Disc Manufacturing

The Compact Disc manufacturing process enjoys the advantages of the disc medium, in which the information is placed on the disc simultaneously with its creation.

However, the CD requires sophisticated manufacturing processes and stringent quality control to guarantee a satisfactory yield. Although manufacturers use different techniques to produce CDs, the manufacturing process always involves three general steps: premastering, disc mastering, and disc replication. Premastering can be accomplished in a recording studio or even on a personal computer. However, disc mastering and replication require specialized equipment found only in disc manufacturing plants. DVD and Blu-ray disc manufacturing is similar to CD manufacturing. The principal difference is the dual substrate construction of DVD discs, and the presence of additional data layers in some DVD and Blu-ray discs.

These differences are discussed in Sections 8 and 9. SACD discs are manufactured similarly to DVD discs.

Pre-mastering

Pre-mastering is the culmination of the recording process and the prelude to disc mastering and replication. In premastering, an audio media is prepared prior to creating a glass master disc. This media contains the final, edited version of the content to be replicated. This version should be recorded at the highest resolution possible, on a media suitable for robust storage. A variety of media are used to hold these recordings. Originally, most audio CDs were manufactured from data on 3/4-in U-Matic videotape cassettes; as noted, this accounts for the selection of 44.1 kHz as the CD sampling frequency. Data was formatted using a digital audio processor such as the PCM-1630 recording to a videocassette recorder. The videocassette contained the following information: video format tracks with digital audio data; analog audio channel 1 with PQ subcode; and analog audio channel 2 with continuous SMPTE (non-drop frame) timecode.

In many cases, Exabyte data tapes are used to hold the audio recording. Exabyte tapes use specially formulated 8 mm Hi-8 videotape and are also used to archive computer data. Exabyte is attractive because glass masters may be created at faster than real time speeds. In other cases, audio data is held on a hard-disk drive or is delivered by the Internet or other network protocols. For audio content, the Disk Description Protocol (DDP) file format is employed to hold an image file of Red Book data and PQ subcode information. Both DDP 1.0 and DDP 2.0 are used; the 2.0 specification writes the table of contents to the end of the tape. Generally, it is recommended to supply a replication plant with an Exabyte 8-mm tape with DDP files (including PQ and ISRC data) that has been verified by the artist and producer. In some cases, audio data is written to CD-ROM disc as 24-bit WAV or AIFF files. On request, a test disc can be sent to the artist and producer.

DAT tapes and CD-R discs can be used to deliver audio content to a replication facility, but their relatively higher error rates and susceptibility to damage make them less than ideal. If they are used, finished media must be checked to ascertain the error count. An analog tape can be used, but it must be converted to an interim digital format. In some cases, the digital source media may not be compatible with the mastering equipment; for example, the sampling frequencies may differ. Although the digital recording could be converted to analog and then to a compatible format, degradation would result; hence, a sampling frequency converter should be used for a digital to-digital transfer without significant deterioration in signal quality.

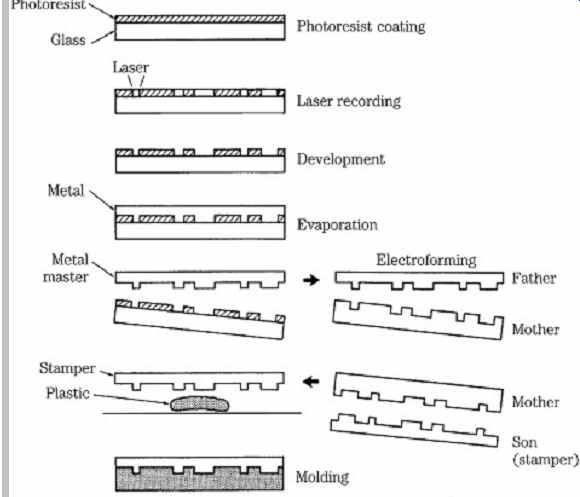

FIG. 20 A summary of the principal steps in the CD disc manufacturing

process.

In many cases, no matter what media resource is used, data is converted to a DDP file with the necessary PQ and ISRC codes and stored on Exabyte 8-mm tape or a hard disk drive. Care must be taken to ensure that equipment uses a stable central clock, and that the signal path is free of defects. From there, data passes to the laser beam recorder (LBR) for disc mastering.

Disc Mastering

Compact Disc mastering is the first process in disc manufacturing; the entire process is shown in FIG. 20. In many cases, a photoresist process is used to create a master disc, employing techniques similar to the microlithography used to manufacture integrated circuits. A glass plate about 240 mm in diameter and 6 mm thick, composed of simple float glass, is washed in alkali and freon, lapped, and polished with a CeO2 optical polisher.

The plate is prepared in a clean room with extremely stringent dust filtering. After inspection and cleaning, the plate is tested for optical dropouts with a laser; any burst dropouts in reflected intensity are cause for rejection of the plate. To prepare the plate for photoresist mastering, an adhesive is applied, followed by a coat of photoresist applied by spin coating. The depth of the photoresist coating is critical because it determines the ultimate pit depth. The plate is cured in an oven and stored, with a shelf life of several weeks. The plate is ready for mastering.

The laser beam recorder is a device that photographically exposes the data spiral into the photoresist on the master glass disc. The LBR may have a control rack consisting of a computer, tape transport, hard disk drive, CD and subcode encoders, and diagnostic equipment. The recorder may use an HeCd or argon ion gas laser, at 442 nm and 458 nm, or 488 nm, respectively, with a numerical aperture (NA) of 0.9. The laser is intensity modulated by an acousto-optical modulator to create the exposing signal corresponding to the encoded data.

Another laser, which does not affect the master disc photoresist, is used for focusing and tracking. The master glass plate coated with photoresist is placed on the LBR and exposed with the laser to create the spiral track, creating the disc contents as the audio signal is played and CD-encoded. During disc mastering, the PQ subcode is uniquely created for the glass master using a subcode editor, and is modulated into the CD bitstream.

Quality of the production discs depends directly on the LBR's signal characteristics such as eye pattern symmetry, signal modulation amplitude, and track following. The length, width, and edge angle of the pits on the replicated discs are subject to the exposure intensity and developing time of the photoresist. To guard against disc contamination, stringent air filtering is used inside the LBR.

Although the optics are similar to those found inside consumer CD players (laser source, polarization beam splitter, objective lens), the mechanisms are built on a grander scale, especially for isolation from vibration. For example, the stylus block may be supported and moved by an air-float slider. The entire mastering process is accomplished automatically, under computer control.

After exposure in the laser beam recorder, the glass master is developed by an automatic developing machine.

Developing fluid washes the rotating disc surface, removing the exposed areas of photoresist, leaving pits in the photoresist. During development, a laser monitors photoresist depth and stops development when the proper engraving depth has been reached; the developing pits form a diffraction grating, reflecting multiple beams. The relative intensity of the beams is monitored to indicate pit geometry. As noted, compromises must be made to determine the optimum practical pit depth. A production pit depth of 0.11 µm to 0.13 µm is typical. Following etching, a metal coating, usually of silver, is evaporated onto the photoresist layer. The master glass plate is ready for electroforming.

