By Gary Stock

------------

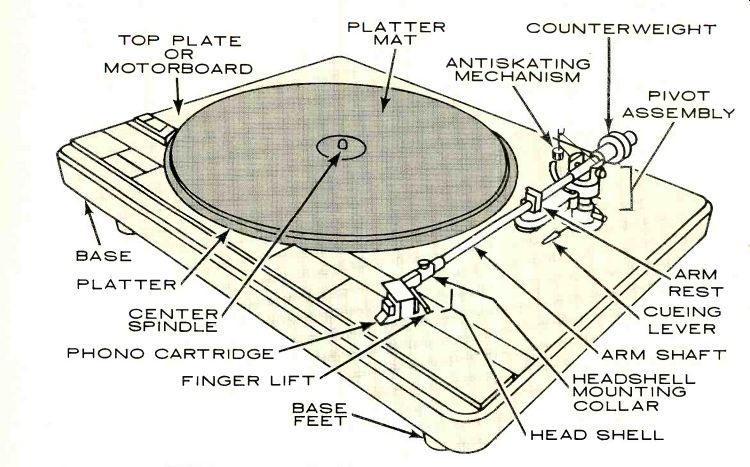

TOP PLATE OR MOTORBOARD BASE PLATTER CENTER SPINDLE PHONO CARTRIDGE FINGER LIFT BASE FEET PLATTER MAT COUNTERWEIGHT ANTISKATING MECHANISM PIVOT ASSEMBLY ARM REST CUEING LEVER ARM SHAFT HEADSHELL MOUNTING COLLAR HEAD SHELL

-----------------

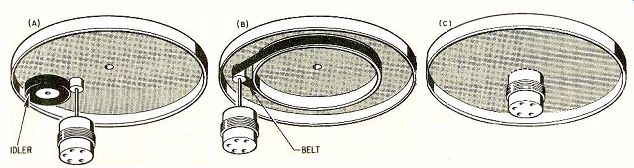

LIKE Gaul, all turntables are divided into three parts-a platter/motor assembly, a tone-arm assembly, and a base that supports both and isolates them from external shock and vibration. The responsibilities of each of these elements would appear to be quite straightforward, and if all went perfectly, platters would rotate silently at precisely the correct speed, arms would permit styli to move freely along the record's spiral groove, and bases would support these two components with the imperturbable solidity of a marble bust of Caesar. Alas, as with all human endeavors, some degree of imperfection is inevitable, even in turntables. To see where the problems arise and what measures are used by design engineers to combat them, let's examine each of the elements individually. Platter and Motor The platter/motor system is comprised of a large disc, or "platter," on which the record rests, and an electric motor. The platter is usually supported at its center by a single main bearing, and an electric motor rotates it either directly or by means of some sort of drive linkage. As shown in Figure 1(A), the platter may be driven by an idler wheel, a small rubbery disc that transmits the rotational force from the motor shaft to the platter. It is possible to transmit a great deal of torque from the motor to platter by this means, and for that reason it has been used extensively on record changers, which at one time required the substantial torque, or rotational energy, provided by an idler-wheel system to operate cycling and shutoff mechanisms. Unfortunately, in addition to turning the platter, idler wheels tend to transfer some of the vibration of the motor to the platter, the record, and finally to the playback stylus. This vibration turns up in the musical signal as rumble, a low-pitched "distant thunder" background noise.

Consequently, most turntable manufacturers, including changer makers, have in the past few years converted to another classic torque-transfer method: belt-drive, an arrangement in which a continuous belt forms a loop around both the motor shaft and the platter or its special inner rim-see Figure 1(B). Because the transfer of torque occurs through a highly flexible, more or less loosely coupled medium, very little mo tor vibration is transferred to the platter.

Belt-drive turntables as a class have relatively low rumble levels, although the loose coupling between platter and motor also reduces the available torque.

The third, most recent type of system, direct-drive, shown in Figure 1(C), has the motor mounted directly beneath the center of the platter, with an extension of the mo tor's shaft serving as the spindle shaft of the platter as well. Although motor and platter are in intimate contact on direct-drive turn tables, the very low rotational speed of the motor effectively avoids many of the vibration-related problems that a higher-speed motor would exhibit, thus enabling direct-drive units to achieve rumble figures in the same range as those of belt-drive tables, and usually far below audibility. Because they do not depend on the friction of a rubber belt or wheel for coupling, many direct drive units apply very high torque to the platter and are commonly used not only in home systems but also in radio stations and discos where the turntable's ability to come up to operating speed rapidly is important.

