of the feedback loop should be sufficient to determine the correct phasing.

Should it be desired to experiment with the level of feedback--if r.f. instability occurs, for example - this can be done by altering the value of the resistor in the feedback loop. If the resistance is increased, there is a decrease in the level of feedback. (A corresponding value of shunt capacitance in the feedback loop must be found empirically.) Except in the unlikely event of r.f. instability, little advantage will be gained from changing the values of components recommended in later sections. Audible improvement is indiscernible when the level of feedback is increased above that indicated for each amplifier.

STEREOPHONIC BALANCE CONTROLS

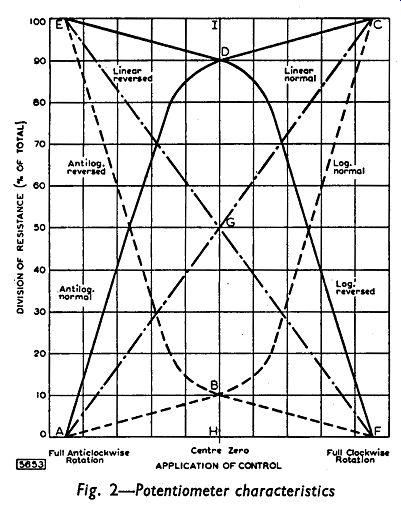

The balance control in stereophonic equipment will often consist of dual-ganged potentiometers connected in the grid circuits of corresponding valve (tube) s in each channel. One of the potentiometers will be connected normally with its minimum-resistance end earthed and the other will be connected in reverse, with its maximum-resistance end earthed. The ganged potentiometers could be either a pair of linear-law potentiometers or one logarithmic-law and one antilogarithmic-law potentiometer. The characteristics of these components, connected normally and in reverse, are shown in Fig. 2.

The lines AGC and EGF are the characteristics of normally and inversely connected linear potentiometers respectively. If these are used for the balance control, then the need for the center-zero arrangement will give an operating point at the intersection G of the two characteristics. The resistance corresponding to IG will appear in series with each grid, and that represented by GH will be between the grid and earth. The signal attenuation caused in each channel by this arrangement will thus be 50 %.

The curves EDF and ADC are respectively the characteristics of a logarithmic potentiometer connected in reverse and an antilogarithmic potentiometer connected normally. The operating point with this combination would be the intersection D, and the signal attenuation in the zero position of the control would be only ID/IH. For potentiometers obeying a 10 % logarithmic law, the attenuation would thus only be 10 %.

POWER SUPPLIES

Fig. 2

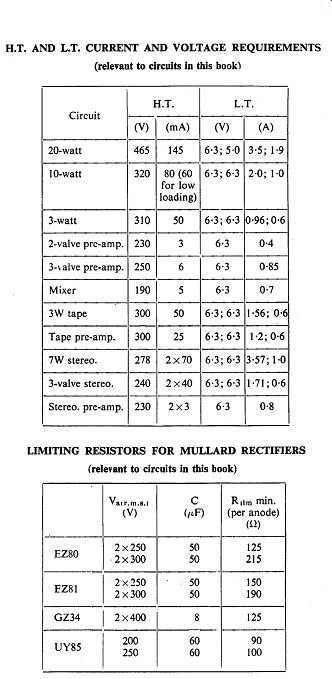

Allowance has been made in the circuits of subsequent sections for adequate h.t. power supplies. The requirements of each item of equipment dictate the type of rectifier to be used and the specification for the mains transformer.

A minimum value Rlimmin. of series resistance is quoted on page 29 for the rectifiers used with the circuits in this guide. If the specification of the transformer does not give a total winding resistance equal to or greater than this minimum, then a resistor must be included in each anode circuit. The amount of series resistance Rt contributed at each anode by the transformer is:

Rt = Rs+n2 Rp

... where Rs = the resistance of half the secondary winding Rp = the resistance of the total primary winding and n = the ratio of the number of turns on half the secondary winding to the number of turns on the whole primary.

The value R of the resistance which must be added to each anode circuit to produce the necessary limiting value Rlimmin. is therefore given by:

R = Rlimmin.-Rt.

A good mains transformer is essential for high-quality equipment. It may be necessary to screen the transformer to reduce the transfer of hum, and a mains filter may also be required if interference arising from the mains supply is experienced.

The policy of using only one connection to the chassis should also be applied to reservoir and smoothing capacitors. It is not advisable to bolt the negative cans of these capacitors directly to the chassis. The cans should be insulated from the chassis and the negative connection made to the common earth lead.

Low-frequency instability can result from inadequate decoupling of the power supply. If this occurs, an increase in the values of the decoupling components or the addition of extra decoupling components may prove beneficial. The extent of this increase must be determined experimentally.

----