In some cases, a nonphotoresist (or "direct-effect") mastering technique is used. Using a glass plate coated with a dye-polymer recording layer, the LBR directs the input signal to an acousto-optical modulator that controls the recording laser. Pits are physically cut directly into the recording layer on the master disc using a blue laser. The system provides a direct-read-after-write (DRAW) function so that the recorded signal can be continuously monitored during mastering. A trailing red laser is focused on the disc just behind the recording laser, but does not affect the recording. Instead, it reads data so that analysis equipment can dynamically control cutting laser power and other critical parameters to ensure optimum pit geometry and decode the EFM signal to evaluate data error rates; this decreases production time.

Electroforming

The metallized master disc is transferred to an electroplating room where the plating process produces metal stampers. First, evaporation is used to coat the master disc with a silver or electroless nickel layer to make it electrically conductive. The master electroplating process imparts a nickel coating on the metallized glass master.

The metal part is separated from the glass master, and any photoresist is removed. This metal disc is called the metal master, or father. Using the same electroplating process, the resulting metal father is used to generate a number of positive nickel impressions, called mothers. The process is repeated to produce a number of negative impression stampers, or sons. Disc substrates are replicated from these stampers. A center hole is precisely punched into the stamper. Stampers are about 300 µm thick-a thick metal foil. Perhaps 30,000 discs may be made from a stamper before wear limits its use.

Disc Replication

Mass production of discs can be accomplished with injection molding to produce disc substrates. A polycarbonate material is used. It is rugged, is one of the most stable of polymeric plastics, and in particular has a low vapor absorption coefficient that is about 70% less than that of polymethyl methacrylate (PMMA) plastic, also known as Plexi-glass. Polycarbonate material has an inferior birefringence specification, especially when produced by injection molding; however, injection molding is a more efficient production method. After experimentation with different kinds of mold shapes and molding conditions, techniques for producing a single piece polycarbonate substrate were achieved. CD birefringence is specified to be less than 100 nm (measured double pass through the substrate). Polycarbonate pellets are heated to about 300°C; molten polycarbonate is injected into the mold cavity, faced on one side by the metal stamper, and the disc substrate (with pits) is produced; water channels in the molds help cool the substrate in less than 5 seconds. The substrate center hole is formed simultaneously.

After molding, a metal layer (about 50 nm to 100 nm thick) is placed over the pit surface to provide reflectivity. In most cases, aluminum is used; however, silver or gold or another metal can be used. The reflection coefficient of this layer, including the polycarbonate substrate (note that the CD player laser must pass through the substrate to the metal layer), is specified to be at least 70%. Aluminum evaporation can be accomplished with vapor deposition in a vacuum chamber. Alternatively, high-voltage magnetron sputtering can be used to deposit the reflective layer. A cold solid target is bombarded with ions, releasing metal molecules that coat the disc. Using high voltages, a discharge is formed between a cathode target and an anode. Permanent magnets behind the cathode form a concentrated plasma discharge above the target area.

Argon ions are extracted from the plasma; these ions bombard the target surface, thus sputtering it; the disc is placed opposite the target and outside the plasma region.

Metallization may take 3 seconds. The metal layer is covered by an acrylic plastic layer with a spin-coating machine, and cured with an ultraviolet light. This layer protects the metal layer from scratches and oxidation. The label is printed directly upon this layer.

The final step in CD manufacturing is inspection and packaging. Finished discs are inspected for continuous and random defects, using automated checking. Discs can be scanned to check for physical defects such as inclusions or bubbles in the substrate, missing metallization and staining, to evaluate the replication process. Scanners can use laser light, regular light, and cameras to quickly check discs. Because no data is read, scanning is fast and thus is often incorporated in the production line to check every disc. Disc readers check error rates, tracking, jitter, and data signal levels. This is more time-consuming and is typically done off-line on selected discs. Other off-line tests can check thickness variation, dynamic balance, and other parameters.

A number of optical, mechanical, and electrical criteria have been established. Molded discs are checked for correct dimensions, lack of flash and burrs, birefringence, reflectivity, flatness (skew angle), and general appearance.

The pit surface is checked for correct pit depth, correct pit volume, and pit form and dimensions. The metallized coating is checked for pinholes and uneven thickness, and uneven or incorrect reflectivity. Birefringence can be checked with a circularly polarized light used to convert the phase change to an intensity variation measured with a photodiode.

Angle deviation measures the angle formed by the normal to the disc in the radial direction. This angle is critical because any deviation causes the reflected laser beam to deviate from its return path through the objective lens. This angle deviation could result from an improper manufacturing method; specifications call for a maximum angle of ±0.6°. Disc eccentricity measures the deviation from circularity of the pit track and the positioning of the center hole. Eccentricity may result if the stamper is not punched correctly or if the stamper is not precisely centered in the injection mold. Also, the electroforming or molding processes introduce some eccentricity in the shape of the pit track. In addition, the player's positioning of the disc in the drive might introduce eccentricity. If it is excessive, it could exceed the ability of the radial tracking servo of the player. Tolerances for deviation from circularity call for maximum eccentricity of ±70 µm. Disc eccentricity must also account for alignment of the center hole.

Specifications call for a center hole tolerance of 0.1 mm. A hole that is off-center can lead to disc imbalance, and noise and resonance errors. Push-pull tracking evaluates the intensity of light returning from the left and right sides of the pit track; it can be used to monitor pit geometry, which affects the overall gain of the tracking servo.

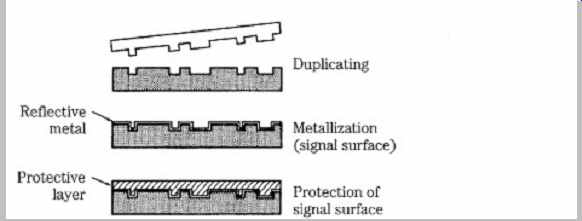

FIG. 21 An example of the in-line hardware used to manufacture Compact

Discs. Critical processes are enclosed in small clean enclosures.

Disc quality can be evaluated by examining the analog RF 3T-11T signal output from a pickup. The I11 signal is derived from reading an 11T pit/land and an I3 signal is derived from a 3T pit/land. ITOP measures the distance from the signal's baseline to the top of the amplitude of an I11 signal. The I3/ITOP ratio must be between 0.3 and 0.7, and the I11/ITOP ratio must be greater than 0.6. The higher the value, the better the signal's condition. Radial noise measures how much a pickup moves side to side to maintain tracking, and thus evaluates the straightness of a pit track. The maximum value is 30, and lower figures are better. Push-pull magnitude measures the magnitude of the tracking signal, which is determined by pit depth. Shallow pits yield a high push-pull magnitude, and deep pits yield a low push-pull. The minimum value for push-pull is 0.04 and the maximum value is 0.09. Crosstalk measures the interference from adjacent pit tracks; it increases as the track pitch is reduced. The maximum value for crosstalk is specified at 50%. Jitter measurements can monitor pit accuracy; maximum peak-to-peak jitter should be less than 50 ns (for modulation frequency of the channel bit clock frequency greater than 4 kHz).