Most contemporary turntables use one of three methods to establish and maintain ac curate speed. The simplest motor type, the so-called induction motor, has its speed determined by the 60-cycles-per-second alter nation of the nominal 120-volt a.c. house current; it is subject to speed variations caused by momentary changes in the line voltage and by the effects of both tone-arm and record-cleaner drag. More sophisticated synchronous motors also use the tightly regulated 60-Hz frequency of house current as a reference to insure speed accuracy, but their internal structure provides a tighter "lock" onto the 60-Hz line, making them less subject to speed variations resulting from voltage shifts. This method, however, cannot compensate for external mechanical causes of speed irregularities. The most advanced type, the servo-controlled speed system, monitors the speed of the motor or platter continuously, comparing it to some reference such as a regulated voltage or an internally generated frequency (often con trolled by a quartz crystal), thus constantly correcting any speed error.

Servo-control systems of some type are invariably used on direct-drive turntables, and a number of belt-drive machines have adopted them as well, but with important differences. Some detect the speed error at the motor shaft and hence cannot correct for speed variations at the platter that may result from belt slippage when the turntable is under load. The more sophisticated systems "read" the platter's rotational speed directly; any deviation from the selected speed produces a prompt corrective effect.

Other parts of the platter/motor system can also influence the character of the sound heard. The composition of the platter and main bearing material may themselves cause problems. A main bearing with loose tolerances or rough contact surfaces will tend to "grind" or wobble on a microscopic scale, adding to whatever rumble is produced by motor vibration; most manufacturers of high-performance turntables therefore polish and fit main bearings to very close tolerances. Some creators of all-out designs go even further, constructing bearings of dissimilar materials such as oil-filled plastic and tempered steel, or suspending the platter on a "cushion" of magnetic repulsion or even compressed air, in an effort to reduce further the rumble produced by the platter-sup port system.

Some designers consider it important that most platters are metal castings or stampings which, if undamped, can "ring" much like a hell. Although the degree of ringing caused by, say, a jarring of the turntable or a loud bass note cannot be heard if unamplified, some engineers believe that it may be transmitted from the platter to the record and stylus to be eventually heard through the loudspeakers as a vaguely un natural boominess or echoing quality in the bass and midrange. The platter mat is there fore thought by some to be an important element, for it deadens ringing and vibration in both the platter and the record in much the same way that a percussionist silences cymbals by pressing them against his body.

The weight of the platter may have an effect on performance too. A massive platter will have much greater inertia than a lightweight one, and it will therefore come up to operating speed less rapidly (though this is rarely a problem in home systems).

Once in motion, however, it will remain relatively immune to momentary variations in drag or motor speed because of its flywheel-like characteristics. Today, however, turn tables that regulate speed by electronic means rather than mechanical inertia are increasingly common, and a turntable with a massive platter casting is not now necessarily superior to a unit with a lighter one.

The Tone Arm

The term "tone arm" has been carried down from the early days of sound reproduction, when arms actually transmitted sound from a diaphragm in the "head shell" down along their length to a horn that projected it at modest volume into the room.

Modern arms, of course, are specifically designed not to transmit sound acoustically; instead, their function is simply to hold the phono cartridge in a proper relationship to the record groove while exerting as little influence of their own as possible. In practice, the accomplishment of this goal faces an awesome array of obstacles, large and small, most imposed by what might be called the "minor sins" of the various parts of the arm.

A primary responsibility of the arm is to allow the cartridge to follow the groove both laterally, as it spirals inward, and vertically, as it pursues its course over warps and other surface irregularities. Theoretically, the arm should present no resistance to this movement whatever, but in practice all arms have both inertia (a concept to be discussed be low), and friction in their bearings (see Bearing Type in the Glossary on page 69).

--- “The simplest solution to the problem of arm-cartridge resonance would be warp-free records, but technology is nowhere close to that goal." ---

Another responsibility of the arm is that of imparting a controlled amount of down ward force (called vertical tracking force) to the cartridge to keep the stylus from losing contact with the groove. Vertical tracking force can be applied in a number of ways.

