Present-day magnetic recording tape is vastly different from the early pre-war German magnetic tapes. As we have seen in an earlier section a more potent oxide, a form of gamma Fe2O3, has been developed. The new oxide displayed a 14 db superiority in output and vastly improved frequency response over German tapes. Known as "red oxide," the new type of magnetic oxide is now accepted as the international standard for magnetic tapes and films. This oxide is now used on all tapes manufactured in this country and is gradually being adopted abroad.

Thanks to the superior magnetic properties of red oxide, coupled with basic improvements in head design, recording speeds have been reduced from the initial 30 ips to 7 1/2 and 3 3/4 ips with excellent results.

Tape Manufacture

Magnetic tape itself is actually composed of many substances, each making an important contribution toward improved physical and magnetic performance. In tape construction, the basic recording material is a magnetic oxide. There are several forms of magnetic oxide which will be discussed.

Magnetic tape is generally made by coating the oxide dispersion, combined with a binder material, on a wide web of plastic backing. Again, there are a wide variety of backing materials in use at the present time, several of which will be examined later in this section.

The oxide is made to adhere to the base material by means of an adhesive or binder incorporated in the tape construction. The binder serves two purposes. One, it holds the iron-oxide particles tightly together in as dense a mass as possible. Two, it holds the oxide firmly to the base material.

The binder also carries a plasticizer, used to keep the tape soft and supple, and a lubricant to help the tape pass the guides and magnetic head with a minimum of friction and wear .

The wide web of coated magnetic oxide is then slit into a variety of widths and lengths. The most common size for home and professional recording studio application is the quarter-inch width. However, telemetering, video tape recording, and other special applications require tapes that are slit to a variety of widths up to a foot or more wide. In addition, magnetic film is available in the standard motion-picture sizes which are 35, 17.5, and 16 mm. The base is identical to motion-picture film. However, instead of being coated with a photographic emulsion, a magnetic iron oxide dispersion is used.

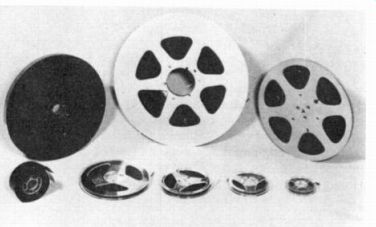

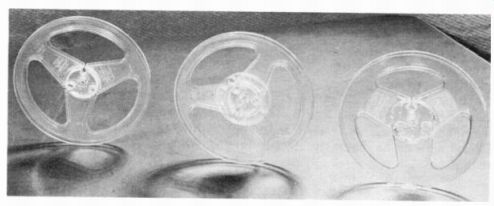

Fig. 10-1. Various Sizes of Magnetic Tape Available.

The quarter-inch tape is available in these standard lengths: 150, 300, 600, 1200, 2400, and 4800 feet. The reel sizes are, respectively, 3, 4, 5, 7, 10 1/2, and 14 inches in diameter. The new "extra play" magnetic tape, offering 50% additional recording time is currently available in 900, 1800, and 3600-foot lengths. Some of the various sizes of magnetic tape available are illustrated in Fig. 10-1. Table 1 in Section 1 illustrated the playing time for various lengths of reels at the different speeds. The manufacturers generally supply more than the labeled footage to allow for threading and to serve as a cushion" on the reel hub. Thus, a 1200-foot reel generally has about 1240 feet.

Backing Materials

The early German tapes used paper as a base material. Paper has several desirable characteristics in that it is quite stable in respect to temperature and humidity changes. However, a big physical limitation to paper-base magnetic tape is that it is fragile and not too pliable or flexible. It will wear easily. Paper tape has also a rough and non-uniform surface. In magnetic-tape coating, the uniformity of coating is extremely important to obtain a consistent output from the tape. If a magnetic oxide dispersion is coated on a rough surface, it naturally will adhere to the counter of the peaks and valleys of the backing surface.

To obtain a more uniform coating surface with greater potential frequency response, a plastic-base tape was introduced. The base used was cellulose.

Cellulose acetate is, to this day, the most common form of backing for magnetic tapes. It possesses several excellent characteristics, having the smoothest surface of any plastic tape yet developed. Consequently, it gives the smoothest magnetic coating which, in turn, yields a more uniform output.