Following packaging and wrapping, discs are ready for distribution. In most cases, the injection machine, sputtering machine, spin coater, and label printer are consolidated into one production unit; it might take a disc 2 minutes to travel from the injection machine to labeling; one unit can produce 2 million discs per year. Equipment used for disc replication is shown in FIG. 21.

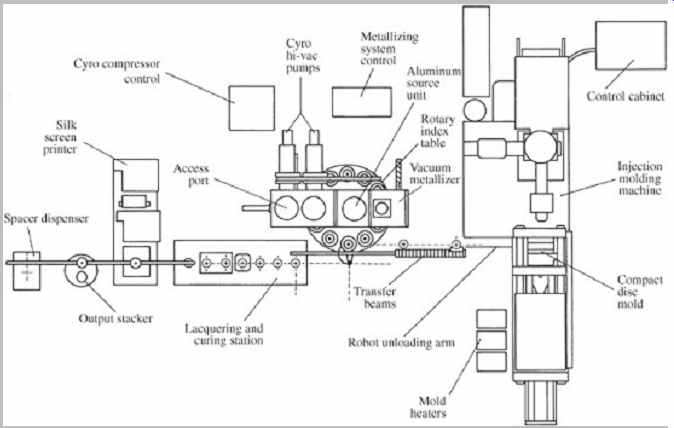

FIG. 22 A simplified road map showing the complex interrelationships between

CD formats.

Alternative CD Formats

The Compact Disc is an efficient storage medium allowing user information to be reliably stored on a low-cost disc using CIRC error correction and EFM coding techniques.

Fortuitously, that medium is available for other storage applications beyond the CD-Audio format (also called CD DA or CD-Digital Audio). Computer software, published material, or audio and video files can be stored in the CD ROM file format. The CD-R standard specifies a write-once disc format, and the CD-RW standard describes a fully erasable disc format. As with many families, the interrelationships between members of the CD family are somewhat complicated, as shown in FIG. 22.

Complications and incompatibilities arose because the CD was originally conceived only as a music carrier; subsequent evolutions occurred in a piecemeal fashion. In contrast, newer formats such as DVD and Blu-ray disc were initially designed for multiple uses. Despite their drawbacks, these alternative CD formats greatly expand the range of applications open to the CD.

CD-ROM

The Compact Disc Read-Only Memory (CD-ROM) format extends the digital audio CD format to the broader application of information storage in general. Rather than store only music, the CD-ROM format is used for diverse data. The CD-ROM format forms the basis for a read-only electronic publishing medium applicable to computer applications and for information distribution such as book publishing, dictionaries, technical manuals, business catalogs, and so on. Its advent represented an entirely new technology of information dissemination. CD-ROM discs use the same disc construction as audio discs, and can be mass produced with the same replication equipment; however, more stringent quality control may be required.

The CD-ROM standard is derived from the CD-Audio standard, but specifically defines a file format for general data storage. Unlike CD-Audio, CD-ROM is not tied to any specific application. Both standards use the 120-mm diameter disc, but with different data formats. The CD ROM standard, sometimes called the Yellow Book, was ROM standard, sometimes called the Yellow Book, was issued in 1983. In 1989, it was also specified in the ISO/IEC 10149 (ECMA-130) standard (International Organization for Standardization/International Electrotechnical Commission).

A Mode 1 CD-ROM disc nominally holds 682 million bytes of user information (333,000 blocks × 2048 bytes).

This storage area is roughly equivalent to 275,000 pages of alphanumerics. The CD-ROM format can store information such as computer applications software, audio files such as WAV or MP3, video files, operating systems, online databases, published reference materials, directories, encyclopedias, libraries of still pictures, parts catalogs, or other types of information. Read-only CD-ROM discs form a publishing medium that is much more efficient than paper. For example, the U.S. Navy investigated the use of CD-ROM to reduce the paperwork on naval ships.

They found that a cruiser carries about 5.32 million pages of documentation, weighing almost 36 tons. That mass of paperwork could be reduced to about 20 CD-ROM discs, weighing 280 grams. On the other hand, the CD-ROM is not ideal for computer applications. The file sizes are not an exact power of 2 as computers prefer, interleaving dictates that large amounts of data must be read to recover any useful information, CLV rotation requires motor speed changes as data is accessed across the disc radius, and CD-ROM is not erasable. However, the CD-ROM data format is widely used to write data to CD-R and CD-RW discs.

The CD-ROM standard uses a data format modified from the CD-Audio standard. Ninety-eight CD frames are summed (as in CD subcode) to form a data block of 2352 bytes (24 byte × 98 frames) in length. A disc is divided into a maximum of 330,000 blocks; a 60-minute disc holds 283,500 blocks. The first 12 bytes of a block form a synchronization pattern, and the next 4 bytes comprise a header field for time and address flags. The remaining 2336 bytes can store user data, or data plus extended error correction, depending on the mode selected. The header contains three address bytes and a mode byte. Addresses are stored as a disc playing time. One address byte stores minutes, the second byte stores seconds, and the third stores block numbers within the second. For example, an address of 62-13-08 identifies the 8th block in the 13th second of the 62nd minute on the disc.

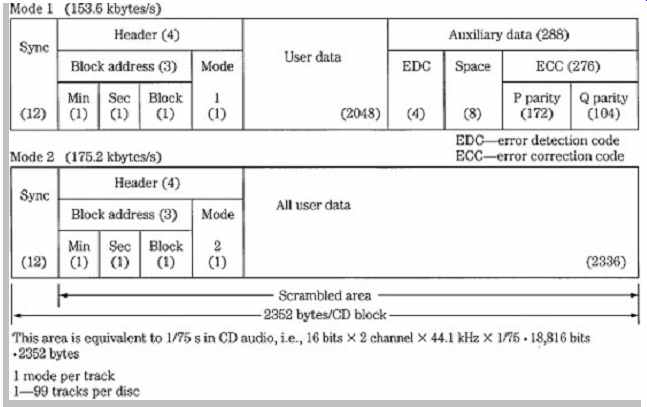

The mode byte identifies three modes, used for two different types of data. There are two data modes, as shown in FIG. 23. The Mode 1 format assigns 2048 bytes of each block to user data. Each block contains 2 kbytes (2 × 1024) of user data; 280 bytes are given to extended error detection and correction (EDC/ECC), which is an extra layer of coding in addition to the basic Red Book CIRC code. The Mode 2 format allows for the full 2336 bytes to be used for user data (14% more data), but in practice is rarely used except when coded in CD-ROM/XA mode (described below). There is also a null mode, Mode 0. In all cases, after sector data is created, the CD-ROM bitstream is applied to conventional CD encoding such that CIRC and EFM, and other processing is applied just as in an audio CD. For example, Mode 1 data thus has two independent layers of error correction (EDC + ECC and CIRC) whereas Mode 2 uses only CIRC coding.

FIG. 23 The CD-ROM specification contains two modes of data block structures.

Mode 1 allows for extended error detection and correction, and Mode 2 provides

capacity for additional user data.

Because of its extended error correction, Mode 1 has the greatest applications. The EDC/ECC field is essential for high-density numerical data storage, which is more demanding than audio data. A GF(28) Reed-Solomon Product Code (RS-PC) is used to encode each block. It produces P and Q parity bytes with (26,24) and (45,43) codewords, respectively. Because the EDC/ECC field is independent and supplements the CIRC error correction code applied to the frame structure, the error rate is improved over that of CD-Audio. In Mode 1, the typical CD ROM bit-error rate is approximately 10^-15, one uncorrectable bit in every 10^15 bits.