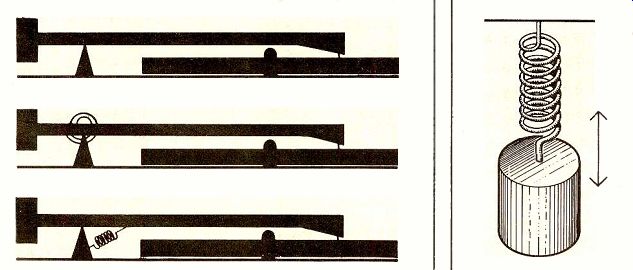

The simplest employs a main counterweight placed behind the pivot to counterbalance the mass of the arm and cartridge. Tracking force is then set by moving a section of the counterweight until an imbalance equal to the desired downward force is achieved. Alternatively, a second small weight is used to apply the actual force after the large weight has balanced the arm. Counterweights and springs are also often used in combination, a counterweight being adjusted initially to balance the arm and a spring in front of (or around) the pivots to apply a downward force. (See Figure 2.) In recent years, steps taken to reduce the tracking-force requirements of phono cartridges have in turn demanded low-mass tone-arm designs. The problem to be dealt with is the arm/cartridge resonance produced by the interaction of arm, cartridge, and record surface. [To diverge for a moment. we might say that all objects tend to vibrate when mechanically excited, and the frequency at which an object prefers to vibrate is its resonance frequency. The classic analogy used in most physics textbooks to describe resonance is that of a weight and spring, as shown in Figure 3. When the weight is moved or excited by some outside force, either directly or via the spring, it will begin to bob up and down at a certain rate, that rate being the resonance frequency of the spring-and-weight system. This frequency will be determined by two factors: the mass of the weight and the "looseness," or compliance, of the spring. A heavier weight or a looser spring will reduce the resonance frequency (make the weight bob more slowly); a slighter weight or stiffer spring will increase it.) A tonearm and cartridge in combination have a resonance frequency that is deter mined by the effective mass (weight) of the tone arm plus cartridge body and the compliance (springiness) of the stylus assembly.

When a record warp excites this resonance, the arm-cartridge combination reacts in much the same way as the weight-and-spring pair, bobbing up and down at the resonance frequency. The stylus interprets this bobbing as a powerful sub-bass signal which, though too low to be heard, can overload the amplifier and drive the speakers so hard that they exhibit substantial amounts of distortion. Even if these infra sonic signals are filtered out before they reach the power amplifier and speakers, the uncontrolled motion of the tone arm can contribute to mistracking and produce flutter effects in the reproduced sound-or, in extreme cases, bounce the stylus completely out of the groove.

The simplest solution to the problem of arm-cartridge resonance would be absolutely flat, warp-free records, but present technology is nowhere close to that goal. Rather, record-player designers must assume that most records will not be absolutely flat and devise solutions with that fact in mind. The solutions generally fall into two categories: tuning (shifting) the resonance frequency to minimize its effect and/or reducing its amplitude by damping.

Resonance tuning relies on the fact that if the arm-cartridge resonance can be made to occur in a certain range of frequencies say, between 10 and 15 Hz-then the arm will be less susceptible to excitation by either record warps or the deep-bass pas sages of the music, since neither generally has any substantial amount of energy in the 10-to 15-Hz range. In most cases this means either using a cartridge with a stiffer stylus suspension or a tone arm with a lower effective mass. Effective mass actually depends less on the total physical weight of the tone arm than on how the mass is distributed along its length. Concentrations of mass near the pivot assembly contribute little to it, whereas mass near the head shell (or at the other extremity, near the counterweight) results in an arm with high effective mass.

Today's better arms reflect these facts; they are often sleek, stripped-down affairs without any unnecessary mass in the head-shell area. Engineers use aerospace materials (carbon fiber and exotic metal alloys) for head shells and arm shafts, or they rely on specially fabricated conventional materials.

Some manufacturers move the head-shell mounting collar back to the pivot assembly.

The other means of raising the resonance, a stiffer stylus assembly, may reduce the bass-region tracking ability of a cartridge or alter its frequency response. Some designers are achieving reasonable compromises between these conflicting demands, how ever, and the trend at present seems to be toward slightly less compliant cartridges.

Damping, the alternative approach to the arm-cartridge resonance problem, can also be effective if the symptoms are not too severe. The procedure analogous to damping with our weight-and-spring example would be to immerse the entire affair in a bucket of water and thus slow its bobbing motion.

With tone arms, this is done indirectly by packing the pivots with jelly-like sub stances, immersing paddles attached to the arm in reservoirs of viscous fluid, or attaching "shock-absorber" devices that ride over the surface of the record adjacent to the stylus. Another type of resonance-damping arrangement has the counterweight attached to the arm by compliant mountings, creating a sort of "vibration parasite"-roughly tuned to the arm-cartridge resonance-that absorbs much of the energy that would otherwise cause the arm to bob. A recent turn table design enables the user to tune the anti-resonant counterweight to the tone-arm resonance precisely. These devices are helpful in stabilizing the arm and quashing any tendency for it to bob or bounce, but many of them still leave it up to the stylus to absorb any abrupt warps.

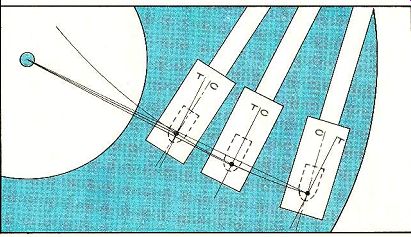

The fundamental job of the tone arm is to serve as a neutral support for the phono cartridge, maintaining the closest possible approximation to ideally "correct" record-playing geometry. An important consideration in this is keeping the stylus assembly in line with the direction of the groove. Since the groove is curved, this means that the stylus assembly should ideally form a perfect tangent to that curve throughout an en tire record side (see Figure 4)--a difficult trick with a pivoted tone arm that sweeps out on a curve of its own in its transit across the record surface.