Cellulose acetate is, also, surprisingly strong. The standard quarter-inch tape has a tensile strength of 5.5 pounds. The new extra-play magnetic tape, using a 30% thinner acetate backing, has a tensile strength of 3.4 pounds. Considering that the maximum tension exerted by tape recorders with proper use does not exceed a few ounces (including the sudden stress on the tape when braking and reversing), cellulose acetate is relatively rugged and holds up well.

The main disadvantage of cellulose acetate is that it is not stable with temperature and humidity. Thus, when the humidity goes up, the tape tends to expand. When the humidity falls, the tape has a tendency to shrink. Expansion and contraction physically distorts the tape.

The ideal backing would have a high strength without stretch, a very low coefficient of humidity expansion, be stable over a wide temperature range, have a perfectly smooth surface, and cost very little.

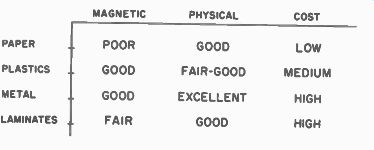

Unfortunately, however, all these ideal qualities are not combined in one tape backing as can be seen in Table n. A newer base material, showing great potentialities, has been recently introduced. Known as polyester film, its common trade name is "Mylar", a registered trade mark of the E. I. du Pont de Nemours and Co.

The polyester backing has some very interesting properties, making it especially suited for tape recording. It is very stable with respect to temperature and humidity. That is, the temperature and humidity can vary widely and it will retain its original shape and size. It has greater strength than acetate, with little yield stretch.

And it still has a relatively smooth surface.

The outstanding property of acetate, accounting for its wide use today, is its excellent surface and thickness uniformity. Polyester suffers in surface uniformity when compared to acetate. However, recent production advances indicate that the surface smoothness of polyester may soon equal that of cellulose acetate.

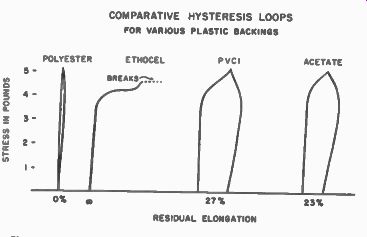

Magnetic tape backing exhibits both a yield point and a break point. Like bending a green twig, the yield point is the point at which the tape, upon being stretched, will not return to its original length but remains partially elongated and misshapen. When a tape is stretched beyond its yield point, the recording on it will be distorted and the tape will be damaged. The graph in Fig. 10-2 illustrates the yield point of various backing materials. When tension reaches the break point, the tape will, of course, snap in two.

TABLE II. A Comparison of the Types of Backing Used for Magnetic Tapes.

PAPER PLASTICS METAL LAMINATES MAGNETIC PHYSICAL COST POOR GOOD LOW GOOD FAIR-GOOD MEDIUM GOOD EXCELLENT HIGH FAIR GOOD HIGH

Therefore, it is far better to have the magnetic tape snap rather than approach its yield point without breaking, thus distorting the recording.

Polyester at 150 gauge exhibits a very excellent stretch recovery, showing no dead stretch up to five pounds tension per 1/4 inch. By ...

COMPARATIVE

HYSTERESIS LOOPS FOR VARIOUS PLASTIC BACKINGS

Fig. 10-2. Yield Point in Tensile Strength of Various Plastic Tape Backings.

... contrast, 140 gauge acetate shows a 23 percent residual elongation at five pounds stress. However, as we have already seen, any consideration of backing strength is largely academic because tensile strength is more than adequate for the tape handling mechanisms that exist today. The additional strength of polyester, while giving an extra margin of safety, is seldom required.

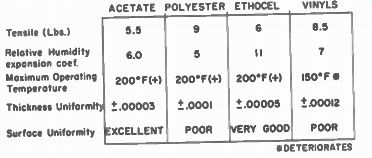

Polyester backing is still substantially more expensive than cellulose acetate, consequently its prime use lies, at the moment, in applications where dimensional stability is of prime importance. For home use it is doubtful that, considering cost, there is a prime advantage of polyester over cellulose acetate backing. A comparison of the physical properties of various backings is given in Table III.

TABLE III.

Physical Properties of Plastic Backings Used in the Manufacture of Magnetic Tape.

ACETATE POLYESTER ETHOCEL VINYLS Tensile (Lbs.)