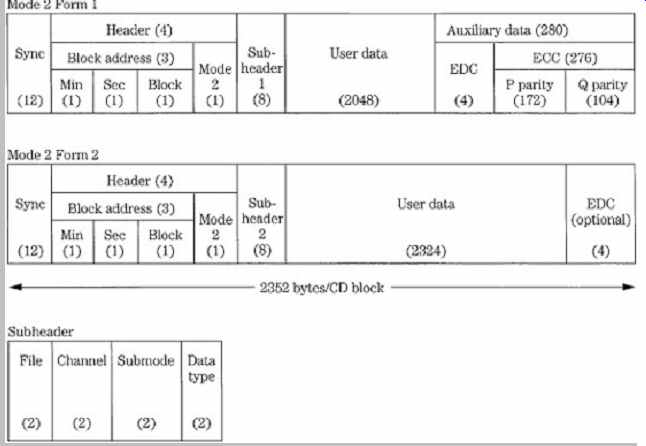

CD-ROM/XA (eXtended Architecture) is an extension to the Yellow Book Mode 2 standard and defines a new type of data track; computer data, compressed audio data, and video and picture data can all be contained on one XA track. CD-ROM/XA Mode 2 differs from CD-ROM Mode 2 because it provides a subheader that defines the block type, as shown in FIG. 24. In this way, the XA track can interleave Form 1 and Form 2 blocks; this is useful in some applications. Specifically, XA defines two types of blocks:

Form 1 for computer data and Form 2 for compressed audio/video data. The former provides a 2048-byte user area, and the latter provides 2324 bytes. CD-Audio data cannot be placed on an XA track. The XA data rate is 1.4 Mbps. Clearly, special processing is needed to decode the various data types found on an XA disc. Some players are dedicated to specific types of CD-ROM/XA discs; the Video CD and Photo CD are types of CD-ROM/XA. The CD-ROM/XA format is defined in the White Book. Not all CD-ROM drives support CD-ROM/XA; in some cases a special interface board must be used.

FIG. 24 The CD-ROM/XA data format is based on the CD-ROM Mode 2 format.

It provides two forms: extended error detection and correction, and increased

user data capacity.

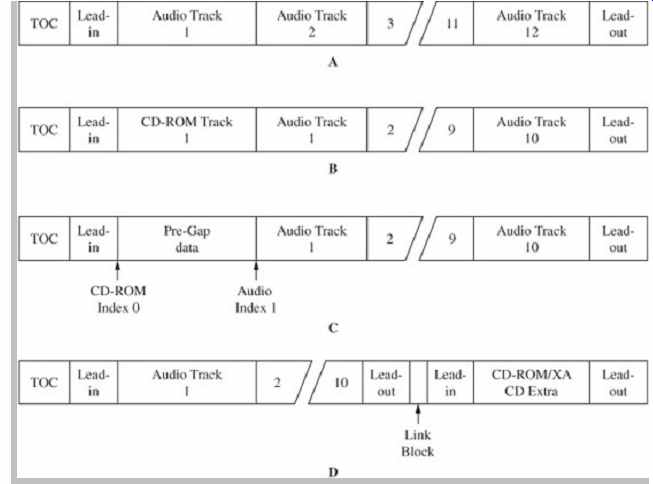

Hybrid audio/data CD formats, sometimes called CD Extra (formerly CD Plus), Enhanced CD, and Stamped Multisession or Mixed Mode, combine several different format types (such as CD-Audio and CD-ROM/XA) on a single disc. For example, a CD Extra disc has Red Book audio data in the first session, with Yellow Book ROM/XA Mode 2, Form 1 format in the second session. Each individual session must use the same data type. A CD Audio player plays the first session, but will not play the second. A CD-ROM drive reads both the audio and non-audio sessions, the latter containing, for example, programming relating to the audio session. For PC and Macintosh compatibilities, a hybrid disc would contain both ISO 9660 and HFS directories with common files such as video that can be shared between platforms.

An Enhanced CD disc is essentially a replicated multisession Orange Book disc, in which each session has lead-in and lead-out areas. CD Extra discs must contain the AUTORUN.INF file to start the multimedia application, as well as CDPLUS and PICTURES folders. The former contains album title, artist, record company, catalog number, track titles with pointers to lyrics, and MIDI files.

The latter contains a JPEG file of the album cover, and other files. CD Extra is described in the Blue Book (issued in 1995).

Alternatively, in Mixed Mode CDs, ROM data is placed in Track 1, while CD-Audio data is placed in subsequent tracks. However, with this design, an audio player may access the ROM track and erroneously output noise rather than muting. To avoid this, a "pre-gap" technique may be used such that ROM data is "hidden" by placing it after the disc TOC, but before the Red Book first track (containing music). ROM data (up to 40 minutes of equivalent playing time) is placed between Index 0 and Index 1 of Track 1, while the music starts at Track 1, Index 1. An audio player thus skips over the data, starting playback at the first music track. However, the pre-gap area is not accessible to all PC software. The track layout of the Red Book CD and several alternative CD types are summarized in FIG. 25.

FIG. 25 Several alternate CD types have been developed to allow both audio

and nonaudio data to be placed in CD tracks. A. Red Book. B. Mixed Mode. C.

Pre gap. D. CD Extra.

As noted, the CD-ROM data format is similar to that of music CDs; music discs can be played on ROM players, but ROM discs are not playable on audio players. A CD ROM drive typically includes D/A conversion and audio output stages, but requires an interface and an external computer for nonaudio data output. In most designs, the consolidation of both functions into one player is ideally cost effective. To permit this, a CD-ROM disc automatically identifies itself as differing from an audio CD (through the Q subcode channel).

Unlike the CD-Audio standard, the CD-ROM standard does not stipulate how data is to be defined. In an effort to provide compatibility, the ad hoc High Sierra group (meeting at Del Webb's High Sierra Hotel and Casino) developed a standard logical file structure; the High Sierra standard was issued in 1985. It was adopted with minor revisions by the ISO as standard ISO 9660 (ECMA-119), "Volume and File Structure of CD-ROM for Information Exchange." It universally specifies how computer data is placed on a CD-ROM disc; to read the data, the computer operating system must be capable of reading the ISO 9660 file structure. Level One 9660 requires that files be written as a continuous stream with file name restrictions similar to the MS-DOS file system. Level Two allows longer file names, and is not usable in MS-DOS systems. Level Three is open-ended. MSCDEX.EXE is an MS-DOS Extension available from Microsoft; it contains extension programming and drivers so that an MS-DOS program can access a CD-ROM. The computer requires both Microsoft Extensions and the device driver for the MPC ROM drive.

MSCDEX.EXE is often placed in the AUTOEXEC.BAT file, and the device driver is loaded from CONFIG.SYS. The computer can then read 9660 file directories and files from the disc.