Early tone arms were simple straight bars, and the angular relationship between stylus and groove was consequently quite oblique through most of the record's playing time, resulting in substantial quantities of a characteristic type of distortion arising from "lateral-tracking-angle error." A study of the geometry of record-playing suggested a way to reduce this distortion: the offset-head configuration, an arrangement in which the cartridge is mounted at a specific angle (determined by arm length) relative to the arm shaft. If this and other aspects of the geometry are properly worked out, the stylus maintains a much more consistently tangential relationship to the groove, generally within a couple of degrees of perfect tangency at any point along the playing radius.

---------------

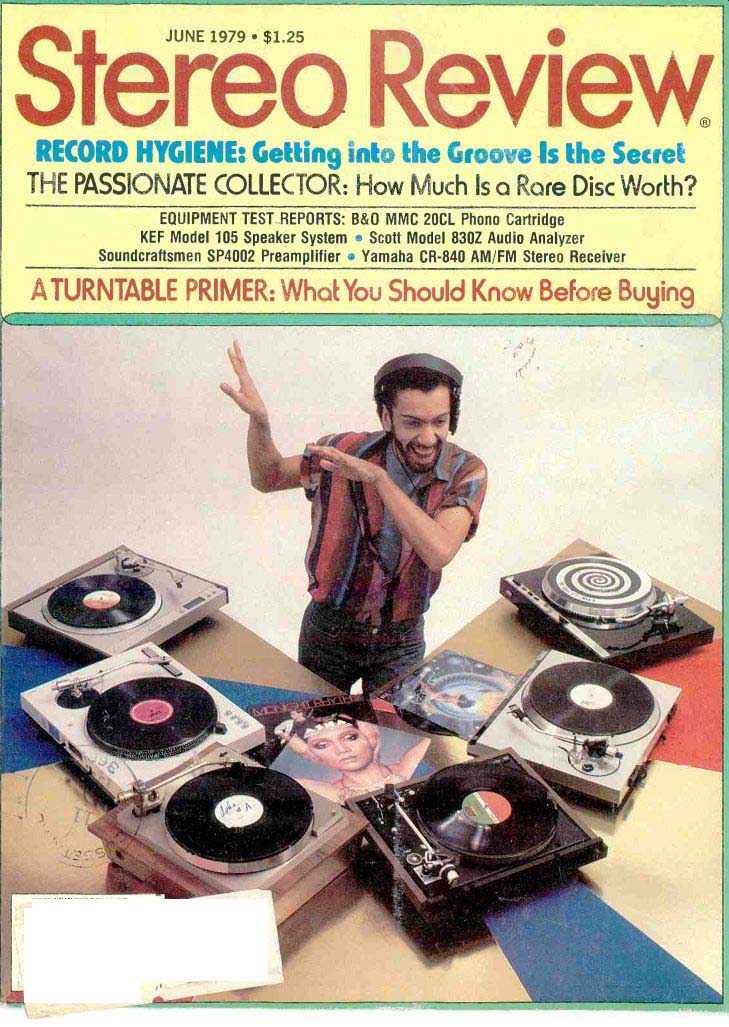

THIS MONTH'S COVER Richie Rivera, disc jockey at New York's SoHo discotheque Flamingo, grooves to the beat as he spins a few hot platters on (1) a Pioneer PL-610, (2) a Kenwood KD 550, (3) an Empire 698, (4) a Dual CS721, (5) a Technics SL 1500 Mk II, and (6) a Sansui SR-838. The disc with the eye-boggling spiral is Chic's "Le Freak."

-------------------

---------------- Fig. 1. Idler drive (A) transfers torque to platter through

a small "wheel." Belt drive (B) improves platter's isolation from

motor vibration. Direct drive (C) mounts the motor under platter spindle;

a low motor speed prevents rumble in the audible range.

------------

Fig. 2. Three common methods of applying tracking force: (top)

the counterweight is imbalanced to provide the tracking force; (middle)

the counterweight fully balances the arm and a spiral spring around the pivot

point applies the vertical force; (bottom) the tracking force is applied

by a spring in front of the arm's pivot point.

Fig. 3. Weight and spring interact to determine resonance frequency much the same as arm mass and stylus compliance do.

----------------

This offset causes the stylus to exert greater lateral pressure on the groove's inner wall than on the outer one. If uncorrected, this imbalance, called skating force, results in uneven stylus and record wear. A complementary opposing force (called antiskating force because it opposes the tendency of the arm to "skate" inward toward the platter spindle) is used to counteract this imbalance, and some means of applying it is incorporated in the majority of arms avail able today. There are several methods of applying antiskating force, such as a coiled spring, the repulsive force of two magnets, or a weight-and-pulley arrangement acting sideways on the arm shaft. These mechanisms are usually coupled to the arm near the pivot assembly, and all exert a more or less steady outward "pull" on the arm.