Relative Humidity expansion coef

Maximum Operating Temperature Thickness Uniformity Surface Uniformity 5.5 6.0 200*F(+)

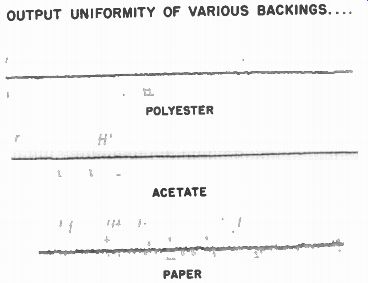

Cellulose acetate backed tape has a superior signal output uniformity to that of other commonly used backings. This is shown graphically in the pen motor charts for cellulose acetate, polyester, and paper given in Fig. 10-3.

OUTPUT UNIFORMITY OF VARIOUS BACKINGS ... POLYESTER, ACETATE, PAPER

Fig. 10-3. Pen-Motor Charts Which Plot the Signal Output Uniformity of Polyester, Acetate, and Paper Backing.

New Tape Construction Trends

An interesting trend in tape construction is toward the use of thinner and thinner backing material to obtain greater recording time. Reducing the thickness of the backing material, coupled with a reduction in the thickness of the oxide coating, does not, surprisingly enough, greatly affect its strength. For example, reducing the backing thickness of cellulose acetate from 140 to 100 gauge, or by 30%, reduces its strength by only 15%. Consequently, tapes of thinner backing material can readily work on all recorders with no particular problem.

The thinner backing possesses several advantages in that it conforms more readily to the head, resulting in greater frequency response. Any magnetic tape backing should be limp and flexible, enabling the tape to conform perfectly to the magnetic head contour. A thick-backing material tends to contact the head improperly, causing amplitude variations. Therefore, a thinner backing material gives better high frequency response with more uniform output.

In addition to cellulose acetate and polyester, there are several other plastic films in use today. They are ethyl cellulose and tensilized polyvinyl chloride, more commonly known as Luvitherm. Luvitherm is now being used extensively in the German magnetic recording industry. Like polyester, the outstanding characteristic of Luvitherm is its low coefficient of humidity expansion. Luvitherm, however, is limited by upper operating temperature, undergoing' deterioration at just above 150 degrees Fahrenheit.

Magnetic Oxides

The early German tapes used a type of oxide known as raven red. This term was conveniently borrowed from the barn paint of the same name. Literally a high grade of barn paint which was painted on a paper backing, the raven red oxide had lower output, especially ...

Fig. 10-4. Performance Curve of High-Output Magnetic Tape Compared with

Conventional Red-Oxide Tape.

... at high frequencies. A substantially higher tape speed was required to attain a satisfactory signal-to-noise ratio and frequency response.

However, with the introduction of black-oxide tape in America, a tremendous increase in output was attained with greatly improved frequency response. The black oxide proved to be an excellent recording medium. However, it possessed the undesirable property of being extremely difficult to erase because of its memory effect. That is, once the tape was erased during subsequent recordings, the supposedly erased recording would tend to reappear in the background.

In order to develop a tape that would avoid this difficulty, and yet maintain good high-frequency response and high output, the present "red oxide" was developed. It has now become a standard in the recording industry.

A still more recent development has been the introduction of high-output oxide. This oxide possesses even greater output (8 db) than the conventional red oxide, for a given distortion as shown in the graph in Fig. 10-4. It is especially useful where noise is a problem in the reproduce process. For example, in home recording equipment where the close proximity of the power transformer and drive motor to the reproduce head induces serious hum, the use of high-output tape with 8 db more output will require 8 db less amplifier gain, reducing noise by that amount.

Also, in self-powered portable recorder applications, the extra sensitivity of the high-output oxide (4 db) means that the tape is especially sensitive to weak sounds. It is also much less likely to overload and distort when subjected to unexpected and sudden loud sounds. Thus, high-output tape provides an extra margin of safety, freeing the operator from the necessity of constantly riding the gain control.

Binder Formulations

The binder is an adhesive that is blended into the magnetic dispersion, making the iron-oxide particles adhere to the backing. Also incorporated in the binder are a number of other elements such as lubricants, preservatives, and plasticizers.

The binder is designed so that it will not be too hard or brittle. If it is too brittle, when the tape rounds a sharp corner, the coating will actually crack and the oxide will chip off. However, the binder should also age well withstanding changes in temperature and humidity , retaining its bond to the backing.

It is equally important that the oxide not be too soft so that the oxide will easily rub off during recording or playback.

Certain types of binders at high temperature become tacky, causing the tape to stick and squeal as it is propelled past the record head. The result is serious high-frequency flutter.