Using extensions to ISO 9660, directories and files can be accessed from diverse platforms. The extension of ISO 9660 for the Unix platform is sometimes called the Rock Ridge extension; this is incorporated in the IEEE P1281 and P1282 standards. The Joliet extension is supported by 32-bit Windows 95/98/NT/2000/XP as well as Macintosh and Linux systems. The El Torito extension can create bootable discs for systems with the proper BIOS. HFS is Macintosh's native Hierarchical Filing System; most CD ROMs authored for the Macintosh adhere to this format.

CD-ROM discs can be authored for multiple platforms; however, executable files can only run on the appropriate platform. Additional incompatibility, such as file formats, file headers, bit resolutions, and sampling frequencies, exists within each platform, with competing CD-ROM systems. In some cases, cross-platform compatibility can be achieved; for example, hybrid CD-ROM titles can be played on PC and Apple platforms. The different data types are physically partitioned on the disc surface.

CD-R

The Compact Disc Recordable (CD-R) format allows users to record their own audio or other digital data to a CD. The format is officially named CD-WO (Write-Once) and it is defined in the Orange Book Part II, issued in 1988. It is a write-once format; the recording is permanent, and can be read indefinitely, but can never be erased or overwritten with new data. Text, audio, video, multimedia, and other executable data can be recorded and applications for CD R are diverse. For example, the monthly phone bill for a large corporation might run 50,000 pages or more, but can be recorded on one CD-R disc. CD-R is ideal for distributing data to a few users or for archiving data. CD-R discs that are used to carry audio and non-audio data prior to CD replication are written with the PMCD (premastered CD) format; the disc contains an index and other information normally found on a CD master tape. CD-R discs with up to 80 minutes (or about 700 Mbytes) of playing time are available. A complete subcode table is written in the disc TOC, and appropriate flags are placed across the playing surface.

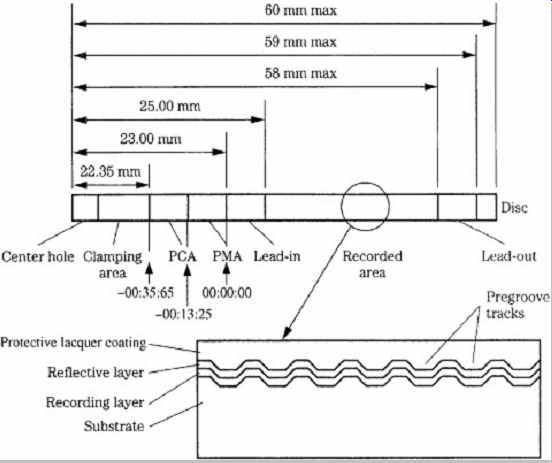

FIG. 26 A CD-R disc holds data in pregrooved tracks.

Data is permanently written into an organic dye-recording layer. The PCA area is used to calibrate the writing laser, and the PMA holds a temporary table of contents.

CD-R discs that are used to record CD-Audio data can be played in Red Book players. However, they differ from prerecorded CD-Audio discs. All user data is recorded as a reflectivity change in a pregrooved track. Two areas are written to the inner portion (22.35 mm to 23 mm radius) of the disc before the Red Book lead-in radius, as shown in FIG. 26. Because these areas are inside the normal lead in radius, conventional CD players do not read them. The PMA (program memory area), starting at -13 seconds (- 00:13:25) relative to the start of the lead-in at 0 seconds, contains data describing the recorded tracks, a temporary TOC, as well as track skip information. When the disc is finalized, this data is transferred to the TOC. Disc-at-once (DAO) recording, described below, does not use the PMA area.

In addition, the PCA (power calibration area), starting at -35 seconds (-00:35:65), allows the laser to automatically make an optimal power calibration (OPC) test recording to determine proper laser power for data recording. The PCA contains a test area and a count area. The count area keeps track of available space in the test area; it contains 100 numbered partitions, each being one ATIP (absolute time in pregroove) frame long. Calibration test data at different (perhaps 15) power levels is written to one partition. This data is read back and an analog signal (not an error rate) from each test recording is compared to an optimal value and used to determine writing power. This is usually performed once each time a disc is loaded, and a count is incremented (up to 100) by filling a count area partition with random data. After this count is reached, no additional data can be written to the disc, even though there may be an open data area. Thus, only 100 recording operations are available; in some recorders, the count is filled after 100 insertions of a given disc. Several methods to more effectively use the count area, and increase recording sessions, have been devised. In some drives, the laser power is continually monitored and adjusted using a method known as Running OPC. The pregrooved program area holds user-recorded information such as track numbers, and start and stop times. A recording is complete when a lead-in area (with TOC), user data, and lead-out area have been written. A maximum of 99 tracks can be recorded on a disc.

As with prerecorded CDs, CD-R discs are built on a polycarbonate substrate, and contain a reflective layer and a protective top layer. However, they are otherwise substantially different. A recording layer comprising an organic dye is sandwiched between the substrate and reflective layer (see FIG. 26). During manufacture, it is applied by spin coating and cured. Together with the reflective layer, it allows a typical in-groove reflectivity of 73% and a carrier-to-noise ratio (CNR) of 47 dB. To achieve the minimum 70% reflectivity standard of CD, as the beam passes through the recording layer and substrate twice, a gold or less-costly silver halide reflective layer is typically used. The dyes employed would corrode an aluminum layer as normally used in prerecorded CDs. The thickness of the metal layer is typically 50 nm to 100 nm. A CD-R disc may look like a regular CD, but is usually distinguished by its recording layer that appears green, yellow-green, or blue. (A gold metal layer is often distinguishing as well; in some cases, when a silver layer is used, it is topped by gold paint.)

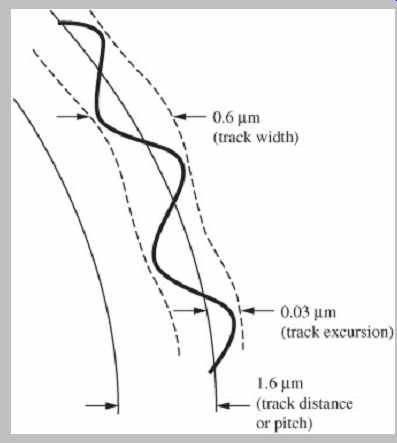

FIG. 27 The CD-R pregroove track is modulated with a ±0.03-µm sinusoidal

wobble with a frequency of 22.05 kHz.

Unlike prerecorded CDs, CD-R discs are manufactured with a pregrooved 1.6-µm pitch spiral track, used to guide the recording laser along the track; this greatly simplifies recorder hardware design and helps ensure disc compatibility. Drives maintain radial position by detecting an 8% reduction in reflected intensity that occurs because of diffraction when a beam is correctly tracking the pregroove. The 0.6-µm wide track is physically modulated with a ±0.03-µm sinusoidal wobble with a frequency of 22.05 kHz as shown in FIG. 27. The wobble allows the recorder to control disc CLV rotation speed (a task accomplished with Red Book discs from the prerecorded data). Furthermore, the 22.05-kHz groove wobble excursion is frequency modulated with a ±1-kHz signal; this is used to create an ATIP absolute time clocking signal. A writing drive reads the ATIP in the lead-in area to determine recommended write power and other information such as write strategies and allowable speeds needed to optimize recording quality. ATIP also specifies the maximum start of the lead-out, which sets recording capacity. Track velocity is set according to disc capacity; for example, 63-minute discs use a 1.4 m/s track velocity and 74-minute discs use 1.2 m/s.