Another, more comprehensive response to these two problems-tracking error and skating force-has engendered a whole separate category of tone arm: the straight-line-tracking arm (also called the tangential, radial, or linear-tracking arm). This type of tone arm moves in a straight line across the record surface and maintains an almost perfect tangential relationship to the groove. By its very nature it requires no skating compensation. Most straight-line-tracking arms operate using servomechanisms that monitor the angular position of the arm shaft and maintain tangency by continuously "nudging" the entire arm assembly inward in tiny increments, although a number of variations on this scheme have also been marketed.

Of late, increasingly close attention has been given to the materials and structural configuration of tone arms. Theoretically, neither the head shell nor the cartridge body should move independently of the arm while the stylus is playing the record. Rather, they should act as an infinitely rigid platform for the stylus as it reacts to the modulations of the groove. No substance, though, is infinitely rigid, and investigators have established that minor vibration and bending in the tone-arm shaft and head shell may in fact "color" the sound of a tone arm. Rigid head shells-constructed of cast aluminum, magnesium alloys, or synthetic materials and integral felt or rubber cartridge dampers have become popular in higher-price turntables. Materials such as titanium, carbon-fiber composites, and fiber-reinforced stain less steel have become increasingly common in arm shafts. Some manufacturers prefer straight arm shafts, claiming they have the virtue of rigidity and resistance to

--- . . . try to set aside any preconceptions you may have about one turntable type's having superior listening quality." ---

flexure, while others stand by curved J-or S-shaped arms, noting that the bends in the shaft reduce some types of vibration. Relatively little evidence is available either in support of or in opposition to claims about the audibility of structural vibration in tone arms, although it seems clear that such effects are unlikely to have any major impact on the sound of a music system.

The Turntable Base

Constructing a proper turntable base would appear to be the simplest assignment among the three basic elements that go to make up a record player. For one thing, the base need not move at all; in fact, its primary responsibility is to resist motion, and in particular to resist imparting any motion or vibration to the tone arm or the platter/ motor assembly. Two types of vibration can affect the audible performance of a turntable: structure-borne vibration, which is transmitted to the turntable base through floor, walls, and furniture, and air-borne or acoustical vibration, which travels through the air to act directly on the tone arm and/or the record. These types of vibration have, in turn, two sources: they may originate in the loudspeaker as it reproduces the music, or they may be the product of various and sun dry jolts, shocks, slammed doors, footfalls, or even heavy outside traffic. In either case, the base design attempts to isolate the record-playing elements from the vibration by making them part of a system whose resonance is low enough to "decouple" it from most of the impinging energy. This is the same principle as that in the weight-and-spring resonant system we discussed relative to tone arms. In this case, the weight is made up of the platter/motor system, the tone arm, and the plate on which they are mounted, while the spring is the turntable's suspension-a term for that part of the base that isolates the two other elements by suspending them in some resilient fashion from the remainder of the base. If the resonance has a low enough frequency and is suitably damped, it can be very effective in ignoring the existence of most outside disturbances.

The suspension may take the form of a number of coiled springs, rubber or foam blocks or straps, or even lunar-module-style compliant "feet" interposed between the record-playing elements and the base. (A variation on this arrangement is used on many direct-drive turntables: the entire turntable, including the record-playing components and the base, rests on compliant feet.) One other characteristic of our weight-and-spring (or any other) resonant system becomes important here: the weight will not be substantially affected by any vibration or motion that occurs at a faster rate than the rate (the resonant frequency) at which the weight bobs up and down. This is easily seen if we imagine ourselves holding the up per end of the spring; a repeated rapid jerking on the spring will have much less effect on the bobbing motion of the weight than a single slow pull. And, since the rate at which the weight normally bobs is controlled by its mass and the looseness of the spring, we can see that a very loose spring and a very heavy weight will render the whole weight-and-spring system relatively immune to all but the slowest and most powerful of resonant influences.

The same principle applies to a turntable: a more massive base and/or a more compliant suspension will more effectively decouple the record-playing elements from most types of vibration because most vibration occurs at a rate much higher than the rate (the resonance frequency) at which the turn table suspension normally moves. This fact is responsible for the recent popularization of turntables with massive bases construct ed of concrete or heavy composite materials. It has also given rise to a new category of accessories: sub-bases-and accessory suspension feet that improve the isolation of a turntable by replacing or supplementing its integral suspension with a second, extremely heavy and/or highly compliant one.

How to Buy

Armed with all this information on the internal workings of turntables, let us now confront the question of how to choose one.