Other tape binders tend to become stiff and hard, curling with temperature changes. Still other binders have a different expansion rate than the backing material, again causing the tape to cup and curl with a change in temperature or humidity. Therefore, it can be seen that the binder as well as the tape backing plays a critical role as to whether or not a tape will cup and curl. The tape must, of course, lie flat against the head, conforming readily at all times, for satisfactory frequency response and uniformity of amplitude.

Tape Lubrication

The tape should be lubricated to improve head wear and reduce frictional vibrations in the tape, causing high-frequency flutter. Lubrication will prolong the life of both the tape and the record heads and guides, as well as giving better recording results.

The lubrication is incorporated in the tape binder itself so that it will last the life of the tape, not wearing off as it would if only the tape surface were lubricated. Included in the binder are a number of other properties such as plasticizers that are employed to keep the tape soft and flexible throughout its life. While binder chemical formulations are closely held trade secrets, also included in the binder are agents which permit tape operation at high and low temperatures and improve the physical performance of the tape. One tape manufacturer uses a silicone lubricating process which actually coats the record head with a thin film of protective lubricant.

Life of Magnetic Tape

Despite universal acceptance of magnetic recording tape in the professional field and its increasing popularity among home users, considerable folklore and unfounded rumor exists even among informed groups.

Confusion is particularly rampant regarding the life of magnetic properties of recording tape. Statements that there is a slow loss of magnetism are without foundation in fact. There is a vast reservoir of references in technical literature relating to the permanency of magnetic materials similar to those used in recording tape. Geological investigations have uncovered natural fields of magnetite which have been magnetized since the formation of the earth. From these and other evidences it may be concluded that the magnetic retentivity of recording tape is infinite unless altered by magnetic means.

On typical broadcast recorders, magnetic tape has been played thousands of times with perfect results. Despite the number of times played, the noise level does not rise as does the surface noise on disc recording or on a film because of clouding. Clean, well adjusted head sand tape guides will assure almost indefinite tape wearing life. Although the magnetic recording medium is much too new to predict the life of tape in actual years, accelerated aging tests have indicated a useful life of at least one hundred years. Broadcasts that typify our contemporary society have been recorded on magnetic tape and sealed in time capsules for posterity, to be opened several hundred years hence.

Storage Precautions

While the magnetic properties of recording tape are very stable over long periods of time, care must be exercised to avoid accidental erasure by exposure to strong magnetic fields Permanent magnets and strong electromagnets will very likely cause erasure if placed within a few inches of the tape. This is the principle used in the so-called bulk erasure process in which an entire reel of tape is demagnetized without unwinding. Since the field necessary to produce erasure must be so intense, it is unlikely that accidental erasure would occur from close proximity to ordinary electric house wiring. Erasure will not take place unless the field is strong enough to exert a noticeable attraction for the tape, or to induce vibration in the tape.

All manufacturers state that, ideally, magnetic tape should be stored in a room with relative humidity being maintained between 40 and 60 per cent with a room temperature of 70° Fahrenheit. However, tape storage under these carefully controlled humidity limits is a ridiculous condition for magnetic tape users to meet. An air conditioning unit that could control room humidity within such a range would cost many thousands of dollars and very few such units exist in the world today.

Realistically, storage of tape at moderate temperatures such as maintained in the home is desirable. Tape that is subjected to extremes of temperature for short periods of time such as in shipment is generally not affected. The same precautions exercised in storage of safety-base film can be applied to magnetic tape. If the tape was subjected to extreme temperature, allow the tape to return to room temperature before using.

High temperature plus high humidities, however, tend to rapidly deteriorate the cellulose-acetate backing of magnetic tape.

The worst condition is high temperature with low humidities.

The backing will tend to dry out and become brittle. Embrittlement of tape will result from exposure to prolonged low humidity which exists in heated areas during cold winter months. Just as woodwork shrinks in winter and swells in summer, the same principle applies to magnetic tape. In winter low temperature is forced into a room and is heated. It can hold more moisture and consequently draws moisture from all objects in the room. Subsequent storage at normal humidities completely restores the desired tape properties, the tape picking up its original moisture and becoming limp again.

If the relative humidity is subject to large variations, magnetic tape can be safely stored in sealed metal cans. Seal the cans with a pressure sensitive plastic or cloth-backed tape if long time storage is anticipated. The use of desiccants or humidifying agents is not recommended because of the difficulty in controlling the results.