The recording mechanism itself can be described as heat-mode memory. Laser light is used to create heat to affect the change in the recording media. For example, an 8-mW laser spot power focused to a diameter of 1 µm yields a power density of 1 × 1010 W/m2; the temperature can rise hundreds of degrees in a microsecond. The recording layer is a photo absorption surface which absorbs this heat energy from the recording laser. A 1 × writing laser beam nominally with 4 mW to 8 mW of spot power (higher power is used for faster writing speeds, for example, 40 mW at 50 ×) and a wavelength of 775 nm to 795 nm passes through the polycarbonate substrate, and heats the organic dye recording layer to approximately 250°C, causing it to melt and/or chemically decompose to form a depression or mark in the recording layer. These depressions or marks create the decreased change in reflectivity (for example, 75% to 25% for an 11T pit) required by standard CD player pickups. During readout, the same laser, reduced to 0.5 mW of spot power, is reflected from the data surface and its changing intensity is monitored. The result is an eye pattern and modulation amplitude essentially identical to that of prerecorded CDs.

Generally, three types of organic dye polymers are used to form the recording layer: cyanine, phthalocyanine, or metal azo. These dye polymers are all chemically tuned to absorb light at 780 nm. Metal-stabilized cyanine-based media are usually recognized by an emerald green or blue green color when a gold metal layer is used; cyanine dye is actually intense blue in color. The green appearance is a combination of the blue dye and gold metal layer; when a silver metal layer is used, with its wavelength independent reflectivity, the cobalt blue color is apparent. When heated by the writing laser, the dye degrades to create a mark with decreased optical reflectivity. Very generally, because the CD-R standard was originally devised using cyanine dyes, discs using cyanine dye are reliable in a wide range of recorders and laser powers, and at a wide range of writing speeds. In addition, cyanine dye has a relatively broad range of sensitivity to light resulting in a broader spot power margin for the writing laser (6.0 mW ± 1.0 mW). This makes cyanine more suitable for a range of recording speeds and laser powers, and also offers greater compatibility. Generally, when writing to cyanine, recorders can use longer laser pulses to create 3T-11T marks.

Phthalocyanine-based media have a yellow-green or gold color appearance (it is colloquially called "gold") when using a gold metal layer; the dye itself has a semi transparent, nearly colorless yellow-green color. An advanced phthalocyanine dye is also used; it has an aqua color. During recording, the heated dye layer spot melts and shrinks, and the polycarbonate substrate expands to create a pit or mark. Very generally, phthalocyanine media is said to have greater longevity because it is stable and less sensitive to ordinary light. However, this lower sensitivity results in a small spot power margin for the writing laser (5.0 mW ± 0.5 mW), thus the writing speed and laser power must be more carefully controlled.

Generally, when writing to phthalocyanine, recorders can use shorter pulses to create 3T-11T marks.

In some cases, metallized azo dye is used as the recording layer in CD-R media; its deep blue color is preserved when backed with a silver layer, and it appears green when backed by a gold layer. Even discs that use the same type of recording layer material can perform differently. Variations in recording layer thickness, reflective layer thickness, and different protective layers can affect disc-recording characteristics.

Organic dye layers are affected by aging. The dye layer will deteriorate over time because of oxidation and material impurities. In addition, the organic dye is sensitive to ultraviolet light and will degrade. Cyanine dye is more prone to degradation than phthalocyanine, which is inherently stable. To evaluate life expectancy of CD-R discs, discs are subjected to a variety of conditions that accelerate aging. For example, unrecorded and recorded media can be subjected to 65°C and 85% RH (relative humidity) for 2 months. (This equates to a 45-year duration at 22°C and 55% RH.) Discs can also be subjected to bending and scratch tests. Criteria such as BLER, E22, E32, and burst errors, described in Section 5, can be measured to determine end-of-life. In one test, errors were higher on media recorded after age testing than on media recorded prior to testing. Age testing degraded the recordability of the media more than its storage capability.

Both unrecorded and recorded media should be stored in clean jewel cases in a stable environment of 10 to 15°C and 20 to 50% RH, and protected from sunlight and other radiation courses.

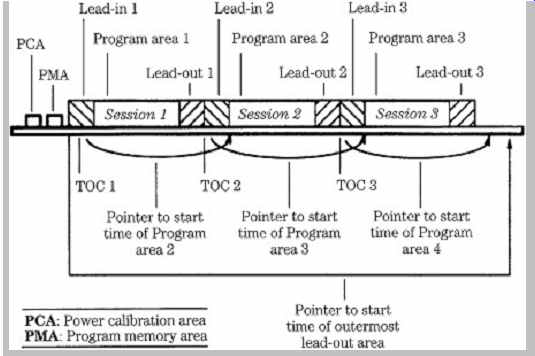

FIG. 28 CD-R multisession recordings form a series of sessions across

the disc surface, each with its own lead-in, program, and lead-out areas.

Shelf life of cyanine media is said to be from 10 to 100 years with nominal storage conditions. The typical BLER error rate is less than 20 per second, well below the Red Book CIRC tolerance of 220. In an accelerated aging test, the life expectancy of phthalocyanine discs was calculated to be 240 years. Ultimately, human carelessness, resulting in scratches, is probably the single biggest threat to CD-R longevity. The U.S. Mail is selectively irradiated by high energy electronic beams. Irradiation can tint polycarbonate substrates, decrease reflectance, and increase error rates.

However, radiation-induced errors are small and are corrected by error-correction codes; during testing, no uncorrectable errors resulted.

The Orange Book Part II defines both single session (regular) and multisession (hybrid) recording; a session is defined as a recording with lead-in, data, and lead-out areas. With single session recording, sometimes called disc-at-once (DAO) recording, a disc is recorded in its entirety, without interruption. The recorder records a TOC in the lead-in portion of the disc, data tracks, and a lead-out area, so any standard player can read the disc. A PMCD (premastered CD) recording used as a master is an example of a DAO application. Tracks can be recorded back to back without a gap; this allows for crossfades between tracks. When recording DAO, it is recommended to first create a disc image, a file that includes all the data to be recorded.

Alternatively, track-at-once (TAO) recording allows single or multiple tracks to be written in a session; this is the most widely supported recording method. After the program tracks are written, the recorder writes the TOC and lead-in areas, and lead-out areas. The writing laser is turned off after each track; this creates a gap between tracks. A partially recorded disc can be played on the CD R recorder, but cannot be played on a CD-Audio player until the session ends when the final TOC and lead-out areas are recorded. Most recorders permit an unwanted track (such as a false start) to be marked and deleted from the TOC so the CD-R player (and CD-Audio players recognizing skip-ID flags) will skip over it. Recorders using TAO can also write a single-session CD-R.