The first step should be to resolve what you want your turntable to do aside from rotating and playing the record. The simplest turntable type, the full manual, requires the user to perform all the operations related to its use: positioning and cueing the arm, turning the turntable motor on and off, and lifting the arm from the record at the end of each side. Semi-automatic units perform some of these operations for the user: they may lift the arm at the disc's end, shut the motor off, or both. Fully automatic units perform these functions and also place the arm on the disc, but they do not automatically play more than a single record in sequence. That requires a multiplay turntable, or changer.

For the tape enthusiast, who uses a turn table only for transcribing discs to tape, a fully manual unit is adequate. Others interested primarily in a constant flow of back ground music obviously will benefit from a multiplay turntable. Most of us, however, fall into an intermediate category, normally using our turntables in the single-play mode but occasionally requiring some automatic functions for parties and the like. Mentally review your present listening habits to determine which type will be most suitable to your needs, basing your decision either on those operating capabilities you feel you "miss" (or never use) in your present sys tem or (if you are buying a first system) those capabilities you believe will most closely correspond to your musical tastes and frequency of listening.

Try to set aside any preconceptions you may have about one turntable type's having superior listening quality. The performance of multiplay, automatic, and semiautomatic turntables has improved so in the past few years that any one of them is now very nearly the equal-when properly set up and equipped with an appropriate cartridge-of a fully manual unit. The very fine sonic distinctions that still do exist are likely to be audible only in systems approaching the state of the art.

As part of this first "qualifying" stage, be candid with yourself and make a mental note of any price-related, cosmetic, or dimensional requirements you may have. If the turntable must cost less than $200, have a matte-black finish to match other components, or fit on a shelf of particular dimensions, include these criteria in your thinking at the outset. Also note any "whiz-bang" ...

Fig. 4. Tracking error occurs because pivoted arms move inward

along an arc, thus preventing constant perpendicularity between the stylus

axis and record groove.

-------------

GLOSSARY OF RECORD-PLAYER SPECIFICATIONS

TECHNICAL specifications, like foreign languages, can be difficult to understand without a bit of interpretation, so the following glossary of the most common turntable specifications includes information on how the more important measurements are made and how the resulting numbers can some times be used to compare turntable and tone-arm performance.

Arm Friction describes the resistance of a tone arm to being moved either vertically or horizontally, primarily because of the inherent friction of the bearings in the arm's pivot assembly. A large amount of friction can have a significant effect on record and stylus wear. Pivot friction less than 10 percent of the tracking force (for ex ample, an arm-cartridge combination tracking at I gram having no more than 100 milligrams-0.1 gram-of friction in either the vertical or horizontal plane) was formerly thought to be acceptable, but some engineers in recent years have concluded that much small er amounts of arm friction can, under certain circumstances, affect listening quality and record wear. Most high performance turntables now have arm-friction specifications of 50 milligrams or less in both planes of motion.

BearingType defines the mechanical characteristics of the bearings that permit the arm to pivot while tracking the record. There are many different types of bearings, all designed to re duce arm friction to a minimum yet be reasonably rugged. The tone-arm friction specification, rather than the bearing type, should be used to evaluate the efficacy of a given arm's bearing assembly, however, even though it tells you little about durability.

Cable Capacitance is an electrical property of the cables connecting the turntable to the receiver or amplifier.

Many phono cartridges are greatly affected by the electrical "load" presented by the preamplifier input and connecting cables, with the result that the midrange and high-frequency response of the cartridge may be altered.

Proper match of the cartridge with the cables and the preamp input requires knowing what capacitance the cartridge requires and what capacitance the preamp and cables provide. The best starting point for adjusting these load conditions is to select a turntable having cables with relatively low capacitance--preferably under 100 picofarads. More capacitance, if needed, can be added with an accessory component or an additional length of cable. If you have selected a cartridge already and know what capacitance it requires (some are noncritical), then the two variables are the preamp and the cables. Many late-model components have a switch-selected choice of input capacitance/resistance available. A knowledgeable dealer will be able to guide you through the fine points of cartridge/cable/preamp interfacing.

Effective Arm Mass is the term for the portion of the arm's mass that affects the arm-cartridge resonance. A large part of this mass is contributed by the head shell (and the cartridge it holds), although the arm tube and counterweight contribute as well. For purposes of comparing specifications, it can be said that the lower of two effective arm masses is superior (for reasons explained in the text). Good contemporary turntables should have effective arm masses (excluding cartridge) no higher than 20 grams; state of-the-art arms using exotic materials may have masses as low as 5 grams.

Maximum Tracking Error defines the extent to which the tone arm causes the stylus to deviate from true tangency to the record groove. Measured in degrees per inch of record radius, it is determined by arm length and geometry as well as by the degree of precision of cartridge mounting and setup. Although whether moderate tracking-error distortion is audible is a controversial point, high-performance tone arms usually have maximum tracking errors no greater than 0.5 degree per inch.