The tape should be stored, wound loosely on its reels. Many professional recorders wind the tape far too tightly on the reel during rewind or in the normal forward position. Thus, when the tape goes through several humidity cycles, expanding and contracting, the pressure and tensions built up severely stretch and deform the tape. To avoid this condition, the tape, before being stored, should be rewound with very low tension. Before using a tape that has been stored for any appreciable length of time, the tape should be rewound through a recorder to relieve any tensions that may have set in while the tape was wound on the reel.

Print-Through Problems

When tape is wound on a reel, the magnetic field from one layer tends to somewhat magnetize the adjacent layers of tape, causing a signal transfer. This is called print through or cross-talk. The signal transfer can be heard either ahead or behind the recorder signal, depending on which layer the transfer came from. Often both the pre-print and the post-print signal can be heard.

Print occurs mostly in staccato-type recordings in the middle frequencies such as when, suddenly, a voice is heard, then stops, and all is quiet. Consequently, the print is then heard as either a pre- or post-echo of the voice.

Print-through has been considered an inherent disadvantage of magnetic recording. However, generally the print is far enough below the sound level on the tape to cause no trouble. In fact, in nearly all home-type recorders, the noise level in the reproducing amplifier alone is far higher than the print. However , by contrast, on professional machines that employ excellent amplifiers with very little background noise, the print is sometimes audible.

One theory advanced concerning the cause of print is that in every magnetic material there are many "soft" particles. As we have already seen, "soft" magnetic materials are easily magnetized. The normal "hard" iron-oxide particles that are coated on a tape coating require a strong magnetic field before they become magnetized. The bias and record signals are many times stronger than the field that is left on the tape. Consequently, any "soft" particles in the tape are weak enough to become magnetized from the recorded signals on the adjoining tape layers.

According to one school of theorists, the weak "soft" particles line themselves up with the magnetic field on the next tape layer on the reel. It is obvious that any shaking field such as a bias or magnetic field will aid the "soft" particles in lining up. So, therefore, a stored reel of magnetic tape should be kept away from any magnetic fields. Also, a high temperature will aid "soft" magnetic particles in lining up.

It is also believed the strong bias used during the record pro cess makes the particles susceptible to print. That is, when the tape is being recorded, the particles are sensitized and, more or less shaken up, are left in a random position out of their normal field. As a result, they are highly susceptible to magnetism from adjacent fields. Then when wound on a reel next to a turn of tape that has a highly recorded signal, the weak particles will very easily line up with the adjacent layer.

Despite lack of agreement regarding the cause of print, considerable information about print has already been accumulated. It is interesting to note that during print the magnetic particles line up very rapidly at first because of their highly sensitized position. But, as time goes on, the rate of print becomes progressively less.

The signal-to-print ratio is the ratio of the maximum recorded signal, often assumed to be that signal which produces 3% harmonic distortion, compared to the print or echo level.

If one were to make a recording, then play it back in a matter of several seconds after it was recorded, let us assume a 50 db signal-to-print ratio would be noted. However, if five minutes were allowed to lapse before playing the tape, a 48 db signal-to-print ratio would be present. If one were to wait an hour, the signal-to-print ratio would be 47 db and, after 5 hours, 46 db. Following 8 hours, very little more happens to the signal-to-print ratio. Typically, it would settle down to a value of approximately 45 db and never become worse.

However, if the reel is played several times through a recorder, it is obvious that the print layers will not line up in precisely the same pattern. That is, with each tape winding, the area which has received the print will not line up exactly adjacent to the tape area that first made the print. Then, each time the tape is played, the same signal source will print in a slightly different area. Consequently , the print will eventually become noise. Although obvious, few people realize that if a tape with a high signal-to-print ratio is played several times, print no longer remains print but turns into noise and is heard as hiss.

Splicing Problems and Techniques

One of the most appealing and useful characteristics of magnetic tape is the ease with which it may be cut, edited, and re-spliced without impairing the quality of the recorded information on the tape. The fact that tape ends can be joined so easily has led to careless techniques which have resulted, inevitably, in considerable trouble in recorder operation.