The Orange Book Part II also specifies multisession (hybrid) recording in which sessions can be recorded one or a few at a time. Tracks can be written one at a time and recording can be stopped after each track. Separate recording sessions are permitted, each with its own lead-in TOC, data, and lead-out areas, as shown in FIG. 28. This session structure is required so Red Book players will recognize the beginning and end of segments. Each time a session is created, about 13.5 Mbytes (6750 blocks) of capacity is lost to lead-in and lead-out areas (22 Mbytes is used for the first session). The lead-in for a session occupies about 8.8 Mbytes, and the lead-out for a session occupies about 4.4 Mbytes (the lead-out for the first session occupies about 13.2 Mbytes). Clearly, this is inefficient for adding small amounts of data. TAO recorders allow multisession recording, in addition to single-session recording. With TAO recording, multiple tracks can be written to a session, adding data one track at a time; no lead-in or lead-out is written until the session is closed. This saves disc space, but the session cannot be read by most players until the session is closed. Older CD-ROM drives and all CD-Audio players can read only the first session on a multisession disc. Thus, multisession recording typically is not used for CD-R audio discs. Photo CD and some CD ROM titles, are examples of multisession discs.

In multitrack recording, data is appended to a disc in tracks that are at least 2 seconds long (about 300 sectors or 700 kbytes). Tracks can contain one or more files and the session is left open between write operations. Individual tracks are separated by a 150-sector gap. After a track is written, track numbers and timings are written in the PMA; a link block is written where the laser turns off before it is temporarily moved to the PMA. When the session is closed, the TOC is written, the link blocks are hidden, and the disc can be removed from the drive.

By using the CD portion of the Universal Disk Format (CD-UDF), CD-R discs can perform packet writing so that small amounts of data can be efficiently written. For example, whereas multisession recording requires large data overhead, packet-writing overhead might consume less than 4 Mbytes per disc. Packet writing can be performed on CD-R media, making them functionally similar to small hard-disk drives. Data in a file can be appended and updated without rewriting the entire file.

Because the data structures are so small, buffer under-run is alleviated. Packets of data (variable or fixed length) are written to a disc without closing either a track or a session, and without updating the TOC or PMA. Instead, system information about the partial track is placed in the Track Descriptor Block in the pre-gap before the track. A packet contains user data along with associated link blocks.

Special blocks called run-in and run-out allow a recorder to synchronize data, and they also contain interleaved data from other blocks. Written data comprises a link block, four run-in blocks, user data, and two run-out blocks. Fixed length packets allow data to be randomly erased and rewritten without accounting for different packet size; however, disc capacity is decreased to about 500 Mbytes.

Variable-length packets allow greater disc capacity because mapping is fixed when data is written. Not all CD recorders support packet writing. Packet writing, also called block append, is defined in the Orange Book Part II for CD-WO. Packet writing is also defined in the ISO 13490 specification. The UDF Bridge file format is used in DVD, as described in Section 8.

Both stand-alone and peripheral CD-R recorders have been developed. Stand-alone recorders allow users to record discs and perform simple editing of tracks and subcode. These are intended for audio use and apply Serial Copy Management System (SCMS) data to the recorded program. Peripheral CD-R recorders interface to a host computer via a SCSI or other interface; many recorders are packaged as half-height drives. The recorders operate at speeds much faster than real time, generating all synchronization, header, CIRC, and EFM processing required by the CD standard. Depending on the software package, various degrees of data manipulation are possible; for example, a software application can consolidate fragmented files and specify the physical location of CD-ROM data on a disc so that retrieval time is shorter. When a CD-R disc is authored according to the ISO 9660 file format, the disc can be read on multiple platforms.

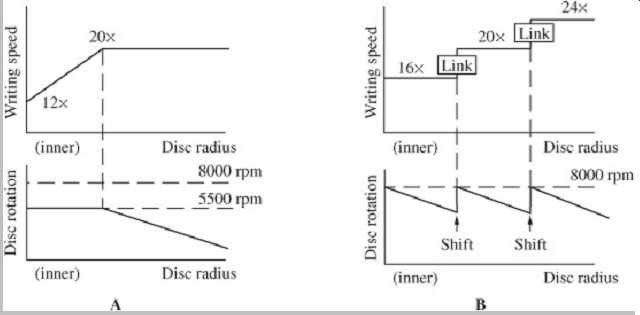

FIG. 29 To optimize data transfer speed, disc drives can employ several

techniques. A. In a PCAV drive, inner radii are read using CAV and outer radii

are read using CLV. B. In a ZCLV drive, different CLV speeds are used across

the disc radius.

Real-time recorders operate at a 150-kbps rate; however, higher-speed recorders are widely used (higher laser power is needed at high speeds). Higher-speed recorders may provide lower error rates than single-speed recorders; this may be because in single-speed writing, the laser remains focused for a longer time and an unwanted annealing process may be caused by the added heat.

Recorders with OPC can avoid this effect. Discs suitable for high-speed recording are specially approved for reliability.

At 1 × speed, a disc spins at about 539 rpm when the head is placed on the inner radius and it slows to 210 rpm at the outer radius. At 16 ×, for example, the speeds are about 8000 and 3200 rpm respectively; a 50 × drive might reach speeds in excess of 12,000 rpm. CLV is efficient when reading an audio disc at 1 × speed; it is relatively easy to change speeds when accessing different tracks at different radii. However, at high speeds, it is difficult to quickly change high disc speeds over a range of radii. To accommodate high disc velocities, some disc drives use partial constant angular velocity (PCAV) to spin the disc at a lower fixed speed near the inner radius, and then shift to CLV near the outer radius. For example, a 20 × drive might start reading the inner radius at 12 × using a CAV method, as shown in FIG. 29A. As reading progresses and the pickup moves outward, the transfer rate increases. When a 20 × speed is reached, the drive switches to CLV and the data rate is constant at 20 × (3000 kbps). Some drives use zoned constant linear velocity (ZCLV), in which different fixed writing speeds (operating in a CLV mode) are used in discrete regions of the disc as shown in FIG. 29B. For example, a 24 × drive might use 16 ×, 20 ×, and 24 × in different radii of the disc. Writing is suspended as the drive shifts speeds; to provide writing continuity, data is held in a buffer. In any high-speed drive, high-speed writing is not possible across the entire disc radius.

In some high-speed drives, the laser beam is diffracted to create multiple laser spots, one spot per groove. Multiple pickups receive simultaneous data, thus increasing the effective data-reading rate, particularly when reading sequential data.

Discs designed for high-speed writing are designed to accept the thermal effects of higher-power lasers, and the substrate and track must be mechanically sound and accurate. High-speed disc writers must use modified write strategies to allow for thermal effects; for example, the drive can read parameters encoded on the blank media to optimize the level and duration of the power region that initiates a recorded mark. The drive must also be mechanically able to withstand high velocities. For example, vibration caused by an eccentric or unbalanced disc must be minimized. Drives are relatively unaffected by vibration when reading because autotracking can use a robust error signal based on large (60%) changes in intensity of reflected light. However, drives are more sensitive to vibration when writing because tracking is performed with push-pull methods that must rely on small (5 to 10%) variations in reflected light intensity from the unrecorded pregroove. Also, contamination on a disc surface is relatively unimportant when reading data, but any obstruction to a writing laser will result in a permanent error.

The Orange Book specifies that jitter for CD-R discs should be less than 35 ns.