Rumble is the generic term for a variety of low-frequency noises generated in the turntable by the motor (or, occasionally, the platter's center bearing). Modern high-performance turntables rarely produce audible rumbling noises, but the infrasonic frequencies that are part of the rumble often have an indirect impact on the sound of a system in that they tax the signal-handling capabilities of both the amplifier and the speaker, driving one or both into distortion.

Turntable rumble is measured in a number of ways. "Weighted" rumble measurements, which discount infra sonic rumble frequencies, are less revealing of the performance limitations of a turntable than "unweighted" figures, which measure the level of both infrasonic and higher-frequency types of rumble. The various types of weighted measurements are customarily identified on specification sheets by abbreviations (DIN A, DIN B, ARLL, JIS, etc.) that indicate the organization that promulgated the measurement method. Just remember that these methods differ, and the figures they produce can be used for purposes of comparison only within the same measurement system. Contemporary medium-price turntables should have DIN, ARLL, or JIS weighted rumble specifications of-50 dB or better (better meaning numerically larger: -50 is larger than -45) and unweighted figures of-30 dB or more. Rumble figures of -60 dB weighted and -40 dB unweighted are commonly found in state-of-the art players.

Range of Speed Adjustment de scribes the amount by which the rotational speed of the turntable platter (and therefore the pitch of the record ed music) can be slowed down or speeded up. Since the most common reason for a speed-adjustment control is to permit a recording to be matched in key signature or tempo to music being performed by the listener (or lately, in disco, to a second musical selection), the degree of adjustment required will be largely determined by individual needs. For those who don't anticipate any such musical or transcription activity, the presence or absence of this feature can be disregarded-unless you happen to have perfect pitch.

Stylus-to-pivot Distance describes the effective length of the tone arm and is related to the minimum amount of tracking error an arm will have. Theoretically, a longer tone arm will have lower tracking error-but also higher effective mass. Most manufacturers have found that balancing these conflicting requirements to obtain a low-mass arm with low tracking error yields a stylus-to-pivot distance of 8 1/2 to 9 inches (216 to 229 millimeters).

Arms with less than about 8 inches (203 millimeters) of stylus-to-pivot distance will have higher tracking error unless they are straight-line-tracking types.

Wow and Flutter are two names for cyclic variations in pitch, generally caused in turntables by small changes in the rotational speed of the turntable platter. Wow introduces a slow, recur rent slurring of musical and vocal phrases, while flutter adds a rapid wavering quality, not unlike a singer's vibrato, to instruments and voice. Like rumble, wow and flutter can be measured in several ways (denoted by the initials of the various standards organizations). Again, if specifications are to be compared, they must have been measured in the same way. Wow and flutter figures for high-performance turntables generally range no higher than 0.08 percent (when measured using the common DIN measurement standard), but other measurement standards will yield smaller numbers.

-----------------

". . . rely as much on your own 'hands-on' evaluation of a turntable as you do on its specifications."

--------

... sort of controls you would like, such as re mote control or front-plate mounted switches, as well as any preferences related to the turntable's country of manufacture or the proximity of service facilities.

With these considerations noted and the field of possibilities that much diminished, make up a list of those turntables you know of that meet all your requirements, whether you've encountered them in test reports, annual buyer's guides, or in friends' systems.

Follow this with a visit to a number of audio dealers, setting forth your requirements fully and firmly to the salespeople and noting what their recommendations are. From these sources, develop a second, combined list of a half-dozen or so units that meet your criteria in all respects.

THE second step in choosing a turntable involves a set of brief in-store experiments to be performed on each of the turntables you're considering. Each experiment should give you information on a specific part of a turntable's performance. If possible, try to complete these experiments on all of the turntables you're considering within a span of one or two days so that your recollection of the "feel" and sonic performance of each will be fresh in your mind.

1. To check the cueing and control smoothness, operate all the controls of the unit several times while a record is playing, checking to see if any extraordinary degree of loving tenderness is needed to keep the arm from being jarred; a turntable that re quires the delicate touch of a neurosurgeon to prevent the arm from skipping is obviously to be avoided. Cue the arm up and down several times with the amplifier's volume control set fairly high. Any loud crash (distinct from the music) as the stylus rises from or touches the surface of the record suggests that the cueing device might harm your record collection in extended use.

2. Take a strobe disc (available at most electronics hobby stores) with you to check the effects of putting an accessory record-cleaning arm, a second record, or some other additional element of weight or drag on the rotating platter. If any of these devices has the effect of altering the speed for more than a moment when put on the platter, and the turntable's vernier speed control can't compensate for it, you will not be able to use them on the turntable in question. (A turntable's built-in strobe will serve as well as a separate strobe disc.)