At least six months is required to properly train a good tape editor. Considerable skill is demanded in professional recording studios for which there is no substitute for experience. Many professional tape editors prefer to splice without the use of either a mechanical splicer or splicing block. However, this does not mean the rank amateur cannot make acceptable splices. Provided a few simple rules and precautions are followed, the novice can make splices which will be as strong as the magnetic tape itself -- splices which will wear without fraying or loosening and which can be detected insofar as magnetic performance is concerned only by the most sensitive computer-type recorders.

Most pressure-sensitive tapes now on the market have adhesives which are unsatisfactory for use in splicing magnetic tape. Splices in the wound roll of tape are subject to considerable pressure and temperature variations, and the adhesive used in ordinary pressure-sensitive tapes will "creep" or "bleed" around the splice. This is a particularly serious condition, since not only the strength of the splice is impaired but also the adhesive invariably contaminates the magnetic side of the tape, causing adjacent layers to adhere, one to the other, resulting in the loss of the recorded information in the contaminated area due to poor head contact. The adhesive can also transfer to the heads and guides of a recorder, and thus ruin a considerable amount of tape.

To prevent trouble from the adhesive of the tape, a specially formulated splicing tape is available, guaranteeing trouble-free performance if properly used.

Translucent white in color, this acetate-backed, pressure sensitive tape for splicing is universally used with quarter-inch magnetic tape. Its mil and a half thickness provides thin yet strong splices. Its pressure-sensitive adhesive has these thermosetting characteristics: The bond with the magnetic tape increases under the effects of time and temperatures. Also, the adhesive will not ooze or bleed around the edges of the splice. The splicing tape eliminates any tendency to gum up recording heads or cause adjacent layers of tape to stick together on the reel. This standard splicing tape is available in standard rolls 7/32", 1/2", 3/4" in width by 66 feet, or by 150 inches in length.

Apart from considerations of strength, the excellence of a splice in magnetic tape editing can best be judged by the degree of disturbance it causes upon playback. The use of the right splicing tape material, together with proper splicing methods, can produce splices which are essentially "acoustically invisible." In the quarter-inch magnetic tape field the diagonal butt splice is by now a tradition. Such splices, properly made, wear without fraying or loosening. To make a perfect splice the ends of the tape to be joined should be held in some rigid fashion to prevent displacement while the splice is being made. There are three ways of doing this: A. The most common method, even among professional tape editors, is to hold the tape securely between fingers, cutting with a pair of scissors.

B. By laying on a flat surface (example, soft wood block or sheet of rubber) and cutting with a razor blade. This technique can be further improved by placing a straight edge along one side to position both tapes.

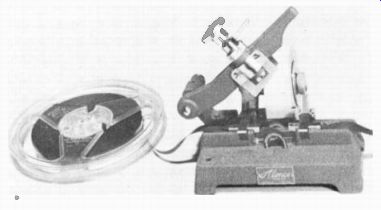

Fig. 10-5. Standard Splicing Blocks for Use by Home Hobbyists.

C. By using a commercially available splicing block. Fig. 10-5 shows one for use by home hobbyists. A professional -type splicer for magnetic tape is shown in Fig. 10-6.

Fig. 10-6. Professional Splicer for Magnetic Tape Manufactured by Alonge

Products.

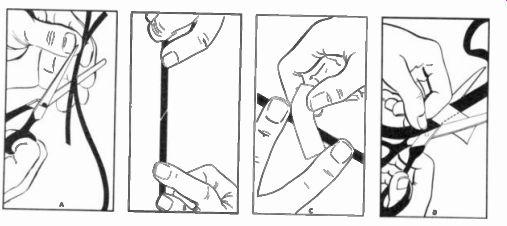

The two ends of the magnetic tape to be spliced should be overlapped sufficiently to enable easy cutting and true alignment of both tape ends, as shown in Fig. 10-7A , providing the recorded information will allow this much tape to be removed. Naturally, no cutting will be done at all if a break in the tape is being repaired. Line up the ends of the tape so both sections are butted and are in alignment with each other (see Fig. 10-7B ). The splicing tape must always be placed on the backing (or "shiny") side of the magnetic tape.

Fig. 10-7. The Correct Method of Splicing Tape.

For quarter-inch wide magnetic tape, the angle of the cut ends is not critical but one must use a diagonal cut to avoid a "pop" at the splice point. All angles are measured from the edge of the tape A 90 cut is to be avoided always. As the angle of the cut edge becomes smaller, the strength, flexibility, and magnetic invisibility of the splice becomes greater. A 45° angle is satisfactory although a 30° splice is approximately as strong and flexible.