Two types of CD-R discs are sold: for computer use, or for music use. The discs are otherwise physically identical, but during mastering (of the blank) a mandatory Disc Application Code is embedded in the ATIP information contained in the pre-groove lead-in area. Three types of discs are defined: Types 1a and 1b for restricted use and Type 2 for non-restricted use. Type 1a is used for CD-ROM or professional audio recording. Type 1b is used for special purpose applications such as a Photo CD and can only be written to by those specialized recorders. Type 2 discs are for consumer audio recording. Stand-alone consumer CD-R audio recorders will not record unless that code is present. Thus, only music-use discs can be used; their higher cost is used to compensate artists. Computer use CD-R discs are used in CD-R drives connected to a host computer; these discs can also be used to record music to a disc, using computer-use discs. Clearly, copyright laws should be observed. Music-only CD-R discs are sometimes referred to as CD-R-DA (Digital Audio).

Although CD writing on a PC is relatively simple, some care must be taken; the computer must provide a steady stream of data, while simultaneously interleaving, error correcting, and formatting the data. Many systems can transfer data from either tape or hard disks to the recorder, and can produce CD-Audio, CD-ROM (including CD ROM/XA), and Photo CD discs. Generally, a hard-disk drive with fast access (10-ms seek time) is required, connected to the PC via a fast (10 to 20 Mbytes/s) interface to the PC bus. During recording, any interruption in the data stream at the recording laser will render a disc unusable.

Most CD-R recorders contain a cache memory (1.2 to 4 Mbytes); this helps prevent data stream problems from buffer underrun. Some users recommend several measures to help ensure successful writing: partition the staging drive to hold the disc image, create a real ISO image file (as opposed to a virtual image comprising lookup addresses of data to be written) of the data, defragment the hard drive, and test before writing. Some users recommend hard-disk drives with embedded servo tracks so that automatic thermal recalibration will not interrupt the data stream; alternatively, hard drives with unobtrusive recalibration procedures can be used. In addition, network services, auto-answer fax software, sound utilities, screen savers, virus checkers in resident memory, and TSR (terminate and stay resident) programs should be turned off during recording to prevent glitches in the bitstream.

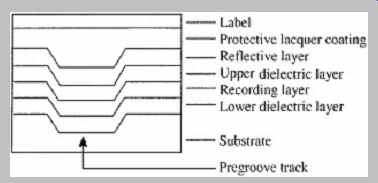

FIG. 30 The CD-RW recording layer is sandwiched between two dielectric

layers.

CD-RW

The Compact Disc ReWritable (CD-RW) format allows data to be written, read, and erased and rewritten. The format is officially named CD-E and it is described in the Orange Book Part III standard, issued in 1996. A CD-RW drive can read, write, and erase CD-RW media, read and write CD-R media, and read CD-ROM and CD-Audio media. The data can comprise computer programs, text, pictures, video, audio, or other files. CD-RW disc capacity is about 700 Mbytes. A CD-RW disc has an embedded aluminum layer and a recording layer that appears gray.

Altogether, there are five layers built on the polycarbonate substrate: a dielectric layer, a recording layer, another dielectric layer, a reflective aluminum layer, and a top acrylic protective layer, as shown in FIG. 30. This phase change recording technology allows thousands (on the order of 105) of rewrite cycles.

As in CD-R, the writing and reading laser follows a pre-groove across the disc radius. However, whereas CD-R uses a dye-recording layer, the CD-RW format employs a phase-change recording layer comprising an alloy of silver, indium, antimony, and tellurium. This metal exhibits a reversible crystalline/amorphous phase change when recorded at one temperature and erased at another, as described in Section 6. The recording layer on the blank disc is in crystalline form; it is translucent thus light is reflected from the metal layer above it. Data is recorded by directing a laser (8-mW to 14-mW spot power) to heat an area of the crystalline layer to a temperature above its melting point (500 to 700°C). When the area re-vitrifies rapidly, it becomes amorphous and absorbs light, and the decreased change in reflectivity can be detected. A low-power laser (perhaps 0.5-mW spot power) is used to read data.

Because the crystalline form is more stable, the material will tend to change back to this form; thus, data can be erased using an annealing process. When the recording surface is heated by a lower laser spot power of perhaps 4 mW to 8 mW to its transition temperature (200°C) and cooled gradually, it returns to its original crystalline state.

Unlike dye-polymer technologies, phase-change recording is not wavelength-specific.

Rewriting is accomplished through direct overwriting.

Rather than completely erase a disc side, this "on the fly" erase feature allows the last recorded audio track to be erased simply by erasing the subcode reference to that track while leaving the recorded data in the recording layer.

With this method, recorded tracks can be erased individually, working sequentially backward from the last recorded track, to provide editing control without requiring total erasure.

A technique called Running Optical Power Calibration determines the correct laser power levels when individual discs are loaded, and monitors and adjusts the power level to compensate for surface contamination such as fingerprints. Unlike CD-R recording in which the laser is turned on for the duration of the pit formation, in CD-RW, the laser is repeatedly switched between its write or erase power, and a low bias power (less than 1 mW) that is equal to the power used to read the disc. This switching is performed so that the recording alloy layer will not accumulate excess heat, thus creating overly large marks.

The dielectric layers comprise silicon, oxygen, zinc, and sulfur; they control the optical response of the media and increase the efficiency of the laser by containing the heat that is used to record data on the recording layer. They also thermally insulate and protect the pregroove, substrate and reflective layers, and mechanically restrain the recording layer material.

As with CD-R, two types of CD-RW discs are sold: for computer use, or for music use. The discs are physically identical, but a permanently recorded flag is placed on music-use discs; stand-alone consumer CD-RW audio recorders will not record unless that flag is read. Music-only CD-RW discs are sometimes referred to as CD-RW-DA (Digital Audio).

The reflectivity of CD-RW discs is only about 15 and 25% (amorphous and crystalline states, respectively). They generally cannot be played in conventional CD players (many DVD players do play CD-RW discs) or CD-ROM drives. A CD-RW drive is required, or a MultiRead drive capable of reading lower reflectivity discs. Such drives contain an automatic gain control (AGC) circuit to compensate for the lower reflectivity and signal modulation.

The AGC boosts the gain of the signal output from the photodiodes. To facilitate this, CD-RW discs carry a code that identifies them as CD-RW discs to the player. CD-RW drives are commonly found as PC peripherals. Software supports TAO, DAO, and multisession recording. When CD-RW discs are appropriately formatted, the CD-UDF specification permits easy file-by-file rewriting. In particular, users can write to the CD-RW drive by simply dragging and dropping.

CD-MO

The Orange Book Part I defines a Compact Disc Magneto Optical (CD-MO) standard; data can be written, erased, and rewritten. Two types of discs are defined: a disc with a premastered area (recorded with pits) containing CD-ROM data plus a writable area, and a disc that is completely writable. Because writable data is read via changes in light polarization rather than intensity, CD-MO discs are not playable in CD-Audio or CD-R drives (however, CD-MO drives can play CD-Audio and CD-R discs). A CD-Audio player can read the premastered area on a CD-MO disc. In some ways, the MiniDisc was an evolution of the CD-MO specification.