3. To evaluate the suspension characteristics of the turntable in the showroom, sharply rap the shelf surface on which the turntable rests while the unit is playing the silent lead-out end groove of a record. Don't rap too hard, and listen, with the amplifier volume set fairly high, for a corresponding thump from the loudspeakers. Repeat the rapping several times at different spots on the shelf, striking both the top and side of the shelf. If you are not sure that the thump you hear is in fact coming from the speakers, have a friend do the tapping while you listen directly in front of the speaker. Any reproduction of the thump suggests fairly serious shortcomings in the turntable's sus pension and the distinct possibility that you will encounter acoustic-feedback problems in home use. Bear in mind, however, that an unusually rickety shelf (not completely un known in audio shops) may invalidate the experiment because it will move or resonate when rapped, setting the whole turntable in motion. If several different brands all fail this test, then you are rapping too hard.

4. Both the rumble and the flutter performance of a turntable can be evaluated using a record designed for that purpose, such as STEREO REVIEW'S SRT 14 test record, which comes with detailed instructions for use (available for $7.98, plus applicable sales tax, from Test Record, Dept. 679, P.O. Box 278, Pratt Station, Brooklyn, N.Y.

11205). A rough evaluation of the rumble level of a turntable can also be made by playing the silent between-selection grooves of a normal record at high volume through a loudspeaker having extended bass response.

An acoustic-suspension speaker (rather than a vented or passive-radiator design) is preferable for this experiment. A turntable with relatively high rumble will cause the woofer cones of the speakers to flutter wildly back and forth, whereas a unit with acceptable rumble should cause only barely detectable motion.

5. Cartridge selection is a topic complex enough to justify a whole separate discussion (the subject was last covered in the January 1977 issue of STEREO REVIEW) and is therefore beyond the scope of this article.

However, when you have made a tentative cartridge selection (or accepted the recommendation of a dealer), it might be useful as a final check on arm-cartridge compatibility to perform one final experiment. The Shure TTR 115 test record ($5.50 from a Shure dealer or from Shure Brothers, Inc., 222 Hartrey Avenue, Dept. 67, Evanston, Ill. 60204) contains a track that permits an ob server to determine the arm/cartridge resonance of a turntable by watching the motion of the arm as this track is played; instructions enclosed with the record explain the procedure in greater detail. Note that a tone arm and cartridge with a combined resonance in the wrong range of values are not always hopelessly incompatible. A lighter bead shell or the removal of extraneous mass in the head-shell region may solve moderate problems. In most cases, how ever, the solution will of necessity be either a cartridge having lower compliance or some type of add-on damping device.

The Bottom Line

Having downgraded or eliminated some of the turntables on your list as a result of these tests, compare their published specifications and note any substantial differences. In most cases, the degree of difference between two specifications will not be a vast one, nor is it likely that a unit with re ally poor specifications will have done well in the series of experiments you've per formed. Differences of less than 5 dB in the rumble figure, 0.01 percent in wow-and-flutter, or half an inch in arm length are unlikely to have any impact on the sound quality of one turntable relative to another, but a difference in, say, cueing smoothness will re veal itself every time you use the turntable.

Remember also, relative to specifications, that the cutting lathes used to make records have definite, fairly well-defined limits of rumble, wow-and-flutter, and speed stability. Rumble figures better than about 45 dB unweighted and wow-and-flutter specifications in the 0.025 percent range represent about the best performance to be found in record-making machinery, so the benefits of a record-playing machine with far superior specifications are debatable. In cases where a number of turntables have done equivalently well in your handling and experiments, either superior specifications or a significant advantage in price can serve as a "tie-breaker" in helping you to make a final choice, but rely as much on your own "hands-on" evaluation of a turntable as you do on its specifications.

Certain other factors will (and should) influence a final choice: how much you trust your dealer and the package price of the turntable, cartridge, and any other components involved are two obvious points to take into account. When evaluating a pack age price, by the way, beware of a cartridge the dealer throws in either at no charge or for a nominal price. The cartridges supplied in such deals are usually budget units suit able enough for a turntable under $150 or so, but for a better turntable insist on a known (and higher-price) cartridge brand.

Using these criteria, it should be possible to choose a turntable-and to have confidence in the accuracy of your decision without too much head-or heartache. One final caution is in order, though: try to avoid any extended quest for the Holy Grail, a fa bled turntable in a given price range that will be Superior in Every Respect to its competition. By and large, such turntables do not exist (if they did, this job of discussing the buying process would be enormously simplified). Today's audio industry is global in scale and highly competitive in nature, and the best current technology is generally available to a large number of manufacturers simultaneously. Inevitably, several turn tables in a given price range will provide equally good performance and value per dollar, and any one of them will be fully suitable for a given type of use. Good luck and good hunting.

Also see:

Link | --KEEPING IT CLEAN--RECORD HYGIENE: The scanning electron microscope reveals some fascinating secrets, by GEORGE ALEXANDROVICH

Link | --EQUIPMENT TEST REPORTS

Source: Stereo Review (USA magazine)