A piece of standard splicing tape is centered over the butted ends parallel to the splice as shown in Fig. 10-7C. The width of the splicing tape used should never exceed 3/4" for general work since wider tapes impair flexibility. After firmly pressing the splicing' tape into position, rub firmly with the fingernail or other semi-hard object to press out all air bubbles. The excess splicing tape is trimmed by cutting into the magnetic tape slightly as shown in Fig. 10-7D. Thus danger of exposed adhesive from the splicing tape is eliminated. H The techniques of splicing magnetic film in the motion-picture industry differ widely from the procedures followed in editing 1/4" magnetic tape. Because of sprocket holes and the stiffer backing employed in the manufacture of magnetic film, rigidity is increased. Consequently, the edges of the splice have a tendency not to conform as readily when passing through the head, tending to lift at the edges of the splice.

A different type of splicing tape is employed in editing magnetic film. While identical in adhesive characteristics to standard splicing tape, the tape is cut to 35 mm, 17.5 mm, and 16 mm widths. Also translucent white, it is available with either double or single perforations for standard sprocket holes. No thicker than regular splicing tape, it is made with a tough polyester backing.

Reel Design and Construction

Reels for magnetic tape also play an important role in the recording process. Reels for magnetic tape must meet a variety of exacting requirements. First, the reel must not in any way distort the tape. Reels with large openings in their hubs in which the tape can become deformed are undesirable. As tape is wound on a reel, tremendous pressures are built up within the inner turns. Any threading slot, especially if it is large, will tend to deform the tape at that point.

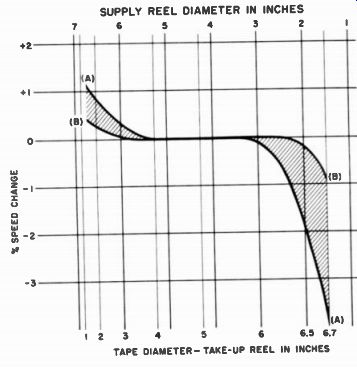

Fig. 10-8. Chart Showing Percent of Speed Change as the Reel Hub Diameter

Changes.

In addition, the 7-inch plastic reel, the most common reel size, should have a 2 1/4 inch minimum hub diameter to avoid timing errors as we have seen in the section on motor-boards. The timing error problem is perhaps the most serious consideration. Fig. 10-8 shows typical speed changes for a number of recording machines. It can be seen that recorders tend to speed up at the beginning of a reel due to high tension on the wind up side, and tend to slow down at the end due to high tension on the supply reel. Referring to Fig. 10-8, the per cent of speed change for the 2 1/4-inch hub diameter (curve B) is much less than that of the 1 3/4-inch hub diameter (curve A). At the 2 1/4- inch hub diameter, most of the timing error occur ring on the 1 3/4-inch hub reel will be corrected. A 2 3/4-inch hub gives still closer timing re suits and is used in applications demanding precision programming.

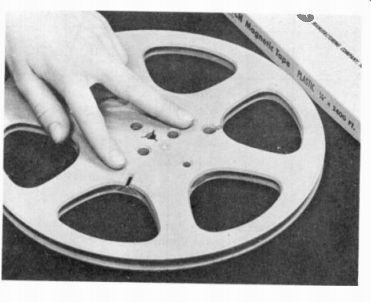

A comparison of the three hub diameters used for 7-inch reels is shown in Fig. 10-9.

Fig. 10-9. Three Types of 7-lnch Reels with the Three Hub Diameters.

However, earlier standard magnetic tape wound on the 1 3/4-inch hub reel averaged .0022 inches in thickness. Since the thickness of new present-day standard tape is 2 mils, it was often difficult to place 1200 feet of older-type tape on the 2 3/4-inch hub reel without the tape spilling over the edge.

Fig. 10-10. The 10.5-inch Plastic Reel Which Can Be Adapted for Use with

Various Recording Machines.

In addition, the reel flanges should be straight and true so that they will not rub either edge of the tape. There should also be a method of locking one end of the magnetic tape to the reel and securing it with several turns on the reel so that it will not pull free. The tape should lay flat against the thread-up device and not leave a hump on subsequent turns. The NARTB 10 1/2 -inch plastic reel, for example, provides a unique post thread -up device.

On the large size NARTB 10 1/2-inchand 14-inch reel, the tape is supplied on either a metal hub or on a metal hub with flanges. Also a plastic replacement for the 10 1/2-inch metal hub with flanges with its large center hole is available. The major change is the reduction of distance between the flanges to a value of 0.270 inches. This reel is manufactured from glass-filled plastic. With the changes in the distance between flanges, the winding characteristics have been greatly improved. A large center hole is used for those professional recorders that use a hold -down clamp to secure the reel to the pedestal.

A supplemental 10 1/2-inch plastic reel has also recently been developed. This reel has a small center hole, corresponding to the 7-inchreel, and contains other drive holes to adapt it to the recording machines of various manufacturers. This reel also contains both conventional and V-type thread-up slots as shown in Fig. 10-10.

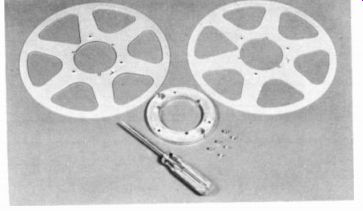

Fig. 10-11 A. The NARTB 10.5-lnch Reel Shown Disassembled.

Unless care in storage is exercised, this type of glass-filled plastic reel is subject to a certain amount of warpage, thus minimizing its improved winding advantages.

Because there is a cost saving in ordering 2400 or 4800 feet of tape on a NARTB hub without flanges, some recording engineers prefer to screw on their own flanges as illustrated in Figs. 10-1 1A and B. Also, several recorders operate using only a hub without flanges to eliminate any possibility of the edge of the tape scraping on the reel flanges, causing wow and flutter. However, on a properly designed tape recorder, the tape should ride between the flanges and at no time scrape on them.

A number of evolutions have been made in the metal NARTB hub which have greatly improved it. One improvement is that the surface of all good present-day metal hubs has been ground. Since the hub is made from a die-cast mould, the surface of an unground hub is mottled, resulting in tape distortion near the center of the reel. Also, the grinding of a metal hub leaves the surface exactly the same diameter across the hub's entire width. Because the hub has exactly the same diameter, the tape will not be distorted through receiving a long edge.

Fig. 10-11B. The NARTB 10.5-Inch Reel Assembled.

Fig. 10-12. A Self-Loading Cartridge for Use in Pre Recorded Tape.

A new development in 10-1/2-inch narrowing down of the hub. The hub was hubs and reels is the originally designed to be 350 mils thick. This left ample room between the tape edges and each flange. The purpose, of course, was to prevent scraping and rubbing on the flanges. However, during the fast forward and rewind on professional machines, the tape would wind in a sloppy manner, causing some turns of the tape to be higher than other turns. During storage, when the flanges of the reel would be slightly compressed, the higher turns would be crushed. Consequently, there has been a recent trend to narrow the metal hub down to 0.260 from 0.270 inches.

The reduction of the metal hub thickness can be accomplished in two ways. One, the thickness of the hub can be milled down and ordinary flanges installed. While this provides a good solution, the center line of the reel is now in the wrong position for the recorder. This can be solved by re-adjusting the pedestal heights of the recorder, however, throwing them out of adjustment for other reels. A second solution is to place spacers, such as screws with a large head or washers, outside the flange area to raise the reel to the right height when using the narrowed down hub.

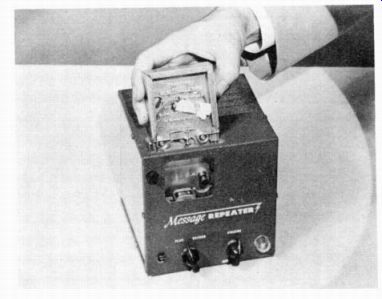

Fig. 10-13. A Variation of the Cartridge Mechanism for Magnetic Tape

Used in this Message Repeater Manufactured by the Mohawk Business Machines

Corp.

As previously mentioned, the new plastic 10 1/2-inch plastic reel has automatically incorporated a narrowed down hub in the plastic mould, requiring no further attention. Since the distance between flanges has been reduced to 0.270 inches, the reduction in distance was accomplished by moulding a thicker plastic flange. While the 10 1/2 -inch plastic reel is subject to warpage, it is expected that with the solution of this problem, the reels will soon be perfected.

A new development in pre-recorded magnetic tape eliminates the need for reel threading. A plastic self-loading cartridge such as shown in Fig. 10-12 is used. Another variation of the cartridge method, which is used in a message repeater, is shown in Fig. 10-13.